Thingiverse

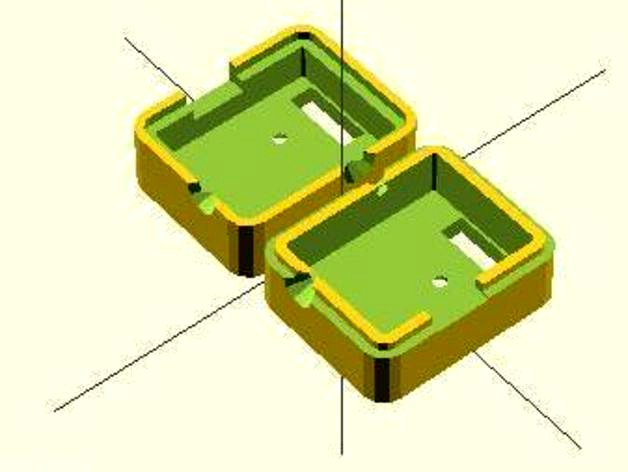

Customisable Electronic Device Packaging by M_G

by Thingiverse

Last crawled date: 3 years ago

Note: After 2 years of workhorse use, this Thing is no longer being supported or developed! Please try the updated and more feature complete version located here http://www.thingiverse.com/thing:66030

This OpenSCAD script will generate a 2 part fit together packaging which connect together using simple lips.

One of the objects will have an internal lip the other one will have an external lip. The ridges left by 3d printing provide grooves which acts as teeth to secure the 2 halves.

It can also create simple square or cylindrical cutouts on any face of the top or bottom half

4 cylindrical support posts can also be added on the bottom or top half to help position a PCB or similar device

You can specify fit and tolerances

All these features can be turned on/off from the control variables section

With this script you can easily make packaging for almost any electronic device you are working on!

This looks complicated but it has saved me a huge amount of time making custom packages for people over the past few days. The most recent versions (2012_05_29-Tyndall_Generic_Device_Packaging-v1.6.scad) have options for easily adding mouse ears, support posts, having cutouts not penetrate the outer face for better surface finish, generating only 1 side or both, incorporating other parts and models of internal electronics and showing the device assembled or as side by side parts!

Changes from previous versions:

v1.6

Incorporates improvements from brians physiological health board case v2.6

better support for adding parts, changing features and changing layout using control variables

Can select how tall the 2 halves are relative to each other

Added method to choose whether to have fully cut or covered cutouts

Added optional mouse-ears

more logical method for creating circular and square cutouts in preparation for array based system

simplified method for controlling lip tolerance

abandoned some features from v1.5 such as profiled lips in quest for simplicity

method optionally adding posts to top and bottom

variables for controlling support posts on top and bottom separately

pasted contents of mouse ears and rounded cuboid as modules rather than accessing them as external files so now you only need to download the one file!!!

no conical cutouts for now... sorry!

v1.5

adjusted a few values after receiving SLA proto-types

increased height of posts

added support structures on top side

decrease diameter of support structures on top side sightly to allow for brackets at end of 40 way

decreased z clearance

v1.4

added angled lip (Cube_cone_cylinder_minkowski sum) for better mating of top and bottom parts when made via SLA/SLS etc

new more simplistic rounded cuboid module

moved around the cutout for the uUSB so that there wasn't such a thin piece of plastic above it

changed post type to nub as SLA should be able to handle the resolution

added easier control of orientation of parts relative to each other using single variable side_by_side

added axis labels to most faces and tyndall logo to bottom

added new fit type for super accurate manufacturing techniques such as SLA

v1.3

Fix cutout positions for TOP SQUARE East and BOTTOM SQUARE West side

Fix position of base of support posts on bottom half

v1.2

Fixed Inner and Outer Lip Clearance implementation

Added ability to generate support posts on bottom half of either nub or screw hole type

v1.1

???This version was lost in a computer crash. GRRRR!

???It implemented the ability to choose the reference point for measurements for each side

???Let this be a lesson!

???Back your stuff up regularly and on separate devices!

v 1.0

Ensure pcb_clearance and fit clearance is taken into account

fit type values changed

force_fit from 0.4 to 0.2

hold_fit from 0.6 to 0.3

slide_fit from 0.8 to 0.4

free_fit from 1to 0.5

add cylinder & square holes to all faces

allowed to stack or see side by side

replace 0.1s with a_bit

check holes on top & bottom sides meet properly

This OpenSCAD script will generate a 2 part fit together packaging which connect together using simple lips.

One of the objects will have an internal lip the other one will have an external lip. The ridges left by 3d printing provide grooves which acts as teeth to secure the 2 halves.

It can also create simple square or cylindrical cutouts on any face of the top or bottom half

4 cylindrical support posts can also be added on the bottom or top half to help position a PCB or similar device

You can specify fit and tolerances

All these features can be turned on/off from the control variables section

With this script you can easily make packaging for almost any electronic device you are working on!

This looks complicated but it has saved me a huge amount of time making custom packages for people over the past few days. The most recent versions (2012_05_29-Tyndall_Generic_Device_Packaging-v1.6.scad) have options for easily adding mouse ears, support posts, having cutouts not penetrate the outer face for better surface finish, generating only 1 side or both, incorporating other parts and models of internal electronics and showing the device assembled or as side by side parts!

Changes from previous versions:

v1.6

Incorporates improvements from brians physiological health board case v2.6

better support for adding parts, changing features and changing layout using control variables

Can select how tall the 2 halves are relative to each other

Added method to choose whether to have fully cut or covered cutouts

Added optional mouse-ears

more logical method for creating circular and square cutouts in preparation for array based system

simplified method for controlling lip tolerance

abandoned some features from v1.5 such as profiled lips in quest for simplicity

method optionally adding posts to top and bottom

variables for controlling support posts on top and bottom separately

pasted contents of mouse ears and rounded cuboid as modules rather than accessing them as external files so now you only need to download the one file!!!

no conical cutouts for now... sorry!

v1.5

adjusted a few values after receiving SLA proto-types

increased height of posts

added support structures on top side

decrease diameter of support structures on top side sightly to allow for brackets at end of 40 way

decreased z clearance

v1.4

added angled lip (Cube_cone_cylinder_minkowski sum) for better mating of top and bottom parts when made via SLA/SLS etc

new more simplistic rounded cuboid module

moved around the cutout for the uUSB so that there wasn't such a thin piece of plastic above it

changed post type to nub as SLA should be able to handle the resolution

added easier control of orientation of parts relative to each other using single variable side_by_side

added axis labels to most faces and tyndall logo to bottom

added new fit type for super accurate manufacturing techniques such as SLA

v1.3

Fix cutout positions for TOP SQUARE East and BOTTOM SQUARE West side

Fix position of base of support posts on bottom half

v1.2

Fixed Inner and Outer Lip Clearance implementation

Added ability to generate support posts on bottom half of either nub or screw hole type

v1.1

???This version was lost in a computer crash. GRRRR!

???It implemented the ability to choose the reference point for measurements for each side

???Let this be a lesson!

???Back your stuff up regularly and on separate devices!

v 1.0

Ensure pcb_clearance and fit clearance is taken into account

fit type values changed

force_fit from 0.4 to 0.2

hold_fit from 0.6 to 0.3

slide_fit from 0.8 to 0.4

free_fit from 1to 0.5

add cylinder & square holes to all faces

allowed to stack or see side by side

replace 0.1s with a_bit

check holes on top & bottom sides meet properly

Similar models

thingiverse

free

WIMUv3 Packaging based on Customisable Electronic Device Packaging by M_G

... logos

mouse ears

partial cutouts to enable larger cutouts (acting as support) whilst preserving quality and strength of wall/lip

thingiverse

free

Shoelaces Attachment by M_G

...to those of mass produced sla clear resin wimuv3 packaging i.e. 30.6 32.5 38.5

0.2

added cutout_radius variable

0.1

first attempt

thingiverse

free

Brian's Physiological Health Board Case v2 by M_G

...ewrite of brians autocad generated case to be easier to make

v1.1

changed some sizes

v1.0

original non-parametric autocad version

thingiverse

free

Electronic Device packaging for Seán's Multi Radio Device by M_G

...r end of antenna board

v1.0

first attempt at packaging for sean's multi radio layer based on v1.5 of generic packaging script

thingiverse

free

Parametric Club Holder v2 by M_G

...x's strap holder

v1.1

changed some sizes to make it easier to use without rework

v1.0

original non-parametric autocad version

thingiverse

free

KK2.1 Flight Control Snap fit bottom case by Jonny1983

...added some tabs which snap over the top half.

i printed mine with support, might get away without it as the lip is quite small.

thingiverse

free

Electronic Dice Packaging by M_G

...heres are very cumbersome

also i have attached a screenshot of a labview gui that calculates which side of the dice is facing up.

thingiverse

free

PSP game controller by diederrr

...ed psp logo from back for cleaner prints, changed bottom clip for tighter connection and snap fit, added thumb tab to bottom clip

thingiverse

free

Expansion Hub XT 30 support by my_Evil_Twin

...b support device was designed by ftc team robocracy 9773. you can learn more about us on our website: http://www.ftcrobocracy.org

thingiverse

free

Alex's WIMU holder by M_G

...holes size from 30mm->1" wide belt

v0.2

changed belt thickness 2->3

added loop holes on short axis

v 0.1

first attempt

Customisable

turbosquid

$8

Alarm Clock - Customisable Colours

...ck - customisable colours for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1334214)

turbosquid

$25

Male Base Rigged Customisation Ready

...del male base rigged customisation ready for download as fbx on turbosquid: 3d models for games, architecture, videos. (1246465)

turbosquid

$10

JBL GO Bluetooth Speaker | Customisable

... | customisable for download as obj, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1424994)

3d_ocean

$6

Customisable DNA Strand with Style Options

...s, hand drawn and text splines. model can be as detailed or low poly as needed. separate obj model is included. help file is i...

3d_ocean

$8

Medicine bottles with customisable labels

...und tablets, one with capsules. these are high res models with good topology, and utilise mental ray shaders and lighting. the...

3d_ocean

$9

Medicine Pill Packet

...medicine pill packet 3docean custom customisable drug packet drugs medicine medicine box medicine packet mental...

3d_ocean

$3

Wooden Ruler

...and as part of a stationary set up. includes customisable numbers, and...

3d_ocean

$45

Macca 3d Model

...and vray. this file is ‘render-ready’ with all materials and textures. this can be easily customised to create your own brandi...

3d_ocean

$25

Masjid Model

... and vray. this file is ‘render-ready’ with all materials and textures. this can be easily customised to create your own brand...

3d_ocean

$4

Realistic Iris Texture

...eye eye texture human iris layers realistic texture fully customisable iris texture in psd file. in 3 different colours....

Device

3ddd

$1

device

...device

3ddd

device

3ddd

$1

device

...device

3ddd

device

turbosquid

$25

Device

...royalty free 3d model device for download as ma, max, and obj on turbosquid: 3d models for games, architecture, videos. (1431298)

archive3d

free

Device 3D Model

...device 3d model

archive3d

equipment device

device- 3d model for interior 3d visualization.

archive3d

free

Device 3D Model

... model

archive3d

device

device n050608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Device 3D Model

...e 3d model

archive3d

device gear

device - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$24

ICG Device

...turbosquid

royalty free 3d model icg device for download as on turbosquid: 3d models for games, architecture, videos. (1692389)

3d_export

$5

rope tighten device

...rope tighten device

3dexport

rope tighten device

3d_export

$5

front clamping device

...front clamping device

3dexport

front clamping device

archive3d

free

Device 3D Model

...e3d

device kitchen ware

device n130208 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

G

3ddd

free

G. Moscatelli

...алка

вешалка 25 / 26 / 27коллекция: belle heleneбренд: g. moscatelliстрана: италияразмеры: высота - 190 / 195; диаметр - 50 / 60.

3ddd

$1

G Plan Vintage

...g plan vintage

3ddd

винтаж , g plan

g plan vintage armchair

turbosquid

free

G protein

...otein

turbosquid

free 3d model g protein for download as c4d on turbosquid: 3d models for games, architecture, videos. (1309660)

turbosquid

$14

Fence G

...turbosquid

royalty free 3d model fence g for download as fbx on turbosquid: 3d models for games, architecture, videos. (1310122)

turbosquid

$7

G for Gun

...rbosquid

royalty free 3d model g for gun for download as max on turbosquid: 3d models for games, architecture, videos. (1685215)

turbosquid

$5

Letter G

...urbosquid

royalty free 3d model letter g for download as max on turbosquid: 3d models for games, architecture, videos. (1408463)

turbosquid

$5

Letter g

...urbosquid

royalty free 3d model letter g for download as max on turbosquid: 3d models for games, architecture, videos. (1408408)

turbosquid

$5

G Ring

...

turbosquid

royalty free 3d model g ring for download as stl on turbosquid: 3d models for games, architecture, videos. (1285079)

3ddd

$1

Infiniti / G-Chair

...infiniti / g-chair

3ddd

infiniti

www.infinitidesign.it/ita/g-chair.php

3ddd

$1

кресло G-68

...кресло g-68

3ddd

кресло

кресло руководителя g-68

Electronic

turbosquid

$1

electron

...urbosquid

royalty free 3d model electron for download as max on turbosquid: 3d models for games, architecture, videos. (1157488)

turbosquid

$50

electronic

...

royalty free 3d model electronic for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1289427)

turbosquid

$40

Electron

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Electronic game

...electronic game

3docean

electronic games nu pogody wait a minute well

electronic game “well, wait a minute”, “nu pogody”

3ddd

$1

Brilux Electronic

...brilux electronic

3ddd

подвес. brilux electronic. польша. материалы настроены.

3d_export

free

electronic shop

...lectronic shop with high quality interior and exterior. it has tvs smartphone play station printer and many more electronic item.

3ddd

$1

Термостаты OJ Electronics

...ермостаты oj electronics

3ddd

oj electronics , термостат

термостаты фирмы oj electronics

3d_export

$8

electron 714

...electron 714

3dexport

game ready model for export to unreal engine soviet tv electron 714 pbr 4k

3ddd

$1

Термостат OJ Electronics

... oj electronics

3ddd

oj electronics , термостат

термостат occ2-1991 фирмы oj electronics

turbosquid

$60

Electronics Stuff

...

royalty free 3d model electronics stuff for download as max on turbosquid: 3d models for games, architecture, videos. (1624680)

Packaging

archibase_planet

free

Package

...package

archibase planet

cat food package

package n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package dog food petfood

package 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package dog food petfood

package 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package paper bag screw

package n050313 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package cat food dry cat food

package 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package cat food dry cat food

package 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Packaging Box

...packaging box

3docean

3dmodel box packaging packaging box

simple packaging box

turbosquid

$19

Package

...turbosquid

royalty free 3d model package for download as max on turbosquid: 3d models for games, architecture, videos. (1372445)

turbosquid

$1

packaging

...osquid

royalty free 3d model packaging for download as blend on turbosquid: 3d models for games, architecture, videos. (1304457)

3ddd

free

package

...package

3ddd

банка

packing design

M

turbosquid

$20

Stage M&M

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

bag m&m's

...bag m&m's

3ddd

bag m&m's

bag m&m;'s

3d_export

$35

iskander m

...iskander m

3dexport

iskander m 3d model

design_connected

$7

barstool m

...barstool m

designconnected

barstool m computer generated 3d model.

3ddd

free

CACTUS M

...cactus m

3ddd

cactus , lzf

настольный светильник cactus m

производитель lzf

design_connected

$13

Anfora M

...anfora m

designconnected

lzf anfora m computer generated 3d model. designed by herranz, miguel.

3ddd

$1

зеркало M Gastone

...зеркало m gastone

3ddd

зеркало m gastone

зеркало m gastone

design_connected

$16

Dogon M

...dogon m

designconnected

emmemobili dogon m chairs computer generated 3d model. designed by ferruccio laviani.

design_connected

$9

Sunlight M

...sunlight m

designconnected

bonacina pierantonio sunlight m computer generated 3d model. designed by bizzozzero, franco.

3ddd

$1

Karman / Norma-M

...arman , norma-m

http://www.karmanitalia.it/en/prodotto/norma-m/norma-m-ap640n/