Thingiverse

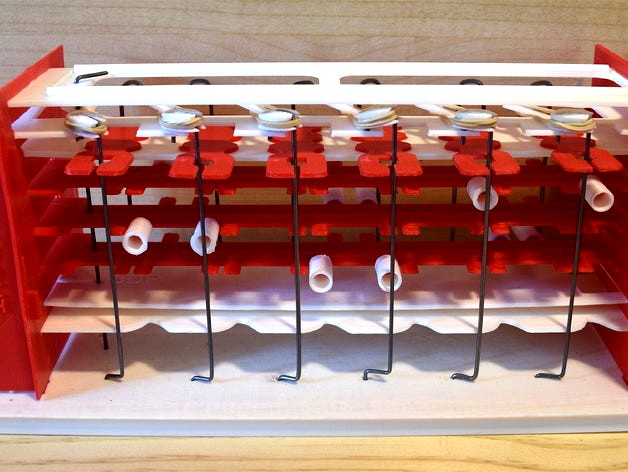

Digicomp I by markz

by Thingiverse

Last crawled date: 3 years ago

Print if you wish. It works as is, but has not been tested against a vintage Digicomp I.

Testing will occur over the next couple of months.

This is a work in progress of a 3d printed recreation of the DIgicomp I, a three-bit computer from the 60's. Thanks to the members of the FriendsOfDigiComp Yahoo group for their help, and their preservation of details about this device, including drawings, photos and manuals. And of course, thanks to ESR, for their genius in creating this product way back when...

The intent of this thingy is to provide a source for those who want to print there own, or to replace missing parts for a vintage device. We'll see if this all works out.

I've finally obtained a DC I off Ebay and am currently updating parts. So far, they're very close. I'll post when complete.

OTHER SOURCES YOU SHOULD KNOW ABOUT:

Looking for a DC I that you don't have to print? Concerned about the cost to print? A wonderful, fully functional recreation of the DC I in card-stock is available from MindsOnToys: http://www.mindsontoys.com/kits.htm

Looking for a DC II ? EvilMadScientist has a beautiful recreation in wood. http://shop.evilmadscientist.com/productsmenu/tinykitlist/375-dcii

And of course, there's a DC II app for IOS devices, if I may tout my own product.https://itunes.apple.com/us/app/virtual-dc-ii/id668402874?ls=1&mt=8

Thanks !

BUILD LIST

Qty-1 Color=White Full Base or Base Modified, full base similar to the original base or

modified base, with two opposite rounded corners for easier printing

Qty-2 Color=Red End-piece or End-piece reinforced

Qty-1 Color=Red Gusset

Qty-1 Color=Red Readout

Qty-3 Color=Red Flipflop

Qty-3 Color=Red Readout Tab or (in white) readout tab with raised numbers

Qty-3 Color=Red Readout Connector (or use short sections of drinking straw)

Qty-6 Color=Red Single Slider

Qty-1-2 Color=Red Double Slider - used in certain calculations

Qty-1 Color White Top Plate

Qty-1 Color White Slider Plate

Qty-1 Color White Reset Clock

Qty-1 Color White Set-Clear Clock

Qty-1 Color White Rod Bearing Plate

Qty-1 Any Color - wire template

Qty-6 Any Color - base Clips

Additionally:

0.055 music wire for rods

0.061 music wire for crank

number 10 rubber bands, Qty- 6

Bend 12 logic rods using the 0.55 music wire

Bend 1 crank using the 0.061 music wire.

Bend a length of wire and bend a 90 degree angle in the end to act as the pin.

Optionally:

Rubber Band Pulleys - qty 6 - my rubber bands keep popping of the top of the logic rods. (Somehow that sounds like it should be censored) So I'd have to take the top plate off, reattach the rubber bands, and put the top plate back on. Maybe I'm doing something wrong, but this got old quickly. Print the rubber band pulleys and pop one onto the top of the logic rods. Put the rubber band in the groove provided. Haven't lost a rubber band since !

BENDING INSTRUCTIONS:.

Print out the wire template, and us hand tools such as those shown in the 'wire bending tools photo'. It's tough work, but after making 12 of them, you'll have it mastered. Be sure that after bending the rod, if very close to matching the template. Try to make squarish corners, especially on top to help the rubber bands stay on. Lay the rod on the table, and make sure it lay's flat all the way from the top to the bottom, or it will cause problems later. With a nod to Norm, be sure to wear (these) safety glasses, and gloves, as music wire can split into sharp shards. Work in an open area, so the wire doesn't poke your mother-in-law or the cat in the eye. Initially, I tried cutting the wires to length but found it way easier to keep the wire longer, giving more bending leverage. Besides the printed wire template, I used a heavy set of needle nose pliers, lineman's pliers, and a mini bolt cutter for cutting the music wire. Yes, you can cut it with the lineman's plier's but it's much easier with the bolt cutter. I used http://www.amazon.com/Knipex-7101200-8-Inch-Action-Mini-Bolt/dp/B000SOSC4Y/ref=sr_1_11?s=power-hand-tools&ie=UTF8&qid=1461523354&sr=1-11&keywords=KNIPEX which I picked up at Menards.

BUILD TIPS:

1) It's important to carefully remove any overprint or schmutz. I tend to print tight on the first layer to make sure it sticks to the print bed. This causes the plastic to spread out on the first layer. This should be cleaned out especially where there is contact with other parts of the device. For instance, one problem was the slot in the front of the sliders must allow a rod to move smoothly into and out of the slot. If the rods catch in the slot the device will not function. Also on each horizontal plate, ensure the overprint is cleaned out in the slot the pin goes through. Each plate must move smoothly past the pin to their full extent without catching.

2) The rod shape has little tolerance. If the horizontal sections of a rod are too long (even slightly), the rod may not move into the correct place, especially with the clock rods.

3) At the top of the rods, where the end goes through the the rod bearing plate, the tail end of the rod may be too long and catch on the sliders. Trim off a bit of the end of the wire if necessary.

4) The crank hole in the base is intentionally tight/undersized (depending on print). It's critical that the crank does not wobble, so carefully ream out the hole just until the crank fits. A tight fit is preferred. If the crank wobbles around, the reliability or function of the device will be affected.

Progress notes:

UPDATE 5/20/16

Continuing to work on documentation at http://www.someoldguycoding.com/projects/digicomp-i/.

Device passes the check out problem from the original manual after a little tweaking.

Once documentation is complete, parts will be shipped to tester to compare against a vintage DCI. If there issues updates will be made

Thanks for your time and interest

mark-

Testing will occur over the next couple of months.

This is a work in progress of a 3d printed recreation of the DIgicomp I, a three-bit computer from the 60's. Thanks to the members of the FriendsOfDigiComp Yahoo group for their help, and their preservation of details about this device, including drawings, photos and manuals. And of course, thanks to ESR, for their genius in creating this product way back when...

The intent of this thingy is to provide a source for those who want to print there own, or to replace missing parts for a vintage device. We'll see if this all works out.

I've finally obtained a DC I off Ebay and am currently updating parts. So far, they're very close. I'll post when complete.

OTHER SOURCES YOU SHOULD KNOW ABOUT:

Looking for a DC I that you don't have to print? Concerned about the cost to print? A wonderful, fully functional recreation of the DC I in card-stock is available from MindsOnToys: http://www.mindsontoys.com/kits.htm

Looking for a DC II ? EvilMadScientist has a beautiful recreation in wood. http://shop.evilmadscientist.com/productsmenu/tinykitlist/375-dcii

And of course, there's a DC II app for IOS devices, if I may tout my own product.https://itunes.apple.com/us/app/virtual-dc-ii/id668402874?ls=1&mt=8

Thanks !

BUILD LIST

Qty-1 Color=White Full Base or Base Modified, full base similar to the original base or

modified base, with two opposite rounded corners for easier printing

Qty-2 Color=Red End-piece or End-piece reinforced

Qty-1 Color=Red Gusset

Qty-1 Color=Red Readout

Qty-3 Color=Red Flipflop

Qty-3 Color=Red Readout Tab or (in white) readout tab with raised numbers

Qty-3 Color=Red Readout Connector (or use short sections of drinking straw)

Qty-6 Color=Red Single Slider

Qty-1-2 Color=Red Double Slider - used in certain calculations

Qty-1 Color White Top Plate

Qty-1 Color White Slider Plate

Qty-1 Color White Reset Clock

Qty-1 Color White Set-Clear Clock

Qty-1 Color White Rod Bearing Plate

Qty-1 Any Color - wire template

Qty-6 Any Color - base Clips

Additionally:

0.055 music wire for rods

0.061 music wire for crank

number 10 rubber bands, Qty- 6

Bend 12 logic rods using the 0.55 music wire

Bend 1 crank using the 0.061 music wire.

Bend a length of wire and bend a 90 degree angle in the end to act as the pin.

Optionally:

Rubber Band Pulleys - qty 6 - my rubber bands keep popping of the top of the logic rods. (Somehow that sounds like it should be censored) So I'd have to take the top plate off, reattach the rubber bands, and put the top plate back on. Maybe I'm doing something wrong, but this got old quickly. Print the rubber band pulleys and pop one onto the top of the logic rods. Put the rubber band in the groove provided. Haven't lost a rubber band since !

BENDING INSTRUCTIONS:.

Print out the wire template, and us hand tools such as those shown in the 'wire bending tools photo'. It's tough work, but after making 12 of them, you'll have it mastered. Be sure that after bending the rod, if very close to matching the template. Try to make squarish corners, especially on top to help the rubber bands stay on. Lay the rod on the table, and make sure it lay's flat all the way from the top to the bottom, or it will cause problems later. With a nod to Norm, be sure to wear (these) safety glasses, and gloves, as music wire can split into sharp shards. Work in an open area, so the wire doesn't poke your mother-in-law or the cat in the eye. Initially, I tried cutting the wires to length but found it way easier to keep the wire longer, giving more bending leverage. Besides the printed wire template, I used a heavy set of needle nose pliers, lineman's pliers, and a mini bolt cutter for cutting the music wire. Yes, you can cut it with the lineman's plier's but it's much easier with the bolt cutter. I used http://www.amazon.com/Knipex-7101200-8-Inch-Action-Mini-Bolt/dp/B000SOSC4Y/ref=sr_1_11?s=power-hand-tools&ie=UTF8&qid=1461523354&sr=1-11&keywords=KNIPEX which I picked up at Menards.

BUILD TIPS:

1) It's important to carefully remove any overprint or schmutz. I tend to print tight on the first layer to make sure it sticks to the print bed. This causes the plastic to spread out on the first layer. This should be cleaned out especially where there is contact with other parts of the device. For instance, one problem was the slot in the front of the sliders must allow a rod to move smoothly into and out of the slot. If the rods catch in the slot the device will not function. Also on each horizontal plate, ensure the overprint is cleaned out in the slot the pin goes through. Each plate must move smoothly past the pin to their full extent without catching.

2) The rod shape has little tolerance. If the horizontal sections of a rod are too long (even slightly), the rod may not move into the correct place, especially with the clock rods.

3) At the top of the rods, where the end goes through the the rod bearing plate, the tail end of the rod may be too long and catch on the sliders. Trim off a bit of the end of the wire if necessary.

4) The crank hole in the base is intentionally tight/undersized (depending on print). It's critical that the crank does not wobble, so carefully ream out the hole just until the crank fits. A tight fit is preferred. If the crank wobbles around, the reliability or function of the device will be affected.

Progress notes:

UPDATE 5/20/16

Continuing to work on documentation at http://www.someoldguycoding.com/projects/digicomp-i/.

Device passes the check out problem from the original manual after a little tweaking.

Once documentation is complete, parts will be shipped to tester to compare against a vintage DCI. If there issues updates will be made

Thanks for your time and interest

mark-

Similar models

grabcad

free

Slider-Crank Mechanism

...der crank mechanism made on fusion 360 with revolute joint, pin and slot joints.

parts: 1) base plate

2) connecting rod

3) crank

thingiverse

free

Rubber Band Bow by ShakinBakin

...r clip at both ends when inserted, cut ends to length

found rolled paper with tape on end for added weight works best for arrows.

thingiverse

free

Weather Station by ilikecake1

...on the radiation shield by micromet. i wanted somthing similar to that, but that i could mount to the...

thingiverse

free

Rubber band adjustable level slider by XoGuSi

...r band is fixed between the sensor and the slider. the other end is fixed with a knot.

the holder works fine and accurate for me.

thingiverse

free

Rubber Tie Hook by easai

.../end that hold the other end of the rubber band.

i made the rubber-tie-hook 'flat' so that it would be easier to print.

grabcad

free

Rotary guide mechanism

...circumference. the condition for the driven rod to rotate is that the length of the crank is longer than the length of the frame.

grabcad

free

slider crank mechanism

... the crank is the rotating part, the connecting rod connects the crank to the slider, and the slider moves along a straight line.

thingiverse

free

Wingspan Player Token and Accessories Box

...there's openings to hold stacks of the round end tokens. there is space enough for 28 tokens, so bring on more expansions. :)

thingiverse

free

Smooth rod straightness tester by fluffgummi

...for strapping down the rod with a rubber-band or similar ...

grabcad

free

Bending machine

...bending machine

grabcad

place the 304 round rod inside the device and bend it at both ends.

Markz

thingiverse

free

Waves by markz

...z

thingiverse

wanted to generate a wave pattern. this worked quite well.

used file to cut with cnc using estlcam

added stl file

thingiverse

free

Modified Motor Mount by markz

...hingiverse

i really liked the stepper motor clamp from the source thing, but was indecisive on where i needed the mounting hole.

thingiverse

free

yet another 2-piece heart shaped box. by markz

...yet another 2-piece heart shaped box. by markz

thingiverse

2 piece heart shaped box.

thingiverse

free

Graphic controller holder tray by markz

...turdy to hold the graphic controller on my lowrider build.

mounts to a vertical surface and holds the controller at a nice angle.

thingiverse

free

Headphone or other hanger by markz

...ariety of headphones or other hangable items.

huge overkill for my set of jam transit headphones -- could have been 50% smaller.

thingiverse

free

USB Microscope stand using conduit by markz

...b microscope. it makes use of two parts from the thingy https://www.thingiverse.com/thing:2424655.

https://youtu.be/xv4tugjt5cq

thingiverse

free

quarter inch phone plug model by markz

... a model of a 1/4 inch phone plug? well here you go...

not really for printing, but if you need a model of one to design around.

thingiverse

free

CPAP Hose Clamps by markz

...able on thingiverse yet. so i made a set of different types. attach with double-sided sticky foam, or 3m command strips. enjoy!

thingiverse

free

Shamrock hangup by markz

...original size was just too much "bling". i'm sure you'll pick a better green. i just used what i had on hand.

thingiverse

free

Laser focus adjustment wheel 12 mm by markz

...

thingiverse

same as original, except resized to be a little thicker and fit a 12 mm focus ring. fits a sunwin 3 w laser module