Thingiverse

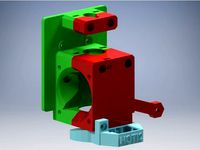

E3D dual head on Velleman VERTEX K8400 with space gain and light by Bo_Ris

by Thingiverse

Last crawled date: 3 years, 1 month ago

Update 19-Mar-2017 New and improved revision of the printhead is available from here.

This set of things allows to upgrade Velleman VERTEX K8400 printer with single- or dual-head E3D hot-end.

Almost all other designs that "marry" K8400 with E3D are reducing print area because of 2 reasons:

new hot-end is bigger than the original and

the fans hanging on E3D heat-sinks take a lot of side or front space.

My design allows to attach E3D hot-end(s) to K8400 and gain extra print space. No need to re-position X and Y home sensors, however you may need to adjust the positions of the pulleys, as the new print head literally uses every single millimeter of available space.

New distance between nozzles is 23 mm; the original was 23.7 mm

X max = 210 mm (0..210); the original was 200 mm (0..200)

Y max = 193 mm (0..193); the original was 180 mm (20..200)

Z max = 190 mm - no change

IMPORTANT: This design fits the GENUINE E3D hot-end http://e3d-online.com/E3D-v6/Full-Kit/v6-1.75mm-Universal-Bowden It cannot be used with Chinese replicas that are bigger in size.DISCLAIMER: This hot-end replacement requires soldering skills. If you don't have such skills, you may end up damaging your printer. If this happens - total responsibility is with you.

Required Parts

One or two E3D v6 HotEnd Full Kit - 1.75mm Universal (with Bowden add-on) (12v). You can purchase them from here: http://e3d-online.com/E3D-v6/Full-Kit/v6-1.75mm-Universal-Bowden

One 40mm x 40mm x 20mm 12V or 15V high speed fan (attached image shows the exact model I used)

Four M4 x 16mm hex socket cup screws

Two M3 x 12mm screws and two M3 x 6mm screws, or

four M3 x 12mm screws and two 5mm high plastic spacers.

Four countersunk screws M3 x 50mm and four self-locking M3 nuts. They all are part of the original hot-end mount and can be re-used.

Two M3 x 10mm screws.

Heater cartridge(s) - one per print head. You MUST reuse the original ones from K8400. Do not install the cartridges that came with E3D as they are for 12V, while the printer supplies 15V DC.

Optionally, six bright white LEDs with 5mm diameter and six 510 Ohm 0.25 W resistors.

Three designs in one

The set of thing files allows to build print head in 3 different configurations.

1) With LED lights and filament cooling ducts

2) With LED lights and no filament cooling

3) With filament cooling and no lights

Print the subset of the files matching your preferred option. See details in file descriptions below.

File Descriptions

main.stl - main body for configurations 1 and 3 (with filament cooling ducts). Print with Touchbed support.

main_no_duct.stl - main body for configuration 2 (without filament cooling ducts). Print with Touchbed support.

holder.stl - central piece holding E3D heat-sinks. Print with Touching Bed support.

holder_with_support.stl - same as holder.stl, but includes easily removable support. Print without support.

right_holder.stl - holding piece for right extruder

left_holder.stl- holding piece for left extruder

insert.stl - extruder board and PTFE Tubing holder. Slides in above the fan.

cable_holder.stl - optional piece allowing to tie and hold the extruder cable

duct.stl - air duct for configuration 3 - without LEDs

duct_with_LEDs.stl - air duct for configuration 1 - with LEDs

LED_holder.stl - LED holding piece for configuration 2 - without duct.

dummy_e3d.stl - This piece replicates E3D shape and should be used in single print-head setup as a replacement of the left extruder. This is required to provide proper air flow.

This set of things allows to upgrade Velleman VERTEX K8400 printer with single- or dual-head E3D hot-end.

Almost all other designs that "marry" K8400 with E3D are reducing print area because of 2 reasons:

new hot-end is bigger than the original and

the fans hanging on E3D heat-sinks take a lot of side or front space.

My design allows to attach E3D hot-end(s) to K8400 and gain extra print space. No need to re-position X and Y home sensors, however you may need to adjust the positions of the pulleys, as the new print head literally uses every single millimeter of available space.

New distance between nozzles is 23 mm; the original was 23.7 mm

X max = 210 mm (0..210); the original was 200 mm (0..200)

Y max = 193 mm (0..193); the original was 180 mm (20..200)

Z max = 190 mm - no change

IMPORTANT: This design fits the GENUINE E3D hot-end http://e3d-online.com/E3D-v6/Full-Kit/v6-1.75mm-Universal-Bowden It cannot be used with Chinese replicas that are bigger in size.DISCLAIMER: This hot-end replacement requires soldering skills. If you don't have such skills, you may end up damaging your printer. If this happens - total responsibility is with you.

Required Parts

One or two E3D v6 HotEnd Full Kit - 1.75mm Universal (with Bowden add-on) (12v). You can purchase them from here: http://e3d-online.com/E3D-v6/Full-Kit/v6-1.75mm-Universal-Bowden

One 40mm x 40mm x 20mm 12V or 15V high speed fan (attached image shows the exact model I used)

Four M4 x 16mm hex socket cup screws

Two M3 x 12mm screws and two M3 x 6mm screws, or

four M3 x 12mm screws and two 5mm high plastic spacers.

Four countersunk screws M3 x 50mm and four self-locking M3 nuts. They all are part of the original hot-end mount and can be re-used.

Two M3 x 10mm screws.

Heater cartridge(s) - one per print head. You MUST reuse the original ones from K8400. Do not install the cartridges that came with E3D as they are for 12V, while the printer supplies 15V DC.

Optionally, six bright white LEDs with 5mm diameter and six 510 Ohm 0.25 W resistors.

Three designs in one

The set of thing files allows to build print head in 3 different configurations.

1) With LED lights and filament cooling ducts

2) With LED lights and no filament cooling

3) With filament cooling and no lights

Print the subset of the files matching your preferred option. See details in file descriptions below.

File Descriptions

main.stl - main body for configurations 1 and 3 (with filament cooling ducts). Print with Touchbed support.

main_no_duct.stl - main body for configuration 2 (without filament cooling ducts). Print with Touchbed support.

holder.stl - central piece holding E3D heat-sinks. Print with Touching Bed support.

holder_with_support.stl - same as holder.stl, but includes easily removable support. Print without support.

right_holder.stl - holding piece for right extruder

left_holder.stl- holding piece for left extruder

insert.stl - extruder board and PTFE Tubing holder. Slides in above the fan.

cable_holder.stl - optional piece allowing to tie and hold the extruder cable

duct.stl - air duct for configuration 3 - without LEDs

duct_with_LEDs.stl - air duct for configuration 1 - with LEDs

LED_holder.stl - LED holding piece for configuration 2 - without duct.

dummy_e3d.stl - This piece replicates E3D shape and should be used in single print-head setup as a replacement of the left extruder. This is required to provide proper air flow.

Similar models

thingiverse

free

E3D v6 hotend (dual) on the K8400 extruder. (new design) by belni

...mm bowden hotend (dual) on the k8400.

this is a new design!

try it.. and tell if you like it.

release early, release often.

thingiverse

free

E3D v6 Bowden adapter for Bulldog XL Extruder by Banjomaster

...ngiverse

printed this part to allow the bulldog xl extruder to work with the

bowden attachment that came with my e3d v6 hot end.

thingiverse

free

Hot End Fan Duct 40 mm - E3D Kossel Mini by FuManchu

...kossel mini. clips onto cooling fins of e3d or similar hot end. use m3 screws to attach...

thingiverse

free

E3D V6/Bowden Extruder Bracket for RepRap by Arron_mollet22

...end and the bowden style extruder.

a full instuctable is at:

http://www.instructables.com/id/3d-printer-extruderhot-end-upgrade/

thingiverse

free

Hot End holder for J Head and E3D V6 by goth2k

...verse

designed originally to fit a wade extruder.

it includes 2 versions for j head (4.6 mm) and 2 versions for e3d v6 (6.1 mm).

thingiverse

free

X cariage for E3D V6 with integrated cooling Fan duct by Printcontrol

... v6 hotend.

the fan duct is directly integrated for easy change of the hotend/extruder.

filament cooling for perfect pla prints

thingiverse

free

E3D v6 Fan Duct (two 30 mm fan extruder and filament cooler ) by pride66

... duct (two 30 mm fan extruder and filament cooler ) by pride66

thingiverse

e3d-v6 fan duct (2 fan extruder and filament cooler )

thingiverse

free

E3D v6 hot end holder (bowden) by 3dworkslv

...e3d v6 hot end holder (bowden) by 3dworkslv

thingiverse

e3d v6 hot end holder (bowden)

thingiverse

free

Prusa i3 MK3 Bowden Extruder for E3D v6 by FabLabCordoba

...e by @karimkfoure.

based on original prusa i3 mk3.

inspired by "bowden x-carriage mount for e3d v6" by jackwaterfall.

thingiverse

free

Dual Direct Extruder - MK8 - E3d - 1.75mm (Flexible Filament) by Marck80

...- 1.75mm - (flexible filament)

ball bearing : 624zz

screws and nut m3

v3: new block extruder

photos and new fan duct incoming....

K8400

thingiverse

free

Vertex K8400 Small Corner part (K8400-HQP-SC) by Hest

...vertex k8400 small corner part (k8400-hqp-sc) by hest

thingiverse

vertex k8400 small corner part (k8400-hqp-sc)

thingiverse

free

Base for K8400 by Hitty

...base for k8400 by hitty

thingiverse

just a base for your k8400 to extend the space for the power adapter.

thingiverse

free

K8400 Fan tool by dergringo

...k8400 fan tool by dergringo

thingiverse

k8400 fan tool

thingiverse

free

Support ventilateur K8400 / Fan support K8400 by ldellanna

........................

fan support for velleman vertex k8400

minimum layer : 0.2mm

printing time in 0.1mm -> max 20 minutes

thingiverse

free

K8400 Scraper holder by Storm67

...k8400 scraper holder by storm67

thingiverse

scraber holder for velleman k8400 vertex

thingiverse

free

Fan Tool K8400 Velleman by dergringo

...fan tool k8400 velleman by dergringo

thingiverse

fan tool velleman k8400

thingiverse

free

Endcap Custom for Vertex K8400 by olechristiandalseth

...endcap custom for vertex k8400 by olechristiandalseth

thingiverse

endcap for vertex k8400

left and right.

thingiverse

free

Vertex K8400 spool holder by simersion

...vertex k8400 spool holder by simersion

thingiverse

spoolholder for vertex k8400

100mm length and 35mm diameter.

thingiverse

free

E3D dual head K8400 by hexxter

...e3d dual head k8400 by hexxter

thingiverse

holder for the e3d hot end on the vertex k8400 printer.

thingiverse

free

Vertex K8400 power switch by Zannddor

...vertex k8400 power switch by zannddor

thingiverse

alternative power switch to the 3d printer vertex k8400

Velleman

thingiverse

free

testing velleman K8200 by treblasnirp

...testing velleman k8200 by treblasnirp

thingiverse

velleman k8200 with abs settings in cura.

thingiverse

free

Velleman solder station by forrozza

...velleman solder station by forrozza

thingiverse

velleman solder station for the gasiron2 but would fit most butane solder irons.

thingiverse

free

Fan Tool K8400 Velleman by dergringo

...fan tool k8400 velleman by dergringo

thingiverse

fan tool velleman k8400

thingiverse

free

Velleman K8055 Box by Cerberus

...berus

thingiverse

a laser cut enclosure for the velleman k8055 relay project board. might fit the k8055n but this is not tested.

thingiverse

free

Velleman Dice Kit Box by Sadesign

...velleman dice kit box by sadesign

thingiverse

box for velleman mk150 electronic dice kit

thingiverse

free

Mini pc holder Velleman k8200 by treblasnirp

...c holder velleman k8200 by treblasnirp

thingiverse

mini pc holder velleman k8200

thx k8200 flat frame clip velleman 3d printer

thingiverse

free

Velleman K8200 Frame Piece by TheMatt2582

...velleman k8200 frame piece by thematt2582

thingiverse

this is a frame part for a velleman k8200.

it's 15cm or 5.91inch long.

thingiverse

free

Velleman robot arm KSR10 gear by spore29

...ot arm ksr10 gear by spore29

thingiverse

gear for velleman ksr10 robot arm kit.

engrenage pour le kit bras robot velleman ksr10

thingiverse

free

Velleman Metal Detector Enclosure by CodeCreations

...enclosure by codecreations

thingiverse

project enclosure for the velleman metal detector kit, commonly available at radio shack.

thingiverse

free

PSU bracket holder for Velleman K8200 by dan241297

...psu bracket holder for velleman k8200 by dan241297

thingiverse

brackets to hols the psu for the velleman k8200

Ris

turbosquid

$20

ris

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Лампа Настольная Vita Ri 22163

...лампа настольная vita ri 22163

3ddd

vita , ri

лампа настольная vita ri 22163

3ddd

$1

Кресло JUMBO RIS-41b

...hymia

стиль: классика

длина: 80

глубина: 85

высота: 155

артикул: ris-41b

варианты отделки: орех, крашенный, с золотом, с серебром

3ddd

free

Диван JUMBO RIS-42b

...hymia

стиль: классика

длина: 155

глубина: 85

высота: 155

артикул: ris-42

варианты отделки: орех, крашенный, с золотом, с серебром

3d_export

$25

Parth 11 riing 3D Model

...ing 3d model

3dexport

parth 11 riing 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gorgsalvatore 109549 3dexport

3d_export

$10

M4A1 rifle RIS version 3D Model

...m4a1 rifle ris version 3d model

3dexport

rifle gun weapon

m4a1 rifle ris version 3d model figlif 1347 3dexport

3ddd

$1

Centennial Regulation Pool Table by RI Anderson

...by ri anderson

3ddd

brunswick

бильярдный стол в стиле ар-деко centennial regulation pool table by ri anderson

размеры 264x147x81h

turbosquid

$2

KWA SR5 RIS - 4inch HandGuard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$199

Tank Type 5 Chi-Ri Japan

...el tank type 5 chi-ri japan for download as max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1640853)

cg_studio

$59

Colt M4A1 Carbine RIS Assault rifle3d model

...s .c4d .lwo .obj - colt m4a1 carbine ris assault rifle 3d model, royalty free license available, instant download after purchase.

Bo

3d_export

$5

boing

...boing

3dexport

boing plane

turbosquid

$19

Boing boing Park

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Boing 747

...boing 747

3ddd

boing 747 без текстур

3ddd

$1

Bo concept

...bo concept

3ddd

boconcept , декоративный набор

bo concept

3ddd

$1

Bo Concept / Pinto

...bo concept / pinto

3ddd

boconcept

bo concept pinto

3ddd

$1

кровать bo concept

...кровать bo concept

3ddd

boconcept

кровать bo concept

3ddd

$1

Bo concept sidebroad

...bo concept sidebroad

3ddd

тумба , boconcept

bo concept

3ddd

$1

Bo-box / Ирис

...bo-box / ирис

3ddd

bo-box

кресло ирис, пр-ль bo-box, коллекция soul. габариты (мм): 720x900x880

3ddd

free

Bo Concept

... ковер

сборник ковров от bo concept

размер - 200х300см, 170х240 см

10 шт.http://www.boconcept.ru

turbosquid

$5

Bo Shuriken

...y free 3d model bo shuriken for download as obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1412495)

Gain

turbosquid

$15

Gaines Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Chair Oscar Gaine 3D Model

...chair oscar gaine 3d model

3dexport

chair oscar gaine 3d model mary 63706 3dexport

turbosquid

$20

Chandelier Hudson Valley Gaines 2216

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Chandelier Hudson Valley Gaines 2222

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Hudson Valley Gaines 2206 and 2202

...tp://www.hudsonvalleylighting.com/productdetails.aspx?item=2202-aob#.vodn9fmsv8e

including files: max 2010, 2013, obj.

turbosquid

$20

Chandelier Hudson Valley Gaines 2206 and 2202

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Hudson Valley Gaines 2100

...tp://www.hudsonvalleylighting.com/productdetails.aspx?item=2100-aob#.votu3pmsv8e

including files: max 2010, 2013, obj.

3ddd

$1

Hudson Valley Gaines 2216

...tp://www.hudsonvalleylighting.com/productdetails.aspx?item=2216-aob#.vn5wlvmsv8e

в архиве файлы max 2010, 2013 и obj.

3ddd

$1

Hudson Valley Gaines 2222

...tp://www.hudsonvalleylighting.com/productdetails.aspx?item=2222-aob#.vnzc-_msv8e

в архиве файлы max 2011, 2014 и obj.

archive3d

free

Door 3D Model

...door 3d model archive3d door front door entrance door gain n150907 - 3d model (*.gsm+*.3ds) for interior 3d...

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

Vertex

3d_export

$10

vertex decorative003

...vertex decorative003

3dexport

vertex decorative_003

3d_export

$10

vertex decorative001

...vertex decorative001

3dexport

vertex decorative_001

turbosquid

$5

Vertex Pendant

...uid

royalty free 3d model vertex pendant for download as stl on turbosquid: 3d models for games, architecture, videos. (1565161)

turbosquid

$5

Vertex Coaster

...uid

royalty free 3d model vertex coaster for download as stl on turbosquid: 3d models for games, architecture, videos. (1565158)

3ddd

$1

Vertex von Vondom

...vertex von vondom

3ddd

vondom

vertex von vondomhttp://www.vondom.com/producto/52/0/vertex/

turbosquid

$3

Vertex Set

...d model vertex vondom set for download as usdz, gltf, and fbx on turbosquid: 3d models for games, architecture, videos. (1599323)

3ddd

$1

VONDOM / VERTEX

...vondom / vertex

3ddd

karim rashid , vondom

designer - karim rashid

3d_export

$15

Vondom Vertex 3D Model

...d model

3dexport

vondom vertex table chair plastic seat furniture furnishing

vondom vertex 3d model rogojin.denis 87870 3dexport

3ddd

$1

VONDOM / VERTEX

..., karim rashid , vondom

designer - karim rashid

3ddd

$1

BUFFET VERTEX

...nical specification :

height 65 cm , width 150 cm , depth 43 cmhttp://www.oppa.com.br/buffet-vertice-4-portas-amarelo

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Head

3d_export

$5

head

...head

3dexport

simulated female head.

3d_ocean

$5

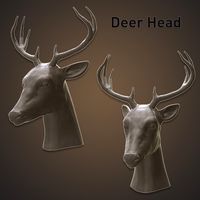

Deer Head

...deer head

3docean

deer head

simple model of deer head with neck.

cg_studio

$25

Marble Head - Head A3d model

... - head a3d model

cgstudio

.ma - marble head - head a 3d model, royalty free license available, instant download after purchase.

turbosquid

$5

Head

...ad

turbosquid

royalty free 3d model head for download as max on turbosquid: 3d models for games, architecture, videos. (1230068)

turbosquid

free

Head

...

turbosquid

royalty free 3d model head for download as blend on turbosquid: 3d models for games, architecture, videos. (1276899)

turbosquid

free

The Head

...urbosquid

royalty free 3d model the head for download as max on turbosquid: 3d models for games, architecture, videos. (1386205)

3d_export

$10

bull head

...bull head

3dexport

bull head

3d_export

$5

girl head

...girl head

3dexport

head girl

3d_export

$5

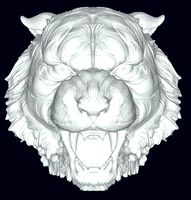

Tigger-head

...tigger-head

3dexport

tigger-head

3d_export

$5

head on a spear

...head on a spear

3dexport

head on a spear

Space

3ddd

free

Space

... space , вытяжка

вытяжка elica space, производство elica evolution

3d_ocean

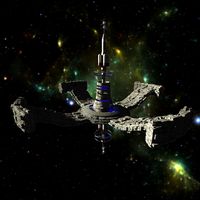

$19

Space station

...space station

3docean

space station

space station

3d_ocean

$7

Space Fighter

...space fighter

3docean

fighter space

space fighter

turbosquid

$5

space

...e

turbosquid

royalty free 3d model space for download as max on turbosquid: 3d models for games, architecture, videos. (1184221)

turbosquid

$2

Space

...turbosquid

royalty free 3d model space for download as blend on turbosquid: 3d models for games, architecture, videos. (1660625)

3d_ocean

$4

Space Station

...space station

3docean

habitat low poly ship space space ship space station vehicle

space station low poly modelled, not textured.

turbosquid

$2

Space

...royalty free 3d model space for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1644726)

turbosquid

$8

Space

...ty free 3d model space for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1521166)

turbosquid

$160

space

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Space

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

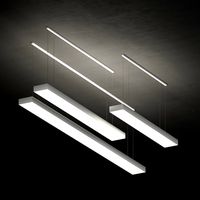

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...