Thingiverse

DemonDeltaTube - Delta Printer in an acrylic tube by DjDemonD

by Thingiverse

Last crawled date: 3 years, 1 month ago

DemonDeltaTube Printer

Update 08-03-2018 Added a carriage suitable for anti-backlash nuts. It is 1mm shorter as the antibacklash nuts springs take up a small amount of space and this affects the leadscrew to nut alignment.

See here for detailed build log http://forums.reprap.org/read.php?178,802910,page=1

This is a repository of the parts for this machine if you want to emulate it. Please attribute.

I have added most of the parts for this machine, extruder is up to you depending on what you want to fit. Recommend ABS/PETG as it does get quite hot inside.

Effector -

Update 11-02-18 Added hole in effector for hotend wiring which was useful as I was assembling it.

Integrates Precision Piezo - Piezo20 nozzle contact sensor (requires a suitable amplifier such as https://www.precisionpiezo.co.uk/product-page/copy-of-piezo-signal-pcb-kit-version) to function, and a drilled 20mm piezo disc, some modification to the endstop cable headers is required currently. Designed for genuine e3d v6 (with integrated miniature bowden coupler), recesses in the side for bonding 30mm blower fans (https://www.precisionpiezo.co.uk/product-page/sunon-blower-radial-fan-5v) space to attach a 30x30x10 fan from the e3d kit, designed to work on the 55mm spacing magball system (Haydn Huntley https://groups.google.com/forum/#!msg/deltabot/485cfVFrFFU/feT5lm8WfIwJ). Assemble piezo sensor as per documentation at https://www.precisionpiezo.co.uk/documents

Make sure magarms are arranged with negative and positive poles at the effector end on each pair of arms, so the arms attract each other when disconnected from the effector. This balances the magnetic fields around the effector otherwise they stop the fans from spinning properly.

Update 08-03-2018 Added a carriage suitable for anti-backlash nuts. It is 1mm shorter as the antibacklash nuts springs take up a small amount of space and this affects the leadscrew to nut alignment.

See here for detailed build log http://forums.reprap.org/read.php?178,802910,page=1

This is a repository of the parts for this machine if you want to emulate it. Please attribute.

I have added most of the parts for this machine, extruder is up to you depending on what you want to fit. Recommend ABS/PETG as it does get quite hot inside.

Effector -

Update 11-02-18 Added hole in effector for hotend wiring which was useful as I was assembling it.

Integrates Precision Piezo - Piezo20 nozzle contact sensor (requires a suitable amplifier such as https://www.precisionpiezo.co.uk/product-page/copy-of-piezo-signal-pcb-kit-version) to function, and a drilled 20mm piezo disc, some modification to the endstop cable headers is required currently. Designed for genuine e3d v6 (with integrated miniature bowden coupler), recesses in the side for bonding 30mm blower fans (https://www.precisionpiezo.co.uk/product-page/sunon-blower-radial-fan-5v) space to attach a 30x30x10 fan from the e3d kit, designed to work on the 55mm spacing magball system (Haydn Huntley https://groups.google.com/forum/#!msg/deltabot/485cfVFrFFU/feT5lm8WfIwJ). Assemble piezo sensor as per documentation at https://www.precisionpiezo.co.uk/documents

Make sure magarms are arranged with negative and positive poles at the effector end on each pair of arms, so the arms attract each other when disconnected from the effector. This balances the magnetic fields around the effector otherwise they stop the fans from spinning properly.

Similar models

thingiverse

free

Delta Effector for E3D V6 by Osechi

...effector offset : 25mm

i use the following parts,

・lj12a3-4-z-bx

・e3d v6 hotend

・3010 fans

・3010 blower fan

・m3 screws & nuts

thingiverse

free

Bracket for E3D Titan/Aero with piezo probe by Whosrdaddy

...ro extruder which can be used with 20mm piezo disc for accurate probing. use sensor board from https://www.precisionpiezo.co.uk/.

thingiverse

free

Ormerod E3D Precision piezo by Dignitate

...piezo-z-probe-kit

update assembly video: https://youtu.be/84nof0ik0gm

assembly video(first version): https://youtu.be/a3f_7nr2nas

thingiverse

free

Creality CR-10s E3D V6 Dual fan Precision piezo Orion by Torstein_H

...80x380mm build volume. i guess the reduction can be tweaked better, but i didnt bother because the build volume is still huge....

grabcad

free

Delta Smart Effector v2 Volcano fan Assembly

...rade https://amzn.to/2v2g8dz

using https://grabcad.com/library/e3d-v6-volcano-heater-block-senor-cartridge-1 for the e3d volcano

thingiverse

free

Reach 3D Precision Piezo Mount by jmg123

...so a funnel that takes a 40mm fan that is used to cool the part being printed.

step file included incase anyone wants to edit it.

thingiverse

free

Upgrade Effector with round fan duct for Kossel / Delta (D810) by Tysonpower

...15 blower type fan (optional)

i designed the effector for my zonestar d810, but it should fit any kossel (~20x30cm build volume).

thingiverse

free

E3D Titan bracket for Hypercube by pivan

...tend is at minimum, take care.

no need to use additional brim, the small mickey mouse ear provided in the model should be enough.

thingiverse

free

Kossel / Delta Mini Effector E3D V6 by hipejoe

... to integrated fan duct for clearance.

fine adjustment to extruder fan for clearance.

finalize parts list.

generic z probe mount.

thingiverse

free

Elongated E3D V6 Fan shroud for Duet Smart Effector And 30mm Blower (radial) Fan Mounts by DjDemonD

...or sunon 5v 0.68w 30mm blower fans, attach these to the ball stud m3 screws with nuts and bond the fans onto then with superglue.

Djdemond

thingiverse

free

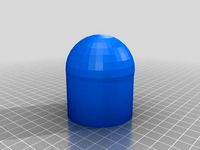

50mm Towball cover Hitch Cap by DjDemonD

...50mm towball cover hitch cap by djdemond

thingiverse

cover for 50mm towball.

thingiverse

free

Duet3D Smarteffector Nimble Mount DjDemonD Remix by DjDemonD

...ess sensitive. you also need to consider the orientation of the large nut to you heatsink when assembling the hotend into the se.

thingiverse

free

Brio Wooden Train Tunnel by DjDemonD

...valley etc.. multiple units can be joined to make a longer tunnel. 80mm diameter so even fairly large trains can make it through.

thingiverse

free

Bowden pushfit locking ring for clone titan and y-splitter by DjDemonD

...for clone titan and y-splitter by djdemond

thingiverse

locking clip for trianglelabs clone titan and y-splitter bowden fittings.

thingiverse

free

3-Way Approach for Brio Thomas Engine Shed by DjDemonD

...ond

thingiverse

i bought one of these engine sheds but didn't have the approach track which is a custom piece so i made one.

thingiverse

free

Precision Piezo - 27mm and 20mm Piezo Disc drill guide. by DjDemonD

... djdemond

thingiverse

drilling guide for piezo discs to centre your drill.

see youtube video here: https://youtu.be/ms1fd0v5z68

thingiverse

free

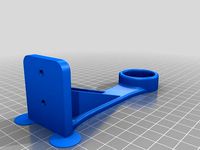

Mechanical Z Endstop for DjDemonD/AndreasL Dual z axis smartrapcore alu by DjDemonD

...babystep z on the first print and used m206 to enter the home offset. (nb. if the nozzle was 1mm too high the m206 z would be 1.)

thingiverse

free

Paper Towel Holder Strengthened Remix by DjDemonD

...t to allow for the strengthening braces. since altering it, it works perfectly in fact i am even using some as spool holders too.

thingiverse

free

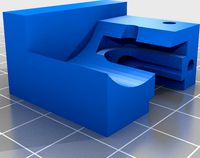

Sensor Test Rig by DjDemonD

...aver. i am not going to provide full build instructions, if you cannot figure out how to build it, should you be testing sensors?

thingiverse

free

Technics 1200 Turntable with spinning record by DjDemonD

... fits over a 5mm motor shaft and spins as my printer prints.

just bond it all together after assembly with superglue or acetone.

Delta

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

Acrylic

turbosquid

$15

Acrylic Lectern For The Chruch - Podium Acrylic

...the chruch - podium acrylic for download as skp, obj, and 3ds on turbosquid: 3d models for games, architecture, videos. (1642137)

3ddd

free

Acrylic bathtub

...acrylic bathtub

3ddd

ванна

acrylic bathtub. size 170x110 cm

turbosquid

$24

Acrylic Stool

...3d model acrylic stool for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1311388)

turbosquid

$9

Acrylic Tables

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Acrylic Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Acrylic Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Table acrylic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Acrylic bath

... empire. originally created in 3ds max 2021 and v-ray next. materials v-ray mtl rubber; chromium; acrylic. modifiers: turbosmooth

3ddd

$1

Acrylic GM

...acrylic gm

3ddd

вентилятор

model is available in retail fanstar

3d_export

$17

Acrylic Chair 3D Model

...acrylic chair 3d model

3dexport

chair furniture acrylic

acrylic chair 3d model shalasaska 7623 3dexport

Tube

archibase_planet

free

Tube

...tube

archibase planet

paint tube stationery

tube - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

tube

...tube

turbosquid

free 3d model tube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1378271)

archibase_planet

free

Tube

...tube

archibase planet

mascara cosmetics make-up

tube 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Tube pants

...tube pants

3dexport

tube pants

3d_export

free

Tube

...tube

3dexport

turbosquid

free

TUBE

...

free 3d model tube for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1672199)

turbosquid

$29

tube

...lty free 3d model tube for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442047)

3ddd

$1

perfume tube

...perfume tube

3ddd

тюбик

perfume tube, тюбик

3ddd

$1

Olivieri Tube

...olivieri tube

3ddd

olivieri

кровать olivieri tube

turbosquid

$22

Tube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.