Thingiverse

DJI S900 / S1000 Retract Leg Mount for Retract Assembly with Mod by krazycanuck2011

by Thingiverse

Last crawled date: 4 years, 7 months ago

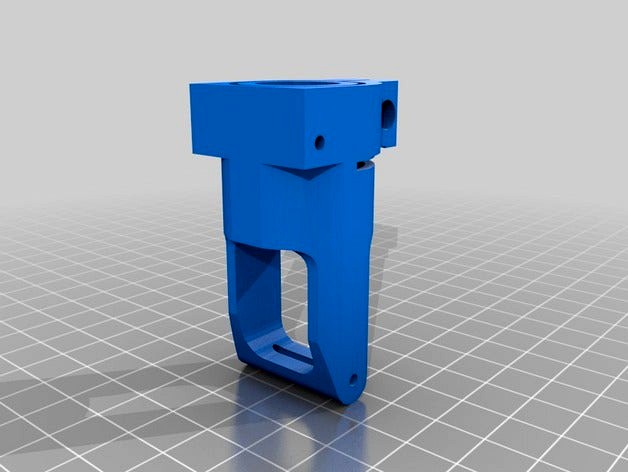

This is the piece of the retract assembly for the DJI S900 and S1000. DJI requires you to buy the entire retract assembly. I only needed a single part and couldn't justify the $400 for the assembly. I had a mechanical engineer design this for me, there maybe future revisions I just printed this myself and it went together like butter. It actually is a 1000 times better replacement part than the original. I am going to switch on the other side which was not damaged in the crash as well...

The holes are for metric 3mm cap screws. I replaced the screws on the landing gear threading into the plastic part with 3mm x 10 mm cap screws and used a washer. Not much to say other than this works, the part should be printed 180 degrees from the orientation it is showing and use 2mm support to get it just so, so all the areas that need support get it, so you can print a good working part.

I will post pics in the coming days, but a truely awesome piece of work by my mechanical engineer friend. Incredible part and highly recommended. I will attempt to ask him to design the other remaining pieces in the next week or two. Cross your fingers everyone....

In the meantime, I would love to have someone else design the entire parts assembly of the retracts for the s900 / s1000.

The original DJI assembly has a lot of weak points and poor design parameters , for example on the piece where the boom goes inside the metal piece for the retract gear, the clamp actually is about 2/3rds the diameter, not at the half way point. At 2/3'rds it places a lot of strain on the original clamp. We redesigned and made the clamp start at 1/2 the diameter of the circle, much better design. We also placed a plug inside the 16mm OD x 14mm ID carbon fiber boom. This supports the boom from both sides and really beefs the gear up a notch for rigidity. The gear is more fluent than ever as long as you dont wrench to 3mm cap screws massively tight into the plastic.

Again a few major upgrades were incorporated into the design. I printed with ABS for strength at 100% infill. I am open to comments on other materials to try. I would refrain from PLA just due to the strength needed for the part. I printed at .2mm, 100% infill with ABS and supports using simplify3d, which I manually inserted into my gcode via simplify3d.

I hope this really helps everyone, I know it helped me a great deal and saved me $400.

The holes are for metric 3mm cap screws. I replaced the screws on the landing gear threading into the plastic part with 3mm x 10 mm cap screws and used a washer. Not much to say other than this works, the part should be printed 180 degrees from the orientation it is showing and use 2mm support to get it just so, so all the areas that need support get it, so you can print a good working part.

I will post pics in the coming days, but a truely awesome piece of work by my mechanical engineer friend. Incredible part and highly recommended. I will attempt to ask him to design the other remaining pieces in the next week or two. Cross your fingers everyone....

In the meantime, I would love to have someone else design the entire parts assembly of the retracts for the s900 / s1000.

The original DJI assembly has a lot of weak points and poor design parameters , for example on the piece where the boom goes inside the metal piece for the retract gear, the clamp actually is about 2/3rds the diameter, not at the half way point. At 2/3'rds it places a lot of strain on the original clamp. We redesigned and made the clamp start at 1/2 the diameter of the circle, much better design. We also placed a plug inside the 16mm OD x 14mm ID carbon fiber boom. This supports the boom from both sides and really beefs the gear up a notch for rigidity. The gear is more fluent than ever as long as you dont wrench to 3mm cap screws massively tight into the plastic.

Again a few major upgrades were incorporated into the design. I printed with ABS for strength at 100% infill. I am open to comments on other materials to try. I would refrain from PLA just due to the strength needed for the part. I printed at .2mm, 100% infill with ABS and supports using simplify3d, which I manually inserted into my gcode via simplify3d.

I hope this really helps everyone, I know it helped me a great deal and saved me $400.