Thingiverse

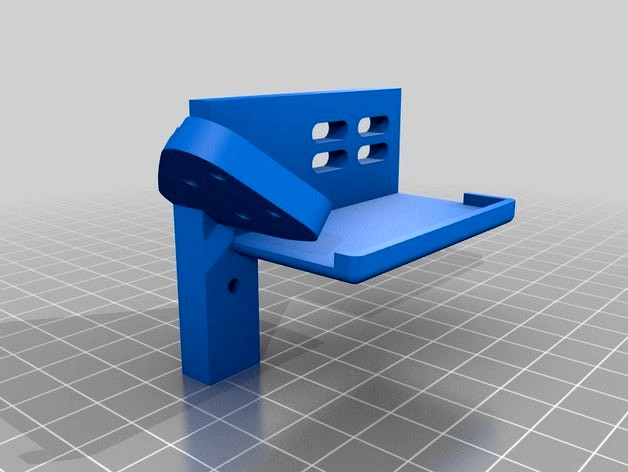

Da Vinci 1.0 AiO MK8 Conversion for PETG by Tdevil50

by Thingiverse

Last crawled date: 3 years ago

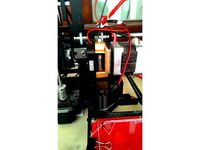

Wanted to get the Da Vinci to print more exotic filaments. What a pain in the @33!!! Well I have found a simple setup that works for PLA and PETG. I have successfully printed PETG over the last month with no problems. Going to start trying higher print quality now that I have cleaned up the look of the cables. The video is of the circuit board plate mount being printed. I am using Simplify3D and happy so far, the new update 3.0? is kind of glitchy though. Put a little double stick tape under the circuit board to hold it down. Then added small section of filament into the filament cartridge so the alarm won't go off. :)

I have also moved to Kapton tape for the bed. Haven't used anything else since.

Parts needed:

1x MK8 Extruderhttps://www.amazon.com/gp/product/B01F6LW4MO/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

1x Extruder Tube:https://www.amazon.com/gp/product/B01I4ZQU6U/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Heatsink:https://www.amazon.com/gp/product/B016W7IZLK/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1

Heated Ends:https://www.amazon.com/gp/product/B00L4UXQ42/ref=oh_aui_detailpage_o05_s01?ie=UTF8&psc=1

Heated Block:https://www.amazon.com/gp/product/B0188OLMNS/ref=oh_aui_detailpage_o05_s02?ie=UTF8&psc=1

2x Long Metric bolts:

M3x25 mm bolt for extruder and heat sink.https://www.amazon.com/AXA120-Socket-Button-10-Piece-M3x25mm/dp/B0035XQY4U/ref=sr_1_6?ie=UTF8&qid=1471312056&sr=8-6&keywords=m3x25+mm

2x Cable Chain:https://www.amazon.com/Black-Plastic-Chain-Carrier-Router/dp/B00880AVL2/ref=sr_1_1?s=hi&ie=UTF8&qid=1471300420&sr=1-1&keywords=cable+chain

Kapton Tape:https://www.amazon.com/gp/product/B00U1X3XLY/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1

I bought 100K Ohm Thermistors just incase. Good thing as I needed them. I soldered my own up and used these. You may want to find some premade.https://www.amazon.com/gp/product/B00UFBIRVI/ref=oh_aui_detailpage_o05_s02?ie=UTF8&psc=1

Quick and easy change out. Also allows for quick return to original parts. The toughest part is taking the original pulley off the stepper motor, but even that wasn't difficult. Use a pulley puller or a butane torch with pliers to remove. A quick google search will show you what I mean. If this sounds to difficult you can also just order another stepper motor.

As for under the bed I used some old Ink Jet printer insulation covered in Kapton tape to keep the underside insulated. Pre-heating is fast and stays level during printing. The fan cools everything down for little time in between prints.

Hope someone can get something out of this. Thanks

I DO NOT TAKE ANY RESPONSIBILITY FOR THE MODS YOU DO TO YOUR MACHINE.

I have also moved to Kapton tape for the bed. Haven't used anything else since.

Parts needed:

1x MK8 Extruderhttps://www.amazon.com/gp/product/B01F6LW4MO/ref=oh_aui_detailpage_o07_s00?ie=UTF8&psc=1

1x Extruder Tube:https://www.amazon.com/gp/product/B01I4ZQU6U/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Heatsink:https://www.amazon.com/gp/product/B016W7IZLK/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1

Heated Ends:https://www.amazon.com/gp/product/B00L4UXQ42/ref=oh_aui_detailpage_o05_s01?ie=UTF8&psc=1

Heated Block:https://www.amazon.com/gp/product/B0188OLMNS/ref=oh_aui_detailpage_o05_s02?ie=UTF8&psc=1

2x Long Metric bolts:

M3x25 mm bolt for extruder and heat sink.https://www.amazon.com/AXA120-Socket-Button-10-Piece-M3x25mm/dp/B0035XQY4U/ref=sr_1_6?ie=UTF8&qid=1471312056&sr=8-6&keywords=m3x25+mm

2x Cable Chain:https://www.amazon.com/Black-Plastic-Chain-Carrier-Router/dp/B00880AVL2/ref=sr_1_1?s=hi&ie=UTF8&qid=1471300420&sr=1-1&keywords=cable+chain

Kapton Tape:https://www.amazon.com/gp/product/B00U1X3XLY/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1

I bought 100K Ohm Thermistors just incase. Good thing as I needed them. I soldered my own up and used these. You may want to find some premade.https://www.amazon.com/gp/product/B00UFBIRVI/ref=oh_aui_detailpage_o05_s02?ie=UTF8&psc=1

Quick and easy change out. Also allows for quick return to original parts. The toughest part is taking the original pulley off the stepper motor, but even that wasn't difficult. Use a pulley puller or a butane torch with pliers to remove. A quick google search will show you what I mean. If this sounds to difficult you can also just order another stepper motor.

As for under the bed I used some old Ink Jet printer insulation covered in Kapton tape to keep the underside insulated. Pre-heating is fast and stays level during printing. The fan cools everything down for little time in between prints.

Hope someone can get something out of this. Thanks

I DO NOT TAKE ANY RESPONSIBILITY FOR THE MODS YOU DO TO YOUR MACHINE.

Similar models

thingiverse

free

12 Function Deep Dish Button Box by coyoteyz13

..._title_o03_s00?ie=utf8&psc=1

https://www.amazon.com/gp/product/b07vhcb1q4/ref=ppx_yo_dt_b_search_asin_title?ie=utf8&psc=1

thingiverse

free

Y-6 Multicopter Frame by ashkip

...azon.com/gp/product/b00tf8uy9a/ref=oh_aui_detailpage_o00_s01?ie=utf8&psc=1

soldering iron, supplies and a lot of patience :-)

thingiverse

free

Filament Dry Box

...g5ntfgu/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=utf8&psc=1

spool holder is a remix of https://www.thingiverse.com/thing:2047554

thingiverse

free

3 Panel Lithophane by RyanEMoore

...iteboard-multi-use/dp/b078lx554x/ref=sr_1_1_sspa?ie=utf8&qid=1516375131&sr=8-1-spons&keywords=8x1mm+magnets&psc=1

thingiverse

free

40A Power Supply Cover W/LCD Display by hkgary_g

...lpage_o06_s01?ie=utf8&psc=1

power socket

www.amazon.com/gp/product/b06xnmt3wl/ref=oh_aui_detailpage_o06_s00?ie=utf8&psc=1

thingiverse

free

U360gts, small frame

...ectronics&sr=1-1-catcorr

more information about the project:

https://github.com/raul-ortega/u360gts/blob/master/wiki/index.md

thingiverse

free

40mm Oculus Touch-Beat Saber-Darth Maul Controller Mount by Son_of_a_Gun

...safety-tape/dp/b01e7g1au6/ref=sr_1_1_sspa?ie=utf8&qid=1530578786&sr=8-1-spons&keywords=rubberized+grip+tape&psc=1

thingiverse

free

LED Paracord Dog Collar, Rechargeable by DemonicArchr

...utf8&psc=1

18650 charger board - https://www.amazon.com/gp/product/b01lhd9d7e/ref=oh_aui_detailpage_o02_s00?ie=utf8&psc=1

thingiverse

free

Sonoff Enclosure by JeffLZ

...title_o00_s00?ie=utf8&psc=1

https://www.amazon.com/gp/product/b00qvb6qpu/ref=ox_sc_saved_title_1?smid=atvpdkikx0der&psc=1

thingiverse

free

Turntable

...amp;psc=1

m3 screws m3x6 or m3x8https://www.amazon.com/gp/product/b07twz7x38/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=utf8&psc=1

Tdevil50

thingiverse

free

Snowman - Winter Fun by Tdevil50

...and used less materials. thanks to cloudj for the idea. keep the kids busy outside while you drink all the hot chocolate. enjoy!

thingiverse

free

Star Wars Full Size Lightsaber Stand Customizable by Tdevil50

... lightsaber stand customizable by tdevil50

thingiverse

multiple configuration for lightsaber stands. this is a work in progress.

thingiverse

free

Desk Hanger Customizable by Tdevil50

...e platform to be changed to fit a need. feel free to customize as you see fit. i hold no responsibility for the use of this item.

thingiverse

free

Airbrush Paint Bottle Holders by Tdevil50

...n drawer. simple design nothing special here.

the prints themselves are 150mm x 150mm so they can be adapted to most bin systems.

thingiverse

free

Logitech C920 Camera Mount for Da Vinci by Tdevil50

...erse

this is a mount to use on the front of the da vinci door for the logitech c920 camera. may also work with the c910 as well.

thingiverse

free

Dual or Single Spool Filament Holder and Idler by Tdevil50

.../www.thingiverse.com/thing:767317 design. used with https://www.thingiverse.com/thing:736446 rear holder design for the da vinci.

thingiverse

free

Fan Power Box with Pot Control by Tdevil50

... up so the prongs won't need to be cut off to not hit the power switch.

my extruder is having issues with small lettering. :(

thingiverse

free

Mandalorian Risers by agaliarethz

...on "star wars full size lightsaber stand customizable" by tdevil50 there are a custom raises with mandalorian logo and...

thingiverse

free

XYZ Da Vinci Carbon Filter Fan Housing by Tdevil50

...n pad made by aqua globe. it is 10"x30" and can get about 8 pads out of it. i would guess that is equal to over a year.

Aio

turbosquid

$59

eGo Aio

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

AIO table bench chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$59

VRay Building Materials S02 - AIO for C4D

... with vray building materials s02 materials library for cinema 4d. this is all in one material library for my building materia...

3d_ocean

$19

10 x Hi-Res Porcelain Textures - AIO

...f my series of 10 floral porcelain/ceramic textures. all textures are hi-res custom made textures and can be used for ceramic,...

3d_ocean

$19

25 Standard Liquids Materials Pack AIO for C4D

...is all-in-one material library of my series of 2 cinema 4d standard liquid materials series. it contains 25 standard liquid ma...

turbosquid

$39

E3D - HP Elite One 1000 G1 AiO 34 inches model

...1000 g1 aio 34 inches model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1245758)

3d_ocean

$30

121 Standard Ground/Terrain Materials-AIO for C4D

...n: this is all-in-one material library of my series of 8 cinema 4d standard ground/terrain materials series. it contains 121 s...

3d_ocean

$55

Standard Clothes Material Pack-AIO for Cinema 4D

...ll-in-one material library of my series of 6 cinema 4d standard clothes materials libraries. it contains 94 standard cloth mat...

3d_ocean

$89

171 Standard Stone Materials Pack AIO for C4D

...s all-in-one material library of my series of 10 cinema 4d standard stone materials library series. it contains 171 standard s...

3d_ocean

$75

114 Standard FX Materials Pack AIO for Cinema 4D

...ll-in-one material library of my series of 8 cinema 4d standard fx materials series. it contains 114 standard fx materials. i ...

Mk8

3d_export

$99

Mitsubishi Lancer Ralliart sedan 2004 3D Model

...lancer ralliart sedan 2004 3d model 3dexport mitsubishi ralliart mk8 2004 2005 4-door sedan saloon japan japanese eighth generation...

3d_ocean

$89

Mitsubishi Lancer Ralliart sedan 2004

...2004-2005 4-door eighth generation japan japanese mitsubishi mitsubishi ralliart mk8 ralliart saloon sedan the 3d model was created on...

thingiverse

free

MK8 by IsaiRochaSegura

...chasegura

thingiverse

in this thing i share a replace bar for mk8 extruder. i include the solidworks files for any modification.

thingiverse

free

MK8 Duct by ombranova

...mk8 duct by ombranova

thingiverse

duct for extruder mount mk8 on prusa i3

thingiverse

free

MK8 Flex Guide by loganjkd

...mk8 flex guide by loganjkd

thingiverse

just an inset for the mk8

thingiverse

free

MK7 / MK8 Mold by JMDesigns

...mk7 / mk8 mold by jmdesigns

thingiverse

mk7 / mk8 mold

thingiverse

free

Support extruder MK8 by rickshaolin

...support extruder mk8 by rickshaolin

thingiverse

support extruder mk8

thingiverse

free

MK8 Fan bracket by rocktang2003

...mk8 fan bracket by rocktang2003

thingiverse

mk8 fan bracket

thingiverse

free

HyperCube Mk8 mount by machala737

...hypercube mk8 mount by machala737

thingiverse

remix hypercube mk8 mount

thingiverse

free

mk8 fan holder by everythingother

...mk8 fan holder by everythingother

thingiverse

this is mk8 amazing fan holder

Vinci

3d_export

$9

clcok vinci

...clcok vinci

3dexport

clcok vinci

3ddd

$1

willisau vinci chair

...willisau vinci chair

3ddd

willisau , vinci

vinci chair from willisau ag.

design_connected

$13

Vinci chair

...vinci chair

designconnected

willisau vinci chair computer generated 3d model. designed by ballendat, martin.

3ddd

$1

BOVA-комод-vinci

...bova-комод-vinci

3ddd

bova , комод

bova-комод-vinci

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

3d_export

$25

a - leonardo da vinci

...a - leonardo da vinci

3dexport

a - leonardo da vinci<br>antiquity

turbosquid

$10

Pouf Vinci

...ty free 3d model pouf vinci for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1507069)

turbosquid

$30

Da Vinci

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

machine- leonardo da vinci

...machine- leonardo da vinci

3dexport

machine- leonardo da vinci

3d_export

$25

mortar - leonardo da vinci

...mortar - leonardo da vinci

3dexport

mortar - leonardo da vinci

Petg

turbosquid

$9

Chandra rugs T-PETG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$6

Makita lawn mower motor cover

...makita lawn mower motor cover for print . plastic petg carbon or...

3d_export

$5

snorkel connector snorkel bracket snorkel holder

...free to comment or cantact me via dm. pla, petg and abs should be fine for printing although i...

3d_export

$8

mounting of a front wing of the bicycle for a fork rockshox

...20 mm. 3d printing settings plastic - nylon / petg rafts - yes. supports - yes. resolution - 0.16...

3d_export

$15

E30 tweeter pods speaker mounts

...plastic, interlayer adhesion is poor, i want to try petg ...

3d_export

free

danish lunch

...made in thindercad and printed on ender3 max,<br>i used petg filament and have painted with vajjejo model paint.<br>this is...

3d_export

$21

stock adapter grand power stribog

...from cyma zhukov and install stock on new adapter. petg settings 0,10 - 0,15, infill 100%, supports everywhere, brim....

3d_export

$7

shimano xt-slx brake level piston guide right top

...with printed parts: i recommend: plastic - nylon / petg rafts - yes. supports - yes. resolution - 0.16....

3d_export

$7

shimano xt-slx brake level piston guide left top

...with printed parts: i recommend: plastic - nylon / petg rafts - yes. supports - yes. resolution - 0.16....

3d_export

$29

cup holder b m w e90-91-92-93

...cup holder b m w e90-91-92-93 3dexport printed with petglt;br>infil 20-40%<br>speed: 50mm/s<br>i make this design for people who don't...

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.

0

turbosquid

$12

Calligraphic Digit 0 Number 0

...hic digit 0 number 0 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389318)

3d_export

$6

set-0

...set-0

3dexport

turbosquid

$6

hedge 0

...yalty free 3d model hedge 0 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1450353)

turbosquid

$5

Nuber 0

...oyalty free 3d model nuber 0 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1564674)

turbosquid

$22

0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Steam Locomotive Fowler 4F 0-6-0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Liquid Number 0

... model liquid number 0 for download as c4d, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1689919)

turbosquid

$45

Dragon360_perspShape_tmp.0.jpg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Rocks Debris 0

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

wood-guardrail-fence 0

...wood-guardrail-fence 0

3dexport

wood-guardrail-fence 0<br>3ds max 2015

Da

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere mary 387/6+3

3ddd

$1

Luce da Vivere

...luce da vivere

3ddd

luce da vivere

luce da vivere

cristalline 494/12 rosso/cromo

turbosquid

$6

Cabinet DA

...ty free 3d model cabinet da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1637312)

turbosquid

$6

Bookcase DA

... free 3d model bookcase da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639996)

turbosquid

$5

Wardrobe DA

...y free 3d model wardrobe da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1661117)

turbosquid

$5

Partition DA

... free 3d model partition da for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1640359)

3ddd

$1

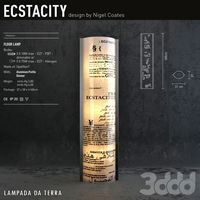

Ecstacity_LAMPADA DA TERRA

...ecstacity_lampada da terra

3ddd

ecstacity

торшер ecstacity_lampada da terra

3ddd

$1

leonardo da vinci

...leonardo da vinci

3ddd

всадник , лошадь

leonardo da vinci

turbosquid

$60

DA-ExoticWeapons

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$32

DA-SpikedChainMace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)