Thingiverse

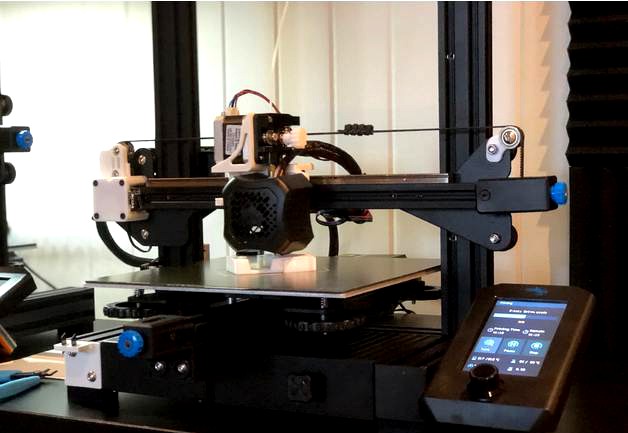

Ender 3 V2 Linear Rail Direct Drive X-Axis Conversion V1 by VonTaube

by Thingiverse

Last crawled date: 3 years, 3 months ago

Ender 3 X-Axis Linear Rail Direct Drive Conversion V1

Notes:

Linear Rail Mount must be printed in PETG, ASA or a higher temp material

Linear Rail Belt Guide V5 is an updated right side X-Axis idler mount. Extra support to resist torqueing/twisting effect.

Required Hardware:

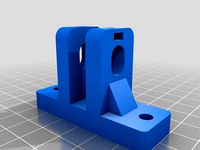

Direct Drive RE BLTouch - Linear Rail mount v3

Linear Rail Carriage: M3x8 (x4)

Hot End: M3x20 (x2) + M3 Nut (x4) +M3 Washer (x4)

Fan Shroud: M3x12 (x1)

BLTouch: M3x6 (x2)

Extruder: OEM hardware

Belt: 2mm Pitch 6mm Width

Material: PETG/ASA or high temp material recommended

X-Axis Stepper Pulley Cover v3

Idler Pulleys: Creality idler pulleys (x2) OR (5mm bore x 10mm width idlers) (x2)

Idler Pulley Mounting: M5x20 (x2) + M5 Nut (x2) + M5 Washer (x2) + Bearing Sleeve v0 (x2)

X-Axis Cover: OEM Hardware

End Stop Switch: OEM Hardware

Linear Rail Belt Guide v4

Idler Pulley: Creality idler pulleys (x1) OR (5mm bore x 10mm width idlers) (x1)

Idler Pulley Mounting: M5x20 (x1) + M5 Nut (x1) + M5 Washer (x1) + Bearing Sleeve v0 (x1)

Belt Guide Mounting: OEM Hardware

300mm MGN12H Mini Linear Rail with MGN12H Carriage Block

MGN12H Rail: M3x8 (x4) + M3 T-Slot Nuts (x4)

Installation

Remove all track rollers, belt tensioner and guide belt. Set aside print head.

Install linear rail, on top of x-axis extrusion, with at least four M3x8 screws and M3 T-slot nuts. Be sure to mount within 5mm of x-axis stepper cover on left side of printer.

Install Linear Rail Belt Guide v4 idler pulley with M5 hardware and mount assembly to upper track roller hardware above belt tensioner.

Prep 3D Printed Linear Rail Carriage:

Remove fan shroud and hot end from OEM carriage.

Install (2x) M3x20 screws from back to front of linear rail carriage. These will act as studs to mount the hot end on the front.

Moving to the front of the linear rail carriage, secure (2x) M3 Nuts and (4x) M3 Washers on your M3x20 studs in the following order:

Carriage/Stud -> M3 Washer - > M3 Nut -> M3 Washer -> Hot End -> M3 Nut (This can be seen in the above image of the hot end with fan shroud removed)

Before installing the OEM fan shroud, you will need to trim off a locating tab on the left side of the shroud. This locating tab is on the side closest to the X-Axis Stepper, near the BLTouch mount.

Using (1x) M3x12 install OEM fan shroud from the backside of carriage. Use the existing locating tab to orient the fan shroud correctly, tighten down shroud from the back of the carriage with the upper hole on tensioner side.

Install Belts

Trim the crimped ends off two OEM creality x-axis belts and slot the remaining crimped ends into either side of the linear rail carriage.

Once belts are attached you can go ahead and install the carriage to the linear rail block. You will be routing the belt through both the X-Axis Stepper Pulley Cover v3 and belt tensioner as you install each. Join the belts in the center above the rail.

Alternatively, you can purchase a 5m roll of 6mm wide 2mm pitch belt and trim to size. If using this method you must install the X-Axis Stepper Pulley Cover v3 and belt tensioner first, then route the belt from top down through both sides and secure to the linear rail carriage.

Install Linear Rail mount v3 (If using two belt method)

Using (4x) M3x8 mount the prepped linear rail carriage to the linear rail carriage block

Install X-Axis Stepper Pulley Cover v3

Install the (2x) idler pulleys to the cover using M5x20, M5 Nut, M5 Washer and Bearing Sleeve v0

Remove OEM x-axis stepper cover and move end stop limit switch to new linear rail x-axis cover.

Mount linear rail x-axis cover to stepper with OEM hardware. Route belt through x-axis idler pulleys and stepper gear before mounting the screws for the cover.

Install Belt Tensioner

Install belt tensioner with belt coming straight out of the hole in the top, wrapping around Linear Rail Belt Guide v4 idler pulley.

Finishing Belts

a. Two Belts

If using two OEM creality belts you can now join the belt in the center of the x-axis above rail. Center to avoid belt joint/seam going over idler pulley on either end of rail during operation.

b. Single Belt (5m)

Once belt is routed through both side of the printer start the belts through the bottom of the carriage.

Secure carriage to linear rail block with M3x8 (x4)

Crimp belt and tension

See Ender 3 V2 Direct Drive link below for extruder install infohttps://www.thingiverse.com/thing:4621486

Notes:

Linear Rail Mount must be printed in PETG, ASA or a higher temp material

Linear Rail Belt Guide V5 is an updated right side X-Axis idler mount. Extra support to resist torqueing/twisting effect.

Required Hardware:

Direct Drive RE BLTouch - Linear Rail mount v3

Linear Rail Carriage: M3x8 (x4)

Hot End: M3x20 (x2) + M3 Nut (x4) +M3 Washer (x4)

Fan Shroud: M3x12 (x1)

BLTouch: M3x6 (x2)

Extruder: OEM hardware

Belt: 2mm Pitch 6mm Width

Material: PETG/ASA or high temp material recommended

X-Axis Stepper Pulley Cover v3

Idler Pulleys: Creality idler pulleys (x2) OR (5mm bore x 10mm width idlers) (x2)

Idler Pulley Mounting: M5x20 (x2) + M5 Nut (x2) + M5 Washer (x2) + Bearing Sleeve v0 (x2)

X-Axis Cover: OEM Hardware

End Stop Switch: OEM Hardware

Linear Rail Belt Guide v4

Idler Pulley: Creality idler pulleys (x1) OR (5mm bore x 10mm width idlers) (x1)

Idler Pulley Mounting: M5x20 (x1) + M5 Nut (x1) + M5 Washer (x1) + Bearing Sleeve v0 (x1)

Belt Guide Mounting: OEM Hardware

300mm MGN12H Mini Linear Rail with MGN12H Carriage Block

MGN12H Rail: M3x8 (x4) + M3 T-Slot Nuts (x4)

Installation

Remove all track rollers, belt tensioner and guide belt. Set aside print head.

Install linear rail, on top of x-axis extrusion, with at least four M3x8 screws and M3 T-slot nuts. Be sure to mount within 5mm of x-axis stepper cover on left side of printer.

Install Linear Rail Belt Guide v4 idler pulley with M5 hardware and mount assembly to upper track roller hardware above belt tensioner.

Prep 3D Printed Linear Rail Carriage:

Remove fan shroud and hot end from OEM carriage.

Install (2x) M3x20 screws from back to front of linear rail carriage. These will act as studs to mount the hot end on the front.

Moving to the front of the linear rail carriage, secure (2x) M3 Nuts and (4x) M3 Washers on your M3x20 studs in the following order:

Carriage/Stud -> M3 Washer - > M3 Nut -> M3 Washer -> Hot End -> M3 Nut (This can be seen in the above image of the hot end with fan shroud removed)

Before installing the OEM fan shroud, you will need to trim off a locating tab on the left side of the shroud. This locating tab is on the side closest to the X-Axis Stepper, near the BLTouch mount.

Using (1x) M3x12 install OEM fan shroud from the backside of carriage. Use the existing locating tab to orient the fan shroud correctly, tighten down shroud from the back of the carriage with the upper hole on tensioner side.

Install Belts

Trim the crimped ends off two OEM creality x-axis belts and slot the remaining crimped ends into either side of the linear rail carriage.

Once belts are attached you can go ahead and install the carriage to the linear rail block. You will be routing the belt through both the X-Axis Stepper Pulley Cover v3 and belt tensioner as you install each. Join the belts in the center above the rail.

Alternatively, you can purchase a 5m roll of 6mm wide 2mm pitch belt and trim to size. If using this method you must install the X-Axis Stepper Pulley Cover v3 and belt tensioner first, then route the belt from top down through both sides and secure to the linear rail carriage.

Install Linear Rail mount v3 (If using two belt method)

Using (4x) M3x8 mount the prepped linear rail carriage to the linear rail carriage block

Install X-Axis Stepper Pulley Cover v3

Install the (2x) idler pulleys to the cover using M5x20, M5 Nut, M5 Washer and Bearing Sleeve v0

Remove OEM x-axis stepper cover and move end stop limit switch to new linear rail x-axis cover.

Mount linear rail x-axis cover to stepper with OEM hardware. Route belt through x-axis idler pulleys and stepper gear before mounting the screws for the cover.

Install Belt Tensioner

Install belt tensioner with belt coming straight out of the hole in the top, wrapping around Linear Rail Belt Guide v4 idler pulley.

Finishing Belts

a. Two Belts

If using two OEM creality belts you can now join the belt in the center of the x-axis above rail. Center to avoid belt joint/seam going over idler pulley on either end of rail during operation.

b. Single Belt (5m)

Once belt is routed through both side of the printer start the belts through the bottom of the carriage.

Secure carriage to linear rail block with M3x8 (x4)

Crimp belt and tension

See Ender 3 V2 Direct Drive link below for extruder install infohttps://www.thingiverse.com/thing:4621486

Similar models

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount by SaberShip

...rts:

x1 stock 608zz idler bearing

x1 stock m3 bolt and nut

x2 stock m5 bolts

x2 stock m5 t-slot nuts

x2 m3 x 10 screws

x2 m3 nuts

thingiverse

free

Prusa i3 X-Axis Tensioner by BillyKalfus1

...rew pulls the tensioner closer to the back of the axis mount, pulling the pulleys back, and increasing the tension in the x-axis.

thingiverse

free

Tronxy X5S - Linear Guide Rails Conversion Kit

...s on slider_plate_right_part7 / slider_plate_left_part8 / hotend_plate_part10 / hiwin_x_plate_part12 / left_spacer_body_v2 _part1

thingiverse

free

Kossel carriage with implant screw support for belt tension and endstop trigger adjustable by 3DPW

...ll circle on belt, insert the circle to be belt holder. pull belt then the belt will be tighted. use zip tie to tighten the belt.

thingiverse

free

Tronxy Y axis stabilizer prototype by Damiken

...e pressing them into them. included are pics for reference. the zip tie is unnecessary, just from a problem with my motor damper.

thingiverse

free

Hictop 3dp11 Adjustable Y Idler Mount 2.0 by SaberShip

...ler pulley for 6mm wide gt2 belt

1x m5 x30 bolt

1x m5 nylon lock insert nut (regular m5 nut may work)

2x m3 x10 screws

2x m3 nuts

thingiverse

free

Better Y axis for flsun cube with belt tensioner by MichaelLamb

...at will loosen over time causing headaches... unfortunately that does not correct crooked 8mm rods that came with the printer...

thingiverse

free

Adimlab Gantry-S X Axis Tensioner

...the pulley.

m4 x 25 or m4 x 30 screw and a backing nut to keep this screw from spinning.

m4 nylock nut to insert into the knob.

.

thingiverse

free

Makergear Prusa simple X-axis belt tensioner by Prestonf

...adjustable x-axis belt tensioner for the makergear prusa that takes the place of the two 8mm washers for the x-axis idler pulley.

thingiverse

free

Prusa Steel X axis with tensioner and 8mm leadscrew support by fedewolfie

...ner and a m5 screw and nut for the toothed idler, i use a cheap aliexpress toothed idler with a m5 bore.

prints without supports.

Vontaube

thingiverse

free

Sanding Wedge by VonTaube

...sanding wedge by vontaube

thingiverse

hardware:

1x m4 nut

1x m4x25

thingiverse

free

Ergonomic Wrist Rest by VonTaube

...ergonomic wrist rest by vontaube

thingiverse

ergonomic wrist rest

thingiverse

free

Bottle Cap Grip by VonTaube

...bottle cap grip by vontaube

thingiverse

bottle cap grip

use a high-strength, fast-bonding adhesive to attach parts.

thingiverse

free

Rigid Industries Dually D2 Bezel by VonTaube

...rigid industries dually d2 bezel by vontaube

thingiverse

rigid industries dually d2 front bezel

thingiverse

free

Ender 3 SD Card Holder by VonTaube

...ender 3 sd card holder by vontaube

thingiverse

creality ender 3 sd card holder

thingiverse

free

Weber Summit BBQ Door Latch V2 by VonTaube

...weber summit bbq door latch v2 by vontaube

thingiverse

weber summit door latch v2

thingiverse

free

Cabin Style Bird House by VonTaube

...ontaube

thingiverse

cabin style bird house

designed as a nesting shelf with 3 open sides to attract robins (non-cavity nesting).

thingiverse

free

Ender 3 X-Axis Motor Cover by VonTaube

...ender 3 x-axis motor cover by vontaube

thingiverse

remake of ender 3 oem x-axis stepper cover.

thingiverse

free

Fanatec Podium Nexus 7 Tablet Mount by VonTaube

...fanatec podium nexus 7 tablet mount by vontaube

thingiverse

fanatec podium dd1/dd2 nexus 7 tablet mount

thingiverse

free

TPU Accessory Clamp 1"-2.25" by VonTaube

... 1"-2.25" by vontaube

thingiverse

tpu accessory clamp 1"-2.25"

note: riser mount.stl - 20mm height increase.

Conversion

thingiverse

free

Converse keychain for Converse's fan by theletech

...converse keychain for converse's fan by theletech

thingiverse

please print in 0.15 or 0.2 for the best quality

thingiverse

free

Blockjacker arm conversion

...blockjacker arm conversion

thingiverse

a conversion for a giant robot. mirror to print l and r arms

thingiverse

free

Converse Shoes by spekdesign

...converse shoes by spekdesign

thingiverse

simple converse shoes (left + right) intended for small prints with minimal detail.

thingiverse

free

Conversation Hearts by PfLibrarian

...n hearts by pflibrarian

thingiverse

conversation hearts with three different candy heart phrases. great for valentine's day!

thingiverse

free

associated B4 conversion pancar

...associated b4 conversion pancar

thingiverse

associated b4 conversion pancar

thingiverse

free

Rotofury Elite Conversion by Hooliganblasterco

...rotofury elite conversion by hooliganblasterco

thingiverse

rotofury elite conversion, reversable

thingiverse

free

Conversation Hearts

... the heart instead of popped out. get creative if you like and fill the indents with paint or glitter and seal to make an impact!

thingiverse

free

Conversion Kit Box (Slide Conversion Kit) by Ziggi42

...nd tpu (buffers).

everything you have to know is in the readme.txt or look at print settings misc.

thanks and gimme a like!!!

sfo

thingiverse

free

BOOMBASTIC .22 CONVERSION by mussy

...boombastic .22 conversion by mussy

thingiverse

this is a .22 rim fire blank conversion... enjoy

thingiverse

free

20mm Fan conversion by fluxcore

...20mm fan conversion by fluxcore

thingiverse

conversion from a 20mm fan to a blower or extractor.......unfinished

Linear

thingiverse

free

MGN12 Linear Guide + MGN12H Long linear carriage by Artu66

...//pl.aliexpress.com/item/free-shipping-for-12mm-linear-guide-mgn12-l-300mm-linear-rail-way-mgn12c-or-mgn12h-long/32540712851.html

thingiverse

free

LM16UU Linear bearing

...lm16uu linear bearing

thingiverse

linear bearing...

thingiverse

free

linear Slide by pmf10

...linear slide by pmf10

thingiverse

linear slide.

thingiverse

free

Linear extrude by Gutenber3D

...linear extrude by gutenber3d

thingiverse

linear extrude

thingiverse

free

LInear Rail by Galione1

...linear rail by galione1

thingiverse

linear rail with slider.

thingiverse

free

Linear Slide by xM0NKEYM4Nx

...linear slide by xm0nkeym4nx

thingiverse

tetrix linear rack

thingiverse

free

linear bearing 8mm

...linear bearing 8mm

thingiverse

linear bearing 8mm lm8uu

thingiverse

free

Linear bearing by ilVerza

...linear bearing by ilverza

thingiverse

linear bearing for y axis

thingiverse

free

Vex Linear by Greaser57

...vex linear by greaser57

thingiverse

plastic part for the vex linear kit

thingiverse

free

Linear Axis by wizard23

...linear axis by wizard23

thingiverse

a linear axis i wanted to test.

V1

thingiverse

free

Pinquin v1 by bjarkemape

...pinquin v1 by bjarkemape

thingiverse

pinquin v1

thingiverse

free

Minion v1 by bjarkemape

...minion v1 by bjarkemape

thingiverse

minion v1

thingiverse

free

Arrowhead V1 by ogill117

...arrowhead v1 by ogill117

thingiverse

arrowhead v1

thingiverse

free

Duct Vortex V1

...duct vortex v1

thingiverse

duct vortex v1

thingiverse

free

ParaBracci Bolt V1

...parabracci bolt v1

thingiverse

parabracci bolt v1

thingiverse

free

ParaMotori Bolt V1

...paramotori bolt v1

thingiverse

paramotori bolt v1

thingiverse

free

ParaBracci ThunderStorm V1

...parabracci thunderstorm v1

thingiverse

parabracci thunderstorm v1

thingiverse

free

ParaBracci Bit V1

...parabracci bit v1

thingiverse

parabracci bit v1

thingiverse

free

ParaMotori ThunderStorm V1

...paramotori thunderstorm v1

thingiverse

paramotori thunderstorm v1

thingiverse

free

ParaMotori Bullet V1

...paramotori bullet v1

thingiverse

paramotori bullet v1

Rail

thingiverse

free

VECTOR rail

...vector rail

thingiverse

vector rail

thingiverse

free

Railing

...railing

thingiverse

for gaming and modeling

thingiverse

free

Fingerboard rail

...fingerboard rail

thingiverse

cool rail for fingerboarding!!!!

thingiverse

free

Guide Rail

...guide rail

thingiverse

different guide rail options. i found the long rail provide to most stability.

thingiverse

free

Rail for Tramways

...rail for tramways

thingiverse

it is just a replacement for the rails of tramways.

thingiverse

free

Scope rail by rundown

...scope rail by rundown

thingiverse

scope rail for a lower rail.

thingiverse

free

Picatinny Rail

...u need.

this rail segment has a 1 inch wide baseplate. this surface is what i used to glue the rail into the target application.

thingiverse

free

Dovetail Rail

... and realized it used a dovetail rail contrary to a picatinny rail, made this and super glued it on my rifle, no problems so far.

thingiverse

free

Ak side rail mount with extra rail by HomieStarks

...ak side rail mount with extra rail by homiestarks

thingiverse

just added another rail on it.

thingiverse

free

Nerf Rail to Picatinny Rail Adapter by mshukr1

...y rail adapter. you can either print a long 'combined' rail, or separate parts, and glued them together (easier to print)

Drive

thingiverse

free

USB Drive / Flash Drive / Pen Drive Case by BrosJr

...usb drive / flash drive / pen drive case by brosjr

thingiverse

spare part for a broken usb drive case.

my mom´s request :-)

thingiverse

free

Turret Drive

...turret drive

thingiverse

drive key and housing

thingiverse

free

USB Flash Drive Holder of Drives by paxamime

...ot of flash drives for various purposes so while 20 drives may sound like a lot, this is only one of 3 that i am currently using.

thingiverse

free

Ender3 Direct drive duel drive mount

...have created for the ender3 and should fit the cr10 printers. this is for the duel drive mount version not the standard version.

thingiverse

free

Drive Shaft by RedMerlin

...drive shaft by redmerlin

thingiverse

a drive shaft.

thingiverse

free

Driving Message by Mariblueruby

...driving message by mariblueruby

thingiverse

cheeky driving message

thingiverse

free

G-Drive External Hard Drive Case by EvanVS

...ve case by evanvs

thingiverse

this is a case for an external usb harddrive.

this case is designed to fit the "g-drive"

thingiverse

free

MK2 Drive Bashguards

...mk2 drive bashguards

thingiverse

bashguards for the mk2 avio at gear drive!

thingiverse

free

Harmonic drive

...harmonic drive

thingiverse

harmonic drive i made, uses 7.9 mm steal ball bearings. make sure to split into parts before printing

thingiverse

free

Waterjet Drive

...waterjet drive

thingiverse

waterjet model

Direct

thingiverse

free

IeC Direct - Basculating MK8 Direct Extruder by Immaginaecrea

...iec direct - basculating mk8 direct extruder by immaginaecrea

thingiverse

another mk8 direct extruder

thingiverse

free

Directed Numbers by hachihung

...directed numbers by hachihung

thingiverse

directed numbers model for students playing

thingiverse

free

Direct Extruder by ManfredSaemann

...direct extruder by manfredsaemann

thingiverse

conversion of the ender-6 to direct extruder with filament guide.

thingiverse

free

Directional Marker (Arrow) by Crazy_Diver_84

...directional marker (arrow) by crazy_diver_84

thingiverse

directional marcer for cavediving

thingiverse

free

Direct Drive Delta by gustofusion

...direct drive delta by gustofusion

thingiverse

direct drive delta

thingiverse

free

Direct Drive Extruder by djBo

...ig big fan of this)

compact bowden extruder

one piece simple direct drive extruder

mariusmartin's direct drive extruder

thingiverse

free

Sapphire Pro bowden to direct

...sapphire pro bowden to direct

thingiverse

bracket model for direct extruder.

thingiverse

free

cable manager for zav direct

...cable manager for zav direct

thingiverse

cable manager for zav direct

thingiverse

free

Direct mounting NEMA17 by adolf81

...direct mounting nema17 by adolf81

thingiverse

direct mounting nema17 for cnc

thingiverse

free

Sunlu direct extruder by masbytes

...sunlu direct extruder by masbytes

thingiverse

adapter for direct extruder for sunlu s8

Ender

thingiverse

free

Ender-5

...ngiverse

3d model of ender-5.

attention: there are some changes in later versions on ender-5, so use this 3d model with caution.

thingiverse

free

USB Holder (Ender 3 / Ender 3 Pro)

...usb holder (ender 3 / ender 3 pro)

thingiverse

usb holder that easily mounts to the ender 3 / ender 3 pro lcd housing

thingiverse

free

Ender 3V2 LCD Cover with Ender Dragon by PhotoBud

...mplistic cover with extruded ender dragon and handle designed on fusion 360 to cover and protect the lcd screen of the ender 3v2.

thingiverse

free

ENDER 3

...ender 3

thingiverse

this is my first upgrade for ender 3 printer from long extruder to short extruder

thingiverse

free

Simple QUICK PRINT LCD Cover for Creality Ender-3/Ender-3s/Ender-3 Pro/Ender-5 by 1MavZ

...e quick print lcd cover for creality ender-3/ender-3s/ender-3 pro/ender-5 by 1mavz

thingiverse

quick and simple upgrade print...

thingiverse

free

Mini Ender 3

...mini ender 3

thingiverse

mini ender 3

thingiverse

free

Ender Dragon by piisawesome314159

...ender dragon by piisawesome314159

thingiverse

the ender dragon with a base.

thingiverse

free

Ender 3 / Ender 3 / Pro - 3D Filament Support

...ender 3 / ender 3 / pro - 3d filament support

thingiverse

filament holder for plug-in ender 3 / ender 3 / pro 3d printers

thingiverse

free

Filament Guide for ENDER 3 and ENDER 3 V2 by muhannad703

...filament guide for ender 3 and ender 3 v2 by muhannad703

thingiverse

ender 3 v2

thingiverse

free

fancover ender 3

...fancover ender 3

thingiverse

fan cover for ender 3

V2

thingiverse

free

Schleuder V2 / Slingshot V2 by Ju5tMak3

...schleuder v2 / slingshot v2 by ju5tmak3

thingiverse

schleuder v2 / slingshot v2

have fun

thingiverse

free

V2 by LeoRadstrom

...v2 by leoradstrom

thingiverse

v2

thingiverse

free

Yugioh V2

...yugioh v2

thingiverse

yugioh v2

thingiverse

free

WOPR v2

...wopr v2

thingiverse

wopr v2

from the "wargame" film

thingiverse

free

KeyHolder V2

...keyholder v2

thingiverse

keyholder v2.

for those who don't like to hear keys shaking.

thingiverse

free

v2 deck by ltl20

...v2 deck by ltl20

thingiverse

v2 deck

thingiverse

free

pinquin v2 by bjarkemape

...pinquin v2 by bjarkemape

thingiverse

pinquin v2

thingiverse

free

Minion v2 by bjarkemape

...minion v2 by bjarkemape

thingiverse

minion v2

thingiverse

free

LogoAlpha v2 by AlphaProject

...logoalpha v2 by alphaproject

thingiverse

logoalpha v2

thingiverse

free

Arrowhead V2 by ogill117

...arrowhead v2 by ogill117

thingiverse

arrowhead v2

Axis

thingiverse

free

Axis

...axis

thingiverse

had no dowels laying around so modeled an axis in 360

thingiverse

free

Axis

...axis

thingiverse

an right handed cartesian axis. notches indicate positive rotation direction.

thingiverse

free

CR10S X-axis & Y-axis spacer

...cr10s x-axis & y-axis spacer

thingiverse

4mm spacer for x-axis & y-axis on the cr10s.

thingiverse

free

AXYS KEYCHAIN

...axys keychain

thingiverse

polaris axys platform keychain

thingiverse

free

for Axis by bassemwagih

...for axis by bassemwagih

thingiverse

axis diameter = 1.3 cm

thingiverse

free

Axis Tree - 3 and 5 Axis by zefram

...and 5 axis by zefram

thingiverse

flexible 3 and 5 axis tree signpost to demonstrate or remind the axes on a 3 or 5 axis machine.

thingiverse

free

Linear Axis by wizard23

...linear axis by wizard23

thingiverse

a linear axis i wanted to test.

thingiverse

free

2 adjustable axis (Y-Z Axis) by NerdCorner

... (y-z axis) by nerdcorner

thingiverse

detailed explanation in my blogpost: https://nerd-corner.com/2-adjustable-axis-cad-design/

thingiverse

free

z axis motor holder for metal x axis to go from prusa I2 x axis to I3 x axis by brunoschoofs

...al x axis from aliexpress

that is like a prusa i3 x-axis to fit on your prusa i2

the bottom holder are comming to patience please

thingiverse

free

Z axis regulation

...z axis regulation

thingiverse

z axis regulation without synchronization, for artillery

3

thingiverse

free

Raspberry 3 and 3+ case

...raspberry 3 and 3+ case

thingiverse

case for raspberry 3 and 3+ wit fan

thingiverse

free

Cube Dissection Puzzle/ Model for 3^3 + 4^3 +5^3 = 6^3 by lgbu

...: oxford university press. (p. 203). the authors gave credit to a solution in eureka, the magazine of the cambridge archimedeans.

thingiverse

free

Makeblock Aluminum Pieces 3*3/3*9

...makeblock aluminum pieces 3*3/3*9

thingiverse

makeblock pieces 3x3 and 3x9 recreated for 3d printing

thingiverse

free

Floss 3 Lite - lollipop 3

...floss 3 lite - lollipop 3

thingiverse

antenna mount for floss 3 lite.

thingiverse

free

3 by obstacledaddy

...3 by obstacledaddy

thingiverse

3

thingiverse

free

????????? ??? ??????? 3 ?? by Rigel

...????????? ??? ??????? 3 ?? by rigel

thingiverse

????????? ??? ??????? 3 ??

thingiverse

free

oloid 3

...oloid 3

thingiverse

oloid 3

thingiverse

free

A stand 3

...a stand 3

thingiverse

a stand 3.

thingiverse

free

Tischlampe #3

...tischlampe #3

thingiverse

tischlampe #3

thingiverse

free

3/8 to 3/4 grommet by quikniq

...3/8 to 3/4 grommet by quikniq

thingiverse

3/8" to 3/4" grommet.