Thingiverse

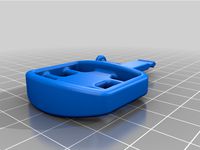

EC-RE011 Campagnolo 8 Speed Ergo right shifter Spring Carrier by elhalpern

by Thingiverse

Last crawled date: 3 years ago

Campagnolo # EC-RE011 8 Speed Ergo Right side (rear derailleur) Spring Carrier-

Your Campy Ergo 8 speed can shift like new again.

It's frustrating working to keep an older bike alive and original, when manufacturers discontinue repair parts. Fortunately Campagnolo has used the same "g-springs" in newer versions of their brake/shifters, but the spring carrier is no longer available. Printing it in plastic might last a while if you print with strong material and a very high fill percentage. I printed it using PLA just to test the fit and it worked fine, but it's not worth the hassle of changing it out to leave a plastic part in place.... IF YOU WANT IT TO LAST A LONG TIME, use a service that will print in steel, aluminum, stainless steel, or titanium.

FYI - The hex bolt that locks down the thumb lever and the spring assembly is a left-hand thread.... clockwise to loosen.

The current version posted on Thingiverse is V5 and has corrections to the g-spring pivot hole diameters and distance from center as well as some added reinforcment. This was drawn in Solidworks and dimensioned using a sample part and a pair of dial calipers.

Three of the images shown are an actual part printed by i.Materialise.com using their "steel" (bronze infused). Simply copy them on the STL file and let them know the O.O. is 25.47mm. It's three grams heavier than the original part, but should last forever. I also had to open up the spring holes after delivery with a 0.059" drill bit. (3D printing is funny on small holes. My model is dead on, but 3D printers tend to have issues with tolerances on small holes due to material particle size or handling of such.)

The bronze infused steel material is very hard. I heard my bit chattering on the drill press and stopped to add cutting oil. No problem opening up the holes after some oil... use a vise to hold the part and avoid breaking the bit off in the part, and take your time. The photo makes it look like bronze, but it drills like steel and has a more silver look in person. I compared the looseness of the springs in their pivot holes on a healthy, but used carrier, to the drilled 3D printed version with 0.059" holes and the printed part has less slop while the springs still pivot freely.

I installed the steel printed carrier (coated in grease to lessen corrosion) with new g-springs, and with new Campy cables & wires. More than 3600 miles on it (Nov 2020) with more than 3000 shifts, and the shifting is smooth and reliable. Everything works perfect. No problem under stress with me (200+lbs) out of the saddle and standing on the pedals in all gears. No slip or gear jumping. This works fine. I'll continue revise this dialog as I put more miles on the printed steel part.

UPDATE - My ride on 9/23/19 the thumb shifter went soft and it would no longer hold the gears above the center of the cassette. I knew immediately that either the 3D Printed part, or the G-springs had failed. That evening, I disassembled the right shift lever and was happy to see a broken G-spring. The printed part was in pristine condition and everything worked fine after I loaded a new pair of G-Springs. I got close to 2000 miles from the new pair of G-springs I loaded during my initial rebuild using the newly printed-steel carrier. Campagnolo suggests a rebuild with new G-Springs and cable wires every 3000 miles. Nice to know my part outlasted theirs ;-).

Keep in mind that I did this in 2016, and since then the metal 3D printing business has grown like a weed. While I recommend iMaterialize, I am certain they have competitors in the U.S.A. that can match or beat the $32 and ship quicker. I just haven't had the need to search out another vendor.

My test-bed bike for this is a 1994 Trek OCLV 5500 with Chorus all around except for an SRAM pc-871 chain.

keywords - rear, right, 1994, 1995, 1996, cracked, broken, replacement, ergo power, spring carrier, retainer, Chorus, c-record, record, 8 speed, EC-RE011, carrier, ecre011

BTW - for those new to 3D printing (or CNC machining), there can be imperial/metric confusion when passing around CAD files. It is always good practice to tell the person or company handling the printing a single obvious dimension so they can make certain their process is printing to the right scale. The outside diameter of this part is 1.003 inches (25.47mm). Sharing this info with your vendor will avoid buying a part that doesn't fit.

COMMENTARY on Ergo 8 speed: As a recent owner of an 8 Speed Chorus group and experience with Shimano Dura Ace 7800, Shimano 600/Ultegra, and Campy Nuevo/Super Record, I feel the Ergo 8 is very solid. The biggest problem is availability of spare parts and so far the only odd issue is the right side hidden cone in the freehub. This freehub is very difficult to get a dead on cone adjustment and in some case the hidden cone floats freely making it impossible to setup without a very tiny amount of play. Using a temporary pair of jam nuts on the cluster side makes it easier to manage the adjustment on the left side. Even with this minimal play the group rides and performs well under load, I would own another Ergo 8 bike as long as I can find spare parts. The play is so minimal that it can't be felt with the wheel removed from the bike by just trying to move the axel. It can only be felt when the wheel is back on the bike by grabbing the wheel near the brakes... and even then, most people won't feel it.

Your Campy Ergo 8 speed can shift like new again.

It's frustrating working to keep an older bike alive and original, when manufacturers discontinue repair parts. Fortunately Campagnolo has used the same "g-springs" in newer versions of their brake/shifters, but the spring carrier is no longer available. Printing it in plastic might last a while if you print with strong material and a very high fill percentage. I printed it using PLA just to test the fit and it worked fine, but it's not worth the hassle of changing it out to leave a plastic part in place.... IF YOU WANT IT TO LAST A LONG TIME, use a service that will print in steel, aluminum, stainless steel, or titanium.

FYI - The hex bolt that locks down the thumb lever and the spring assembly is a left-hand thread.... clockwise to loosen.

The current version posted on Thingiverse is V5 and has corrections to the g-spring pivot hole diameters and distance from center as well as some added reinforcment. This was drawn in Solidworks and dimensioned using a sample part and a pair of dial calipers.

Three of the images shown are an actual part printed by i.Materialise.com using their "steel" (bronze infused). Simply copy them on the STL file and let them know the O.O. is 25.47mm. It's three grams heavier than the original part, but should last forever. I also had to open up the spring holes after delivery with a 0.059" drill bit. (3D printing is funny on small holes. My model is dead on, but 3D printers tend to have issues with tolerances on small holes due to material particle size or handling of such.)

The bronze infused steel material is very hard. I heard my bit chattering on the drill press and stopped to add cutting oil. No problem opening up the holes after some oil... use a vise to hold the part and avoid breaking the bit off in the part, and take your time. The photo makes it look like bronze, but it drills like steel and has a more silver look in person. I compared the looseness of the springs in their pivot holes on a healthy, but used carrier, to the drilled 3D printed version with 0.059" holes and the printed part has less slop while the springs still pivot freely.

I installed the steel printed carrier (coated in grease to lessen corrosion) with new g-springs, and with new Campy cables & wires. More than 3600 miles on it (Nov 2020) with more than 3000 shifts, and the shifting is smooth and reliable. Everything works perfect. No problem under stress with me (200+lbs) out of the saddle and standing on the pedals in all gears. No slip or gear jumping. This works fine. I'll continue revise this dialog as I put more miles on the printed steel part.

UPDATE - My ride on 9/23/19 the thumb shifter went soft and it would no longer hold the gears above the center of the cassette. I knew immediately that either the 3D Printed part, or the G-springs had failed. That evening, I disassembled the right shift lever and was happy to see a broken G-spring. The printed part was in pristine condition and everything worked fine after I loaded a new pair of G-Springs. I got close to 2000 miles from the new pair of G-springs I loaded during my initial rebuild using the newly printed-steel carrier. Campagnolo suggests a rebuild with new G-Springs and cable wires every 3000 miles. Nice to know my part outlasted theirs ;-).

Keep in mind that I did this in 2016, and since then the metal 3D printing business has grown like a weed. While I recommend iMaterialize, I am certain they have competitors in the U.S.A. that can match or beat the $32 and ship quicker. I just haven't had the need to search out another vendor.

My test-bed bike for this is a 1994 Trek OCLV 5500 with Chorus all around except for an SRAM pc-871 chain.

keywords - rear, right, 1994, 1995, 1996, cracked, broken, replacement, ergo power, spring carrier, retainer, Chorus, c-record, record, 8 speed, EC-RE011, carrier, ecre011

BTW - for those new to 3D printing (or CNC machining), there can be imperial/metric confusion when passing around CAD files. It is always good practice to tell the person or company handling the printing a single obvious dimension so they can make certain their process is printing to the right scale. The outside diameter of this part is 1.003 inches (25.47mm). Sharing this info with your vendor will avoid buying a part that doesn't fit.

COMMENTARY on Ergo 8 speed: As a recent owner of an 8 Speed Chorus group and experience with Shimano Dura Ace 7800, Shimano 600/Ultegra, and Campy Nuevo/Super Record, I feel the Ergo 8 is very solid. The biggest problem is availability of spare parts and so far the only odd issue is the right side hidden cone in the freehub. This freehub is very difficult to get a dead on cone adjustment and in some case the hidden cone floats freely making it impossible to setup without a very tiny amount of play. Using a temporary pair of jam nuts on the cluster side makes it easier to manage the adjustment on the left side. Even with this minimal play the group rides and performs well under load, I would own another Ergo 8 bike as long as I can find spare parts. The play is so minimal that it can't be felt with the wheel removed from the bike by just trying to move the axel. It can only be felt when the wheel is back on the bike by grabbing the wheel near the brakes... and even then, most people won't feel it.

Similar models

thingiverse

free

Campagnolo Ergo 8 End Cap by elhalpern

...right in and will replace original lost or broken parts. version 2 was uploaded to provide spring clearance for the thumb lever.

grabcad

free

Shifter part

...shifter part

grabcad

shifter part, without spring hole and grooves.

road bike

thingiverse

free

Campagnolo CS-002 8 speed cassette spacer ring by elhalpern

...'d love to know what material, what printer, type of platform (tape on aluminum, glass, etc..) and what thicknesses you ran.

thingiverse

free

Bike Shifter (Friction) by nothinglabs

...out any problems.

with 300+ miles on same shifter - i'm reasonably confident it's pretty solid and should last a while.

thingiverse

free

Bike: Bowden holder for handlebar shifter - Schaltzuggegenhalter Fixie Single Speed by mad_tom

...flat handlebar, since it's not nice to shift up/down gears at this low place, i created this "schaltzuggegenhalter"

thingiverse

free

Jeep CJ5 3 Speed Shift Knob Two Color by WashingtonApple

... vapor treatment to give it a nice shine. the shift pattern is placed slightly to the left to make it more visible to the driver.

thingiverse

free

SRAM attack 8 replacement handle by BotLawson

...the model.

included the solidworks 2019 part file to make it easier to update the grips for better comfort or different shifters.

cg_trader

$3

Bike gear shifter | 3D

...al special additional hardware.

i made this for the bike because i have brake it too many times to buy new every time i broke it.

thingiverse

free

Carrier for Sparkfun RS232 level shifter by dmatsumoto

...ach the pcb to it, and then double stick tape everything to my lcd. the pcb attaches to the carrier via the included jackscrews.

thingiverse

free

Nexus 3 speed Shift Handle by Biker1978

...ive any feedback on design or strength improvements as this is still a work in process. please be kind and thank you in advance.

Re011

3dwarehouse

free

ARANDELA OXALÁ - RE011

...arandela oxalá - re011

3dwarehouse

arandela oxalá - re011

3dwarehouse

free

Arandela+Oxalá+RE011

...arandela+oxalá+re011

3dwarehouse

3dwarehouse

free

Arandela+Oxalá+RE011.skp

...arandela+oxalá+re011.skp

3dwarehouse

3dwarehouse

free

Arandela Oxalá RE011 - Bella Iluminação

... material: metal e vidro cor: dourado e transparente tensão: bivolt potência: 2x25w(50w) soquete: g9 medida: 33,5cm x 26cm x 39cm

3dwarehouse

free

ARANDELA OXALÁ 39X33,5X26CM METAL E VIDRO DOURADO E TRANSPARENTE - BELLA ILUMINAÇÃO RE01

...compre com desconto em: https://www.inspirehome.com.br/arandela-oxala-39x33-5x26cm-metal-e-vidro-dourado-e-transparente-bella-iluminac-o-re011/p fabricante bella iluminação modelo re011 ...

Elhalpern

thingiverse

free

Optiplex 160 Stand by elhalpern

...pture slots and grabs the pc more than an inch up its sides. it's a free alternative to dell's # cn-0j163g - j163g

enjoy!

thingiverse

free

Engine Key Briggs & Stratton # 794696 by elhalpern

...

a second version has been uploaded that does not have the support feature for those with resin or sintering printers. 1/27/2020

thingiverse

free

Hyundai Elantra Vent Slide by elhalpern

...vane.

use and install at your own risk. no warranty. user assumes all risk and may freely modify design to suit personal needs.

thingiverse

free

Holder for "Tube cutter hand tool trapezoid blade" by PredatorJr by elhalpern

...d a holder that protects fingers and the blade without changing the set of the filament. just a rubber band to hold it in place.

thingiverse

free

3TTT Stem Plug by elhalpern

...u may need to select metric conversion in slicing software so that it prints the correct size.

keep your stem bolt clean and dry.

thingiverse

free

Engine Key Tecumseh 430492 35062 for Yard Machines 24inch Snow Blower by elhalpern

...rn

thingiverse

replacement key for a yard machines 24" snow blower with a 7hp tecumseh engine key number 430492 or 35062

thingiverse

free

Vent Shield Acer Aspire AXC series by elhalpern

...this shield still allow the cpu to breath, but prevent dust and water mist or droplets from falling directly into the vent holes.

thingiverse

free

Campagnolo Ergo 8 End Cap by elhalpern

...right in and will replace original lost or broken parts. version 2 was uploaded to provide spring clearance for the thumb lever.

thingiverse

free

Honda CRV 02-05 Rear Window Wiper Bridge by elhalpern

...e" solves this issue and protects your rear wiper from getting burnt out or broken and provides reliable rear window wiping.

thingiverse

free

Gerber Baby Food Jar Holder by elhalpern

...s, and anything small. i'm sure some new parent will also appreciate the form and function of this at feeding time. enjoy !

Campagnolo

turbosquid

$28

Campagnolo wheel from maserati

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

campagnolo bike by jpo85

...campagnolo bike by jpo85

thingiverse

campagnolo logos for vintage racing bike

thingiverse

free

Campagnolo Porsche wheels scale 1/25 by Tomaszke

...olo porsche wheels scale 1/25 by tomaszke

thingiverse

campagnolo style wheels for a revell porsche 911 carrera rs 3.0 scale 1/25

thingiverse

free

Campagnolo Pedal Bearing Cap by Mi3Dke

...l original part, but the replacement cap fits and does its job to protect the bearing from dirt.

the fusion 360 file is attached.

thingiverse

free

Campagnolo Ergopower 10s shifter gear by Chnillapoil

...opower 10s shifter.

unobtanium without buying a complete shifter.

please leave your comments and i appreciate to see your makes !

thingiverse

free

Campagnolo cassette holder by kevwill

...e different size lock rings: 26mm, 27mm, and 29mm threads. there is also a cap without threads for cassettes without lock rings.

thingiverse

free

Campagnolo Freehub Bearing Press by diepeter

...of m10 / m8 threaded rod, and some nuts. the recession on the bottom of the design holds a washer with an outer diameter of 20mm.

thingiverse

free

Campagnolo Ergo 8 End Cap by elhalpern

...right in and will replace original lost or broken parts. version 2 was uploaded to provide spring clearance for the thumb lever.

thingiverse

free

Campagnolo CS-002 8 speed cassette spacer ring by elhalpern

...'d love to know what material, what printer, type of platform (tape on aluminum, glass, etc..) and what thicknesses you ran.

Ergo

turbosquid

$30

ergo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

HOESCH - ergo

...hoesch - ergo

3ddd

hoesch , ванна

акриловая ванна hoesch-ergo размерами 2075х1075мм.

3ddd

$1

MP3 Ergo Zen Clip

...o , mp3 , плеер

модель mp3 плеера ergo zen clip

3ddd

$1

Ergo E32C20 LCD Tv

...ergo e32c20 lcd tv

3ddd

ergo , телевизор

материалы и текстуры присутствуют

turbosquid

$9

ERGO black coin

...id

royalty free 3d model ergo black coin for download as max on turbosquid: 3d models for games, architecture, videos. (1496182)

turbosquid

$9

ERGO gold coin

...uid

royalty free 3d model ergo gold coin for download as max on turbosquid: 3d models for games, architecture, videos. (1496179)

turbosquid

$20

Rattan furniture ERGO

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Ergo Suspended Light

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Ergo Road Handlerbars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Ergo Libs 3D Model

...ergo libs 3d model

archive3d

сabinet case

Shifter

turbosquid

free

Gear Shifters

...quid

royalty free 3d model gear shifters for download as max on turbosquid: 3d models for games, architecture, videos. (1661839)

cg_studio

$100

Shifter Kart3d model

...shifter kart3d model

cgstudio

.max - shifter kart 3d model, royalty free license available, instant download after purchase.

turbosquid

$14

Logitech G29 Shifter

...oyalty free 3d model logitech g29 shifter for download as c4d on turbosquid: 3d models for games, architecture, videos. (1220158)

turbosquid

$3

Bycicle Front Shifter Shimano XTR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$39

Go Kart 3D 3D Model

...car gokart go-kart road transport ride quad vehicle racing shifter cart go kart 3d 3d model codethislab 55170...

3d_export

$10

Clutch 3D Model

...3d model animated rigged phyzics simulated low poly gear shifter clutch 3d model florincristian 97692...

3d_sky

free

shifter

...shifter

3dsky

mixer

corona

thingiverse

free

shifter plates for a shifter im making by stockcar

...shifter plates for a shifter im making by stockcar

thingiverse

making a shifter for online racing.

unity_asset_store

$15

Shifter

...m dary palasky and speed up your game development process. find this & other characters options on the unity asset store.

thingiverse

free

Skull Shifter by ColeDowns

...skull shifter by coledowns

thingiverse

just a shifter

Ec

turbosquid

$260

Eurocopter EC 135

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$129

EC-120B Colibri

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$72

ave ec-360e

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$69

Liebherr EC-H

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

evermotion

$24

Eurocopter EC-130 am73

... helicopter with all textures, shaders and materials. it is ready to use, just put it into your scene. evermotion 3d models shop.

cg_studio

$139

EC-130V Hercules3d model

...gulf fire awacs

.3ds .dxf .max .obj - ec-130v hercules 3d model, royalty free license available, instant download after purchase.

cg_studio

$269

EC-145/BK-1173d model

...

cgstudio

.3ds .c4d .fbx .lw .ma .max - ec-145/bk-117 3d model, royalty free license available, instant download after purchase.

humster3d

$15

Yamaha EC-03 2013 Blueprint

...13 blueprint 3d model in the format you need. all our 3d models was created on real car base and maximally close to the original.

3d_export

$100

Eurocopter EC 135 3D Model

...eurocopter ec 135 3d model

3dexport

eurocopter ec135

high poly models

humster3d

$75

3D model of Ferrari SP12 EC 2012

...etailed 3d model of ferrari sp12 ec 2012 in various file formats. all our 3d models were created maximally close to the original.

Carrier

3d_export

$5

adhesive tape carrier

...adhesive tape carrier

3dexport

adhesive tape carrier

turbosquid

$120

Troop Carrier

...quid

royalty free 3d model troop carrier for download as skp on turbosquid: 3d models for games, architecture, videos. (1532045)

turbosquid

$25

Truck carrier

...quid

royalty free 3d model truck carrier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1563111)

turbosquid

$7

Battle Carrier

...uid

royalty free 3d model battle carrier for download as lwo on turbosquid: 3d models for games, architecture, videos. (1654772)

3d_export

$20

Universal carrier

...a real “universal”: reconnaissance, transportation of military cargo, towing artillery. the model is as detailed as voxels allow.

turbosquid

$10

Cyclone carrier

...lty free 3d model cyclone carrier for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1381936)

3d_ocean

$95

Aircraft Carrier

... very easy to get the sea wave and the sunset. all necessary files are included and could be used directly. if you donR...

turbosquid

$5

firewood carrier

...model firewood carrier for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1452769)

3d_export

$5

gas carrier ship

...gas carrier ship

3dexport

gas carrier ship 3d model high quality for animation

turbosquid

$150

Troop Carrier

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Spring

3d_export

free

spring

...spring

3dexport

spring

3ddd

$1

Spring

... , spring

кресло spring фабрики potocco (италия)

длина 84

ширина 79

высота 100

design_connected

$16

Spring

...spring

designconnected

cappellini spring chairs computer generated 3d model. designed by erwan bouroullec.

3ddd

$1

Еmmemobili Spring

...еmmemobili spring

3ddd

еmmemobili , spring

кресло еmmemobili spring

design_connected

$11

Spring

...spring

designconnected

de padova spring chairs computer generated 3d model. designed by damian williamson.

turbosquid

$5

Spring

...

turbosquid

royalty free 3d model spring for download as skp on turbosquid: 3d models for games, architecture, videos. (1148583)

turbosquid

$1

Spring

...

turbosquid

royalty free 3d model spring for download as fbx on turbosquid: 3d models for games, architecture, videos. (1351471)

3ddd

$1

Еmmemobili Spring

...mobili spring

3ddd

emmemobili , spring

кресло еmmemobili spring, вариант в мягкой обивке

3d_export

$5

Ball spring

...ball spring

3dexport

ball spring

3ddd

$1

Смеситель SPRING

... fir italia , смеситель

смеситель spring, две модели, производитель fir italia!

Speed

turbosquid

$50

speed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

speed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

speed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Speed Camera

...model is separate and named appropriately. this is perfect for any type of scene from a road side, architectural or motorway s...

turbosquid

$25

Speed Buggy

...urbosquid

royalty free 3d model speed buggy for download as on turbosquid: 3d models for games, architecture, videos. (1209512)

turbosquid

$4

Speed Sign

...turbosquid

royalty free 3d model speed sign for download as on turbosquid: 3d models for games, architecture, videos. (1251518)

3d_export

$10

variable speed bicycle

...variable speed bicycle

3dexport

variable speed bicycle

3d_export

$5

High - speed aircraft

...high - speed aircraft

3dexport

high speed plane

turbosquid

$185

Speed Boat

... free 3d model speed boat for download as skp, blend, and obj on turbosquid: 3d models for games, architecture, videos. (1606216)

turbosquid

$5

Speed bag

...y free 3d model speed bag for download as blend, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1577878)

Right

turbosquid

$6

To the right

...squid

royalty free 3d model to the right for download as max on turbosquid: 3d models for games, architecture, videos. (1200265)

turbosquid

$5

Pass Right

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$14

southern right whale

...southern right whale

3dexport

detailed model of southern right whale

3d_export

$10

Tibet right

...tibet right

3dexport

dimensions of the pencil case 404/1982/380 mm

3d_export

free

right arrow

...e <br> file contains the <br> and <br> formats.<br>you can use it for presentation slides or 3d printing.

design_connected

$16

Feng Chaise Right

... chaise right

designconnected

ligne roset feng chaise right lounge chairs computer generated 3d model. designed by didier gomez.

3d_export

$5

Right arrow 3D Model

...right arrow 3d model

3dexport

right turn sign signal signage direction

right arrow 3d model ryisnelly100 88745 3dexport

turbosquid

free

Keep Right Sign

...rbosquid

free 3d model keep right sign for download as blend on turbosquid: 3d models for games, architecture, videos. (1522189)

turbosquid

$55

Anatomical right Skeleton

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

No Right/Left Turn

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

8

turbosquid

$6

Rock 8-8

...urbosquid

royalty free 3d model rock 8-8 for download as obj on turbosquid: 3d models for games, architecture, videos. (1659393)

3ddd

$1

Italamp 387/8+8

...italamp 387/8+8

3ddd

italamp

люстра italamp 387/8+8

размеры 92x71h

3ddd

$1

8 марта

...8 марта

3ddd

8 марта

кресло 8 марта

design_connected

$16

No 8

...nected

photo-realistic 3d models of the sibast no 8 armchair from sibast for 3d architectural and interior design presentations.

3d_export

$5

hinge 8

...hinge 8

3dexport

hinge 8

3d_export

$5

iphone 8

...iphone 8

3dexport

iphone 8

turbosquid

$69

iPhone 8 and iPhone 8 Plus

... free 3d model iphone 8 and iphone 8 plus for download as max on turbosquid: 3d models for games, architecture, videos. (1202442)

turbosquid

$12

Calligraphic Digit 8 Number 8

...hic digit 8 number 8 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389341)

3ddd

free

PLANTS 8

...plants 8

3ddd

цветок , горшок

plant 8,,, hope u all like it

3ddd

$1

8 Марта / Amadey

...8 марта / amadey

3ddd

8 марта

8 marta amadey