Thingiverse

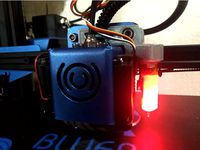

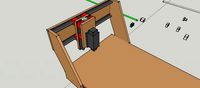

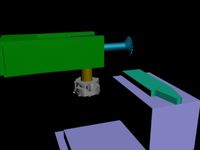

CNC Z-probe with a (small) microswitch by WalterSKW

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is a Z-probe for a CNC router. Basically I had issues with those cheap touchplates as I tended to forget to connect the wire to the bit...

So this is a design based on the microswitch one can find in the endstops for 3D-printers.

See the picture for the model.

(I you are looking for a model with a 'normal' microswitch : have a look here)

I mounted 2 RED LEDs (in series with a 100 ohm resistor / Not needed on a Stepcraft machine - I removed the resistor). Connection is in parallel with the switch.RED leds because of the lower forward voltage (~1,6V). If you want another color like blue you should use only one LED (Blue : ~3,3V)

The switch is connected with the C and the NC contacts.

I used piece of spare 8mm steel rod between the switch and the bit.

To flatten the ends, I used my pillar drilling machine and a piece of sandpaper.

Printed with a 0,4mm nozzle and 0,2mm layers in clear PETG.

The height correction is approx 30mm (depending on the piece of steel rod you use)

The repetitivity is excellent. 10 probes gave 10 identical values.

Some video'shttps://youtu.be/VvNJ-5EQj_Mhttps://youtu.be/08NVT6iv0V0https://youtu.be/A3sQ0L70QQghttps://youtu.be/MQkDcnywv6I

Can be checked with a macro I wrote for UCCNC :

// -----

// Purpose : Check probe for repeatability

// Author : WHu

// -----

// Date Version Remarks

// 20180825 1.0 Base

// -----

//

//

double Zmin = -100; //Max.Z depth

double Feedrate = 200; //Feedrate for probing

double retractheight = 20; //The retract height

double MinimumZ= 1000000; // Min measured Z height

double MaximumZ= -1000000; // Max measured Z Height

double AverageZ= 0; // Average Z height

double MaxDev=0; // Max registered deviation

double Deviation=0; // intermediate value, actual deviation

double MeasuredZ=0; // Actual measured Z height

int i=0; // loop counter

//

for(i=0; i<10;i++)

{

exec.Code("G31 Z" + Zmin + "F" + Feedrate); // Start probing

while(exec.IsMoving()){} // Wait until movement stopped

exec.Wait(1000); // Safety wait for the UC100 syncronisation

MeasuredZ=exec.GetZmachpos(); // read actual Z-height

AverageZ= AverageZ + MeasuredZ; // Add to average

if (MeasuredZif (MeasuredZ>MaximumZ) MaximumZ=MeasuredZ; // New maximum value ?

Deviation= Math.Abs(AverageZ/(i+1) - MeasuredZ);

if (Deviation > MaxDev) MaxDev = Deviation;

// Uncomment line below to show the intermediate value

//MessageBox.Show("Probe[" + (i+1) + "]: "+ MeasuredZ+"\nMin value :"+MinimumZ+"\nMax value :"+MaximumZ+"\nMax Deviation :"+MaxDev);

double Zup = exec.GetZmachpos() + retractheight;//Calculate the new coordinate for the retract of Z axis

exec.Code("G00 G53 Z" + Zup); //Retract the Z-axis

while(exec.IsMoving()){} // Wait until movement stopped

}

if(MaxDev<0.001) MaxDev=0; // Absurd to show these values. Even 0.001 is just a gimmick for the Stepcraft ...

MessageBox.Show("Average value :"+AverageZ/10+"\nMin value :"+MinimumZ+"\nMax value :"+MaximumZ+"\nMax Deviation :"+MaxDev);

So this is a design based on the microswitch one can find in the endstops for 3D-printers.

See the picture for the model.

(I you are looking for a model with a 'normal' microswitch : have a look here)

I mounted 2 RED LEDs (in series with a 100 ohm resistor / Not needed on a Stepcraft machine - I removed the resistor). Connection is in parallel with the switch.RED leds because of the lower forward voltage (~1,6V). If you want another color like blue you should use only one LED (Blue : ~3,3V)

The switch is connected with the C and the NC contacts.

I used piece of spare 8mm steel rod between the switch and the bit.

To flatten the ends, I used my pillar drilling machine and a piece of sandpaper.

Printed with a 0,4mm nozzle and 0,2mm layers in clear PETG.

The height correction is approx 30mm (depending on the piece of steel rod you use)

The repetitivity is excellent. 10 probes gave 10 identical values.

Some video'shttps://youtu.be/VvNJ-5EQj_Mhttps://youtu.be/08NVT6iv0V0https://youtu.be/A3sQ0L70QQghttps://youtu.be/MQkDcnywv6I

Can be checked with a macro I wrote for UCCNC :

// -----

// Purpose : Check probe for repeatability

// Author : WHu

// -----

// Date Version Remarks

// 20180825 1.0 Base

// -----

//

//

double Zmin = -100; //Max.Z depth

double Feedrate = 200; //Feedrate for probing

double retractheight = 20; //The retract height

double MinimumZ= 1000000; // Min measured Z height

double MaximumZ= -1000000; // Max measured Z Height

double AverageZ= 0; // Average Z height

double MaxDev=0; // Max registered deviation

double Deviation=0; // intermediate value, actual deviation

double MeasuredZ=0; // Actual measured Z height

int i=0; // loop counter

//

for(i=0; i<10;i++)

{

exec.Code("G31 Z" + Zmin + "F" + Feedrate); // Start probing

while(exec.IsMoving()){} // Wait until movement stopped

exec.Wait(1000); // Safety wait for the UC100 syncronisation

MeasuredZ=exec.GetZmachpos(); // read actual Z-height

AverageZ= AverageZ + MeasuredZ; // Add to average

if (MeasuredZ

Deviation= Math.Abs(AverageZ/(i+1) - MeasuredZ);

if (Deviation > MaxDev) MaxDev = Deviation;

// Uncomment line below to show the intermediate value

//MessageBox.Show("Probe[" + (i+1) + "]: "+ MeasuredZ+"\nMin value :"+MinimumZ+"\nMax value :"+MaximumZ+"\nMax Deviation :"+MaxDev);

double Zup = exec.GetZmachpos() + retractheight;//Calculate the new coordinate for the retract of Z axis

exec.Code("G00 G53 Z" + Zup); //Retract the Z-axis

while(exec.IsMoving()){} // Wait until movement stopped

}

if(MaxDev<0.001) MaxDev=0; // Absurd to show these values. Even 0.001 is just a gimmick for the Stepcraft ...

MessageBox.Show("Average value :"+AverageZ/10+"\nMin value :"+MinimumZ+"\nMax value :"+MaximumZ+"\nMax Deviation :"+MaxDev);

Similar models

thingiverse

free

Removable Bed Leveling Probes for Anycubic Kossel Linear V3 (with microswitch without lever) by unimatrix099

...shed and the mean value is 24.4 then the offset is set with command "m851 z-24.4" - the offset is minus the mean value

thingiverse

free

Mendel90 z-probe with microswitch and servo 9g by Ixotdog

...mendel90 z-probe with microswitch and servo 9g by ixotdog

thingiverse

mendel90 z-probe with microswitch and servo 9g

thingiverse

free

Alien Z Probe auto deploy and retract by JochemczykAndWard

...ct mechanism which is springless, decreasing the effector load. we have repeatedly taken sub 50micron readings using this probe.

thingiverse

free

CNC Z-probe with a (normal) microswitch by WalterSKW

... the original design for more info.

it is the same thing. only the bottom part has been modified to receive a larger microswitch.

thingiverse

free

Hypercube Evolution Diamond Extruder HXT900 Servo Microswitch Z Probe by Budiman7x

...t combine hypercube evolution, marlin 2.0, and cool diamond extruder (clone version)

the dual fan 40mm you can browse on my thing

thingiverse

free

Autolevel Probe Tip by sushiyaki

...probe tip for kossel mini.

i used it for my rostock machine with 2x m2 6mm screws and nuts.

video: http://youtu.be/wcph6fes2j4

thingiverse

free

Kossel Mini Custom Z Probe Retractable - 3mm probe by kalazzerx

...

all in all the probe is now a lot more sturdy that the original allen wrench version and i can make the probe any length i want!

thingiverse

free

Z probe by bjbsquared

...o level out material deviations when i cut items that are non-conductive. it consists of a push button switch and 2.5mm hardware.

thingiverse

free

TwoTrees Bluer 3dTouch suport by kakarotojmsc

...multiplicator_z 5"

"#define babystep_zprobe_offset "

https://www.paypal.com/donate?hosted_button_id=zqtmyur24g2ke

thingiverse

free

CrashProbe (Z auto leveling by Crash) by Dexerit

...8 x0 y0 ;home x and y only

g29 ;3 point bed probe

g1 z.5 f200 ;force probe retraction

source: http://reprap.org/wiki/crashprobe

Walterskw

thingiverse

free

2020 T-connector by WalterSKW

...2020 t-connector by walterskw

thingiverse

just a simple t-connector to connect to 2020-bars using 5mm bolts.

thingiverse

free

Endstop mount for 2040 extrusion by WalterSKW

...2040 extrusion by walterskw

thingiverse

another 2040 extrusion endstop mount

printed in pet with a 0,6mm nozzle and 0,4mm layers

thingiverse

free

Spacers for NEMA17 steppers (back) by WalterSKW

...spacers for nema17 steppers (back) by walterskw

thingiverse

several spacers to fill the gap...

2, 3, 4, 5, 6, 8 mm

thingiverse

free

Dettol Drip tray (DE) by WalterSKW

...ip tray (de) by walterskw

thingiverse

added a 'german' version with a cut out at the back.

see 'be' version here

thingiverse

free

Titan Aero & Volcano model by WalterSKW

...by walterskw

thingiverse

on request ...

the model i assembled for my printhead design.

feel free to use it for your own designs.

thingiverse

free

JBL Flip3 stand by WalterSKW

...lip3

printing

just print in whatever you like to print.

around 80mm bridging if you want to give that a try. otherwise : support!

thingiverse

free

Battery cover for LG G4 battery by WalterSKW

...ery cover for lg g4 battery by walterskw

thingiverse

simple cover for a lg g4 spare battery. (bl-51yf)

straightforward to print.

thingiverse

free

Peper and Salt grinder holder by WalterSKW

...r and salt grinder holder to avoid spilling salt and pepper on the table.

made for 65mm diameter grinders.

printed in black hips.

thingiverse

free

Endstop mount for 2040 extrusion (90°) by WalterSKW

...walterskw

thingiverse

an endstop mount for 2040 extrusion.

see pictures ...

printed in petg with a 0,6mm nozzle and 0,4mm layers

thingiverse

free

Pauls Y-Idlers for 3mm bearings by WalterSKW

...erse

someone (no not someone) asked me to make a version for 3mm bearings

this is a "redesigned" version of this thing

Microswitch

3d_export

$5

Microswitch

...microswitch

3dexport

microswitch<br>verts 287<br>faces 499

thingiverse

free

Microswitch With Roller12,7X5,6mm by scorpio_man30ro

...microswitch with roller12,7x5,6mm by scorpio_man30ro

thingiverse

microswitch with roller12,7x5,6mm

thingiverse

free

Microswitch hack by Terminus

...microswitch hack by terminus

thingiverse

turn a microswitch into an on / off switch.

thingiverse

free

Microswitch holder by rgthane

...microswitch holder by rgthane

thingiverse

this was designed for a cnc limit microswitch.

thingiverse

free

Microswitch holder by peze78

...microswitch holder by peze78

thingiverse

holder for microswitch for use in diy applications

thingiverse

free

Microswitch holder by bwitz

...icroswitch that is not part of a 3d printer. i needed this for my automated chicken coop to check if the door is open or closed.

thingiverse

free

Endstop Holder, Microswitch by PropsFactory

...endstop holder, microswitch by propsfactory

thingiverse

this is a small endstop holder for microswitch, 8mm rod

thingiverse

free

Microswitch by NilsR

...t as a reference test object as these microswitches are more or less the same over various manufacturers. this is the large type.

thingiverse

free

Silent microswitch for mouse

... diameter of 0.5mm.

i decline any responsibility for damage caused to the equipment in which these microswitches will be mounted.

thingiverse

free

X carriage with microswitch by Swejper

...oswitch by swejper

thingiverse

this is a remix to keep the microswitch on the carrier and use the original flsun v5 clone hotend

Probe

turbosquid

$25

Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Mars probe space space exploration lunar probe

...be space space exploration lunar probe for download as max on turbosquid: 3d models for games, architecture, videos. (1630876)

turbosquid

$35

Space Probe

...osquid

royalty free 3d model space probe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1571168)

turbosquid

$15

Space Probe

...osquid

royalty free 3d model space probe for download as obj on turbosquid: 3d models for games, architecture, videos. (1314864)

turbosquid

$25

Robot Probe

...y free 3d model robot probe for download as fbx, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1537490)

turbosquid

$1

Dental Probe

...e 3d model dental probe for download as ma, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1312400)

turbosquid

$60

Police Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Dental Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Space probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cassini Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

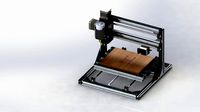

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Small

3d_export

$10

small bed

...small bed

3dexport

small bed design for small house or small room with storage

3d_export

$10

small house

...small house

3dexport

a small house. the project of a small country house.

3d_ocean

$4

Small Cake

...small cake

3docean

cake food small

just a small cake ready for render

3d_export

$6

small armchair

...small armchair

3dexport

small armchair

3d_export

$5

a small world

...a small world

3dexport

a small world

3d_export

$5

small room

...small room

3dexport

small cozy room

3d_export

$5

small tank

...small tank

3dexport

small tank modeling in blender

design_connected

free

small lounge

...small lounge

designconnected

free 3d model of small lounge

design_connected

$11

Watermelons Small

...watermelons small

designconnected

watermelons small computer generated 3d model.

3d_export

$5

small house

...small house

3dexport

a small cozy house on the foundation, the interior is missing.