Thingiverse

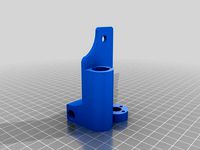

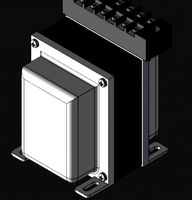

Dual Auto Leveling Prusa i3 Reworked X-Idler Tensioner with T8 Leadscrew by Godvalve

by Thingiverse

Last crawled date: 3 years ago

These parts are drop-in replacements for the Prusa i3 Reworked X-axis assembly and is meant to be used with the Herringbone Prusa i3 Reworked Greg's Extruder (http://www.thingiverse.com/thing:1446842) The following changes were made to the original parts:

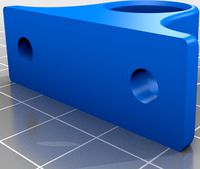

X-IDLER

1) A belt tensioner was added that can be used with either a 4x40mm bolt or a 5x40mm bolt. A nested nut trap is used to catch the smaller 4mm nut.The tensioner has an effective range of 11mm. An access port has been added to the side of the x-idler body in order to access the nut trap during installation or in the event that the nut trap becomes rounded. The tensioner has been designed around the 608ZZ bearing and is meant to be used with the included bearing guide. There is a 0.75mm clearance between the edge of the bearing guide and the tensioner body to prevent the belt from slipping off.

2) The inner diameter of the 8mm smooth rod holes was reduced in order to make it more difficult for the rods to slip. The ends of these holes were also closed up in order to keep the rods from slipping out the back.

3) The Z-axis nut trap was removed and replaced with a platform to catch a floating Z-axis switch. This is a design change similar to Crota's March 17 2014 design (http://www.thingiverse.com/thing:273805). However, this design's implementation of Crota's part more closely mirrors the technique used on the Robo 3D R1 printer. The Marlin firmware needs to be modified as explained by Crota to use this feature.

4) Multiple versions of the floating Z-axis platform are included in order to make this part compatible with printers using 5mm threaded rods, 8mm threaded rods, and T8 leadscrews.

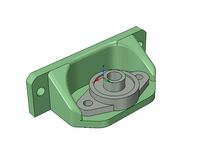

X-MOTOR-END

1) Similar to the X-Idler above, the Z-axis nut trap was removed and replaced with a platform to catch a floating Z-axis switch. Having dual limit switches (on both ends of the X-axis assembly) eliminates the possibility of the nozzle being driven hard into the print bed in the event that one axis is lower than the other. This arrangement also allows for separate measurements to be taken on both sides of the print bed in order to calculate the the exact orientation of the printing surface relative to the nozzle for all points on the print bed.

2) Similar to the X-Idler above, multiple versions of the floating Z-axis platform are included in order to make this part compatible with printers using 5mm threaded rods, 8mm threaded rods, and T8 leadscrews.

X-IDLER

1) A belt tensioner was added that can be used with either a 4x40mm bolt or a 5x40mm bolt. A nested nut trap is used to catch the smaller 4mm nut.The tensioner has an effective range of 11mm. An access port has been added to the side of the x-idler body in order to access the nut trap during installation or in the event that the nut trap becomes rounded. The tensioner has been designed around the 608ZZ bearing and is meant to be used with the included bearing guide. There is a 0.75mm clearance between the edge of the bearing guide and the tensioner body to prevent the belt from slipping off.

2) The inner diameter of the 8mm smooth rod holes was reduced in order to make it more difficult for the rods to slip. The ends of these holes were also closed up in order to keep the rods from slipping out the back.

3) The Z-axis nut trap was removed and replaced with a platform to catch a floating Z-axis switch. This is a design change similar to Crota's March 17 2014 design (http://www.thingiverse.com/thing:273805). However, this design's implementation of Crota's part more closely mirrors the technique used on the Robo 3D R1 printer. The Marlin firmware needs to be modified as explained by Crota to use this feature.

4) Multiple versions of the floating Z-axis platform are included in order to make this part compatible with printers using 5mm threaded rods, 8mm threaded rods, and T8 leadscrews.

X-MOTOR-END

1) Similar to the X-Idler above, the Z-axis nut trap was removed and replaced with a platform to catch a floating Z-axis switch. Having dual limit switches (on both ends of the X-axis assembly) eliminates the possibility of the nozzle being driven hard into the print bed in the event that one axis is lower than the other. This arrangement also allows for separate measurements to be taken on both sides of the print bed in order to calculate the the exact orientation of the printing surface relative to the nozzle for all points on the print bed.

2) Similar to the X-Idler above, multiple versions of the floating Z-axis platform are included in order to make this part compatible with printers using 5mm threaded rods, 8mm threaded rods, and T8 leadscrews.

Similar models

thingiverse

free

Prusa i3 Rework Leadscrew Z-axis w/Delrin Nut by Trilitheum

...s just plastic and they will strip out, but even just slightly more than finger tight and these have been snug and stable for me.

thingiverse

free

leadscrew brass nut to m5 nut adapter by hackermagnet

...dard m5 threaded rods and m5 nuts on your prusa i3 rework 1.5 for z axis without changing the x_end_motor and x_end_idler parts.

thingiverse

free

X-motor&idler for Prusa i3 rework for 6mm threaded rod by Alex_Post

...lex_post

thingiverse

this is version of the elements of the x-axis for 6 mm threaded rods and nuts 6mm printer prusa i3 rework.

thingiverse

free

Prusa i3 Z Axis Idler by chinzw

...z axis mounts.

you need to print 2x shims, they interface the 5mm thread to the 8mm hole in the 608 bearings.

bom:

2x608 bearings

thingiverse

free

Prusa i3 X Idler Tension modification/ 5mm Z screw by OgreMills

...idler tension modification/ 5mm z screw by ogremills thingiverse similar to other x axis mods. puts tension on x...

thingiverse

free

Prusa Steel X axis with tensioner and 8mm leadscrew support by fedewolfie

...ner and a m5 screw and nut for the toothed idler, i use a cheap aliexpress toothed idler with a m5 bore.

prints without supports.

thingiverse

free

Prusa MK3 x-axis modified for T8 nut and endstop by melancholist

...nd motor parts from prusa i3 mk3 for printer i'm making. the parts are redone so that they accept t8 nut and endstop switch.

thingiverse

free

Prusa i3 X-Ends for Z Acme Leadscrew by ffleurey

...-rod,-350mm-length-tr8*8-acme-leadscrew

the upgraded belt tensioner can be found here: http://www.thingiverse.com/thing:160636.

thingiverse

free

prusa i3 Z axis top for leadscrew 8mm by Benn25

...al diameter) to fit inside.

to print the right side, you just have to mirror reverse this one.

you can print with infill at 100%.

thingiverse

free

Z-axis anti backlash for Prusa i3 by Tech2C

...place this object over them and slot it in the nut trap of the x-axis motor mount and x-axis idler.

http://youtu.be/j5w2-83ppvm

Godvalve

thingiverse

free

Parts Drawer by Godvalve

...parts drawer by godvalve

thingiverse

a replacement parts drawer for a stacking organizer.

thingiverse

free

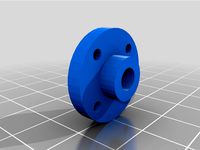

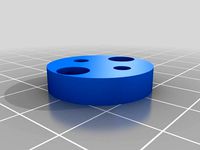

Bearing guide 608ZZ by Godvalve

...e

thingiverse

these bearing guides print out 0.5mm larger than the original parts listed with the prusa i3 and prusa mendel i2

thingiverse

free

Wall mounted pliers bin by Godvalve

...wall mounted pliers bin by godvalve

thingiverse

a wall mounted bin to hold small cutting pliers off of the work area.

thingiverse

free

Card Discard Tray by Godvalve

... piles. this tray was designed for the game 'spite and malice' but can be used for any card game requiring discard piles.

thingiverse

free

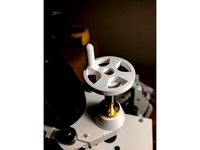

3D Filament Roll Insert (Robo3D R1+) by Godvalve

...ament roll insert (robo3d r1+) by godvalve

thingiverse

a version of the filament spool holding insert provided by the robo3d r1+

thingiverse

free

Printable Fidget Spinner by Godvalve

...ed for reprap printers with heated build plates. print out the spinner frame twice and glue it together. see picture for example.

thingiverse

free

Wall mounted dry erase pen bin by Godvalve

...always trying to find where i had left the dry erase markers so i created a wall mounted bin to keep them beside the white board.

thingiverse

free

Nema 17 Conceptualization Model by Godvalve

...ded to visualize the position of the motor in order to determine how my design worked with a gt2 40t aluminum timing belt pulley.

thingiverse

free

Reprap Prusa i3 LM8UU Linear Bearing Conceptualization Model by Godvalve

...f the parts that i am incorporating into my 3d printer design work. this is a model of the lm8uu bearing used in reprap printers.

thingiverse

free

4X AA Battery Box by Godvalve

...nating positive and negative ends that have wires soldered to them. all plates i've listed push easily into this printed box.

T8

turbosquid

$2

CFL Light T8 36W

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

CFL Light T8 18W

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

humster3d

$75

3D model of Volvo XC90 T8 2015

... detailed 3d model of volvo xc90 t8 2015 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$15

Fluorescent Fixture 3D Model

...fluorescent fixture 3d model 3dexport lighting fixture t8 fluorescent tube lamp fluorescence bulb electrical electric energy saving...

3d_export

$12

Fluorescent Tube 3D Model

...fluorescent tube 3d model 3dexport lighting fixture t8 fluorescent tube lamp fluorescence bulb electrical electric energy saving...

3dfindit

free

BGI94487 T8

...bgi94487 t8

3dfind.it

catalog: rcm

thingiverse

free

Lock Collar T8

...lock collar t8

thingiverse

lock collar t8, m4 nut (press fit).

thingiverse

free

Adapter M5 to T8 by Mitka

...adapter m5 to t8 by mitka

thingiverse

adapter m5 to t8

thingiverse

free

T8 LEAD SCREW by RichardJean

...t8 lead screw by richardjean

thingiverse

t8 lead screw

thingiverse

free

JUWEL T8 Clip 94025

...juwel t8 clip 94025

thingiverse

juwel t8 clip 94025 for aquarium reflecor

Leadscrew

thingiverse

free

Leadscrew Support by The_Custom_Side

...w support for 8mm leadscrew.

printed in 0.25mm petg

requires bearing (16mm od, 8mm id).

no supports, no rafts, 20% gyroid infill.

thingiverse

free

Hook for M8 Leadscrew

...hook for m8 leadscrew

thingiverse

hook which holds on m8 leadscrew without pressure on the screw

thingiverse

free

X Idler Leadscrew by GOO2014

...x idler leadscrew by goo2014

thingiverse

x idler leadscrew

thingiverse

free

10mm Leadscrew Knob by carboncopy101

...10mm leadscrew knob by carboncopy101

thingiverse

this is a knob for a 10mm leadscrew for manual turning. enjoy.

thingiverse

free

nut for m5 leadscrew by mbzn

...nut for m5 leadscrew by mbzn

thingiverse

created to use as a nut for m5 threaded bar in place of a leadscrew

thingiverse

free

8mm Leadscrew Crank by dakahler

...igned for the cyclone pcb, but can be used on any 8mm leadscrew.

the captive nut for the set screw is designed to be heat-staked.

thingiverse

free

Z leadscrew support for KFL08 by bajmar

...z leadscrew support for kfl08 by bajmar

thingiverse

z leadscrew support for kfl08

thingiverse

free

X-Axis Leadscrew Idler by brisinger

...x-axis leadscrew idler by brisinger

thingiverse

x-axis leadscrew idler

thingiverse

free

Leadscrew Adapter by PhoenixZip

...rew, and it does not fit our lorei printers.

this adapter allows use of holes that are 16mm apart to our (roughly) 11.85mm holes.

thingiverse

free

Trintcore z-axis modified leadscrew by grubeludouche

... modified leadscrew by grubeludouche

thingiverse

this is a mod to fit a t8 pitch leadscrew, replacing the original m8 leadscrew.

Idler

3d_export

$20

telescopic stacker belt conveyor

...and the actual components are as follows cema c idler cema c impact roller dodge bearing avoid tension bearing...

3d_export

$49

Liebherr R9250 Tracks - Crawler

...main parts: bottom rollers car bodies final drives top idler front idlers slewing rings-turntable bearings sprockets text track chains...

3d_export

$119

JD - 953MH Tracked Log Loader

...boby with engine<br>main body bolts<br>main body grilles<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right track chain<br>right track links<br>right track protector<br>right...

3d_export

$129

JD - 959MH Tracked Feller Buncher

...boby with engine<br>main body bolts<br>main body grilles<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right track chain<br>right track links<br>right track protector<br>right...

3d_export

$119

JD - 959MH Tracked Log Loader

...boby with engine<br>main body bolts<br>main body grilles<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right track chain<br>right track links<br>right track protector<br>right...

3d_export

$119

JD - 953MH Tracked Harvester

...tool - lower<br>moving limbing tool - upper<br>pedals<br>right - front idlerlt;br>right - rear idler<br>right feed rollers<br>right track chain<br>right track links<br>right...

thingiverse

free

Idler seat by jcen517

...idler seat by jcen517

thingiverse

idler seat

thingiverse

free

Idler by GEON_3D

...idler by geon_3d

thingiverse

idler para extrusor 1,75

imprimir en abs, petg o cualquier material resistente

thingiverse

free

wade idler by nautilux

...wade idler by nautilux

thingiverse

wade idler reforzado

thingiverse

free

Idler Frame by Dinusha

...idler frame by dinusha

thingiverse

idler frame specially for the belt conveyors.

Reworked

3d_export

$25

riva aquarama 1970

...visualization, as well as, if desired, it can be reworked for 3d printing. in the near future, a model...

3d_export

$8

Mosaic 1 3D Model

...outdoor indoor vector ceramic glass mosaic decorative mosaic manually reworked into a vector. the image is then modified in...

3d_export

$65

sci-fi scene for rendering restyling - tesla

...colors with the name, metal, light metal, dark metal, reworked renders for preview and processed in photoshop using a...

3d_export

$22

a filter assembly and inspection line

... by solidworks, proe, ug and other three-dimensional software. the details are detailed. welcome to download.<br>报错 笔记 双语对照

3d_export

$19

muuto raw chair

...ths: 54<br>depth: 51<br>height: 76<br>textures: 3000x4000 jpeg.<br>scene objects are organized by groups.

3d_export

$12

desert rocks stock in blender

...cement and bump" feature, for the "surface" tab of the material<br>packlist: 3 blender files, 8 textures 2k.

3d_export

$10

arclinea principia

...the essence, with the basic principles of the kitchen, reworked new steel technology and natural wood cutting. the extraordinary...

thingiverse

free

Doughnut Rework by Johhnny

...doughnut rework by johhnny thingiverse i reworked tzani's mobius doughnut for dual...

thingiverse

free

Beanie the Transformer rework by Whirl55

...beanie the transformer rework by whirl55 thingiverse found and reworked head pin and all...

thingiverse

free

AM10 - am8 rework Y

...am10 - am8 rework y

thingiverse

totaly rework to turn your am8 into an am10 with only 2 pieces

Tensioner

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$5

tension ring

...oyalty free 3d model tension ring for download as fbx and stl on turbosquid: 3d models for games, architecture, videos. (1553452)

turbosquid

$3

Tension Chair

...free 3d model tension chair for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1251503)

3d_export

$5

transformador de tension

...transformador de tension

3dexport

transformador de tension entrada 460vac salida 220vac marca audax

turbosquid

$20

Motorbike Chain Tensioner

...y free 3d model motorbike chain tensioner for download as stl on turbosquid: 3d models for games, architecture, videos. (1428322)

turbosquid

$25

TENSION-WOOD-CHAIR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

tension-bentwood-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Tension engagement ring

...n engagement ring for download as obj, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1491631)

3d_export

$10

Ruby Tension set Ring 3D Model

...ruby tension set ring 3d model

3dexport

tension set ruby ring in 18k

ruby tension set ring 3d model rehansheikh 25254 3dexport

turbosquid

$20

Superficial Tension Exp. Image.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

Auto

3d_export

$5

auto

...auto

3dexport

auto

3ddd

$1

auto

...auto

3ddd

max7

turbosquid

$69

AUTO

...to

turbosquid

royalty free 3d model auto for download as obj on turbosquid: 3d models for games, architecture, videos. (1453538)

3d_export

$10

Auto

...auto

3dexport

3d_export

free

auto

...auto

3dexport

3ddd

$1

Auto posters

...auto posters

3ddd

машина

auto posters

turbosquid

$50

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$28

Auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Leveling

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)