CG Trader

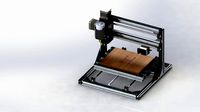

CNC Machine

by CG Trader

Last crawled date: 1 year, 10 months ago

CNC redirects here. For other uses, see CNC (disambiguation).

Numerics redirects here. For the field of computer science, see Numerical analysis.

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is sliced before the instructions (or the program) are generated. 3D printers also use G-Code. CNC is a vast improvement over non-computerized machining that must be manually controlled (e.g. using devices such as hand wheels or levers) or mechanically controlled by pre-fabricated pattern guides (see pantograph mill). In modern CNC systems, the design of a mechanical part and its manufacturing program are highly automated. The part's mechanical dimensions are defined using CAD software and then translated into manufacturing directives by computer-aided manufacturing (CAM) software. The resulting directives are transformed (by post processor software) into the specific commands necessary for a particular machine to produce the component and then are loaded into the CNC machine. Since any particular component might require the use of several different tools – drills, saws, etc. – modern machines often combine multiple tools into a single cell. In other installations, several different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD drawing.

Motion is controlling multiple axes, normally at least two (X and Y),[3] and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate movements, or in older designs, motors through a series of step-down gears. Open-loop control works as long as the forces are kept small enough and speeds are not too great. On commercial metalworking machines, closed-loop controls are standard and required to provide the accuracy, speed, and repeatability demanded. equipment machinery industrial tool medicine machine technology illustration business chemistry scientific industry presentation robot science advertising architecture isolated closeup contemporary industrial machine

Numerics redirects here. For the field of computer science, see Numerical analysis.

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is sliced before the instructions (or the program) are generated. 3D printers also use G-Code. CNC is a vast improvement over non-computerized machining that must be manually controlled (e.g. using devices such as hand wheels or levers) or mechanically controlled by pre-fabricated pattern guides (see pantograph mill). In modern CNC systems, the design of a mechanical part and its manufacturing program are highly automated. The part's mechanical dimensions are defined using CAD software and then translated into manufacturing directives by computer-aided manufacturing (CAM) software. The resulting directives are transformed (by post processor software) into the specific commands necessary for a particular machine to produce the component and then are loaded into the CNC machine. Since any particular component might require the use of several different tools – drills, saws, etc. – modern machines often combine multiple tools into a single cell. In other installations, several different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD drawing.

Motion is controlling multiple axes, normally at least two (X and Y),[3] and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate movements, or in older designs, motors through a series of step-down gears. Open-loop control works as long as the forces are kept small enough and speeds are not too great. On commercial metalworking machines, closed-loop controls are standard and required to provide the accuracy, speed, and repeatability demanded. equipment machinery industrial tool medicine machine technology illustration business chemistry scientific industry presentation robot science advertising architecture isolated closeup contemporary industrial machine

Similar models

cg_trader

$11

CNC Machine

...chnology equipment machine machinery electronics mechanical tool robot power connection electricity industrial industrial machine

grabcad

free

CNC machine

...ifications by following a coded programmed instruction and without a manual operator directly controlling the machining operation

cg_trader

$18

CNC Machine

...ifications by following coded programmed instructions and without a manual operator directly controlling the machining operation.

grabcad

free

CNC Machine

...mputer software, which is embedded inside the tools. cnc is commonly used in manufacturing for machining metal and plastic parts.

grabcad

free

CNC Router Machine

...are embedded in a microcomputer attached to the tool. it is commonly used in manufacturing for machining metal and plastic parts.

grabcad

free

CNC Create Programming Instruction Works Machine Tools Manufacturing Process

...cnc create programming instruction works machine tools manufacturing process

grabcad

computer numerical control programming

grabcad

free

CNC milling design.

...e end result of the machining process is a specific part or product that is created using a computer aided design (cad) software.

grabcad

free

CNC Router

...e opposite of “old-school” devices that are manually controlled by hand wheels or levers, or mechanically automated by cams alone

grabcad

free

CNC Router

...ntrolled machine that uses computer programming to control a high speed rotating cutter to perform cutting and shaping operations

grabcad

free

CNC Milling Machine

... 3d profile. use cam software to make the program g code to instruct servo motor then the cutter moving along the path of g code.

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

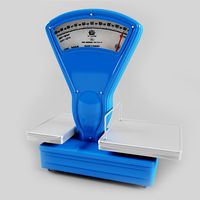

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.