Thingiverse

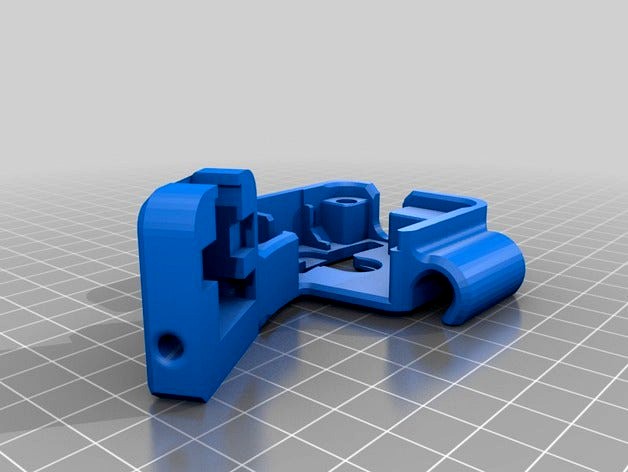

Cr-10 Filament Sensor Bracket & Tutorial by IsaacMDesigns

by Thingiverse

Last crawled date: 3 years ago

Overview:

I designed a Bracket to hold a filament run-out sensor i bought off ebay.

When the filament runs out, in this order it will:

Pause the print

retract filament to stop oozing,

move the head away to allow filament change

resume back where it initially stopped.

Properties:

It slips over the Extruder, and also has a cable holder integrated.

The design allows it so you can use a small amount of PTFE tube to make it easier for the filament to guide into the extruder motor.

Sensor Light up green when there is filament detected

You Will Need:

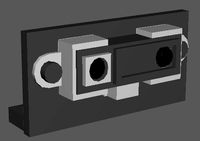

-Sensor:

AliExpress: https://goo.gl/FutpoC

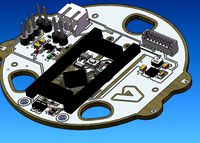

-Connectors for Raspberry pi:http://r.ebay.com/9g8yce

-RaspberryPi running Octoprint

Setup Steps:

print out Filament Sensor and Lid

Install Sensor inside housing (will be a tight fit)

Wire up Sensor to Raspberry Pi. ( follow tutorial if stuck https://youtu.be/j7JfQXTf16U)

Install "Filament Sensor Reloaded" plugin on Octopi

Stock Firmware:

Set Pin: 7

Debounce Time: 400ms

Switch type: Normally Open

-Board Pin Mode: Board Mode

Pause Print When Out of Fliament : (Tick)

Now Edit Pause and Resume GCode (refer to photos below)

Firmware 1.10+

(Currently seems firmware is ignoring M600 L0, so please follow stock firmware setup if you manage to figure out how to stop m600 retracting the filament. please let me know in the comments)

Set Pin: 7

Debounce Time: 400ms

Switch type: Normally Open

-Board Pin Mode: Board Mode

-Out of Filament GCODE: M600 E-5 L0 X10 Y10 Z5

Pause Print When Out of Fliament : (No Tick)

updates:

(D,M,Y)

14/08/2017: Edited G-code pause function as the steppers were disabling after 60 seconds of the filament running out which led to printer loosing its coordinates. Now should stay on for 6 hours

14/08/2017: Better Lid design and better model design with smaller extruder cover hole, there should be no printing issues now.

27/08/2017: Added a dust cover for the extruder opening

up-coming:

updated Gcode

better lid design

fixed model hollow slicing issues

Printing without supports

I designed a Bracket to hold a filament run-out sensor i bought off ebay.

When the filament runs out, in this order it will:

Pause the print

retract filament to stop oozing,

move the head away to allow filament change

resume back where it initially stopped.

Properties:

It slips over the Extruder, and also has a cable holder integrated.

The design allows it so you can use a small amount of PTFE tube to make it easier for the filament to guide into the extruder motor.

Sensor Light up green when there is filament detected

You Will Need:

-Sensor:

AliExpress: https://goo.gl/FutpoC

-Connectors for Raspberry pi:http://r.ebay.com/9g8yce

-RaspberryPi running Octoprint

Setup Steps:

print out Filament Sensor and Lid

Install Sensor inside housing (will be a tight fit)

Wire up Sensor to Raspberry Pi. ( follow tutorial if stuck https://youtu.be/j7JfQXTf16U)

Install "Filament Sensor Reloaded" plugin on Octopi

Stock Firmware:

Set Pin: 7

Debounce Time: 400ms

Switch type: Normally Open

-Board Pin Mode: Board Mode

Pause Print When Out of Fliament : (Tick)

Now Edit Pause and Resume GCode (refer to photos below)

Firmware 1.10+

(Currently seems firmware is ignoring M600 L0, so please follow stock firmware setup if you manage to figure out how to stop m600 retracting the filament. please let me know in the comments)

Set Pin: 7

Debounce Time: 400ms

Switch type: Normally Open

-Board Pin Mode: Board Mode

-Out of Filament GCODE: M600 E-5 L0 X10 Y10 Z5

Pause Print When Out of Fliament : (No Tick)

updates:

(D,M,Y)

14/08/2017: Edited G-code pause function as the steppers were disabling after 60 seconds of the filament running out which led to printer loosing its coordinates. Now should stay on for 6 hours

14/08/2017: Better Lid design and better model design with smaller extruder cover hole, there should be no printing issues now.

27/08/2017: Added a dust cover for the extruder opening

up-coming:

updated Gcode

better lid design

fixed model hollow slicing issues

Printing without supports

Similar models

thingiverse

free

Prusa Filament Out Sensor by jmillerfo

...ands. other applications could utilize this accessory as long as they rely on gpio4 (board pin 7) to signal filament exhaustion.

thingiverse

free

Filament Run Out Sensor Wanhao D6/ Monoprice Ultimate by Empiricus

...oop and the print will not resume. if someone has figured out a good gcode script for the d6 to use with the pi pins please post.

thingiverse

free

Hypercube Filament Guide With Filament Out Sensor

...ut goes high when the filament runs out. that will make the printer pause, and more filament can be loaded and the print resumed.

thingiverse

free

Filament sensor with groove mount for prusa enclosure filament rod by revillete

...h groove mount for prusa enclosure filament rod by revillete

thingiverse

this can pause your print when your filament runs out.

thingiverse

free

Pot Lid Knob/Handle by Thirkell

...n embedded m6 square nut. pause the print in this position to insert the nut med print. use m600 in gcode to pause automatically.

thingiverse

free

Filament Run Out Sensor Holder

...printer. it holds the sensor for filament runout to so it will pause the print and wait for you to return and change out a roll.

thingiverse

free

Filament Runout Sensor for Marlin and Octoprint by murathanaraz

...o when paused extruder will go to the corner and unload the filament and wait for loading. check google for m600 command details.

thingiverse

free

Filament FAULT Detector using Octoprint by re-NABLE_Vertus

...led instructions seehttp://e-nable.org/2017/10/17/do-your-prints-fail-because-filament-gets-tangled-or-because-filament-runs-out/

thingiverse

free

MP Select Mini End of Filament Sensor + Filter Combo Mount by mosesIRL

...holder with this part. having the spool at a 90 degree angle puts too much lateral tension on the part and can kink the filament.

thingiverse

free

Filament guide with run-out sensor for Ender 3 PRO by plasmocz

... ender 3 pro when use aluminum upgrade dual gear mk8 extruder.

extruder upgrade: https://www.aliexpress.com/item/33041168934.html

Isaacmdesigns

thingiverse

free

Martian II - Antenna Bracket by IsaacMDesigns

...martian ii - antenna bracket by isaacmdesigns

thingiverse

a bracket to hold sma extension.

for 32mm high.

thingiverse

free

Wall Hook (Picture-frame Hanger Adapter) by IsaacMDesigns

...all hook (picture-frame hanger adapter) by isaacmdesigns

thingiverse

just a little converter to hook light objects on your wall.

thingiverse

free

Evolve Motor Belt Cover by IsaacMDesigns

...mm wheels - tested

107mm wheels - untested

equipment:

2x ( m4 x 20 or m4 x 21 )

2x (m4 washers)

reference photo for installation.

thingiverse

free

Taranis X-Lite Lanyard Adaptor by IsaacMDesigns

...ical areas.

support:

if you appreciate the design and want to help me out with my university fees any donations are welcome. :-)

thingiverse

free

CR10_Filament out switch with guide by RebelTerry

...he print head will move to a safe location. resume the print through the octoprint interface.

good luck! hope you find it useful.

Cr

turbosquid

$15

Creazioni CR-673 CR-4461

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Ravak CR 055.00

...ravak cr 055.00

3ddd

ravak , смеситель

ravak cr 055.00

turbosquid

$100

CR-002

...

turbosquid

royalty free 3d model cr-002 for download as stl on turbosquid: 3d models for games, architecture, videos. (1686037)

3ddd

$1

Ravak CR 012.00

...ravak cr 012.00

3ddd

ravak , смеситель

смеситель ravak cr 012.00

3ddd

free

Консоль CR Currin

...ь , cr currin

консоль cr currin

ширина - 1675 мм

глубина - 510 мм

общая высота - 810 мм

3ddd

$1

CR 39444

...0

диаметр: 100

тип патрона: gu5,3 gu10

количество ламп: 1

мощность: 35w

цвет: золото хрусталь

материал: металл хрусталь exclusive

3d_ocean

$89

Honda CR-Z

...www.youtube.com/watch?v=rrbb4d4lypk ` he honda cr-z‘s exterior styling is formed around a “one-motion wedge” concept with a lo...

3ddd

$1

Creazoni / STEFY CR-8901

...creazoni / stefy cr-8901

3ddd

creazoni

creazioni stefy cr-8901

turbosquid

$60

Chain-CR-001

...squid

royalty free 3d model chain-cr-001 for download as stl on turbosquid: 3d models for games, architecture, videos. (1680536)

turbosquid

$99

Honda CR-Z

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Tutorial

evermotion

$548

Bundle - All Tutorials

...g vol. 2

the secret training book

the secret fx training dvd

san juan video tutorial

car4ever vol. evermotion 3d models shop.

turbosquid

$9

Physics - Tutorial

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

tutorial chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

WINE GLASS ( with tutorial)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Spotlight - Tutorial Model

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

evermotion

$60

San Juan Video Tutorial

...ial is splited into 9 chapters with fully narrated video in both english and spanish language version. evermotion 3d models shop.

3d_export

$25

Water Splashing Tutorial 3D Model

...tutorial 3d model

3dexport

max vray tutorial water splash editable poly

water splashing tutorial 3d model cglesson 65446 3dexport

3d_export

$75

Robot Model and tutorial 3D Model

...al ray tutorial silver glow tri polygon model blue high tech mech design

robot model and tutorial 3d model adelsb7 25144 3dexport

turbosquid

free

Glass Ball Tutorial + sample

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$79

Vray Grass Tutorial 3D Model

...ass tutorial 3d model

3dexport

grass vray exterior landscape garden house fur

vray grass tutorial 3d model sbgwolf 31481 3dexport

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Bracket

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket n280911 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder corbel bracket

bracket 9 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 10 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel console bracket

bracket 11 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder console bracket

bracket 12 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 13 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.

10

turbosquid

$25

10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

turbosquid

$24

Chandelier MD 89310-10+10 Osgona

... chandelier md 89310-10+10 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1218762)

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.