Thingiverse

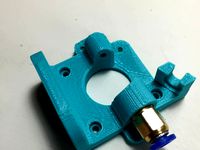

Compact Extruder for 3mm filament by BoByS

by Thingiverse

Last crawled date: 3 years, 1 month ago

Just print the parts. Use 2pcs M3x10 screws to attach to the motor (left side). Use M3x16 screw for the idler-to-extruder body. The bearing is standard 608 skate bearing. Attach it with M4x10 (Notice that it's M4, not as the original M5!). If you have M4x12 which is more common in my case - use the spacer. For the Idler tension - you can use a M3 screw bigger than 12mm in length! It's a good idea to put a spring there as you have a notch with which you'll be able to change the filament easily!

Use a push-fitting for 6mm OD PTFE tube (4mm ID). I have a Chinese E3D version all-metal extruder and the PTFE tube came with it.

Notice that the screws for holding the Bowden compact extruder to the frame are M4! In the original part - it's M3. When you print with 3mm fila, it's a good idea to hold it steady to the frame. :)

Enjoy!

Update #2:

Finally I was able to make everything fit with the 1/8'' brass push-fitting for 6 OD PTFE tube. Everything looks nice - but there is important note that in 1/8'' version - you'll need a 24T gear drive wheel. Like this one: http://www.ebay.com/itm/26T-Tooth-5mm-Bore-Brass-Filament-Drive-Gear-For-DIY-3D-Printer-Extruder-/141353563206?hash=item20e9543446:g:sjoAAOSwEK9TzNeZ

I haven't test it with a hot-end yet... I mount a motor with less torque - if it's working with it, it will work with every motor that has more torque. :) Still waiting for the hot-end to arrive (I hope it will be this week).

Use a push-fitting for 6mm OD PTFE tube (4mm ID). I have a Chinese E3D version all-metal extruder and the PTFE tube came with it.

Notice that the screws for holding the Bowden compact extruder to the frame are M4! In the original part - it's M3. When you print with 3mm fila, it's a good idea to hold it steady to the frame. :)

Enjoy!

Update #2:

Finally I was able to make everything fit with the 1/8'' brass push-fitting for 6 OD PTFE tube. Everything looks nice - but there is important note that in 1/8'' version - you'll need a 24T gear drive wheel. Like this one: http://www.ebay.com/itm/26T-Tooth-5mm-Bore-Brass-Filament-Drive-Gear-For-DIY-3D-Printer-Extruder-/141353563206?hash=item20e9543446:g:sjoAAOSwEK9TzNeZ

I haven't test it with a hot-end yet... I mount a motor with less torque - if it's working with it, it will work with every motor that has more torque. :) Still waiting for the hot-end to arrive (I hope it will be this week).

Similar models

thingiverse

free

Compact direct drive extruder by jmz_52

...-m6 fittings

ptfe tube od 3mm / id 2mm

springs length 22mm / od 7.5mm / id 5.2mm

drive gear

m5x10 and m3x6, m3x8 and m3x16 screws

thingiverse

free

Compact direct drive bowden extruder 3mm filament by puvijain

...fied the inlet section in the scad to house push fit for od 6mm ptfe tube.

inlet and outlet section have interchanged functions.

thingiverse

free

Simple Direct Drive Bowden Extruder by arms22

...5791/

x1 smf105zzhttps://www.monotaro.com/p/3460/9574/

x4 m3 20mm cap screw

x1 od 3mm id 2mm 50mm ptfe tube

x1 od 4mm bowden tube

thingiverse

free

Greg's wade v5 - PTFE mod by ThePhilStrongProject

...;s wade extruder v5 which has been modified to allow a ptfe tube to be used to guide the filament.

use 4mm od / 2mm id ptfe tube.

thingiverse

free

3mm Filament Bowden Adapter for K8200 by B4R

...filament in tube and then put the screws in (the filament prevents the tube from sqeezing on itself).

-remove filament and voila!

thingiverse

free

1.75mm Direct Drive Extruder by tosjduenfs

... to use ptfe tubing to guide filament to the extruder you can print the ptc (push-to-connect) holder for the top of the extruder.

thingiverse

free

Bowden extruder for 1.75mm filament and 1/8" push fit coupling (used for 4mm OD tubing) by sheffdog

...fit coupling, it now screws in perfectly straight off the printer, i also tapered the filament entrance to the push fit coupling.

thingiverse

free

Drybox Filament Pass-Through

...

any comments and suggestions for improvements appreciated ;-)

feel free to remix, fusion 360 files are included in the download.

thingiverse

free

cr-10s pro direct drive conversion holder by imranaliuk

...he metal extruder you buy

1 x stepper motor wire extension or solder and extend original

the rest of parts are already on machine

thingiverse

free

Compact Bowden Extruder, direct drive 1.75mm (Flexible Filament inlay) 4mm Tube, M5 pushfit by sobo84

...ment. works great for me.

maybe you have to cut it a little bit.

idler:

i glued anwasher with epoxid on it. it is just perfect!

Bobys

turbosquid

$19

Boby Armor V2

...free 3d model boby armor v2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1230855)

3d_export

$75

Mercedes Sclass Boby kit 3D Model

...class boby kit 3d model

3dexport

mercedes s600 body kit bumper autoparts

mercedes sclass boby kit 3d model fridrix 14802 3dexport

3d_export

$5

Guitar key 3D Model

...guitar key 3d model

3dexport

guitar key music tool accessories

guitar key 3d model bobi 13691 3dexport

3d_export

$5

Collection screwdriver 3D Model

...screwdriver 3d model

3dexport

collection screwdriver ndustrial tool work-shop

collection screwdriver 3d model bobi 13381 3dexport

3d_export

$10

Earth 3D Model

...xport

earth character characters animated animation ecology move bone nature person skin biped

earth 3d model bobi 22729 3dexport

3d_export

$35

trex dinosaur tyrannosaurs

...isplacement map for the feet only and sperated map for the teeth and tongue and eye with booth bump map<br>enjoy this model

3d_export

$119

JD - 953MH Tracked Log Loader

...ith this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you.<br>markos 3d

3d_export

$129

JD - 959MH Tracked Feller Buncher

...ith this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you.<br>markos 3d

3d_export

$119

JD - 959MH Tracked Log Loader

... in this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you.<br>markos 3d

3d_export

$119

JD - 953MH Tracked Harvester

...ith this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you.<br>markos 3d

Compact

3d_export

$5

compact freezer

...compact freezer

3dexport

the compact freezer is product about refrigeration machine

3d_ocean

$8

Compact Cassette

...

80s album analog audio cartridge cassette compact digital electronics lp mp3 music play record sound tape vinyl

compact cassette

design_connected

$20

Eames Compact

...eames compact

designconnected

herman miller eames compact computer generated 3d model. designed by eames, charles.

3d_ocean

$2

Compact Disc

...compact disc

3docean

album audio cd compact disc dvd laser disc movie music

a cd

3d_export

$10

land compacter

...land compacter

3dexport

turbosquid

$1

Compact knife

...quid

royalty free 3d model compact knife for download as obj on turbosquid: 3d models for games, architecture, videos. (1557900)

3d_export

$12

compact rotary broach

...compact rotary broach

3dexport

compact tool for drilling hexagonal holes in lathes!

turbosquid

free

Lada Compact

... 3d model lada compact for download as max, max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1623122)

turbosquid

$59

Compact Truck

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Compact kitchen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3Mm

turbosquid

$25

Single 3mm Gemstone Flower Gold Ring

... flower gold ring for download as max, obj, 3ds, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1529737)

3d_export

$5

eternity ring

...ring 3dexport eternity wedding rings for small fingers with 3mm diamonds on it. diameter of this ring is 14.7...

3d_export

$20

ring ak 2

...2 3dexport size 16<br>weight 18к-18,16 / 14к-15,18 / 925-12,71<br>gems 3mm2pcs / 1.1mm-1pc /...

3d_export

$8

case lcd 2004 stl

...dimension: height: 73mm width: 180mm depth: 30mm wall thickness: 3mm ...

3d_export

$5

sapphire and diamond ring

...16.88 and sapphire stones have 3.1mm and diamonds have 3mm diameter. i don't recommend to rescale it you can...

3d_export

$6

pearls ring

...for any inquiries and modifications.<br>editable 3d.<br>ring rail size:52<br>thickness rail: 1.2mm*3mmlt;br>weight gold: 4.6gr silver 925: 3.31...

3d_export

$5

racing drone frame

...drone frame 3dexport fdv racing drone<br>size:152*152mm<br>base plate:4mm<br>side plate : 3mmlt;br>top plate:1.5mm<br>beautiful appearance design,durable in crashing<br>hood engine room design,quick maintenance...

3d_export

$15

generic autopilot master panel for flight simulation

...placed the pushbuttons in position, you have to use 3mm screws to hold them in position. the led must...

3d_export

$5

puzzle cube

...direction to separate. clearance between the parts is around .3mm allowing for smooth movement without binding. since these parts...

3d_export

$50

Knife phoenix

...dimensions:<br>total length - 180mm<br>maximum width - 32mm<br>blade thickness - 3mmlt;br>handle thickness - 6mm<br>multiformat: igs, obj, stl, bip<br>nested 2 obj...

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.