Thingiverse

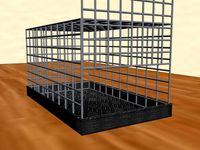

Customiser: Air cage for MK8 extruder with pipe end by Bushmills

by Thingiverse

Last crawled date: 3 years ago

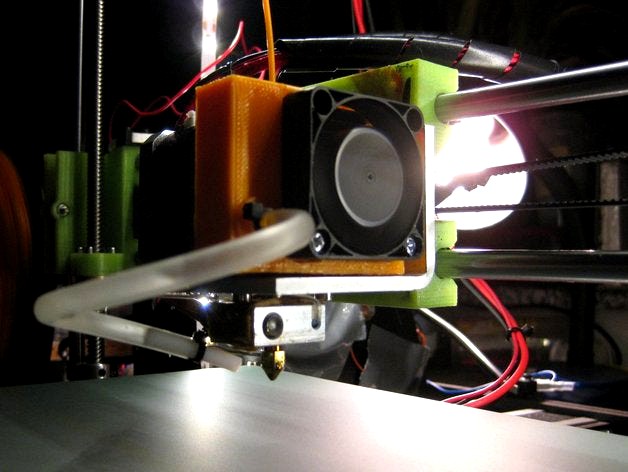

Many fan shrouds for ventilation of the printed object exist, but none of those I looked at matched my needs: they'd not fit, feature a rigid nozzle without adjustment, block sight of nozzle and - more importantly - base layer, disallow intervention by means of a pair of tweezers or related, or are unnecessarily heavy and bulky.

In an attempt to learn from the problems with the solutions I looked at, I decided that air cage, surrounding and trapping air expelled from the cooler, and the nozzle, directing the air towards the object, should be seperate items, allowing the latter to be adjustable.

Here's now my attempt of designing the air cage, with a simple pipe end to attach a piece of flexible tube to it, which carries an air nozzle, clamped to the carrier of the extruder. A piece of wire, to bend nozzle into position, is one possible method of adjustment. I've soldered a paperclip to a crocodile clip. With the crocodile clip I attach the whole nozzle construction to the extruder. The other end of the paperclip goes to a piece of PTFE tube as nozzle, shoved into silicone hose which connects to the air cage pipe end.

This item isn't pretty - it's not really meant to be. Instead I want shape to follow function, as functional aspects bear a heavier weight to me for this application. Please consider that this implementation is still in a very early state, and improvements are not only possible, but likely too. So is it planned to replace the current flexible-tube-and-nozzle solution against a printed double hinged air duct (intended to direct air to the object from the side). As consequence are position and orientation of the opening for the pipe end likely to change to the front. Chances are also that support for a second nozzle, to point at the object from the left, will be added - but given that this should merely involve a second pipe end, or hinged nozzle attachment point, this change is likely to be a trifle. So are probably LED or camera mount points, and their respective cable guides, and given that the .scad file is provided, you can add those to the design just as easily.

Item is fully parametrised, because printers/extruders are very different, which I experienced by the difficulties finding a fitting fan shroud. Some assume that extruder carrier don't protrude from the extruder, so the cooler and fans are floating (no part of extruder below them). Others don't know how little space my extruder provides between screws and cooler, making the fit hard or impossible. And about all I looked at only provided .stl files, for which I have no decent method yet to modify, to make the design suited for my device. I'll probably stop bothering with .stl-only designs completely, and focus on those with sources provided, as a source-less design is bound to die, eventually, because lacking evolutive capabilities.

I'm not sure how much further development will be put into this design, because I currently lean towards E3D'ish designs, and consider the attempts of MK8 improvement as just an intermediate step. Replacement against a E3D bowden setup seems to me the next logical step. This design http://www.thingiverse.com/thing:1632847 by Tech2C is one which I like, with cooling of extruded filament already integrated. It comes as .stl only though, and may need some extent of redoing or convincing.

In an attempt to learn from the problems with the solutions I looked at, I decided that air cage, surrounding and trapping air expelled from the cooler, and the nozzle, directing the air towards the object, should be seperate items, allowing the latter to be adjustable.

Here's now my attempt of designing the air cage, with a simple pipe end to attach a piece of flexible tube to it, which carries an air nozzle, clamped to the carrier of the extruder. A piece of wire, to bend nozzle into position, is one possible method of adjustment. I've soldered a paperclip to a crocodile clip. With the crocodile clip I attach the whole nozzle construction to the extruder. The other end of the paperclip goes to a piece of PTFE tube as nozzle, shoved into silicone hose which connects to the air cage pipe end.

This item isn't pretty - it's not really meant to be. Instead I want shape to follow function, as functional aspects bear a heavier weight to me for this application. Please consider that this implementation is still in a very early state, and improvements are not only possible, but likely too. So is it planned to replace the current flexible-tube-and-nozzle solution against a printed double hinged air duct (intended to direct air to the object from the side). As consequence are position and orientation of the opening for the pipe end likely to change to the front. Chances are also that support for a second nozzle, to point at the object from the left, will be added - but given that this should merely involve a second pipe end, or hinged nozzle attachment point, this change is likely to be a trifle. So are probably LED or camera mount points, and their respective cable guides, and given that the .scad file is provided, you can add those to the design just as easily.

Item is fully parametrised, because printers/extruders are very different, which I experienced by the difficulties finding a fitting fan shroud. Some assume that extruder carrier don't protrude from the extruder, so the cooler and fans are floating (no part of extruder below them). Others don't know how little space my extruder provides between screws and cooler, making the fit hard or impossible. And about all I looked at only provided .stl files, for which I have no decent method yet to modify, to make the design suited for my device. I'll probably stop bothering with .stl-only designs completely, and focus on those with sources provided, as a source-less design is bound to die, eventually, because lacking evolutive capabilities.

I'm not sure how much further development will be put into this design, because I currently lean towards E3D'ish designs, and consider the attempts of MK8 improvement as just an intermediate step. Replacement against a E3D bowden setup seems to me the next logical step. This design http://www.thingiverse.com/thing:1632847 by Tech2C is one which I like, with cooling of extruded filament already integrated. It comes as .stl only though, and may need some extent of redoing or convincing.

Similar models

thingiverse

free

Mk8 Fan Shroud Adjustable by pavel569

...terial. i had to modify it to be able to change the angle of air flow. the nozzle can move now about 25 degrees. it is tight fit.

thingiverse

free

Geeetech MeCreator´s mk8 extruder fan shroud by Lugge

...ng right out of the nozzle

i also included a version of the fan shroud without the sensor mount for those who doesn't use one

thingiverse

free

Customiser: Air cage for MK8 extruder with pipe end - remix by richardradford

...llent design of

https://www.thingiverse.com/thing:1768141

and added some pillars to block the air escaping from upper screw holes

thingiverse

free

Extruder and Omnidirectional Filament Cooler 40mm Fan Shroud/Duct by youssefaly97

...d it yet so i'd like you people to try it out until i get to printing it. my cold end uses 4 screw-on fins for the heat sink.

thingiverse

free

MK8 Extruder for 2020 V-slot with Prusa i3 MK3 fans shroud by papi92

...dy.

fans shroud is original from prusa i3 mk3. extruder cover and nozzle shroud are original prusa files without modification.

thingiverse

free

Larger fan shroud for AL-BMG extruder from trianglelabs

...e fan shroud that came with the kit doesn't fit properly, it sit far from the nozzle. i enlarged the shroud using fusion 360.

thingiverse

free

Print Cooling Fan Shroud Mount for mk8 Extruder by mmbretts

...age at overhangs at higher speeds.

now i am just waiting on the china post to get my fan to me. hopefully this does the trick.

thingiverse

free

Adimlab heat break cooler with Mk8 filament guide

...e.

if using other than the mk8 extruder the hole in the guide will have to be modified to fine tune alignment with extruder tube.

thingiverse

free

Nozzle Cooler for Leapfrog Creatr Dual extruder by Sigma1

...t 4 can be glued on part 3 if necessary.

the cooler is designed for a 60x60mm fan. with a 50x50 fan the airflow is a bit too low.

thingiverse

free

NOZZLE COOLER LEAPFROG CREATR by PATDIJ

...s possible to move the cooler to the left or right

test the bridge torture with the cooler and without

it's very good with it

Bushmills

thingiverse

free

simplistic shelf plank wall mount by Bushmills

... can't come up with anything else to say about. watch the maximum size your printer can print. two shelf supports are needed.

thingiverse

free

OpenSCAD Library: Pipe knees (aka maccaroni maker) by Bushmills

...d maccaroni-like structures. you may want to pull modules pie and torus from this file and write them to their own library files.

thingiverse

free

Customiser: hotbed spring washers for G2 by Bushmills

...all and thinner base. code remains unchanged.

still 9 in a set. pick the 6 nicest, use the remaining washers as 3-point coasters.

thingiverse

free

Customiser: hotbed spring washers by Bushmills

...ings, as used with geeetech g2s, this thing has been reparametrised for 4x6mm springs as http://www.thingiverse.com/thing:1878672

thingiverse

free

Bushmills Whiskey annoying present box by axelsp

...t end up opened like mine did.

stl files included with no text on, fusion360 source with text boxes to modify should you want to.

thingiverse

free

OpenSCAD Library: Parametric honeycomb generator by Bushmills

...tion. preferred way of use is by downloading, removing the customiser section, then add the single file to your openscad library.

thingiverse

free

Remix: Filament Spool Holder by Bushmills

...functional changes to it. well, it has been uploaded here mainly to give the original author a way to access the modified script.

thingiverse

free

Customiser: YAYAKT (Yet Another "Yet Another"-Kind of Thing) by Bushmills

...seful wherever cylindrical meets unbudging. free of charge, coming in the flavour of the material chosen for manufacturing these.

thingiverse

free

Prusa i3 MK2 Y Chassis Bearing Straps by Bushmills

... showed them as artefacts. also removed a positioning error, but refrained from doing a much needed simplification of this thing.

thingiverse

free

Customiser: Thumbwheel with scale (Remix) by Bushmills

...expressed by people who don't have openscad, and are therefore unable to change the relevant variable assignments themselves.

Mk8

3d_export

$99

Mitsubishi Lancer Ralliart sedan 2004 3D Model

...lancer ralliart sedan 2004 3d model 3dexport mitsubishi ralliart mk8 2004 2005 4-door sedan saloon japan japanese eighth generation...

3d_ocean

$89

Mitsubishi Lancer Ralliart sedan 2004

...2004-2005 4-door eighth generation japan japanese mitsubishi mitsubishi ralliart mk8 ralliart saloon sedan the 3d model was created on...

thingiverse

free

MK8 by IsaiRochaSegura

...chasegura

thingiverse

in this thing i share a replace bar for mk8 extruder. i include the solidworks files for any modification.

thingiverse

free

MK8 Duct by ombranova

...mk8 duct by ombranova

thingiverse

duct for extruder mount mk8 on prusa i3

thingiverse

free

MK8 Flex Guide by loganjkd

...mk8 flex guide by loganjkd

thingiverse

just an inset for the mk8

thingiverse

free

MK7 / MK8 Mold by JMDesigns

...mk7 / mk8 mold by jmdesigns

thingiverse

mk7 / mk8 mold

thingiverse

free

Support extruder MK8 by rickshaolin

...support extruder mk8 by rickshaolin

thingiverse

support extruder mk8

thingiverse

free

MK8 Fan bracket by rocktang2003

...mk8 fan bracket by rocktang2003

thingiverse

mk8 fan bracket

thingiverse

free

HyperCube Mk8 mount by machala737

...hypercube mk8 mount by machala737

thingiverse

remix hypercube mk8 mount

thingiverse

free

mk8 fan holder by everythingother

...mk8 fan holder by everythingother

thingiverse

this is mk8 amazing fan holder

Customiser

turbosquid

$8

Alarm Clock - Customisable Colours

...ck - customisable colours for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1334214)

turbosquid

$25

Male Base Rigged Customisation Ready

...del male base rigged customisation ready for download as fbx on turbosquid: 3d models for games, architecture, videos. (1246465)

turbosquid

$10

JBL GO Bluetooth Speaker | Customisable

... | customisable for download as obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1424994)

3d_ocean

$6

Customisable DNA Strand with Style Options

...s, hand drawn and text splines. model can be as detailed or low poly as needed. separate obj model is included. help file is i...

3d_ocean

$8

Medicine bottles with customisable labels

...und tablets, one with capsules. these are high res models with good topology, and utilise mental ray shaders and lighting. the...

3d_ocean

$9

Medicine Pill Packet

...ated in 3ds max with mental ray materials. included in this package: - a lighting set up that is ready to render. the preview ...

3d_ocean

$3

Wooden Ruler

...lity 3d model of a wooden ruler used in desk scenes, and as part of a stationary set up. includes customisable numbers, and logo.

3d_ocean

$45

Macca 3d Model

...and vray. this file is ‘render-ready’ with all materials and textures. this can be easily customised to create your own brandi...

3d_ocean

$25

Masjid Model

... and vray. this file is ‘render-ready’ with all materials and textures. this can be easily customised to create your own brand...

3d_ocean

$4

Realistic Iris Texture

...

fully customisable iris texture in psd file. in 3 different colours. usefull for 3d modeling. with high resolution 2000×2000 px.

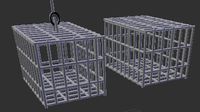

Cage

3d_export

$5

cage

...cage

3dexport

cage

archibase_planet

free

Cage

...cage

archibase planet

cage bird cage birdcage

cage 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cage

...cage

archibase planet

cage bird cage birdcage

cage 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cage

...cage

archibase planet

cage bird cage birdcage

cage 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cage

...cage

archibase planet

bird's cage cage

cage n020909 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cage

...cage

archibase planet

cage

cage monte- 3d model for interior 3d visualization.

3d_export

$7

cage

...cage

3dexport

3d cage model

archibase_planet

free

Cage

...cage

archibase planet

cage

cage n270211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

Cage

...ge

turbosquid

royalty free 3d model cage for download as dwg on turbosquid: 3d models for games, architecture, videos. (1224275)

turbosquid

$4

cage

...squid

royalty free 3d model cage for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1368360)

Pipe

3d_ocean

$3

Pipe

...pipe

3docean

pipe

a high quality pipe with high resolution texture

archibase_planet

free

Pipe

...pipe

archibase planet

pipe conduit piping tubing

pipe unit polymix n210411 - 3d model (*.3ds) for interior 3d visualization.

3d_ocean

$2

Pipes

...pipes

3docean

pipes

a high quality pipes which are ready to use in interiros and contains shader.

3d_export

$10

pipes

...dexport

pipes set – 3d models of a oil pipes for your games/media productions. these are low polygonal models, easy to assemble.

archibase_planet

free

Tobacco pipe

...bacco pipe

archibase planet

tobacco pipe pipe tobacco-pipe

tobacco pipe n020312 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$7

Smoking Pipe - E-pipe

...g pipe - e-pipe for download as 3ds, lwo, obj, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1188985)

archibase_planet

free

Tobacco-pipe

...tobacco-pipe

archibase planet

tobacco-pipe pipe

tobacco-pipe n030312 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Pipe

...pe

turbosquid

royalty free 3d model pipe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1143449)

turbosquid

$7

pipe

...pe

turbosquid

royalty free 3d model pipe for download as prj on turbosquid: 3d models for games, architecture, videos. (1374588)

turbosquid

$2

Pipe

...

turbosquid

royalty free 3d model pipe for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1214323)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Air

3ddd

$1

Calligaris air

...calligaris air

3ddd

air , calligaris

cтул calligaris air

3ddd

$1

Air freshener

...air freshener

3ddd

air freshener , освежитель

air freshener

design_connected

$16

Air

...air

designconnected

flexform air lounge chairs computer generated 3d model. designed by antonio citterio.

turbosquid

$250

Heat pump air air

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

air

...air

3dexport

3ddd

$1

Кухня AIR

...кухня air

3ddd

air , мария

кухня air фабрики "мария"

3ddd

$1

Лампа AIR

...лампа air

3ddd

boconcept , air

настольная лампа air, boconcept. в50½xø32см

3d_export

$40

air deflector

...air deflector

3dexport

air deflector

3d_export

$15

air purifier

...air purifier

3dexport

air purifier

3d_export

$5

macbook air

...macbook air

3dexport

macbook air

End

archibase_planet

free

Cigarettes end

...d

archibase planet

cigarettes end cigarette stub cigar-butt

cigarette-end - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

3d_export

$5

end table

...end table

3dexport

end table 3d model dimensions:(w)60cm×(d)60cm×(h)56cm

turbosquid

$10

End Table

...rbosquid

royalty free 3d model end table for download as max on turbosquid: 3d models for games, architecture, videos. (1570610)

turbosquid

$5

End Table

...urbosquid

royalty free 3d model end table for download as ma on turbosquid: 3d models for games, architecture, videos. (1622809)

turbosquid

$3

End Table

...rbosquid

royalty free 3d model end table for download as fbx on turbosquid: 3d models for games, architecture, videos. (1315115)

3d_export

$5

rope end ring

...rope end ring

3dexport

rope end ring

turbosquid

$2

End Tables

...

royalty free 3d model end tables for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1706896)

turbosquid

$14

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1403051)

turbosquid

$12

End Table

...lty free 3d model end table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1574707)