Thingiverse

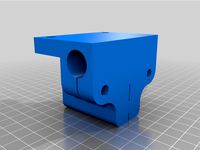

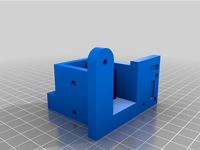

CoreXY Power Carriage by merlinds

by Thingiverse

Last crawled date: 3 years, 1 month ago

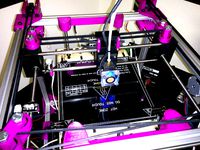

This is the carriage I designed for my custom coreXY printer. It features a compact design, aimed to take advantage of HIP´s high temperature melting point to minimize the spacing between the block and the carriage plate thus allowing me to use an original vulcano block and heat break from e3d combined with a regular mk8 direct drive, and achiving very similar performance as my original titan aero that I have in my other printer.

Notice the following, the spacing between the smooth rods is 59mm from center to center, that can be adjusted in Fusion 360.

If you want to use a clone heat break, notice that you will need to print "Lower Guide For Clone Barrel.stl" to match the 6mm end.

If you are using an original e3d heat break, you may need to expad your mk8 aluminum plate threaded hole from 6mm to 7mm, this can be achieved with a 6mm drill bit and a 7mm male hole maker (dunno the name in english). Either way, you should make some small dents in the upper part of the thread to stop the heat break from going through.

Basically you put the tip of a philips screw drive right next to the top end of the threaded hole and hit it carefully with a hammer to deform the end of the screw and block the heat break. (see Captura.png)

Measure the nema 17 body to match the one i´m using, or edit the brace, it is important to get a tigh fit there.

If you can match the convo of hobb and iddler i´m using, you will get great performance for flex filaments.

Vitamins required:

1 mk8 direct drive (6 or 7mm thread for heat break) with heatsink and fan

1 vulcano heat break with thermistor and catridge

1 e3d heat break

1 nema 17 medium torque

3 lmu8 bearings

1 bltouch

1 centrifugal fan

2 m3 screws with nuts and a few washers

3 m2 or less tiny screws to hold the bracket to the plate

1 big wood screw to hold the cables from the cable holders, get creative here

some teflon tube to fill the lower guidem upper guide and filler screw

Some Amazon items I found that match what I´m using:https://www.amazon.com/Widewing-Geeetech-Extruder-Aluminum-for1-75mm/dp/B07D3TH2Y8/ref=sr_1_1_sspa?ie=UTF8&qid=1528074107&sr=8-1-spons&keywords=mk8+geeetech&psc=1

https://www.amazon.com/SoundOriginal-Humidifier-Aromatherapy-Appliances-Replacement/dp/B071WMHNG5/ref=pd_sim_328_3?_encoding=UTF8&pd_rd_i=B071WMHNG5&pd_rd_r=B8JP879177YK2B8F2C5P&pd_rd_w=6N2kN&pd_rd_wg=TFiwh&psc=1&refRID=B8JP879177YK2B8F2C5P&dpID=51cWTBpsDFL&preST=_SY300_QL70_&dpSrc=detail

https://www.amazon.com/dp/B0773MW3X7/ref=sspa_dk_detail_9?psc=1&pd_rd_i=B0773MW3X7&pd_rd_wg=MqDMU&pd_rd_r=5CG148HWSR9PHYDWBW93&pd_rd_w=2mxV1

If you want to replace the original hub for this one you will need to file the idler a bit so the filament gets squished, once you do the extruder will work great with flex.https://www.amazon.com/Gulfcoast-Robotics-Filament-Printer-Extruder/dp/B07BSR9FWH/ref=sr_1_3?s=industrial&ie=UTF8&qid=1527594418&sr=1-3&keywords=3d+printer+hobbed+gear

https://www.amazon.com/Genuine-Heat-Break-1-75mm-V6-175-BREAK/dp/B077Y2MHW8/ref=sr_1_5?ie=UTF8&qid=1527594748&sr=8-5&keywords=e3d+heatbreak

https://www.amazon.com/Genuine-E3D-Volcano-Block-Heater/dp/B07BFYL3KN/ref=sr_1_10?ie=UTF8&qid=1527594389&sr=8-10&keywords=e3d+volcano

https://www.amazon.com/Hobby-Hangar-NEMA-Stepper-Motor/dp/B079S6JGG3/ref=sr_1_22?s=industrial&ie=UTF8&qid=1527594487&sr=1-22&keywords=nema+17

Notice the following, the spacing between the smooth rods is 59mm from center to center, that can be adjusted in Fusion 360.

If you want to use a clone heat break, notice that you will need to print "Lower Guide For Clone Barrel.stl" to match the 6mm end.

If you are using an original e3d heat break, you may need to expad your mk8 aluminum plate threaded hole from 6mm to 7mm, this can be achieved with a 6mm drill bit and a 7mm male hole maker (dunno the name in english). Either way, you should make some small dents in the upper part of the thread to stop the heat break from going through.

Basically you put the tip of a philips screw drive right next to the top end of the threaded hole and hit it carefully with a hammer to deform the end of the screw and block the heat break. (see Captura.png)

Measure the nema 17 body to match the one i´m using, or edit the brace, it is important to get a tigh fit there.

If you can match the convo of hobb and iddler i´m using, you will get great performance for flex filaments.

Vitamins required:

1 mk8 direct drive (6 or 7mm thread for heat break) with heatsink and fan

1 vulcano heat break with thermistor and catridge

1 e3d heat break

1 nema 17 medium torque

3 lmu8 bearings

1 bltouch

1 centrifugal fan

2 m3 screws with nuts and a few washers

3 m2 or less tiny screws to hold the bracket to the plate

1 big wood screw to hold the cables from the cable holders, get creative here

some teflon tube to fill the lower guidem upper guide and filler screw

Some Amazon items I found that match what I´m using:https://www.amazon.com/Widewing-Geeetech-Extruder-Aluminum-for1-75mm/dp/B07D3TH2Y8/ref=sr_1_1_sspa?ie=UTF8&qid=1528074107&sr=8-1-spons&keywords=mk8+geeetech&psc=1

https://www.amazon.com/SoundOriginal-Humidifier-Aromatherapy-Appliances-Replacement/dp/B071WMHNG5/ref=pd_sim_328_3?_encoding=UTF8&pd_rd_i=B071WMHNG5&pd_rd_r=B8JP879177YK2B8F2C5P&pd_rd_w=6N2kN&pd_rd_wg=TFiwh&psc=1&refRID=B8JP879177YK2B8F2C5P&dpID=51cWTBpsDFL&preST=_SY300_QL70_&dpSrc=detail

https://www.amazon.com/dp/B0773MW3X7/ref=sspa_dk_detail_9?psc=1&pd_rd_i=B0773MW3X7&pd_rd_wg=MqDMU&pd_rd_r=5CG148HWSR9PHYDWBW93&pd_rd_w=2mxV1

If you want to replace the original hub for this one you will need to file the idler a bit so the filament gets squished, once you do the extruder will work great with flex.https://www.amazon.com/Gulfcoast-Robotics-Filament-Printer-Extruder/dp/B07BSR9FWH/ref=sr_1_3?s=industrial&ie=UTF8&qid=1527594418&sr=1-3&keywords=3d+printer+hobbed+gear

https://www.amazon.com/Genuine-Heat-Break-1-75mm-V6-175-BREAK/dp/B077Y2MHW8/ref=sr_1_5?ie=UTF8&qid=1527594748&sr=8-5&keywords=e3d+heatbreak

https://www.amazon.com/Genuine-E3D-Volcano-Block-Heater/dp/B07BFYL3KN/ref=sr_1_10?ie=UTF8&qid=1527594389&sr=8-10&keywords=e3d+volcano

https://www.amazon.com/Hobby-Hangar-NEMA-Stepper-Motor/dp/B079S6JGG3/ref=sr_1_22?s=industrial&ie=UTF8&qid=1527594487&sr=1-22&keywords=nema+17

Similar models

thingiverse

free

gMax, 80/20 frame parts for mods, hacks, and addons by Spudwheelie

...pport-terminal-rocker-toggle-switch/dp/b00zwwyucu/ref=sr_1_15?ie=utf8&qid=1464391427&sr=8-15&keywords=switch+spst#ask

thingiverse

free

Rgb Light Strip Lamp by Ratakis

...lament-dimensional-accuracy/dp/b00mb3cv6k/ref=sr_1_1?ie=utf8&qid=1524145120&sr=8-1&keywords=clear+pla+filament+1.75mm

thingiverse

free

3D Printable 3D Printer by TheJadeRabbit

...r_1_4?ie=utf8&qid=1530916900&sr=8-4&keywords=3d+printer+hotend

code(marlin): https://github.com/marlinfirmware/marlin

thingiverse

free

The Cube Mini Fridge by thewatchmakerfl

...ref=sr_1_2?ie=utf8&qid=1436833279&sr=8-2&keywords=potentiometer&pebp=1436833322445&perid=0pmtmyyyy6vn4mzst3fx

thingiverse

free

Speaker box by Ratakis

...-4ft/dp/b01kstsv76/ref=sr_1_1_sspa?s=electronics&ie=utf8&qid=1521518432&sr=1-1-spons&keywords=aux+cable&psc=1

thingiverse

free

MacBook Pro with Retina Display Vertical Dock by TomExplorador

...er/dp/b008ala6dw/ref=sr_1_3?s=electronics&ie=utf8&qid=1517752168&sr=1-3&keywords=macbook+ethernet+adapter+thunder

thingiverse

free

40A Power Supply Cover W/LCD Display by hkgary_g

...lpage_o06_s01?ie=utf8&psc=1

power socket

www.amazon.com/gp/product/b06xnmt3wl/ref=oh_aui_detailpage_o06_s00?ie=utf8&psc=1

thingiverse

free

TRAXXTRUDER Compact geared extruder by liu_d

...1&keywords=48p+13t

more details are coming! the prototype is waiting on some hardware and photos/video will be uploaded asap.

thingiverse

free

Drones and Droids 2017 by SLForney

...sb li-po charger 300mahttps://www.amazon.com/gp/product/b00ddtl5t0/ref=ox_sc_act_title_1?ie=utf8&psc=1&smid=atvpdkikx0der

thingiverse

free

Laser DL-44 by Dinoman217

...tubing-eventronic/dp/b072pcq2lw/ref=sr_1_5?s=industrial&ie=utf8&qid=1527956002&sr=1-5&keywords=heat+shrink+tubing

Merlinds

thingiverse

free

Eraser and Marker Holder by merlinds

...y merlinds

thingiverse

used some double sided tape to stick it to the bottom of the board in my university. professors loved it.

thingiverse

free

Love Spinner by merlinds

...or my gf, still haven´t printed it, will upload pictures when i do.

i made it for a 22mm bearing and m6 nuts with a .2 clearence.

thingiverse

free

Moto g5 + Spell Book Case by merlinds

...moto g5 + spell book case by merlinds

thingiverse

this is a phone case i made for a friend.

thingiverse

free

Peppa Pig For easy print by merlinds

...hingiverse

just modified the original stl, to make it easier for printing. just put arms and tail flat surface on bed, and print

thingiverse

free

Organic Monitor Stand by merlinds

... monitor. it uses all the space available in a 20x20 bed and is really stable. also you can pass cables or store things under it.

thingiverse

free

Feline Skull by merlinds

...es to him.https://www.youtube.com/watch?v=comsn10azhk&lc=z23bvhlgjymqfjitracdp4342r3vrbspkiirkut4cn1w03c010c.1513420050131187

thingiverse

free

Utility Hexa Tile Durable by merlinds

... designed this one in a way that the little arms are printed layed down on the bed, also i med the whole frame more to my liking.

thingiverse

free

Philips OneBlade 2521 All in one holder by merlinds

...to hold the few accesories for my shaver. ended up mixing two existing designs.

printed with support only below the charger hole.

thingiverse

free

Titan Aero Double Layer Fan by merlinds

..., seriously this pumps some serious cooling, the silicon shell is a must for your heat block.

take a look: http://a360.co/2bbwl2r

thingiverse

free

Filament Spool Rack by merlinds

...unt it in.

in the pictures you will se an actual bearing, that is from an older version that proved to be useless so i remove it.

Corexy

thingiverse

free

CoreXY by Kaz_tech

...corexy by kaz_tech

thingiverse

this is the model of corexy platform. i separately put the parts on this place.

thingiverse

free

corexy plotter by tjwan

...corexy plotter by tjwan

thingiverse

parts for corexy mill inspired by http://der-frickler.net/technik/corexyportal

thingiverse

free

ScribbleJ CoreXY Beta by ScribbleJ

...j/corexy-v1https://github.com/scribblej/corexy-v1#corexy-beta

full gallery of development photos here: http://imgur.com/a/donun

thingiverse

free

CoreXY Emblem by emkajot

...by emkajot

thingiverse

an emblem for your corexy printer.

size: 100mm x 38mm x 2mm.

update: added a version with a proper mount.

thingiverse

free

SolidCore CoreXY Carriage by shanehooper

...olidcore 3d printer. this design could be used in other corexy 3d printers.

also see:https://3ddistributed.com/corexy-3d-printer/

thingiverse

free

CoreXY 3D Printer Model by ReginaFabricam

...bricam

thingiverse

this is an original design of a corexy printer.https://www.tinkercad.com/things/jggr9qk4s4p-3d-printer-corexy

thingiverse

free

coreXY Upper structure Left

...corexy upper structure left

thingiverse

my customized corexy 3d printer upper left parts

thingiverse

free

CoreXY by frankie

...ing machines, etc. the design is described in greater detail at http://www.corexy.com . a video is at http://vimeo.com/40914530 .

thingiverse

free

Endstop block for CoreXY carriage by svkeulen

...endstop block for corexy carriage by svkeulen

thingiverse

endstop for corexy carriage

thingiverse

free

X carriage for the CoreXY MGN12 by hackerbijay

...x carriage for the corexy mgn12 by hackerbijay

thingiverse

x carriage for the corexy frame

Carriage

archibase_planet

free

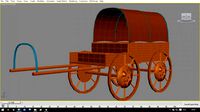

Carriage

...arriage

archibase planet

perambulator baby carriage pram

carriage n250908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

carriage

...carriage

3dexport

old fashion carriage model, more files here:

turbosquid

$140

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1482052)

turbosquid

$25

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1285944)

3d_export

free

carriage

...carriage

3dexport

game cart

3d_ocean

$15

Barrel Carriage

...ieval oak old transport wheels wine wood

this model contains a barrel and a carriage. it is a medieval type of wood oak carriage.

turbosquid

$40

Carriage

...ty free 3d model carriage for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290094)

turbosquid

free

Carriage

...yalty free 3d model carriage for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1239157)

3d_export

$5

Medieval carriage

...medieval carriage

3dexport

medieval carriage in fairy style

turbosquid

$58

Carriage

...d model carriage with scene for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1276262)

Power

turbosquid

$100

power

...ower

turbosquid

royalty free 3d model power for download as on turbosquid: 3d models for games, architecture, videos. (1421990)

3d_export

$5

Power

...power

3dexport

3d_export

$5

power outlets

...power outlets

3dexport

power outlets

3ddd

$1

lion power

...lion power

3ddd

лев , статуя

lion power gold sculpture

3ddd

$1

Sea Power

...

компас , море , часы

часы с компасом sea power

3ddd

free

Meridiani / Power

...power

3ddd

meridiani , круглый

стол power производитель meridiani, диаметр 120,высота 67

3d_export

$5

Power Surge

...power surge

3dexport

the power surge is a all mesh carnival ride to lower in game part count and lag

turbosquid

$8

Airport Ground Power Unit (AXA Power )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Power Houser

...rbosquid

royalty free 3d model power houser for download as on turbosquid: 3d models for games, architecture, videos. (1333800)

3d_export

$5

power outlet

...power outlet

3dexport

power outlet<br>format file maya 2018, 3d max 2017, obj, fbx