Thingiverse

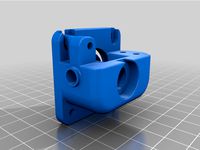

Compact Bowden Extruder Plus by mrm64

by Thingiverse

Last crawled date: 3 years, 1 month ago

This extruder is the 4th generation counted from the original Compact Bowden Extruder.

Updates

2018-04-23: Added type C body and related files

2018-04-23: Updated CG image

2018-06-09: Updated assembly picture

2018-07-04: Added idler V2 files

2018-07-04: Added a printed type C body picture

Basic Data

Extruder type: bowden

Drive method: direct drive

Stepper motor: NEMA 17

Filament diameter: 1.75mm

Drive gear: MK8 drive gear

Push-fit connecter: PC4-M6

Extruder Body Types

Type A

This type can be mounted on a box type printer.

The distance between the two holes of the mount part is 49mm.

If the holes position of the mount part does not match the holes position on the printer side, you can use Blender to edit the STL file and move the holes position.

Type B

This type can be mounted on a printer with T-slot.

Type C

This type can be mounted using a metal bracket or gimbal.

If you replace the motor spacer with a metal bracket, you will need to change the screws(M3x8mm -> M3x10mm, M3x10mm -> M3x12mm) that mounts the stepper motor and extruder, furthermore four sets of screws/nuts/washers for mounting on the printer are also required.

Requirements

Body/Idler

1 x NEMA 17 Stepper motor

1 x Heatsink for Nema 17 stepper motor (optional)

If you printed the body with PLA filament, it would be better to attach a heatsink

1 x MK8 drive gear

Outer diameter: 9mm

Length: 11mm

Hob diameter: 7mm

Bore: 5mm

1‒2 x PC4-M6 push-fit connecter

1 x Threadlocker

Lock the thread on the push-fit connecter

1 x Soft pick

Used to clean the drive gear automatically

1 x 625ZZ bearing (or 625-2RS bearing)

1 x 608ZZ bearing (or 608-2RS bearing)

1 x Small sponge piece (idea from Marco67)

Put into the motor side rectangle hole on the extruder body (to fix the M3 nut position)

2 x M3x8mm pan head screws

When mounting Type C body with metal bracket, change to M3x10mm

2 x M3x10mm pan head screws

When mounting Type C body with metal bracket, change to M3x12mm

2 x M3x15mm pan head screws

2 x M3x40mm screws

Using the flat head screws makes it easier to insert and remove the spring compressor and makes it easier to evenly tighten the left and right screws

When using full thread screw, stick an adhesive tape on a place to touch the idler and the washer board, the idler movement is becomes smooth

2 x Compression springs

Wire diameter: 0.6‒0.8mm

Outer diameter: 5‒8mm

Free length: 12‒15mm

4 x M3 hex nuts

Mount (Type A)

2 x M3 screws

2 x M3 hex nuts

2 x M3 washers

Mount (Type B)

2 x M3 screws

2 x M3 t-slot nuts (or hex nuts)

Mount (Type C with metal bracket)

4 x M3 screws

4 x M3 hex nuts

4 x M3 washers

Print Settings

Body

Nozzle diameter: 0.4mm

Resolution: 0.2mm

Perimeter count: 4

Infill: 30% or higher

Idler

Resolution: 0.2mm

Perimeter count: 4

Infill: 90%

Bearing spacer

Resolution: 0.2mm

Motor spacer

Resolution: 0.2mm

Spring compressor

Resolution: 0.2mm

Washer board

Resolution: 0.2mm

Spring Compressor

The spring compressor has a function to quick release/restore the spring pressure.

Please attach it to the screw head when using the 3D printer, and remove it from the screw head when finished using the 3D printer.

The burden on idlers when 3D printers are not used decreases, and the idlers becomes hard to break.

CBE_IdlerSet*V2.stl

Changes from previous version

Made left and right idlers the same thickness

Reduced cylinder size

Related Thing

1.5 Axis Gimbal for NEMA 17

Updates

2018-04-23: Added type C body and related files

2018-04-23: Updated CG image

2018-06-09: Updated assembly picture

2018-07-04: Added idler V2 files

2018-07-04: Added a printed type C body picture

Basic Data

Extruder type: bowden

Drive method: direct drive

Stepper motor: NEMA 17

Filament diameter: 1.75mm

Drive gear: MK8 drive gear

Push-fit connecter: PC4-M6

Extruder Body Types

Type A

This type can be mounted on a box type printer.

The distance between the two holes of the mount part is 49mm.

If the holes position of the mount part does not match the holes position on the printer side, you can use Blender to edit the STL file and move the holes position.

Type B

This type can be mounted on a printer with T-slot.

Type C

This type can be mounted using a metal bracket or gimbal.

If you replace the motor spacer with a metal bracket, you will need to change the screws(M3x8mm -> M3x10mm, M3x10mm -> M3x12mm) that mounts the stepper motor and extruder, furthermore four sets of screws/nuts/washers for mounting on the printer are also required.

Requirements

Body/Idler

1 x NEMA 17 Stepper motor

1 x Heatsink for Nema 17 stepper motor (optional)

If you printed the body with PLA filament, it would be better to attach a heatsink

1 x MK8 drive gear

Outer diameter: 9mm

Length: 11mm

Hob diameter: 7mm

Bore: 5mm

1‒2 x PC4-M6 push-fit connecter

1 x Threadlocker

Lock the thread on the push-fit connecter

1 x Soft pick

Used to clean the drive gear automatically

1 x 625ZZ bearing (or 625-2RS bearing)

1 x 608ZZ bearing (or 608-2RS bearing)

1 x Small sponge piece (idea from Marco67)

Put into the motor side rectangle hole on the extruder body (to fix the M3 nut position)

2 x M3x8mm pan head screws

When mounting Type C body with metal bracket, change to M3x10mm

2 x M3x10mm pan head screws

When mounting Type C body with metal bracket, change to M3x12mm

2 x M3x15mm pan head screws

2 x M3x40mm screws

Using the flat head screws makes it easier to insert and remove the spring compressor and makes it easier to evenly tighten the left and right screws

When using full thread screw, stick an adhesive tape on a place to touch the idler and the washer board, the idler movement is becomes smooth

2 x Compression springs

Wire diameter: 0.6‒0.8mm

Outer diameter: 5‒8mm

Free length: 12‒15mm

4 x M3 hex nuts

Mount (Type A)

2 x M3 screws

2 x M3 hex nuts

2 x M3 washers

Mount (Type B)

2 x M3 screws

2 x M3 t-slot nuts (or hex nuts)

Mount (Type C with metal bracket)

4 x M3 screws

4 x M3 hex nuts

4 x M3 washers

Print Settings

Body

Nozzle diameter: 0.4mm

Resolution: 0.2mm

Perimeter count: 4

Infill: 30% or higher

Idler

Resolution: 0.2mm

Perimeter count: 4

Infill: 90%

Bearing spacer

Resolution: 0.2mm

Motor spacer

Resolution: 0.2mm

Spring compressor

Resolution: 0.2mm

Washer board

Resolution: 0.2mm

Spring Compressor

The spring compressor has a function to quick release/restore the spring pressure.

Please attach it to the screw head when using the 3D printer, and remove it from the screw head when finished using the 3D printer.

The burden on idlers when 3D printers are not used decreases, and the idlers becomes hard to break.

CBE_IdlerSet*V2.stl

Changes from previous version

Made left and right idlers the same thickness

Reduced cylinder size

Related Thing

1.5 Axis Gimbal for NEMA 17

Similar models

thingiverse

free

![[idbox] Primary Extruder by mrm64](/t/8757992.jpg)

[idbox] Primary Extruder by mrm64

...

washer board

the washer board makes it easy to insert the spring compressor.

attach to the screw head protruding from the idler.

thingiverse

free

![[idbox] Secondary Extruder by mrm64](/t/8757582.jpg)

[idbox] Secondary Extruder by mrm64

...

washer board

the washer board makes it easy to insert the spring compressor.

attach to the screw head protruding from the idler.

thingiverse

free

Compact extruder for Prusa i3 and 42YF22GN050R (2engineers) geared motor with shaft support by denisc

... ...300

#define default_retract_acceleration 300

update 13-sep-2014

added long screws, springs, washers, nuts for idler.

thingiverse

free

Direct Drive Extruder MK8 by squareoctopus

...4 x 16mm hex-head screw

4 m4 x 20mm screw

1 m4 x 30mm screw

2 m4 x 12mm countersunk-head screw

1 compression spring

1 604 bearing

thingiverse

free

Nema 17 motor mount bracket P3Steel by jusebago

...thingiverse

nema 17 motor mount bracket for bowden extruder p3steel

3x m3 nuts.

2x m3 12mm screws..

1x m3 15mm screw, or longer.

thingiverse

free

Nema 17 motor mount bracket by dintid

...r mount bracket

needed a bracket for my universal belted extruder

bom

5x m3 nuts.

4x m3 8mm screws..

1x m3 15mm screw, or longer.

thingiverse

free

Alpha Direct Drive Extruder by engineglue

...upply list; this is a minimal design. you can use m4 bolts and nuts to mount it. it mounts to a standard aluminum mounting plate.

thingiverse

free

U-type direct drive extruder by Sharque

...

m3-nut - 3

m3 cap screw 40mm - 5

m3 cap screw 20mm - 2

m3 screw head noicheskoy - 1

4mm bearing - 1

direct drive gear mk7 or mk8

thingiverse

free

Schematix: Dual Drive Extruder (Fits E3D v6) by Schematix

....d 4mm o.d

springs (some experimentation may be required) however i use the following:

wire diameter: 0.7mm x 6mm o.d x 18mm long

thingiverse

free

C Extruder for MK8 gear and J-head by LordM

...ou can use the same bearings, spring and tension screws.

the plate is flexible having oval holes to be fixed on the x-carriage.

Mrm64

thingiverse

free

Simple S-Hook by mrm64

...simple s-hook by mrm64

thingiverse

simple s-hook

thingiverse

free

Chef's Knife Holder by mrm64

...chef's knife holder by mrm64

thingiverse

supports: no

thingiverse

free

![[idbox] Mini Hook by mrm64](/t/8746867.jpg)

[idbox] Mini Hook by mrm64

...[idbox] mini hook by mrm64

thingiverse

used to hang a binder clip.

thingiverse

free

Wire Shelving Safety Cap by mrm64

...wire shelving safety cap by mrm64

thingiverse

raft: yes

support: no

thingiverse

free

Cubic Filament Colorizer by mrm64

...cubic filament colorizer by mrm64

thingiverse

requirements

polyurethane foam sponge

refill ink for permanent marker

thingiverse

free

Tooth Brush Holder for Tray by mrm64

...tooth brush holder for tray by mrm64

thingiverse

tooth brush holder for tray

thingiverse

free

![[idbox] Top Corner Bracket by mrm64](/t/8779959.jpg)

[idbox] Top Corner Bracket by mrm64

...[idbox] top corner bracket by mrm64

thingiverse

[idbox] top corner bracket

thingiverse

free

![[idbox] Soft Pick Mount by mrm64](/t/8779355.jpg)

[idbox] Soft Pick Mount by mrm64

...[idbox] soft pick mount by mrm64

thingiverse

requirements: soft toothpick

support: no

thingiverse

free

Cone Head Spool Holder by mrm64

...cone head spool holder by mrm64

thingiverse

requirements: grease

resolution: 0.3mm-0.5mm

thingiverse

free

Melamine Foam Tool Holder by mrm64

...melamine foam tool holder by mrm64

thingiverse

requirements: melamine foam (30x30x30mm cube)

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Compact

3d_export

$5

compact freezer

...compact freezer

3dexport

the compact freezer is product about refrigeration machine

3d_ocean

$8

Compact Cassette

...

80s album analog audio cartridge cassette compact digital electronics lp mp3 music play record sound tape vinyl

compact cassette

design_connected

$20

Eames Compact

...eames compact

designconnected

herman miller eames compact computer generated 3d model. designed by eames, charles.

3d_ocean

$2

Compact Disc

...compact disc

3docean

album audio cd compact disc dvd laser disc movie music

a cd

3d_export

$10

land compacter

...land compacter

3dexport

turbosquid

$1

Compact knife

...quid

royalty free 3d model compact knife for download as obj on turbosquid: 3d models for games, architecture, videos. (1557900)

3d_export

$12

compact rotary broach

...compact rotary broach

3dexport

compact tool for drilling hexagonal holes in lathes!

turbosquid

free

Lada Compact

... 3d model lada compact for download as max, max, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1623122)

turbosquid

$59

Compact Truck

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Compact kitchen

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Plus

turbosquid

$2

plus-plus puzzle and lego

...d model plus-plus puzzle and lego for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1662633)

3ddd

$1

Стенка Plus

...стенка plus

3ddd

plus , модная мебель

фабрика "модная мебель", модель plus

3ddd

$1

Спальня METIS plus

... hulsta , metis , спальня

спальня metis plus

design_connected

$11

be plus B+

...be plus b+

designconnected

blå station be plus b+ chairs computer generated 3d model. designed by börge lindau.

design_connected

$11

Bank Plus

...bank plus

designconnected

röthlisberger kollektion bank plus coffee tables computer generated 3d model. designed by atelier oi.

3ddd

$1

elos Plus

... candela

elos plus — мультифункциональный аппарат для проведения лазерного и ipl лечений

3ddd

$1

Calligaris Even Plus

...calligaris even plus

3ddd

calligaris

calligaris_chair_even plus

design_connected

$29

Basket Plus

...nconnected

photo-realistic 3d models of the basket plus bed from bonaldo for 3d architectural and interior design presentations.

3ddd

free

Artpole Faktum Plus

... артполе , панель

artpole faktum plus

размеры:

высота 625мм

ширина 800мм

глубина 17мм

3ddd

$1

Мария / Jazz Plus

...мария / jazz plus

3ddd

мария

кухня фабрики мария модель__jazz plus

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.