Thingiverse

crown gears in gearcutting process by faggahz

by Thingiverse

Last crawled date: 2 years, 12 months ago

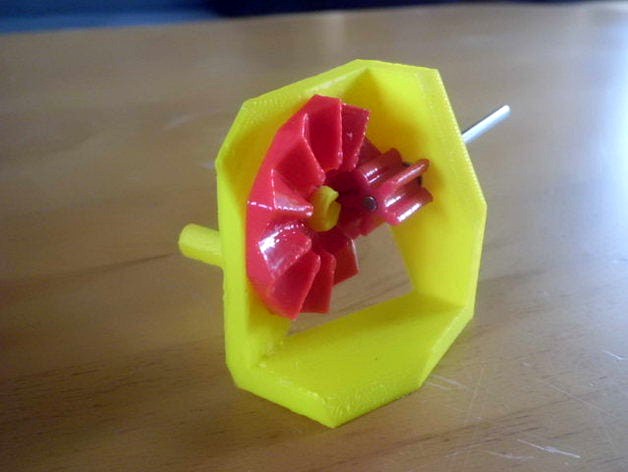

This is an example to make any gears by a gearcutting process. I've worked in the idea of parkinbot.

Crown gears are not a kind of bevel gears. Small gear of crown gears can be moved along it's axis, so there is no precision required. see wikipedia if you need more information.

Very often it is used as cheap gears in toys. Crown gear is made on punched thin sheetmetal. This shape cannot be copied to FDM printing.

Printed thing:

it is printed on the print?.stl files. I have made the holder as a quick and dirty design. Small gear is to small for printed plastic pins, I have used a 3mm steel rod (of a linear slider of an old CD drive). Maybe this gears can be used for educational. I don't see annother practical use.

stl files:

Most problem is the work style of openscad. It generates the cutting tool 100 times and seperately all its vertices to memory.

Then it makes a calculation process to find out the final shape of the object. This results in a very long rendering time because of nested for() loops. Most time I've got in my trials is >1 hour at a 100teeth gear. The mathematical system is very simple. Most work is needed to find out the computational limits and workarounds.

load crown.scad, uncomment gear1().

render [F6] and generate .stl files

uncomment crown_gear().

render [F6] and generate .stl files

load print.scad

select module you want to render and generate .stl files

I have made this 2-step process because it would be hard to design the holder when the crown gear needs to be rendered every time. Also, I have found out, creating the crown gear needs a simple hull cylinder. Inserting spokes and hubs will need more computational power and patience of programmer. It's better to do this at a second process.

(I'm happy to get this solution, even it was a hard process with repairs of non manifold stl's)

I have tested to make high tooth count. This is not perfect for educational use. Characteristics of the crown gear system can be seen better at smaller tooth count.

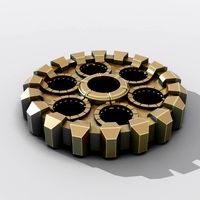

Also, I have tested to make hypoid and bevel gears in the crown cutting process. Hypoid gears normally require a twisted small gear, this will have a lot more vertices and data. So I have used a linear small gear, it will have more compromizes. Bevel crown gear needs some bugfixes. Because I'm working at annother idea to cut real bevel gears, I have not finished the work at bevel crown gears. (It would be a combination of a small spur gear and a crown gear in a matching angle <> 90deg). You will see the result if you'll change the parameters in scad file.

A basic idea in my work on a gear library is the origin point [x,y,z]=[0,0,0]. Axis of the gears will match in the origin point of coordinate system. Position of the thick_end of gears is not needed to make teethcutting process. Gears can be moved easily by translate() and rotate() commands to every point you need.

Annother idea: It is possible to make gears with irregular teeth if you change the tool gear (linear_extrude command) to import of your own gear stl file. Feel free to play with.

gears.scad is a copy of parkinbot's Gear cutting. I have made a change to smoothen the foot of teeth. This will reduce data by 5%.

https://youtu.be/qEten7H_u-A

Crown gears are not a kind of bevel gears. Small gear of crown gears can be moved along it's axis, so there is no precision required. see wikipedia if you need more information.

Very often it is used as cheap gears in toys. Crown gear is made on punched thin sheetmetal. This shape cannot be copied to FDM printing.

Printed thing:

it is printed on the print?.stl files. I have made the holder as a quick and dirty design. Small gear is to small for printed plastic pins, I have used a 3mm steel rod (of a linear slider of an old CD drive). Maybe this gears can be used for educational. I don't see annother practical use.

stl files:

Most problem is the work style of openscad. It generates the cutting tool 100 times and seperately all its vertices to memory.

Then it makes a calculation process to find out the final shape of the object. This results in a very long rendering time because of nested for() loops. Most time I've got in my trials is >1 hour at a 100teeth gear. The mathematical system is very simple. Most work is needed to find out the computational limits and workarounds.

load crown.scad, uncomment gear1().

render [F6] and generate .stl files

uncomment crown_gear().

render [F6] and generate .stl files

load print.scad

select module you want to render and generate .stl files

I have made this 2-step process because it would be hard to design the holder when the crown gear needs to be rendered every time. Also, I have found out, creating the crown gear needs a simple hull cylinder. Inserting spokes and hubs will need more computational power and patience of programmer. It's better to do this at a second process.

(I'm happy to get this solution, even it was a hard process with repairs of non manifold stl's)

I have tested to make high tooth count. This is not perfect for educational use. Characteristics of the crown gear system can be seen better at smaller tooth count.

Also, I have tested to make hypoid and bevel gears in the crown cutting process. Hypoid gears normally require a twisted small gear, this will have a lot more vertices and data. So I have used a linear small gear, it will have more compromizes. Bevel crown gear needs some bugfixes. Because I'm working at annother idea to cut real bevel gears, I have not finished the work at bevel crown gears. (It would be a combination of a small spur gear and a crown gear in a matching angle <> 90deg). You will see the result if you'll change the parameters in scad file.

A basic idea in my work on a gear library is the origin point [x,y,z]=[0,0,0]. Axis of the gears will match in the origin point of coordinate system. Position of the thick_end of gears is not needed to make teethcutting process. Gears can be moved easily by translate() and rotate() commands to every point you need.

Annother idea: It is possible to make gears with irregular teeth if you change the tool gear (linear_extrude command) to import of your own gear stl file. Feel free to play with.

gears.scad is a copy of parkinbot's Gear cutting. I have made a change to smoothen the foot of teeth. This will reduce data by 5%.

https://youtu.be/qEten7H_u-A

Similar models

cg_trader

$2

mechanical gears

...ne part having cut teeth

spur, helical, double helical, bevel, spiral bevels, hypoid, crown, worm, rack and pinion, harmonic gear

grabcad

free

Helical Bevel Gear

...o change the direction of a shaft's rotation. bevel gears have teeth that are available in straight, spiral, or hypoid shape.

thingiverse

free

small inline gear box v2 by caj

... that are bent and rusty if you use these type of nails the gears will wear realy fast that stuff acts like sand paper to plastic

grabcad

free

Hypoid gear

... pitch surface is best described as a hyperboloid. a hypoid gear can be considered a cross between a bevel gear and a worm drive.

thingiverse

free

Parametric Bevel Gears by wayland

... there are not actually red and blue lines piercing the gear.

edited: gear teeth can now be triangular or fractionally triangular

grabcad

free

#Bevel Gears

...d. straight bevel gear teeth actually have the same problem as straight spur gear teeth -- as each tooth engages, it impacts the…

thingiverse

free

Reuleaux Planetary gear by faggahz

... around (instead of a toothbar).

twin projects:https://www.thingiverse.com/thing:1439718https://www.thingiverse.com/thing:1414403

thingiverse

free

Working moving gears by ESalamanca

...he gear caps that really mean pins to hold them in place. those two file need to be printed two time because there are two gears.

thingiverse

free

Broken Heart by GregFrost

... bit of a process generating the stls from them.

if someone wants to collaborate on a better way to mount the gears, let me know.

grabcad

free

Bevel_Gear_Set

...r.

6. if you failed to generate gear set even when you follow the all guidelines above, try the ctrl+g button again! thank you!

Gearcutting

thingiverse

free

Asymmetric Planetary Gear by faggahz

...i have made this for a test of parkinbot's gearcutting library. please print this only with xy-size compensation of...

thingiverse

free

Reuleaux Planetary gear by faggahz

...source files and opensource. what's not new: idea of gearcutting i have seen this at user:parkinbot. this is not...

Faggahz

thingiverse

free

Pyraminx sphere by faggahz

...required, no springs.

lubrificate with vaseline. puzzle runs good.

more puzzles here: https://www.thingiverse.com/faggahz/designs

thingiverse

free

Jings Pyraminx Sphere by faggahz

...required, no springs.

lubrificate with vaseline. puzzle runs good.

more puzzles here: https://www.thingiverse.com/faggahz/designs

thingiverse

free

Jings Pyraminx 1 by faggahz

...required, no springs.

lubrificate with vaseline. puzzle runs good.

more puzzles here: https://www.thingiverse.com/faggahz/designs

thingiverse

free

Pyraminx by faggahz

...748971https://www.thingiverse.com/thing:2752158https://www.thingiverse.com/thing:2749991https://www.thingiverse.com/thing:2748069

thingiverse

free

horizontal eggcup by faggahz

...re exclusive on your table, it tastes much better, it is fine art.

( example is printed in pla with manual filament color change)

thingiverse

free

Edge Cover Decoration by faggahz

...f.

edge decoration element symmetric and asymmetric.

print in vase mode (slic3r)

cut 1mm at printbed side

pla white / translucent

thingiverse

free

Jings Pyraminx 2 by faggahz

...required, no springs.

lubrificate with vaseline. puzzle runs good.

more puzzles here: https://www.thingiverse.com/faggahz/designs

thingiverse

free

Trabant Sachsenring Car Logo by faggahz

...e

trabant (east german car) logo

printed in pla silver grey

"radmutter": please make a test print, scale for best fit.

thingiverse

free

Gearcube Globe Holder by faggahz

...wo halves, glue together. prints without support.

scad file will create only one half. other side is mirrored using repetierhost.

thingiverse

free

Wash Machine Gift Box by faggahz

...ts without support. there is a 0.2mm gap between box and lid for xy-compensation of the printer. can be removed in the scad file.

Crown

3d_export

$5

Crown

...crown

3dexport

crown

design_connected

$16

Crown

...crown

designconnected

nemo crown computer generated 3d model. designed by jehs+laub.

3d_export

$25

Crown

...crown

3dexport

crown of rose gold with diamonds. programs used: 3ds max, zbrush, corona render

turbosquid

$7

crown

...turbosquid

royalty free 3d model crown for download as blend on turbosquid: 3d models for games, architecture, videos. (1568306)

turbosquid

$2

crown

...n

turbosquid

royalty free 3d model crown for download as c4d on turbosquid: 3d models for games, architecture, videos. (1177593)

turbosquid

$2

Crown

...n

turbosquid

royalty free 3d model crown for download as obj on turbosquid: 3d models for games, architecture, videos. (1634685)

turbosquid

$1

CROWN

...turbosquid

royalty free 3d model crown for download as blend on turbosquid: 3d models for games, architecture, videos. (1490916)

turbosquid

$7

Crown

...quid

royalty free 3d model crown for download as obj and dae on turbosquid: 3d models for games, architecture, videos. (1617936)

turbosquid

$6

Crown

...quid

royalty free 3d model crown for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1404084)

3ddd

$1

Toyota Crown

...toyota crown

3ddd

toyota

toyota crown

Process

3ddd

$1

Process unit

...process unit

3ddd

статуэтка

process unit

3d_export

$10

stamping process

...stamping process

3dexport

3d_export

$7

a product processing machine

...a product processing machine

3dexport

a product processing machine

3d_export

$7

Auto Rim Processing Machine

...auto rim processing machine

3dexport

auto rim processing machine

turbosquid

$20

stage launching procession

... free 3d model stage launching procession for download as max on turbosquid: 3d models for games, architecture, videos. (1581910)

3d_export

$17

automobile welding parts processing tooling

...automobile welding parts processing tooling

3dexport

automobile welding parts processing tooling

3d_export

$10

processing equipment for automobile wheel rim

...processing equipment for automobile wheel rim

3dexport

processing equipment for automobile wheel rim

turbosquid

$7

Micro Processing Unit (MPU)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

automatic processing line for gearbox pump body

...automatic processing line for gearbox pump body

3dexport

automatic processing line for gearbox pump body

turbosquid

$15

Industrial lamp, processing of mechanical parts

...rial lamp, processing of mechanical parts for download as max on turbosquid: 3d models for games, architecture, videos. (1519481)

Gears

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels 3docean engine engineering gear gears industry machinery mechanical toothwheel wheel pair of gear wheels...

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)