Thingiverse

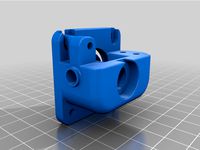

ebay e3d v6 clone bowden nozzle, with a direct drive for a makergear m2 by macsboost

by Thingiverse

Last crawled date: 3 years ago

the nozzle screws into the extruder mount from the bottom. The top of the nozzle is a 1/8" npt female pipe thread. This threads onto the plastic nub of the extruder and helps keep things aligned. The model is parametric and can be modified in inventor should you need to change the nub diameter or design.

The split opening acts as a spring and further supports the nozzle. I had to use a vice to hold the plastic and thread in the heatsink extruder.

It has 40mm fan mounts integrated but I did not use them in the end. They do provide extra strength. The two versions have the fan ears in different locations. I would recommend the version 3.

I have been using 3dx tech abs/nylon alloy with good success for very high temp parts. I like it more than ABS and the cost is the same.

This design is very stiff but allows for poor print quality. I had good results with slic3r and printing 5mm tower supports.

Use a strap wrench to hold the metal extruder while attaching to the plastic.

v4 updates: Improved geometry to allow easier re-loading of the fillament.

Re designed the nub the nozzle screws to for easier threading.

Thickened up the extruder bearing area for better fillament pressure support.

I recommend this over my prior versions.

V5 has the wings removed and is compatible with my latest 50mm fan mount.

The split opening acts as a spring and further supports the nozzle. I had to use a vice to hold the plastic and thread in the heatsink extruder.

It has 40mm fan mounts integrated but I did not use them in the end. They do provide extra strength. The two versions have the fan ears in different locations. I would recommend the version 3.

I have been using 3dx tech abs/nylon alloy with good success for very high temp parts. I like it more than ABS and the cost is the same.

This design is very stiff but allows for poor print quality. I had good results with slic3r and printing 5mm tower supports.

Use a strap wrench to hold the metal extruder while attaching to the plastic.

v4 updates: Improved geometry to allow easier re-loading of the fillament.

Re designed the nub the nozzle screws to for easier threading.

Thickened up the extruder bearing area for better fillament pressure support.

I recommend this over my prior versions.

V5 has the wings removed and is compatible with my latest 50mm fan mount.

Similar models

thingiverse

free

Hemera 4020 parts cooler blower fan mount and nozzle

...will have to glue the fan shroud to the fan.

you can print the mount without supports but supports are needed for the fan nozzle.

thingiverse

free

east3D Gecko Remix E3D fan with integrated layer-fan by delukart

... !hot! to gecko) and opened up the thru-hole a bit to allow the m3 screw to fit easier. (needs to be positioned letter side down)

thingiverse

free

Fan Mount (RigidBot) by walter

...'re not using a build plate, the fan probably may not clear the bed leveling screws (i haven't tried that configuration).

thingiverse

free

Robo3D E3dv6 Fan shroud by NorCAL3D

... of fan shroud on top. you can enlarge the holes as necessary (currently all will thread a 3mm screw) to allow for easy assembly.

thingiverse

free

CTC Dual Extruder Fan Mounts by KimBrown

...e grub screws are easy to access.

hope you enjoy using the new mounts. i used pla @180' with a bed temp of 57'.

enjoy....

thingiverse

free

PrintrBot Plus 1404 Dual Extruder Fan Mount by Bailey5531

... don't line up try mirroring the model and print again, this can be due to the carriage being assembled slightly differently

thingiverse

free

Maker Farm Magnum Fan Scoop by condortool

...e with no problems. make sure when fitting it to the heat sink with the 4 screws that it will not drop down onto the nozzle area.

thingiverse

free

Threaded Nozzle Storage (M6 threads, E3D compatible)

... a portion as a test if not printing in abs.

needs 2 x m3 8mm screws and t-nuts to mount.

update: added a shorter version (v1.3).

thingiverse

free

Insta360 One R Case Mount with Cold Shoes - 1/4 inch Screw Mount by Garry1953

.....

i added a hole to make it easier to clean out the thread supports.

i used cura 4.80 with brim and tree supports at 70% infill.

thingiverse

free

Titan Aero Fan mount (Ender 3/CR10) No Supports! by Rascalgp

...ichtly modified version as mine broke, new version is more stiff and easier to mount, also the ring is now centered on the nozzle

Macsboost

thingiverse

free

MACSBOOST Pro Nameplate by macsboost

...macsboost pro nameplate by macsboost

thingiverse

our logo, 3d-ified

thingiverse

free

CPU fan duct by macsboost

...

air duct for silver habey emc-800s htpc case, biostar th61 itx mini itx intel motherboard with uefi bios, and oem intel cpu fan.

thingiverse

free

Milwaukee M18 V2 Battery adapter by macsboost

...ee m18 v2 battery adapter by macsboost

thingiverse

improved m18 adapter, for milwaukee lithium 18v cordless drill battery packs.

thingiverse

free

dual binding post mount by macsboost

...y macsboost

thingiverse

simple, easy to print heavy duty dual binding post mount. 3/4" standard spacing. 40mm sq footprint

thingiverse

free

Heavy Duty ring light holder by macsboost

... by macsboost

thingiverse

for the makergear prusa, a heavy duty snap on 70mm ring light holder.

a derivative of my prior design.

thingiverse

free

MEGA BASE by macsboost

...ided tape to attach the base inside the teardrop opening and you are good to go. i added some rubber feet to the bottom as well.

thingiverse

free

Anti-Kickdown Spacer for BMW vehicles by macsboost

...ngiverse

this thing prevents full pedal travel, yet allows for 100% throttle. preventing kickdown on modified cars improves et.

thingiverse

free

MACSBOOST Davinci E3D V6 Uberstruder mount. by macsboost

...ch easier to install the extruder. you will likely want to cut about 1/2" off the top of the extruder filament inlet tube.

thingiverse

free

Lm8uu X Carriage with Fan Mount for Prusa Mendel by macsboost

...u x carriage with fan mount for prusa mendel by macsboost

thingiverse

5mm thick beefy version of gregfrosts excellent x carriage

thingiverse

free

52mm gauge pod hood by macsboost

...2mm or 2" automotive gauges. keep the sun off your gauges and make them much easier to read.

easy to print!

lets go racing!

Makergear

thingiverse

free

MakerGear M2 faceplate by TimEdwards

...frame and holds itself in place.

the makergear logo is presumed to be a trademark of makergear, inc., http://www.makergear.com.

thingiverse

free

spacer for Makergear X-Carriage by mic

...spacer for makergear x-carriage by mic

thingiverse

spacer for makergear x-carriage

thingiverse

free

bioprinter for makergear M2 by goldengrape

...for makergear m2 by goldengrape

thingiverse

remix fromhttps://3dprint.nih.gov/discover/3dpx-008366

try to modify my makergear m2

thingiverse

free

Modified Y-stage by MakerGear

...ified y-stage used for the makergear heated build platform. these files may be helpful for botters using or waiting on their hbp.

thingiverse

free

Makergear M2 Fan Bracket by Werner

...makergear m2 fan bracket by werner

thingiverse

makergear m2 fan bracket for use with fan shroud thing:69327

thingiverse

free

MakerGear HotEnd by RaD

...makergear hotend by rad

thingiverse

it helps you to build new mendel90 model.

thingiverse

free

Makergear Z Axis Knob by Aydelott

...makergear z axis knob by aydelott

thingiverse

makergear z axis knob press in steel when the abs is still a little warm

thingiverse

free

Makergear M2 Filament guide by Werner

...ent guide by werner

thingiverse

slightly optimised 3mm filament guide for makergear m2

with provision for 2. mount for small fan

thingiverse

free

Fan Shroud (MakerGear M2) by JohnShawDesign

...by johnshawdesign

thingiverse

tested fan shroud for makergear m2. centers air flow for better overhangs and more direct cooling.

thingiverse

free

MakerGear M2 Tool Holder by wschleter

...thingiverse

a compact toolholder for a makergear m2. mounts to the frame using two existing holes. freecad source file included.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Ebay

turbosquid

$65

micro gear motor (chinese) from ebay - 90 degree - right angle - worm drive - small

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Blown Glass cat

...blown glass cat 3ddd кот , статуэтка blown glass cathttp://www.megazakaz.com/ebayproduct/190842828718 ...

3d_ocean

$15

Social Network Icon Set

...icon set 3docean aim amazon blogger deviantart digg dropbox ebay facebook flickr google plus instagram myspace picasa pinterest reddit...

3d_ocean

$18

Social Network Icons

...3docean aim behance blogger business corporate deviant art digg ebay facebook flickr google plus icon internet linkedin media myspace...

3d_ocean

$15

Amazon Fire Phone

...amazon fire phone 3docean 3d amazon android apple camera ebay fire htc ios ipad iphone ipod justtomas model nokia...

3d_ocean

$30

Social Media 3D Icons and Logos

...icons amazon android at and t baidu bebo digg ebay fedex feed flickr google hi5 imdb linkedin logos myspace...

3d_ocean

$30

Social Media 3D Icons and Logos (Part 2)

...icons amazon android at and t baidu bebo digg ebay fedex feed flickr google hi5 imdb linkedin logos myspace...

3ddd

free

TV стойка (OLIVIA)

...стойка под tv (италия) приблизительная стоимость - 1000 euro (ebay модель предоставляется в форматах: max(2010), obj, fbx, 3ds с...

3d_export

$5

respiration-mask octane render high poly

...airplane<br>surgical mask or n95<br>surgical mask on amazon<br>surgical mask on ebaylt;br>surgical mask one time use<br>surgical mask overnight shipping<br>surgical mask pattern<br>surgical...

3d_export

$5

surgical mask - n95 medical face mask

...airplane<br>surgical mask or n95<br>surgical mask on amazon<br>surgical mask on ebaylt;br>surgical mask one time use<br>surgical mask overnight shipping<br>surgical mask pattern<br>surgical...

M2

turbosquid

$50

M2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

free

M2 Sofa

...m2 sofa

designconnected

free 3d model of m2 sofa by ka design designed by kleine allekotte, joachim.

turbosquid

$10

M2 Browning_LP

...uid

royalty free 3d model m2 browning_lp for download as lwo on turbosquid: 3d models for games, architecture, videos. (1279588)

turbosquid

$120

Browning M2

...y free 3d model browning m2 for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1298501)

turbosquid

$70

m2 collection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Browning M2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Turntable M2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

M2 Carbine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

M2 Grand

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Lego M2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Clone

3d_export

$5

Clones great republic

...clones great republic

3dexport

clones great republic.those same clones from the star wars movie universe.4 clones available.

3d_export

$10

Clone 3D Model

...clone 3d model

3dexport

clone woman girl female lady chamber sci fi

clone 3d model calcm1 51695 3dexport

turbosquid

$5

Clone machine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Clone trooper 3D Model

...nd army soldier trooper

clone trooper 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

Lego Clone Walker

...ree 3d model lego sw clone walker for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1292252)

turbosquid

$15

Clone trooper helmet

...d model clone trooper helmet for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1199355)

archive3d

free

Clone trooper 3D Model

...and army soldier trooper

clonetrooper 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Clone trooper 3D Model

...and army soldier trooper

clonetrooper 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$35

Surface Clone C4D materials

...+ of the most well made materials for maxon’s cinema 4d; on the internet today. each material is crafted with a specific purpo...

turbosquid

$3

Sci-fi cloning vats

...cloning vats for download as 3ds, obj, wrl, x, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290168)

Nozzle

3d_export

$5

nozzle

...nozzle

3dexport

3d_export

$49

fuel nozzles

...fuel nozzles

3dexport

fuel nozzles 3d model. include max, obj, fbx files.

archive3d

free

Nozzle 3D Model

...archive3d

nozzle hair-drier ware

nozzle - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$25

Pirouette Nozzle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Fuel Nozzle

...model fuel nozzle for download as c4d, fbx, obj, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1672732)

turbosquid

$8

Aeration Nozzles

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

laval airjet nozzle

...laval airjet nozzle

3dexport

a simple modified laval nozzle (airjet shooter) for sorting purposes.

3d_export

$36

Gas nozzle 3D Model

... 3d model

3dexport

gas pump nozzle dispenser filling station petrol fuel spout tank gun

gas nozzle 3d model tartino 1945 3dexport

turbosquid

$10

Diecast Jet nozzle

... free 3d model diecast jet nozzle for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1425990)

turbosquid

$39

Rocket nozzle, supressor.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)