Thingiverse

Edge Lit 3D Printed Pendant by dj_segfault

by Thingiverse

Last crawled date: 3 years ago

Overview

I got the idea for this project from Geek Mom Project's Layered Edge-Lit Pendants project. Her project uses a laser cutter to cut out clear and black plastic layers, and screws them together. But not everyone has access to a laser cutter, so I wanted to see if I could do something similar just using a 3D printer. The front and back are opaque, and instead of clear acrylic in the center to diffuse the light, I used clear PLA filament. The front contains the design in the negative space, letting the light from the center shine through.

Like her project, mine is electrically and mechanically simple, as the design has the battery insert into the top sticking out, so it's easy to turn on and off by inserting or removing the battery.

3D Printed Components

3D printed in three different parts that get glued together:

The back piece: Printed in the opaque color of your choice, any infill will do. This holds the back of the battery in, has loops to hang the pendant on, and also has 2 registration pins sticking up that go through the other pieces to guarantee alignment.

The center piece: Printed in clear PLA filament, diffuses the LED light. There is space for the LED body and leads, and the battery. There are holes straight through for the registration pins for alignment. You may want to play with the infill to get the right diffusion pattern for your design. 15% infill worked for me.

The front piece: Printed in the opaque color of your choice, This has the actual image in negative space for the light to shine through. The back of the front piece has 1mm filleted shallow holes for the ends of the registration pins. I provide two different front designs and either will work. You can make your own on the same design for your pendant. You can even make it 3D instead of just a flat disk. Just make sure it's 35mm in diameter, and holes for the registration pins, 12mm across from center and 8mm up from center, 3mm diameter and 1mm fillet.

Here is a link to my models in OnShape so you can see how they were built

Other Components

The LED. I used 3mm LEDs that take 2.2v or 3.2V and draw 20ma (different colors will have different power requirements).

CR2032 3v battery. In my test, this provides about 70 hours of runtime before significant dimming, and are readily available anywhere.

This may not be necessary, but to make better contact and make the pendant more robust, I cut some thin conductive metal that fits on either side of the battery, and used conductive glue to fasten them to the LED wires, so inserting the battery does not mangle the leads. This may not be required depending on how delicate you are with it.

Assembly

Print the front and back in opaque PLA

Print the center in clear PLA

Apply glue to the back and put the clear center on top of the back, making sure the registration holes go through the holes in the center

Put the LED in the slot in the center piece, making sure the wires are on the back and the front, not the sides. I didn't find it necessary to glue the LED in place, but you might.

Glue the metal pieces on the inside of the LED legs using the conductive glue, if you are using them, so the battery will press against the metal pieces and not the wires

Glue the front piece on top of the center piece, making sure to stay clear of your design.

Here's a video of my prototype in action

I got the idea for this project from Geek Mom Project's Layered Edge-Lit Pendants project. Her project uses a laser cutter to cut out clear and black plastic layers, and screws them together. But not everyone has access to a laser cutter, so I wanted to see if I could do something similar just using a 3D printer. The front and back are opaque, and instead of clear acrylic in the center to diffuse the light, I used clear PLA filament. The front contains the design in the negative space, letting the light from the center shine through.

Like her project, mine is electrically and mechanically simple, as the design has the battery insert into the top sticking out, so it's easy to turn on and off by inserting or removing the battery.

3D Printed Components

3D printed in three different parts that get glued together:

The back piece: Printed in the opaque color of your choice, any infill will do. This holds the back of the battery in, has loops to hang the pendant on, and also has 2 registration pins sticking up that go through the other pieces to guarantee alignment.

The center piece: Printed in clear PLA filament, diffuses the LED light. There is space for the LED body and leads, and the battery. There are holes straight through for the registration pins for alignment. You may want to play with the infill to get the right diffusion pattern for your design. 15% infill worked for me.

The front piece: Printed in the opaque color of your choice, This has the actual image in negative space for the light to shine through. The back of the front piece has 1mm filleted shallow holes for the ends of the registration pins. I provide two different front designs and either will work. You can make your own on the same design for your pendant. You can even make it 3D instead of just a flat disk. Just make sure it's 35mm in diameter, and holes for the registration pins, 12mm across from center and 8mm up from center, 3mm diameter and 1mm fillet.

Here is a link to my models in OnShape so you can see how they were built

Other Components

The LED. I used 3mm LEDs that take 2.2v or 3.2V and draw 20ma (different colors will have different power requirements).

CR2032 3v battery. In my test, this provides about 70 hours of runtime before significant dimming, and are readily available anywhere.

This may not be necessary, but to make better contact and make the pendant more robust, I cut some thin conductive metal that fits on either side of the battery, and used conductive glue to fasten them to the LED wires, so inserting the battery does not mangle the leads. This may not be required depending on how delicate you are with it.

Assembly

Print the front and back in opaque PLA

Print the center in clear PLA

Apply glue to the back and put the clear center on top of the back, making sure the registration holes go through the holes in the center

Put the LED in the slot in the center piece, making sure the wires are on the back and the front, not the sides. I didn't find it necessary to glue the LED in place, but you might.

Glue the metal pieces on the inside of the LED legs using the conductive glue, if you are using them, so the battery will press against the metal pieces and not the wires

Glue the front piece on top of the center piece, making sure to stay clear of your design.

Here's a video of my prototype in action

Similar models

thingiverse

free

christmas tree lamp by liljjnic

...he back of the battery pack makes it nice and neat and easier to change the batteries

i hope u enjoy making this as much as i did

thingiverse

free

Letters to hold led strips by santa25

... back and front pieces should clip together, i am going to print them with an opaque filament to see how the light shines through

thingiverse

free

Hole keeper 2.5mm holes - van conversion etc by HowardHarks

...s so that the feet are parallel to the bed before printing. i would recommend using prusa slicer as your slicer for this project.

thingiverse

free

battery holder for leds by custom_prints

...ome holes). if this gets downloaded a lot i will revise it and make some holes instead of having to heat up a pin and make a hole

thingiverse

free

LED Star by DanLuc

...i used lots of hot glue with a glue-gun, to both hold everything in place but also to insulate the wires so they don't touch.

thingiverse

free

Protocol Droid eye backing disks by PandaProps

...r with ca glue

the entire assembly can be hot glued over your brass or plastic eyes or held in place with epoxy putty, tape etc.

thingiverse

free

Pentagon Slice Puzzle by JWidmar

...rger center piece in a way where it wont spill out. push pieces together until dry, pushing the pin in.

sticker, paint and enjoy

thingiverse

free

Thales Liberty Programming Cable by joshutt

...ke to use some hot glue to make sure they are secure. then you can glue the pin holder into the connector. the screw is a 6-32.

thingiverse

free

5S 2P 18650 Battery Holder

...ome holes that let you pass cables through for compact assembly.

feel free to make me a small donation if it was useful to you :)

thingiverse

free

Wall-mounted Siva Logo Lamp by Scharrelese

... you can use the push button on the battery pack to turn the lamp on or off by pressing the whole thing against the wall a little

Dj

3ddd

$1

Midj DJ

... кофейный

кофейный столик midj dj 100http://www.midj.com/products/coffee-table/dj-100

3ddd

$1

dj headphones

...dj headphones

3ddd

наушники

dj headphones

3d_ocean

$18

DJ System

...c

highly detailed model of disco equipment with textures, shaders and materials. it is ready to use, just put it into your scene.

3ddd

$1

DJ-контроллер

... микшер

dj-микшерный пульт hercules djcontrol air+

корпус : 45,5 x 26 см.

текстуры не требуются. polys 50604 verts 81973.

turbosquid

$10

Djs table

...

turbosquid

royalty free 3d model djs table for download as on turbosquid: 3d models for games, architecture, videos. (1684940)

turbosquid

$69

Dj Turntable

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

DJs mixer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

DJ Mixer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Dj Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

dj stuff

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Lit

design_connected

$20

Lit Bonaparte

...lit bonaparte

designconnected

moissonnier meubles lit bonaparte computer generated 3d model.

turbosquid

$15

Lit Headphones

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Building Lit At Night

...yalty free 3d model building lit at night for download as max on turbosquid: 3d models for games, architecture, videos. (1342208)

turbosquid

$3

Stool Chair Lit

...l chair lit for download as obj, fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1275985)

3ddd

$1

LIT DE REPOS (софа)

...lit de repos (софа)

3ddd

grange ковка

модель построена с мебельного каталога grange

lit de repos (софа)

д.198-в.101-г.86 см

turbosquid

$40

jeep untextured well lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Owl Lit Up Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Varaluz / Lit-Mesh Test 6 Light Chandelier

...p://www.wayfair.com/varaluz-lit-mesh-test-6-light-chandelier-231c06nb-vrz2318.html

23" h x 26" w x 26" d

turbosquid

$39

Antique Candle Holder with Lit Candle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Vega - The LED-lit Christmas Star

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Edge

3ddd

free

EDGE

... часы

светильник edge

дизайнер: моторный александрhttp://www.djournal.com.ua/?p=2483

3ddd

$1

Edge

...edge

3ddd

edge

кухня-моноблок, без плинтуса, подвешивается на стену.

3ddd

$1

кровать EDGE

...кровать edge

3ddd

edge

кровать и тумбочки от компании edge

полигоны: 181 253

3ddd

free

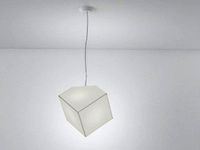

EDGE светильник

...edge светильник

3ddd

edge , подвес

производитель польша

материал метал

3ddd

$1

Artemide Edge

...artemide edge

3ddd

artemide

люстра artemide edge. сделана по фото.

design_connected

free

Edge pendant

...edge pendant

designconnected

free 3d model of edge pendant by fabbian designed by baldereschi, alessandra.

3ddd

$1

EDGE CHANDELIER

...lier фирмы holly hunt. официальный сайт:https://www.hollyhunt.com/showproduct.aspx?productid=3103&manufacturerid;=1

design_connected

$7

Edge 30

...edge 30

designconnected

artemide edge 30 computer generated 3d model. designed by mendini, alessandro.

3ddd

$1

Edge Seat

... банкетка

om website: beltafrajumar.com

designer: jacob pringiers

formats: 3ds, c4d, fbx, obj

3ddd

$1

бра Fabbian Edge

... edge

бра fabbian, модель edge, артикулы d77 d01 15 и edge d 77 d03 15. маленькое бра сделано более корректно

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints