Thingiverse

Diagonal braces for 2020 rails using EMT tubing by ronschauer

by Thingiverse

Last crawled date: 4 years, 8 months ago

I have an FT-5 printer which has had flat plate diagonal braces several places on it for a very long time.

However, recently I noticed that some frame flexing was still present in the front-rear direction during high accelerations.

Because flat plate full diagonal braces would have been both expensive and heavy, I chose to fabricate them from common 1/2" EMT tubing (conduit) such as Home depot SKU 091111020018.

This has an outside diameter of 0.706" and a nominal inside diameter of 0.62" (~15.75mm).

This is both very inexpensive and extremely strong.

24" lengths provided a perfect fit on the sides of the lower portion of the frame.

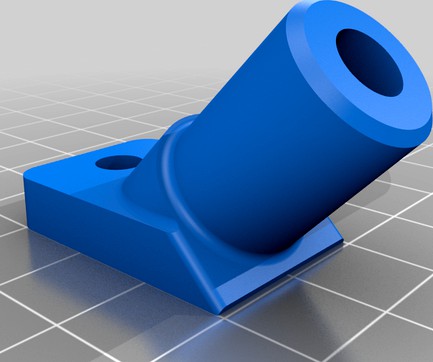

The 45 degree end brackets were necessary for a tight installation.

The brackets I designed utilize 4mm or 5mm screws and t-nuts to attach to the 2020 rail framing.

The 45 degree protrusion is designed to be 15.5mm in diameter but of course it may shrink "as printed".

The tubing was cut to length with a regular tubing cutter by hand, but you could use any method to do this.

Be certain to de-burr the interiors of the tubing ends or they will not fit over the brackets.

It is also a good idea to print one bracket and do a test fit before printing the rest.

Then scale as needed in your slicer to achieve a slip fit to your tubing (leave room for the glue).

The resulting braces are VERY strong and all front-rear frame flexure in my printer has ceased after they were installed.

They do not protrude to the insides or outsides of the 2020 framing so if you have side covers they should not interfere.

By adjusting the length of the conduit I am certain this can be adapted to other printers.

I attached the brackets to the conduit by using "5-minute" epoxy cement, coating the interior of the tubing ends and the 45 degree protrusion of the brackets, one at a time.

If you do the lower end and allow it to harden, then do the upper end and align the brackets by attaching them to the framing as the upper one hardens, they will be perfectly aligned and you should not experience any glue dripping issues.

Wipe off any excess of course.

I also designed in center bores that will accommodate 8mm or 5/16" threaded rod if you prefer to use that instead of the conduit or if you use that instead of glue to hold the brackets into the conduit.

Thanks for looking, I hope these prove useful to you.

However, recently I noticed that some frame flexing was still present in the front-rear direction during high accelerations.

Because flat plate full diagonal braces would have been both expensive and heavy, I chose to fabricate them from common 1/2" EMT tubing (conduit) such as Home depot SKU 091111020018.

This has an outside diameter of 0.706" and a nominal inside diameter of 0.62" (~15.75mm).

This is both very inexpensive and extremely strong.

24" lengths provided a perfect fit on the sides of the lower portion of the frame.

The 45 degree end brackets were necessary for a tight installation.

The brackets I designed utilize 4mm or 5mm screws and t-nuts to attach to the 2020 rail framing.

The 45 degree protrusion is designed to be 15.5mm in diameter but of course it may shrink "as printed".

The tubing was cut to length with a regular tubing cutter by hand, but you could use any method to do this.

Be certain to de-burr the interiors of the tubing ends or they will not fit over the brackets.

It is also a good idea to print one bracket and do a test fit before printing the rest.

Then scale as needed in your slicer to achieve a slip fit to your tubing (leave room for the glue).

The resulting braces are VERY strong and all front-rear frame flexure in my printer has ceased after they were installed.

They do not protrude to the insides or outsides of the 2020 framing so if you have side covers they should not interfere.

By adjusting the length of the conduit I am certain this can be adapted to other printers.

I attached the brackets to the conduit by using "5-minute" epoxy cement, coating the interior of the tubing ends and the 45 degree protrusion of the brackets, one at a time.

If you do the lower end and allow it to harden, then do the upper end and align the brackets by attaching them to the framing as the upper one hardens, they will be perfectly aligned and you should not experience any glue dripping issues.

Wipe off any excess of course.

I also designed in center bores that will accommodate 8mm or 5/16" threaded rod if you prefer to use that instead of the conduit or if you use that instead of glue to hold the brackets into the conduit.

Thanks for looking, I hope these prove useful to you.