Thingiverse

Davinci PLA Mod - featuring Repetier Host/Cura GCode tools by netpipe

by Thingiverse

Last crawled date: 4 years, 7 months ago

i forgot in the davinci eeprom setting for repetier host to put the idle time to 300000 ms (5min) so be sure to add it.

https://www.youtube.com/watch?v=JDYsk1KQaHk 3d printer music :)

https://github.com/tecan/GCODE-Tools/tree/master/GCODE-Pro

https://www.thingiverse.com/thing:447903 mounting bracket from here.

https://www.thingiverse.com/thing:3021660 optical filament sensor

https://steelcityelectronics.com/da-vinci-3d-printer/da-vinci-extruder-thermistor/

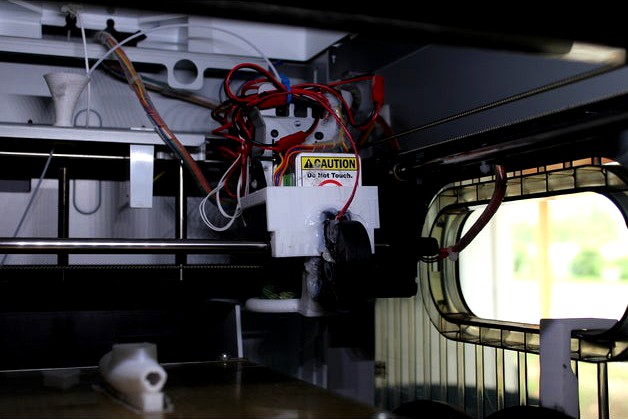

bolt in replacement hotend was from ebay. description. though it only likes to be put in and taken out from the right hand side of the carridge. fan was tied in with existing fan seems to run both ok underpowered. also i had to cut a notch on oneside for the first fin flush with the stock alu throat or it hits on the filament wheel when inserting/removing.

Universal Hotend 3D Printer w/MK10 nozzle f/MK8 MK9 extruder most Extruders

I had to use other thermistor settings repetier thermistor table 5 and 50 both worked for turning off the fan while when cooled, i print PLA at 1.4 x 160= 224. on the value chart which is about 140 deg C hopefully i can get that lower yet to reduce the smell. for the initial layer its at 60 bed and 230 remember that these are not actual temp C values because the table is off by a bit. then the temperature drops to 225 and 50 at zheight 2.24

NTC 3950 Thermistor

Also goto menu -> settings -> bed coating and set the custom height to 22.50 , press < then save eeprom(wait 5-10 seconds before reboot printer so it saves to sd card). should be in the ballpark when you calibrate z , turn motors off and mobe the head around to see if it clears the platform.

Its offset to the right so the ring wont hit the heatbed sand smooth on left side so it does not catch if it does touch.

CAUTION : This hotend has PTFE tube inside which decompose or can melt causing neurotoxins around 260deg C really nasty stuff, always be careful to save yourself trip to the hospital or worse your lungs.

update : i wrecked my ptfe tube a little bit by running out of filament and leaving it on only PLA temps. so maybe we need some firmware mods to cut power if it runs out of filament (bug report has been filed)

A good idea would be to get a mk10 all metal throat/tip kit(ordered mine to try soon) also i will be making a new thermistor tables for various ebay parts to get more accurate readings.

"MK10 All Metal Hotend Upgrade Kit 1.75mm 0.4mm Extruder Nozzle for 3D Printer" 5 dollars on ebay. 0.4mm is too small for stainless drill it out to 0.45 mm or more to prevent jamming. works good using a 0.018" drillbit rocking it back and forth in fingers drill it all the way in and spin it a few times to clean the bore out.was going to try 0.02" but it was not needed and i wanted the percision for tighter parts.

the silicone boot seems to help alot with a wider .5 or .6 nozzle for speed.

flow to 87% for PLA works really good to get partsizes correct.

0.4mm nozzles seem too jam prone so you might want to upsize it.

I bought a box of microdrillbits for 20 dollars iirc it has 0.0180 = 0.45mm drillbit and #73 drillbit 0.609 millimeters they have the round plastic beads on them which make it easy to spin by finger just rock them back and forth it wont take much to do. it helps prevent jamming. minimum extrusion 5mm and retraction 5mm seems to be working.

https://www.youtube.com/watch?v=JDYsk1KQaHk 3d printer music :)

https://github.com/tecan/GCODE-Tools/tree/master/GCODE-Pro

https://www.thingiverse.com/thing:447903 mounting bracket from here.

https://www.thingiverse.com/thing:3021660 optical filament sensor

https://steelcityelectronics.com/da-vinci-3d-printer/da-vinci-extruder-thermistor/

bolt in replacement hotend was from ebay. description. though it only likes to be put in and taken out from the right hand side of the carridge. fan was tied in with existing fan seems to run both ok underpowered. also i had to cut a notch on oneside for the first fin flush with the stock alu throat or it hits on the filament wheel when inserting/removing.

Universal Hotend 3D Printer w/MK10 nozzle f/MK8 MK9 extruder most Extruders

I had to use other thermistor settings repetier thermistor table 5 and 50 both worked for turning off the fan while when cooled, i print PLA at 1.4 x 160= 224. on the value chart which is about 140 deg C hopefully i can get that lower yet to reduce the smell. for the initial layer its at 60 bed and 230 remember that these are not actual temp C values because the table is off by a bit. then the temperature drops to 225 and 50 at zheight 2.24

NTC 3950 Thermistor

Also goto menu -> settings -> bed coating and set the custom height to 22.50 , press < then save eeprom(wait 5-10 seconds before reboot printer so it saves to sd card). should be in the ballpark when you calibrate z , turn motors off and mobe the head around to see if it clears the platform.

Its offset to the right so the ring wont hit the heatbed sand smooth on left side so it does not catch if it does touch.

CAUTION : This hotend has PTFE tube inside which decompose or can melt causing neurotoxins around 260deg C really nasty stuff, always be careful to save yourself trip to the hospital or worse your lungs.

update : i wrecked my ptfe tube a little bit by running out of filament and leaving it on only PLA temps. so maybe we need some firmware mods to cut power if it runs out of filament (bug report has been filed)

A good idea would be to get a mk10 all metal throat/tip kit(ordered mine to try soon) also i will be making a new thermistor tables for various ebay parts to get more accurate readings.

"MK10 All Metal Hotend Upgrade Kit 1.75mm 0.4mm Extruder Nozzle for 3D Printer" 5 dollars on ebay. 0.4mm is too small for stainless drill it out to 0.45 mm or more to prevent jamming. works good using a 0.018" drillbit rocking it back and forth in fingers drill it all the way in and spin it a few times to clean the bore out.was going to try 0.02" but it was not needed and i wanted the percision for tighter parts.

the silicone boot seems to help alot with a wider .5 or .6 nozzle for speed.

flow to 87% for PLA works really good to get partsizes correct.

0.4mm nozzles seem too jam prone so you might want to upsize it.

I bought a box of microdrillbits for 20 dollars iirc it has 0.0180 = 0.45mm drillbit and #73 drillbit 0.609 millimeters they have the round plastic beads on them which make it easy to spin by finger just rock them back and forth it wont take much to do. it helps prevent jamming. minimum extrusion 5mm and retraction 5mm seems to be working.