Thingiverse

Direct Drive DIY Filament Runout Sensor (Ender 3 / 3 Pro) by YorkieOl

by Thingiverse

Last crawled date: 3 years, 3 months ago

Direct Drive DIY Filament Runout Sensor (Ender 3 / 3 Pro)

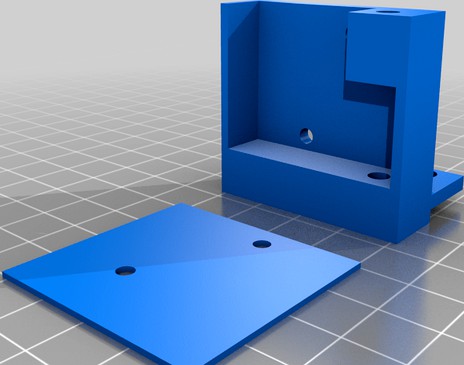

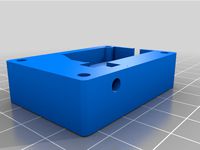

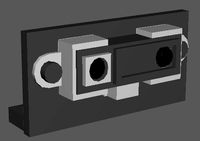

This project uses the V-155-1C25 microswitch with roller..

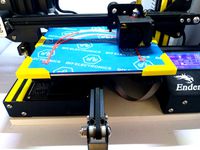

After upgrading to direct drive, my side mounted filament runout sensor became useless to the point I had to disable it.

I have since bought an eSUN filament dryer, which came with a feed tube from the dryer. As the tube fits nicely over the spare bowden tube i have, I decided to design a filament runout sensor that sits on the top bar instead of the spool holder, which is no longer needed..

The small piece of bowden tube is glued in place and is used to guide the filament across the switches roller. Without it, the filament will bend and it will be difficult to feed the filament through the unit. For the wiring, I used common on the side of the switch and normally open (the pin nearest common), so when the filament runs out and the switch

closes, the printer will act. Depending on how your marlin is set up, it may be the other way round for you - in this case, simply wire to common and nc (normally closed).

I have the btt tft35 e3 touch screen and wired to filament (DET)ect. The switch can also be wired to the main board - pin 15 on the skr mini boards I believe. You may want to google 'diy filament runout sensor' for information on your paticular board..

Anyway, I hope this is helpful for otheres and so share it with you here..

This project uses the V-155-1C25 microswitch with roller..

After upgrading to direct drive, my side mounted filament runout sensor became useless to the point I had to disable it.

I have since bought an eSUN filament dryer, which came with a feed tube from the dryer. As the tube fits nicely over the spare bowden tube i have, I decided to design a filament runout sensor that sits on the top bar instead of the spool holder, which is no longer needed..

The small piece of bowden tube is glued in place and is used to guide the filament across the switches roller. Without it, the filament will bend and it will be difficult to feed the filament through the unit. For the wiring, I used common on the side of the switch and normally open (the pin nearest common), so when the filament runs out and the switch

closes, the printer will act. Depending on how your marlin is set up, it may be the other way round for you - in this case, simply wire to common and nc (normally closed).

I have the btt tft35 e3 touch screen and wired to filament (DET)ect. The switch can also be wired to the main board - pin 15 on the skr mini boards I believe. You may want to google 'diy filament runout sensor' for information on your paticular board..

Anyway, I hope this is helpful for otheres and so share it with you here..

Similar models

thingiverse

free

Ender 3 / Pro Direct Drive filament runnout sensor V2.0

... (i bought this one : ebay : 253653306378)

1 x m3 bolt + nut for v-slot verion

1 x m3 bolt + nut / 2 t-nuts for standard version

thingiverse

free

ASX1 runout sensor lead-in with PTFE tube holder by Edbosgra

...l allow you to insert a bowden tube into the filament sensor. i feed my asx1 from a sunlu or esun filament dryer ( i have both)

thingiverse

free

Simple filament runout sensor mount for Ender 3 Pro with direct extruder by qnub

...r.

from the input side if the mount you can insert 6mm tube from dryer or just put filament directly or through my filament guide

thingiverse

free

Ender 3 Pro Filament Guide and Runout Sensor (Roller Microswitch) by deltathings

...s guide: https://www.thingiverse.com/thing:2917932 and this roller microswitch housing: https://www.thingiverse.com/thing:3411145

thingiverse

free

Ender 3 runout detection switch holder

...red into pin 27 or pin 29 on the mainboard.

you will need a small amount of ptfe tube in order to provide a smooth filament path.

thingiverse

free

Filament runout sensor by kranix

...on both the in and out side, i run a bowden from the extruder back to this sensor, where it fits snugly and is held without glue.

thingiverse

free

PTFE Ender 3 Filament Guide by gosunny3d

...y holspeed, this allows me to use a bowden tube from my horizontal filament dryer and spindle to the extruder feed on my ender 3.

thingiverse

free

Filament Runout Ender 3 - To be mounted on top.

...be mounted on top.

thingiverse

converted my ender 3 to direct drive extruder so i needed a new position for the filament sensor.

thingiverse

free

Ender 3 Direct Drive Extruder + Filament Runout Sensor + Dust Filter

...ts... i bought a bunch of them 15mm to 20mm then just cut them to the needed length.

11/01/2019 - slightly modified the cover...

thingiverse

free

Ender bowden filament guide for direct-drive

...g around.

test runs have gone well. i may incorporate a filament runout sensor for the guide at some time.

designed in fusion360.

Runout

3d_export

$6

clamping mechanism of heavy workpiece

...load<br>the inertia force at the maximum acceleration of horizontal runout is less than the retraction side thrust of cylinder.<br>selection...

thingiverse

free

Filament runout sensor by TA1AUB

...filament runout sensor by ta1aub

thingiverse

filament runout sensor

thingiverse

free

Runout filament sensor by davidix68

...runout filament sensor by davidix68

thingiverse

ender 3 runout sensor microswitch case

thingiverse

free

runout sensor -bowden by chroja

...runout sensor -bowden by chroja

thingiverse

runout sensor -bowden

v5 optimalize design

thingiverse

free

Filament runout sensor by jos

.../webshop/cartesio-shop/electronics/filament-runout-sensor

for assembly :http://mauk.cc/mediawiki/index.php/filament_runout_sensor

thingiverse

free

Filament runout by pochetto

...y pochetto

thingiverse

easy filament runout.

1 endstop

1 led

nel firmware attivare la funzione di fine filo e assegnare un pin.

thingiverse

free

Filament runout sensor support by 100s99s

...filament runout sensor support by 100s99s

thingiverse

support for filament runout sensor of direct drive.

thingiverse

free

Swivel mount runout sensor by notnyt

...swivel mount runout sensor by notnyt

thingiverse

608 bearing mounted filament runout sensor

thingiverse

free

Filament runout sensor fastener by Cherepok

...filament runout sensor fastener by cherepok

thingiverse

movable adjustable mount for bigtreetech filament runout sensor.

thingiverse

free

Runout gauge for pulley by tom4cad

...runout gauge for pulley by tom4cad

thingiverse

20t pulley with 5 mm bore. measured runout 0,07 mm

edit

tool with 8mm hole added

Diy

3d_export

free

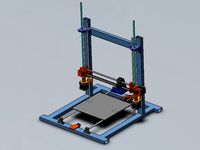

DIY 3D Printer

...diy 3d printer

3dexport

diy 3d printer model

turbosquid

$10

Diy tiered

...l diy tiered for download as max, max, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1603709)

turbosquid

$3

Diy Desk to Bench

...odel diy desk to bench for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1506589)

turbosquid

$2

DIY Moon Light

...model diy moon light for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1501170)

3d_export

$8

DIY CNC Router 3D Model

...diy cnc router 3d model

3dexport

cnc; router; diy; homemade

diy cnc router 3d model maikeru86 58463 3dexport

turbosquid

$5

Diy Kitchen Cabinets

...itchen cabinets for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1197373)

3d_export

free

Download free Diying Plant 3D Model

...download free diying plant 3d model

3dexport

diying plant blender

diying plant 3d model visitorsama 98607 3dexport

3ddd

$1

DIY coffee table + decor

... рамка для фото

кофейный столик diy 400х350х600(h) мм. моделился по фото. внимание: материалы - corona.

turbosquid

$3

Diy Wire Lamp Shade

...free 3d model diy wire lamp shade for download as 3ds and fbx on turbosquid: 3d models for games, architecture, videos. (1347605)

cg_studio

$12

DIY MONGOLIAN LAMB STOOLS3d model

... hair soft pile white

.max - diy mongolian lamb stools 3d model, royalty free license available, instant download after purchase.

Ender

3ddd

$1

Enders / Elegance

...enders / elegance

3ddd

обогреватель

уличный газовый обогреватель enders elegance

высота: 2200 мм

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

turbosquid

$1

pen support for ender 3

...y free 3d model pen support for ender 3 for download as blend on turbosquid: 3d models for games, architecture, videos. (1611282)

3d_ocean

$9

Ender Dragon Minecraft

...ojang obj poly videogames

ender dragon minecraft created with cinema 4d r15 formats included: max 2013 – fbx 2012 – c4d r15 – obj

3d_export

free

Creality ender enclosure webcam mount

...e creality enclosure. sure is better than a tripod. change it up if it helps. i printed pla with 50% infill on my dd ender 3 pro.

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

3d_export

free

ender 3 3d print bed clips

...ed + normal aluminium bed frame of the creality ender 3 = 6mm (b) these clips are designed for glass plate + aluminium bed = 4mm

3d_export

$5

GRUMPY CAT

...grumpy cat 3dexport grumpy cat to print in ender ...

3d_export

$5

Logs fire

...with one multi material for corona and vray r ender. albedo, normal, uvmap, roughness format jpg 4096x4096 models:...

3d_export

$42

excavator

...is the original size. 0.12 mm printing surface creality ender5 ...

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

Pro

turbosquid

$29

Pro

...ree 3d model mac pro for download as obj, c4d, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1505782)

turbosquid

$15

Apple Mac Pro and Pro Display

...ee 3d model apple mac pro and pro display for download as max on turbosquid: 3d models for games, architecture, videos. (1417078)

3d_export

$5

iphone 13 pro max and pro

...3 pro max and 13 pro the model is made in four colors (graphite, gold, silver, and blue), all of which are attached in the files.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

3d_export

$4

macbook pro

...macbook pro

3dexport

macbook pro 13" inch 2020 years model

3ddd

free

GentleLase Pro

... syneron , candela

gentlelase pro аппарат для лазерной эпиляции

turbosquid

$25

PRO frame

...rbosquid

royalty free 3d model pro frame for download as max on turbosquid: 3d models for games, architecture, videos. (1148329)

turbosquid

$5

Alien pro

...osquid

royalty free 3d model alien pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1678446)

turbosquid

$5

iphone11 pro

...uid

royalty free 3d model iphone11 pro for download as blend on turbosquid: 3d models for games, architecture, videos. (1562707)

3ddd

$1

Mac Pro (appel)

...mac pro (appel)

3ddd

компьютер , apple

mac pro

3

turbosquid

$10

Mountain Bike 3 -3 of 3

...model mountain bike 3 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438752)

turbosquid

$6

Rock 3-3

...urbosquid

royalty free 3d model rock 3-3 for download as obj on turbosquid: 3d models for games, architecture, videos. (1628065)

turbosquid

$29

Books 150 pieces 3-3-3

...books 150 pieces 3-3-3 for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1384033)

turbosquid

$3

Genesis 3 Clothing 3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

hinge 3

...hinge 3

3dexport

hinge 3

3ddd

$1

Розетка 3

...розетка 3

3ddd

розетка

розетка 3

turbosquid

$50

is-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Mountain Bike 3 -2 of 3

...model mountain bike 3 (#2 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438750)

turbosquid

$10

Mountain Bike 1 -3 of 3

...model mountain bike 1 (#3 of 3) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1438743)

3d_export

$5

3 CATS

...3 cats

3dexport

3 cats pen holder