Thingiverse

DUAL DyzEnd Pro Mount for Ender 5 by lysithea81

by Thingiverse

Last crawled date: 4 years, 11 months ago

This is a mount for TWO DyzEnd Pro hotends for a dual extrusion upgrade to the Ender 5 printer. True, DyzEnd Pro hotends are pricey, and it adds up when obtaining more than one, but you get what you pay for. My previous attempt I used MicroSwiss hotends and was severely disapponted, they burned out when I ran them to 290C but you can get DyzEnds rated for 500C.

You will have to get a third party main board (I'm getting mixed results with a BigTreeTech and would like to find a better replacement), and of course a second extruder and stepper. I recommend 3DMaker's extruder https://www.3dmakerengineering.com/products/dual_gear_extruder it's way better than the Creality extruder, the only problem with it is before long the fitting will pop out, just superglue it back in when - not if, when - it does.

You also have to update your firmware; I did this through VSCode and Platformio (even works on my Linux tower) and you can get the source code from Marlin's website. Besides the dual extrusion settings, there are Dyze-specific firmware modifications to make; you can get those from DyzeDesign's website. Once you have your firmware.bin file, simply place it on a micro SD card and power cycle your main board with the card inserted.

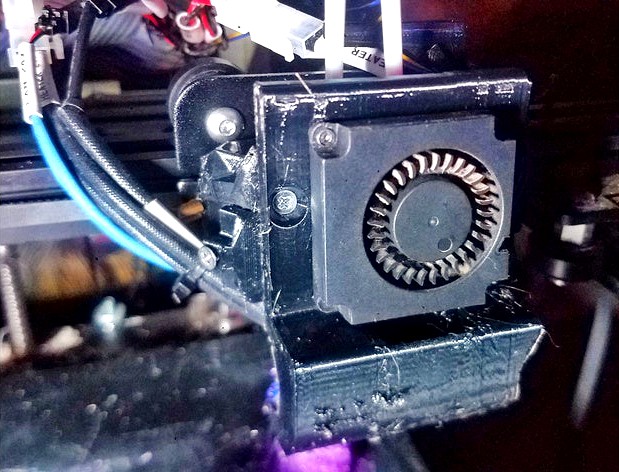

This Thing consists of four parts:

A main body that attaches to your carriage plate using two M3 screws;

A fan holder;

A cap;

A slider that grips the second hotend and allows up and down motion.

Your right-hand side hotend will snap into place on the main body. You can do this before or after installing it onto the carriage plate.

The slider fits onto a track built into the cap. It's a dovetail so works best to hook it on and slide it down from the top. Then your left-hand-side hotend will snap into place on the slider.

Place two long M3 screws through the fan mount, then place your cap/slider/left extruder assembly onto the screws, and tighten the long screws into the main body. (The screws will self-tap the holes, however if yu print this in metal you will have to tap the holes with a tool.)

The first (right) hotend is held stationary between the main body and the cap; the second (left) hotend can slide up and down until the left long bolt and the tightener screw are tightened. The main body also has a hook to place your wiring inside so the wires don't interfere with the homing switches and cause your carriage to jackhammer your gantry.

I used M3x12 and M3x25 screws to bolt this together, although M3x30 would be best. For best results, get the kind with the countersink head for minimim friction.

The reason for the slider is you want your two nozzles to be exactly the same height off the print bed. If you have two of the same size nozzle, the hotends might be exactly the same vertical size. I opted for a 0.4 and a 0.6 for flexibility when printing with wood, glow, etc, and the two nozzles are definitely not the same length, therefore the necessity for the slider.

The way to adjust the nozzle heights is to loosen the left-side long bolt and the tightener screw just enough to allow the slider to move vertically. Then home your bed and adjust the slider up or down until your leveling card shows exactly the same resistance on both nozzles; if you place your leveling card under both nozzles and move it out from under just one nozzle, you should not feel either nozzle "let it down". It may also help to put a very flat object on the bed so you can move the Z in tiny increments until you are pushing against the right nozzle, and can then adjust the slider. Once the slider is in place, tighten the bolts.

The X offset is about 17mm. You can print some dual extrusion testers (here's some good ones: https://www.thingiverse.com/thing:2388496) to help you align. Do not set your offset in your slicer, nor in OctoPrint if you have it; set it in your firmware. You can do this in OctoPrint's terminal; a good starting-point setting is:

M218 T1 X17.50 Y-1.80 Z0.000

M500

These numbers are likely to change slightly any time the mount is loosened and then re-tightened, so be ready to retest and adjust.

You will have to get a third party main board (I'm getting mixed results with a BigTreeTech and would like to find a better replacement), and of course a second extruder and stepper. I recommend 3DMaker's extruder https://www.3dmakerengineering.com/products/dual_gear_extruder it's way better than the Creality extruder, the only problem with it is before long the fitting will pop out, just superglue it back in when - not if, when - it does.

You also have to update your firmware; I did this through VSCode and Platformio (even works on my Linux tower) and you can get the source code from Marlin's website. Besides the dual extrusion settings, there are Dyze-specific firmware modifications to make; you can get those from DyzeDesign's website. Once you have your firmware.bin file, simply place it on a micro SD card and power cycle your main board with the card inserted.

This Thing consists of four parts:

A main body that attaches to your carriage plate using two M3 screws;

A fan holder;

A cap;

A slider that grips the second hotend and allows up and down motion.

Your right-hand side hotend will snap into place on the main body. You can do this before or after installing it onto the carriage plate.

The slider fits onto a track built into the cap. It's a dovetail so works best to hook it on and slide it down from the top. Then your left-hand-side hotend will snap into place on the slider.

Place two long M3 screws through the fan mount, then place your cap/slider/left extruder assembly onto the screws, and tighten the long screws into the main body. (The screws will self-tap the holes, however if yu print this in metal you will have to tap the holes with a tool.)

The first (right) hotend is held stationary between the main body and the cap; the second (left) hotend can slide up and down until the left long bolt and the tightener screw are tightened. The main body also has a hook to place your wiring inside so the wires don't interfere with the homing switches and cause your carriage to jackhammer your gantry.

I used M3x12 and M3x25 screws to bolt this together, although M3x30 would be best. For best results, get the kind with the countersink head for minimim friction.

The reason for the slider is you want your two nozzles to be exactly the same height off the print bed. If you have two of the same size nozzle, the hotends might be exactly the same vertical size. I opted for a 0.4 and a 0.6 for flexibility when printing with wood, glow, etc, and the two nozzles are definitely not the same length, therefore the necessity for the slider.

The way to adjust the nozzle heights is to loosen the left-side long bolt and the tightener screw just enough to allow the slider to move vertically. Then home your bed and adjust the slider up or down until your leveling card shows exactly the same resistance on both nozzles; if you place your leveling card under both nozzles and move it out from under just one nozzle, you should not feel either nozzle "let it down". It may also help to put a very flat object on the bed so you can move the Z in tiny increments until you are pushing against the right nozzle, and can then adjust the slider. Once the slider is in place, tighten the bolts.

The X offset is about 17mm. You can print some dual extrusion testers (here's some good ones: https://www.thingiverse.com/thing:2388496) to help you align. Do not set your offset in your slicer, nor in OctoPrint if you have it; set it in your firmware. You can do this in OctoPrint's terminal; a good starting-point setting is:

M218 T1 X17.50 Y-1.80 Z0.000

M500

These numbers are likely to change slightly any time the mount is loosened and then re-tightened, so be ready to retest and adjust.