Thingiverse

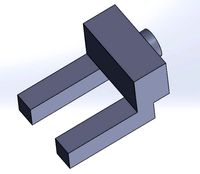

Dimensional thermal test jig (for annealing) by punkgeek

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is a companion for the dimensional calibration tool by LuckyPants. It allows you to place up to 4 of those tools at a 45 degree angle in an oven (or other thermal test environment). I used to for testing how annealing my PLA based parts improves thermal resistance (i.e. can I put these parts in a hot car?). It allows you to use the weight of the part itself to exert a bending force on the middle of the part.

I printed mine in MakerGeeks PETG, but the next time I need to print it I'll probably print it in PLA and then anneal it at 80C for 40 minutes. The PETG did not hold up to temperatures as well as I had hoped.

In addition to this little jig. Here's my notes from my test:

Samples (each sample was 20% gyroid infill, 0.20 layer height):

Brown Solutech PLA (which is pretty crummy and I expected to do poorly - but it did better than expected!).

Yellow MakerGeeks HTPLA

Blue MakerGeeks PETG (this piece was not annealed)

Test environment:

A steam oven Sous Vide mode allowed very fine control of temperature and slow heating/cooling

The PLA and HTPLA parts were annealed in a horizontal orientation in the oven at 80C for 30 minutes. The parts were placed initially in a cold oven, heated and then allowed to cool in the oven.

The PLA/HTPLA and PETG test pieces were placed on the jig and heated in the oven at a series of temperatures. Each temperature was held for 30 minutes. The test temperatures: 50C, 60C, 70C, 75C, 80C, 90C

Findings:

The HTPLA shrunk 1.7% in X & Y and expanded 0.5% in Z during annealing

The PLA shrunk 3% in X & Y and expanded 0.5% in Z during annealing

The PETG started to droop very slightly at 60C, drooped to about a 15% angle by 70C, by 75C it was basically limp on the bottom of the test jig

The PLA had very slight droop (1mm) by 70C, but otherwise resisted the heat just as well as the HTPLA

The HTPLA had no droop at any of the temperatures

Conclusions

PLA does almost as good as HTPLA if you don't mind the shrinkage

HTPLA shrinks a lot less in annealing than regular PLA

Annealed PLA has better temperature resistance than non annealed PETG

Possible further research:

Try higher temps - I stopped at 90C because that's what was easy to test in my oven (and I only needed my parts to survive in a super hot car - which the internet says is about 75C)

I printed mine in MakerGeeks PETG, but the next time I need to print it I'll probably print it in PLA and then anneal it at 80C for 40 minutes. The PETG did not hold up to temperatures as well as I had hoped.

In addition to this little jig. Here's my notes from my test:

Samples (each sample was 20% gyroid infill, 0.20 layer height):

Brown Solutech PLA (which is pretty crummy and I expected to do poorly - but it did better than expected!).

Yellow MakerGeeks HTPLA

Blue MakerGeeks PETG (this piece was not annealed)

Test environment:

A steam oven Sous Vide mode allowed very fine control of temperature and slow heating/cooling

The PLA and HTPLA parts were annealed in a horizontal orientation in the oven at 80C for 30 minutes. The parts were placed initially in a cold oven, heated and then allowed to cool in the oven.

The PLA/HTPLA and PETG test pieces were placed on the jig and heated in the oven at a series of temperatures. Each temperature was held for 30 minutes. The test temperatures: 50C, 60C, 70C, 75C, 80C, 90C

Findings:

The HTPLA shrunk 1.7% in X & Y and expanded 0.5% in Z during annealing

The PLA shrunk 3% in X & Y and expanded 0.5% in Z during annealing

The PETG started to droop very slightly at 60C, drooped to about a 15% angle by 70C, by 75C it was basically limp on the bottom of the test jig

The PLA had very slight droop (1mm) by 70C, but otherwise resisted the heat just as well as the HTPLA

The HTPLA had no droop at any of the temperatures

Conclusions

PLA does almost as good as HTPLA if you don't mind the shrinkage

HTPLA shrinks a lot less in annealing than regular PLA

Annealed PLA has better temperature resistance than non annealed PETG

Possible further research:

Try higher temps - I stopped at 90C because that's what was easy to test in my oven (and I only needed my parts to survive in a super hot car - which the internet says is about 75C)

Similar models

thingiverse

free

Jeep Liberty KJ - Radio Fader Knob

...n but they will go on, you may need something to push them on with, but this ensures the fit is snug and they won't fall off.

thingiverse

free

Kodama Trinus PLA Leveling Jig by Gelf1907

....

you will need to print one leveling base, 2 of each the left and right arms and 2 crossbars. hardware needed is in the pdf.

thingiverse

free

Hot Water Heater Element Removal Tool by jawebb

...d protopasta htpla and anneal in an over @ 200 degrees fahrenheit for 20 minutes on the oven rack. let it cool and start turning.

thingiverse

free

Dishwasher pods/tablet basket by pesekr

...d pla by fiberlogy.

please don't forget to use support for the hooks and i recommend to use support also on sides with holes.

thingiverse

free

Coffee Cup Coaster Made From Coffee by Wasatch

...stortion. let it cool down slow (just turn the oven off or use time bake)https://www.3dhubs.com/salt-lake-city/hubs/wasatch-brian

thingiverse

free

Coffee mug/cup by GabrielMcG

...pport angle to 55 degrees to minimize support defects toward the bottom of the mug and still allow enough support for the handle.

grabcad

free

Thermal Resistance

...thermal resistance

grabcad

thermal resistance i had to recreate for my work. g 1 1/4 thread

thingiverse

free

Sink Strainer V3 & V4 by Thomllama

...eal in the oven or boil. i use maker geeks raptor pla and anneal and i'm able to wash these in the dishwasher without issues!

thingiverse

free

Graphics Card Backplate (GTX1070) by happypig123123

...ng the print (i have a single extruder printer) after if started printing the letters. (i used prusa slicers color print feature)

thingiverse

free

Star Trophy by ARMAND252

...le star trophy i made for my wifes preschool

prints well in pla and petg

pla 205c bed 55c

petg 250c bed 70c

used sa filament

Punkgeek

thingiverse

free

Monitor stand by punkgeek

...monitor stand by punkgeek

thingiverse

a monitor stand - you can adjust scale for your application.

thingiverse

free

Kitchen lid organizer by punkgeek

...kitchen lid organizer by punkgeek

thingiverse

my wife made these little shelves to organize tupperware style lids.

thingiverse

free

aeropress goo containment tray by punkgeek

...nkgeek

thingiverse

this is a simple tray to add to the aeropress station. it keeps coffee goo from dripping out onto the shelf.

thingiverse

free

bird feeder window hangar by punkgeek

... you to hand a hummingbird feeder on a glass pocket window. you can attach the hangar to the window with three pieces of velcro.

thingiverse

free

fence post cap by punkgeek

...gn file in case you want to customize it for a different size of post. please comment or post a make if you find this useful ;-)

thingiverse

free

Sonex flap handle by punkgeek

...ou to ensure it works for your application.

if you do use this item i'd appreciate a $20 paypal donation to my beer fund. ;-)

thingiverse

free

Customizable idler pully by punkgeek

...e different bearing sizes or to change the size of the pulley. here's the web editable version of the 3d model (in onshape).

thingiverse

free

Garmin/Gopro style mount for radar tail light by punkgeek

...ick ties to attach a gopro or garmin rtl-510 radar to your bike. i can add a link to the onshape design file if anyone wants it.

thingiverse

free

aircraft stick grip by punkgeek

...ick dimensions): https://cad.onshape.com/documents/d86e2c682adb2a7bc8aa23fa/w/e5ff83d70fa1989e385eb9dd/e/d9604c87dbf82bc272c03592

thingiverse

free

Pop rivet cable ties by punkgeek

...sk. assume they can fail. fellow plane builders: i ask for a paypal donation to me of $5 if you use these, so i can buy a beer.

Annealing

3d_export

$10

automatic enameled wire conveyor line

...g, labeling, weighing, scanning, palletizing, conveying, etc. enameled wire scheme, please use solidworks 2012 and above to open!

3d_export

$49

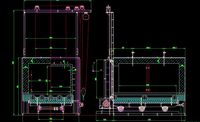

drawing of 3x2x15m full fiber trolley resistance furnace

...resistance furnace. it is a special equipment for quenching, annealing normalizing and tempering of metal products in natural atmosphere,...

thingiverse

free

Induction Annealer by Russ10

...n annealer by russ10

thingiverse

these are the 3d printed parts used in making an auto feeding induction annealer. more info at:

thingiverse

free

Case Annealer Heat Sink Prototype by bigblack

...case annealer heat sink prototype by bigblack

thingiverse

the last picture is of the final product turned on a lathe

3dfindit

free

DIN 315 - annealed cast iron, zinc-plated (A2K), blue passivated

...din 315 - annealed cast iron, zinc-plated (a2k), blue passivated

3dfind.it

catalog: wuerth

thingiverse

free

Annealing Tube Clip for Charmilles 290F/330F by cudakid03

...old our larger tubes in the retracted position and added a counterbore on the back side to clear the nutsert on the 330f machine.

thingiverse

free

Brass Annealing Station by msgbean

...ation dimensions to bend the cartridge holder and added a misc. parts list.

updated 1/21/21: added a drum drawing for dimensions.

thingiverse

free

prototype planoconvex lens with a customisable lens curvature for being processee by the sacrificial coat & annealing salt method by Dr_Froggy_rD

...free of salt frost effect but the bubbles inside affects the lens...

maybe some will be more successful

best regards

dr_froggy_rd

thingiverse

free

Nema 17 driven cartridge case feeder for an induction annealer by wombatordnance

...r and a way to drive it. (you could fit another motor using an adapter with a nema 17 flange, i might draw one up and upload it.)

Thermal

3d_export

free

thermal mugs

...thermal mugs

3dexport

disposable thermal mugs modeled in cinema 4d, render in corona

3d_export

$37

thermal cam

...thermal cam

3dexport

turbosquid

$46

Thermal Camera

...ermal camera for download as max, 3ds, fbx, obj, stl, and dwg on turbosquid: 3d models for games, architecture, videos. (1696144)

cg_studio

$45

Thermal bath3d model

...hermal bath3d model

cgstudio

.3ds .max - thermal bath 3d model, royalty free license available, instant download after purchase.

turbosquid

$3

Thermal Desorption Tube

...del thermal desorption tube for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1283030)

turbosquid

$5

Thermal Coffee Mug

...del thermal coffee mug for download as 3ds, obj, fbx, and 3dm on turbosquid: 3d models for games, architecture, videos. (1243586)

turbosquid

free

Araska Thermal Katana

...a thermal katana for download as blend, fbx, obj, x, and gltf on turbosquid: 3d models for games, architecture, videos. (1662962)

turbosquid

$179

Resort Thermal Center

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$69

Thermal power plant

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$70

Thermal tunnel for screen printing

...odel thermal tunnel for screen printing for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1310569)

Jig

turbosquid

$25

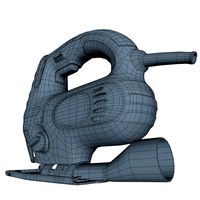

jig-saw_mid_SM

...uid

royalty free 3d model jig-saw_mid_sm for download as obj on turbosquid: 3d models for games, architecture, videos. (1244761)

turbosquid

$20

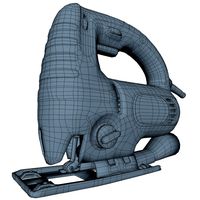

jig-saw_low

...osquid

royalty free 3d model jig-saw_low for download as obj on turbosquid: 3d models for games, architecture, videos. (1244760)

turbosquid

$10

jig-saw_hi

...bosquid

royalty free 3d model jig-saw_hi for download as obj on turbosquid: 3d models for games, architecture, videos. (1244757)

turbosquid

$7

Jig Armchair

...squid

royalty free 3d model jig armchair for download as max on turbosquid: 3d models for games, architecture, videos. (1648936)

turbosquid

$5

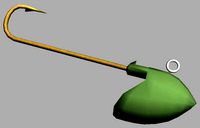

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Tail

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dimensional

turbosquid

$5

Dimensional Gateway

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

3-Dimensional Purple

...3-dimensional purple

3ddd

1326 - 889. пригодится для перин и одеял.

3d_export

$20

4 Dimensional Cube 3D Model

...4 dimensional cube 3d model

3dexport

4d cube

4 dimensional cube 3d model shaputer 7644 3dexport

3d_export

$8

SNK CONTROLLER TEAM DIMENSIONAL 3D 3D Model

...controller team dimensional 3d equipo maniobras armas cuerpo

snk controller team dimensional 3d 3d model lococr98 86977 3dexport

3d_export

$180

automated three-dimensional garage

...the purchase.<br>designed with solidworks 2017;vray with keyshot<br>-------------------------------------------------

cg_studio

$59

three-dimensional console, concept device3d model

... .obj .max - three-dimensional console, concept device 3d model, royalty free license available, instant download after purchase.

3d_export

$20

three-dimensional modeling and rendering of shaver

...low, the material texture maps are correctly aligned and set up correctly - the texture format is jpg/png/exr /hdr - four cameras

3d_export

$8

coats and skirt 3d

...coats and skirt 3d 3dexport three-dimensional design of clothes with software marvelous and...

3d_export

$6

3d clothing

...3d clothing 3dexport three-dimensional design of clothes with software: marvelous and clo3d and...

3d_export

$12

automatic pipe cutting machine

...aspects and high efficiency. the drawings contain three-dimensional and two-dimensional engineering drawings, and a list of...

Test

turbosquid

$99

test

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1251637)

turbosquid

$63

TEST

...st

turbosquid

royalty free 3d model test for download as max on turbosquid: 3d models for games, architecture, videos. (1446233)

turbosquid

$1

test

...st

turbosquid

royalty free 3d model test for download as fbx on turbosquid: 3d models for games, architecture, videos. (1360941)

3d_export

free

johnny test

...johnny test

3dexport

johnny test 3d

turbosquid

$15

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Test

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

gripper test

...gripper test

3dexport

robot gripper test model