Thingiverse

Emco Unimat 3 SL Taig lathe generic boring head adapter by 1944GPW

by Thingiverse

Last crawled date: 2 years, 10 months ago

There have been a few Unimat boring head designs over the years.

For instance the Compact Micrometer Boring Head' by GA Harding described in Model Engineer 4th June 1982 and 'A Small Boring Head for the Unimat 3' by BR Davies in Model Engineer 7th November 1980.

A US eBay seller sometimes lists a boring head made for the Unimat but as far as I am aware this has an imperial thread not metric.

Also there is a unit from a UK supplier but it is quite expensive and often listed as out of stock.

Considering the above, this solution uses a generic common (and importantly - cheap!) 2" diameter boring head from eBay.

These are for larger lathes than the Unimat and introduce their own problems, but if action is taken to mitigate these (see below) then this unit works admirably well on a tiny lathe.

Having bought the boring head for a larger lathe (Myford ML7), I realised it might be fitted to the Unimat by machining an adapter plate from steel, threaded M14 internally and for the head externally.

However that idea remained on the backburner. Recently I wanted to do some boring so I entertained the idea of a printed plastic one, for light duty.

The problems mentioned above are, firstly, the head size is a little larger than I would prefer, but this is no obstacle.

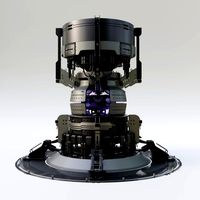

The other problem introduced by a larger chunk of spinning metal is the balance. As you can see from the photos, I placed an old bolt with some nuts and washers as a counterweight to compensate the head and toolbit offset.

This reduced the vibration down to a very low level and the plastic adapter had absolutely not the slightest bit of trouble in handling the machining task.

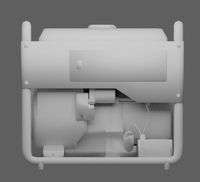

The photos show a frame from an IBM Selectric typewriter being bored to suit a larger mechanism, after careful concentric alignment to the existing hole. I used cutting fluid to start with but found it easier to spray a tiny squirt of WD40 on whilst cutting, with good results. The pieces of red duct tape are self-reminders that I have locked the cross slide and carriage.

SAFETY NOTE

Take special care in using this tool. Unlike a stationary lathe toolpost bit, the sharp toolbit itself is now moving. It may have a counterweight added which has the potential to catch loose clothing, or become a flying object itself.

Remember the closer your fingers come to the spinning boring head, the closer you come to an unplanned trip to hospital. Be very careful.

RUNNING THE SCRIPT

Open the Customiser and select your lathe from the dropdown listbox.

Please Note that the first time it runs, it will take a few minutes to generate the preview and longer for the final render. So be patient and go get yourself a cup of tea while you wait.

PRINTING INSTRUCTIONS

I made a few prototypes to get the external thread size to properly fit the 1-1/2" x 18 TPI of the boring head.

I used two Unimat tommy bars held in a vice (with soft jaws) and attempted to thread the head on, using a centrepunch as a tommy bar through the head (see photo).

It turned out a thread diameter of 1.5 (ie. 1-1/2") was far too tight so I reduced it to 1.46" which was not tight enough.

The script is thus set at 1.48" diameter which is pretty snug. If it's too tight just select a smaller diameter from the Customiser and print again.

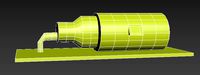

The adapter is purposely about 2mm longer on the inner surface than necessary. This is so you can mount the adapter on the mandrel and face the surface down so it is perfectly flat (see photo).

I printed the adapter from PETG as this plastic is oil and grease resistant. Print at 100% (completely solid) infill for maximum regidity. This is a small print and not much filament is consumed anyway.

USAGE

To accommodate a 1/4" toolbit I trimmed a small strip of soft aluminium, rolled it to a U shape and fitted the bit into it and the head.

It goes without saying that, as with all machining operations on the Unimat, take light cuts. Patience is the key.

OTHER SMALL LATHES

This script nominally produces an adapter for the Unimat 3 (M14x1) headstock but select the dropdown to do Unimat SL (M12x1) and Taig / Sherline (3/4"x16TPI).

Since the facets is set quite high, generation may take from minutes to a few hours. STLs for these lathes are provided so you don't need to wait that long.

NOTE I HAVE NOT TESTED THE SL, TAIG OR SHERLINE SIZES only the U3 so if you do try it and they don't fit please let me know and I'll correct it (I do have an SL and a Taig, but other priorities then making the adapters for them).

Use this at your own risk and I am not responsible for whether it works (or doesn't) for you.

For instance the Compact Micrometer Boring Head' by GA Harding described in Model Engineer 4th June 1982 and 'A Small Boring Head for the Unimat 3' by BR Davies in Model Engineer 7th November 1980.

A US eBay seller sometimes lists a boring head made for the Unimat but as far as I am aware this has an imperial thread not metric.

Also there is a unit from a UK supplier but it is quite expensive and often listed as out of stock.

Considering the above, this solution uses a generic common (and importantly - cheap!) 2" diameter boring head from eBay.

These are for larger lathes than the Unimat and introduce their own problems, but if action is taken to mitigate these (see below) then this unit works admirably well on a tiny lathe.

Having bought the boring head for a larger lathe (Myford ML7), I realised it might be fitted to the Unimat by machining an adapter plate from steel, threaded M14 internally and for the head externally.

However that idea remained on the backburner. Recently I wanted to do some boring so I entertained the idea of a printed plastic one, for light duty.

The problems mentioned above are, firstly, the head size is a little larger than I would prefer, but this is no obstacle.

The other problem introduced by a larger chunk of spinning metal is the balance. As you can see from the photos, I placed an old bolt with some nuts and washers as a counterweight to compensate the head and toolbit offset.

This reduced the vibration down to a very low level and the plastic adapter had absolutely not the slightest bit of trouble in handling the machining task.

The photos show a frame from an IBM Selectric typewriter being bored to suit a larger mechanism, after careful concentric alignment to the existing hole. I used cutting fluid to start with but found it easier to spray a tiny squirt of WD40 on whilst cutting, with good results. The pieces of red duct tape are self-reminders that I have locked the cross slide and carriage.

SAFETY NOTE

Take special care in using this tool. Unlike a stationary lathe toolpost bit, the sharp toolbit itself is now moving. It may have a counterweight added which has the potential to catch loose clothing, or become a flying object itself.

Remember the closer your fingers come to the spinning boring head, the closer you come to an unplanned trip to hospital. Be very careful.

RUNNING THE SCRIPT

Open the Customiser and select your lathe from the dropdown listbox.

Please Note that the first time it runs, it will take a few minutes to generate the preview and longer for the final render. So be patient and go get yourself a cup of tea while you wait.

PRINTING INSTRUCTIONS

I made a few prototypes to get the external thread size to properly fit the 1-1/2" x 18 TPI of the boring head.

I used two Unimat tommy bars held in a vice (with soft jaws) and attempted to thread the head on, using a centrepunch as a tommy bar through the head (see photo).

It turned out a thread diameter of 1.5 (ie. 1-1/2") was far too tight so I reduced it to 1.46" which was not tight enough.

The script is thus set at 1.48" diameter which is pretty snug. If it's too tight just select a smaller diameter from the Customiser and print again.

The adapter is purposely about 2mm longer on the inner surface than necessary. This is so you can mount the adapter on the mandrel and face the surface down so it is perfectly flat (see photo).

I printed the adapter from PETG as this plastic is oil and grease resistant. Print at 100% (completely solid) infill for maximum regidity. This is a small print and not much filament is consumed anyway.

USAGE

To accommodate a 1/4" toolbit I trimmed a small strip of soft aluminium, rolled it to a U shape and fitted the bit into it and the head.

It goes without saying that, as with all machining operations on the Unimat, take light cuts. Patience is the key.

OTHER SMALL LATHES

This script nominally produces an adapter for the Unimat 3 (M14x1) headstock but select the dropdown to do Unimat SL (M12x1) and Taig / Sherline (3/4"x16TPI).

Since the facets is set quite high, generation may take from minutes to a few hours. STLs for these lathes are provided so you don't need to wait that long.

NOTE I HAVE NOT TESTED THE SL, TAIG OR SHERLINE SIZES only the U3 so if you do try it and they don't fit please let me know and I'll correct it (I do have an SL and a Taig, but other priorities then making the adapters for them).

Use this at your own risk and I am not responsible for whether it works (or doesn't) for you.

Similar models

thingiverse

free

Sherline Tailstock lock handle + bit by kohjbeng

...u don't have to use up a toolbit). the hex head is most likely a bit oversized so you may need to file it down to a snug fit.

thingiverse

free

Emco Unimat SL Handwheel by WG73

...wg73

thingiverse

handwheel for emco unimat sl lathe.

print it, use it or change it.

freecad source file are available.

have fun!

thingiverse

free

Stepper motor support for Sherline lathes by lcalcena

...s and milling.

i use m4 bolt and nut for the clamp and m3 bolts for the stepper plate

https://www.youtube.com/watch?v=owygmdw_opi

thingiverse

free

Emco Unimat SL CNC Conversion by oet

...emco unimat sl cnc conversion by oet

thingiverse

i'm working on a cnc conversion kit for the emco unimat sl lathe

3dwarehouse

free

Sherline Lathe top Cross Slide Table

...my own measurements, so it might not be 100% exact, but was taken with a digital scale. #lathe #mill #model #sherline #sieg #taig

3dwarehouse

free

Sherline Lathe Tooling Plate

... the forces generated from milling. this model is still being made, check back for updates. #lathe #milling #seig #sherline #taig

thingiverse

free

Emco Unimat SL Fixed Steady (Lünette) by WG73

...e

fixed steady for unimat sl lathe

video: https://youtu.be/mdnfpgyawci

print it, use it, change it.

freecad source file included

3dwarehouse

free

Sherline or Taig Vise, part 1 of 4 , Left Jaw

...midification it could be used on a taig or similar small machine. this design is based on tryally's videos...

thingiverse

free

Sherline/Taig Spindle Nose Protector by billmckillip

...low for good action between the pla and the steel nose thread.

it has a knurled external finish for ease of mounting and removal.

cg_trader

$10

Unimat DB or SL compatible motor pulley | 3D

...le motor pulley | 3d

cg trader

the model based on unimat db/sl lathe's motor pulley, with 3 slots for holding driving belts.

1944Gpw

thingiverse

free

Cable clip with screw or nail fixing tab by 1944GPW

...orks but is very tight and the cable is pinched too much. any opening larger than 120 degrees makes the cable too easy to remove.

thingiverse

free

Headphone holder suitable for adhesive tape fixture by 1944GPW

... even 10% or 5% would be fine, most computer headphones aren't heavy.

feel free to modify the openscad script to your liking.

thingiverse

free

Folding slat camping table clip by 1944GPW

...urpose.

update: i have added the profile dxf and openscad script so you can adjust it to suit your own circumstances if you like.

thingiverse

free

Teletype paper tape splicing and alignment guide jig by 1944GPW

...aper tape that is fully functional (as used in this thing's photo).

for more info visit https://github.com/1944gpw/ptap2dxf

thingiverse

free

DEC PDP-11 keyring keyfob by 1944GPW

...s or use a backing plate but i was happy that wasn't needed.

shown is the keyfob attached to the console key for a pdp-11/05.

thingiverse

free

Myford ML7 lathe leadscrew handwheel pointer by 1944GPW

...e excess should do the trick.

the openscad script is included if you want to see how the pointer solid model is cobbled together.

thingiverse

free

Shower towel / face washer hook for glass wall or extruded edge shower recess by 1944GPW

...e these from white petg printed at 100% infill for maximum strength and also so there were no internal cavities to trap moisture.

thingiverse

free

Knob to suit Ryobi Pro Cut II line trimmer / whipper snipper / strimmer / weed whacker head by 1944GPW

...itable thick clothing and so on when operating.

power tools such as line trimmers can be extremely dangerous so always take care.

thingiverse

free

Desk benchtop cable fascia filler plug grommet by 1944GPW

...ions it should work fine.

as a courtesy please leave my name as the author of the program.

thanks, and i hope you find it useful.

thingiverse

free

DEC PDP-11 H960 rack fascia panel clip by 1944GPW

...at as a small addition (countersunk holes replacing the posts) and updated this script, set steel_screws to 1 in the customizer.

Unimat

thingiverse

free

Unimat Motor gear by pcco

...unimat motor gear by pcco

thingiverse

its is a unimat motor gear

thingiverse

free

Unimat Motor gear by powercam

...unimat motor gear by powercam

thingiverse

motor gear replacement

thingiverse

free

Emco Unimat SL Handwheel by WG73

...wg73

thingiverse

handwheel for emco unimat sl lathe.

print it, use it or change it.

freecad source file are available.

have fun!

thingiverse

free

Emco Unimat SL CNC Conversion by oet

...emco unimat sl cnc conversion by oet

thingiverse

i'm working on a cnc conversion kit for the emco unimat sl lathe

thingiverse

free

Emco Unimat SL Fixed Steady (Lünette) by WG73

...e

fixed steady for unimat sl lathe

video: https://youtu.be/mdnfpgyawci

print it, use it, change it.

freecad source file included

thingiverse

free

Conversione CNC Emco Unimat SL supporto inferiore by domlan77

...rto mancante per la modifica alla unimat sl, in futuro completerò il progetto con elettronica, poleggie e scatola per elettronica

thingiverse

free

MY6812 motor mount brackets, Unimat 3 motor upgrade by mkarliner

...y6812 which can then be connected to the headstock shaft via a timing belt. i printed the clamp and bracket in petg for strength.

thingiverse

free

Unimat Lathe Tool Holder by dvanommen

...achine that flings metal chips everywhere! a shroud for the psu and controller are in the works. so far cardboard does the trick)

thingiverse

free

DRO for Emco Unimat 3 by GuzZzt

...instructions to modify a left-hand caliper. a small differece is that my build need two small 3mm holes for mounting at each end.

thingiverse

free

DRO mount for Emco Unimat 3/4, MJ-189 mini lathe by drayson

...liper is well seated and the caps have a tight fit.

use the clamping screw of the caliper to mount it to the carriage driver arm.

Taig

thingiverse

free

Spindle wrench for a Taig mill by ponko

...spindle wrench for a taig mill by ponko

thingiverse

spindle wrench for a taig mill

thingiverse

free

Taig Lathe RH Foot by MTXMUGEN

...taig lathe rh foot by mtxmugen

thingiverse

adds much needed support to the taig lathe!

thingiverse

free

taig lathe end cap -pressfit- by MTXMUGEN

...taig lathe end cap -pressfit- by mtxmugen

thingiverse

press fit endcap for the taig lathe!

thingiverse

free

Taig Tool Light by smontanus

...equired to construct the light and a schematic to help with electronics construction. these were printed in black and orange abs.

thingiverse

free

Indicator Holder for Taig Lathe by NickAmes

...dicator on the bed of a taig lathe, allowing it to measure movement of the carriage. designed for indicators with a 3/8 in. stem.

thingiverse

free

Taig Lathe Bolt Hobber Revised by mde091234

...obber, but extended to work with the tool holder on my mini lathe. the original came from http://www.thingiverse.com/thing:234155

thingiverse

free

er16 and Taig collet holder for Kennedy toolbox by nozzle_police

...lder/rack for taig and two sets of er16 collets. made to fit into one of the larger drawers in a kennedy machinist's toolbox.

thingiverse

free

Taig 5019CR mill stock column top table

...ontroller on top of taig coumn in order to save some space.

the z-axis home sensor link:https://www.thingiverse.com/thing:3923297

thingiverse

free

Spindle camera for TAIG micro CNC mill by AnthonyT

... supplied for accurate center point positioning.

use paper with dots on it for rotation center calibration. example pdf included.

thingiverse

free

Indicator Holder for Taig Lathe_Mk 2

...10-32 screw and nut and one 8-32 screw and nut. i put a thumb screw cap on the clamping screw to make it that much easier.

enjoy!

Emco

3ddd

free

Аксессуары Emco classic

...такан , дозатор

набор аксессуаров в ванную emco classic. хром, стекло. hdri в комплекте.

3ddd

free

Emco\Polo

...еменный набор аксессуаров для ванны.http://www.emco-bath.com/produkte/bad-accessoires/overview/produktbereich/3602.html

3ddd

$1

Рабочее место EMCO UAB

...х цветового исполнения + тканевый аксессуар

размеры:

389 x 492 x 823(h)ммhttp://www.emko.lt/naive.

размер модели 7мб.

3d_sky

free

Emco classic accessories

...sories

3dsky

emco brush soap-dish glass batcher

a set of accessories for the bathroom emco classic. chrome, glass. hdri complete.

3d_sky

free

Emco \ Polo

...n range of accessories for the bath.http://www.emco-bath.com/produkte/bad-accessoires/overview/produktbereich/3602.html

thingiverse

free

emco toolpost dremel 8200 mount by iainanderson

...emco toolpost dremel 8200 mount by iainanderson

thingiverse

mounts a dremel 8200 cordless to an emco compact 5

thingiverse

free

Emco Unimat SL Handwheel by WG73

...wg73

thingiverse

handwheel for emco unimat sl lathe.

print it, use it or change it.

freecad source file are available.

have fun!

thingiverse

free

Emco Unimat SL CNC Conversion by oet

...emco unimat sl cnc conversion by oet

thingiverse

i'm working on a cnc conversion kit for the emco unimat sl lathe

thingiverse

free

Emco Swing bandsaw by mcentric

...and mounting hole locations are pretty exact.

i made this quick model to aid in the design of a pivoting wall mount for the saw.

thingiverse

free

Emco Maximat Super 11 Feed Gears by adamj12b

...emco maximat super 11 feed gears by adamj12b

thingiverse

127 and 120 tooth feed gears for the emco maximat super 11.

Lathe

archibase_planet

free

Lathe

...lathe

archibase planet

lathe turning lathe

lathe n050213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$19

Lathe

...lathe

3docean

industrial lathe machine tool workshop

lathes conventional model with some simple textures.

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

turbosquid

$25

lathe

...e

turbosquid

royalty free 3d model lathe for download as max on turbosquid: 3d models for games, architecture, videos. (1248841)

turbosquid

$30

lathe

...squid

royalty free 3d model lathe for download as ma and max on turbosquid: 3d models for games, architecture, videos. (1408225)

turbosquid

$25

Lathe

...

royalty free 3d model lathe for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1387058)

turbosquid

$2

Lathe

... free 3d model lathe for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1693117)

3d_export

$65

lathe

...lathe

3dexport

simple rendering of the scene file

archive3d

free

Lathe 3D Model

...ive3d

lathe turning lathe

lathe n050213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Lathe 3D Model

...3d model

archive3d

lathe milling machine

lathe n240807- 3d model for interior 3d visualization.

Sl

turbosquid

$50

sl

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$45

Sl Bed

...oyalty free 3d model sl bed for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1625378)

3ddd

$1

CILEK SL ACTIVE

...cilek sl active

3ddd

cilek

шкаф фирмы cilek из коллекции sl active white

3ddd

$1

CILEK SL ACTIVE

...cilek sl active

3ddd

cilek

cilek active (sl active white) sla-1304 кровать «selen»

3ddd

$1

Cilek SL ACTIVE

...k sl active

3ddd

cilek , стеллаж

cilek active (sl active white) 1501-sla стеллаж «hayal»

3d_export

$20

mercedes benz sl 1963

...mercedes benz sl 1963

3dexport

mercedes benz sl 1963

3ddd

$1

Орбитрек SL 116

...116

3ddd

детская площадка

уличный орбитрек sl 116 производства inter atleticahttp://diso.interatletika.com/product259/

3ddd

free

Брусья SL 105

... детская площадка

уличные брусья sl 105 ,производства inter atleticahttp://diso.interatletika.com/product247/

3ddd

free

Турник SL 117

... турник

уличный турник sl 117 производства inter atletica.http://diso.interatletika.com/product258/

3ddd

$1

Kettle scarlett sl 1501

...kettle scarlett sl 1501

3ddd

kettle , чайник

kettle scarlett sl 1501

Boring

turbosquid

$14

Emoji Bored

...del emoji bored for download as 3ds, obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1426688)

turbosquid

$8

Bore Plug

...model bore plug for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1156742)

turbosquid

$99

Downdraught Single Bore Carburetor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

The boring company - Brick PBR 2K Textures

...s for download as blend, max, unitypackage, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1688870)

archibase_planet

free

Drill

...drill archibase planet boring rig rig drill drill n070807 - 3d model for...

archive3d

free

Drill 3D Model

...drill 3d model archive3d boring rig rig drill drill n070807 - 3d model for...

archibase_planet

free

Drill

...drill archibase planet boring mill perforator driller drill pro 1 - 3d model...

archive3d

free

Drill 3D Model

...drill 3d model archive3d boring mill perforator driller drill pro 1 - 3d model...

3d_export

$5

Metal chess set 3D Model

...metal chess set 3d model

3dexport

metal wood chess set bored game

metal chess set 3d model ilai.prz 64938 3dexport

3d_export

free

Dragon Ak47

...ore axis. the muzzle is threaded for the installation of various muzzle devices such as a muzzle brake or a blank-firing adaptor.

Adapter

3d_export

$10

Adapter 3D Model

...adapter 3d model

3dexport

adapter

adapter 3d model mur 20260 3dexport

archive3d

free

Adapter socket 3D Model

...dapter socket adapter

adapter socket n090211 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$400

cell adaptation

...

royalty free 3d model cell adaptation for download as blend on turbosquid: 3d models for games, architecture, videos. (1701655)

archive3d

free

Adapter 3D Model

...ups pc equipment

adapter extron n180813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

usb adapter

...royalty free 3d model usb adapter for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1582234)

turbosquid

$15

Power adapter

...free 3d model power adapter for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1510024)

turbosquid

$8

USB adapter

...e 3d model usb adapter for download as max, fbx, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1713542)

turbosquid

$30

adapter.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Nokia Adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Universal adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Generic

3d_export

$17

Generator

...generator

3dexport

generator

archibase_planet

free

Generator

...base planet

generator electric generator

generator electric n300715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$20

Generation

...generation

designconnected

knoll generation computer generated 3d model. designed by formway design.

3d_export

$8

generator

...generator

3dexport

generator - obj, 3ds, fbx.

3d_export

$7

generator

...generator

3dexport

generator extures 4k resolution, basecolor -normal -metallic -ao-roughness-height tris:3084

turbosquid

free

generator

...rator

turbosquid

free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1492909)

3ddd

$1

general

...general

3ddd

генерал

turbosquid

$99

generator

...urbosquid

royalty free 3d model generator for download as ma on turbosquid: 3d models for games, architecture, videos. (1514125)

turbosquid

$20

Generator

...rbosquid

royalty free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1244841)

turbosquid

$2

Generator

...rbosquid

royalty free 3d model generator for download as fbx on turbosquid: 3d models for games, architecture, videos. (1245541)

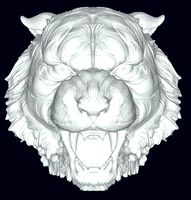

Head

3d_export

$5

head

...head

3dexport

simulated female head.

3d_ocean

$5

Deer Head

...deer head

3docean

deer head

simple model of deer head with neck.

cg_studio

$25

Marble Head - Head A3d model

... - head a3d model

cgstudio

.ma - marble head - head a 3d model, royalty free license available, instant download after purchase.

turbosquid

$5

Head

...ad

turbosquid

royalty free 3d model head for download as max on turbosquid: 3d models for games, architecture, videos. (1230068)

turbosquid

free

Head

...

turbosquid

royalty free 3d model head for download as blend on turbosquid: 3d models for games, architecture, videos. (1276899)

turbosquid

free

The Head

...urbosquid

royalty free 3d model the head for download as max on turbosquid: 3d models for games, architecture, videos. (1386205)

3d_export

$10

bull head

...bull head

3dexport

bull head

3d_export

$5

girl head

...girl head

3dexport

head girl

3d_export

$5

Tigger-head

...tigger-head

3dexport

tigger-head

3d_export

$5

head on a spear

...head on a spear

3dexport

head on a spear

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder