Thingiverse

CNC Eye Protection for laser engraving ( 1610 / 2418 / 3018 ) by SnitDesigns

by Thingiverse

Last crawled date: 3 years ago

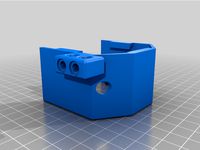

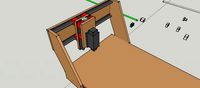

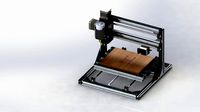

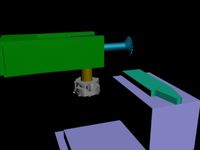

I created this thing with Tinkercad to attach to my CNC Fan Mounthttps://www.thingiverse.com/thing:2954044

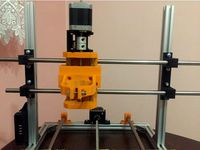

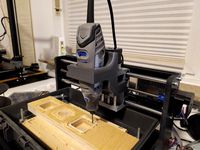

to provide some basic protection for nearby eyes whilst engraving. As stated in the Fan Mount thing I believe the X-Z carriage for all the machines listed are the same so it should fit them - the pictures here are on my 3018 and most were taken during engraving.

NOTE I am NOT an eye doctor, engineer, optics specialist, safety expert, etc. - in fact I'm not that bright at all so if you somehow find a way whilst using this device to damage your eyesight, hearing, libido, etc. with your laser engraver I am not responsible! My engraver is on a desk adjoining my main work area and this thing keeps casual glances and passing family from getting the full impact of reflected laser energy. Always wear your safety glasses when dealing with lasers! All that being said the curtain appears safe to view the laser through but it doesn't cover all areas of exposure 100%.

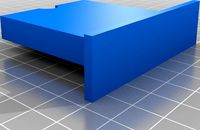

The one tricky bit on this build will be finding the material to block the light. I'm using some "Welders Curtain" that I managed to acquire from the machine shop where I work, normally the "curtain" comes in large (4', 6', etc.) panels which when attached to a frame can be used to block the light from a welder at work. I failed to find any supplier of smaller pieces of this material so if you know a welder and can get some great, otherwise this may not be for you. There are probably other materials that could be used that I'm unaware of, there is a 1mm allowance for thickness in the curtain holder designs to accommodate the "curtain".

I wanted to be able to pop this item on and off when needed so I didn't want to use hardware, I've created some spring clips on the parts - safe to say that despite my best efforts prints this small will always be fragile and these clips are no exception(!). You're more likely to break them when assembling/disassembling the frame, once they are in place on the machine the forces from the CNC moving will not harm them, and even if you break a piece or two off the overall effect of all the clips will (probably) keep it attached just fine.

There is a picture with a rough template for the curtain material, note this was my first attempt and if/when I cut a new one I will extend forward and backward a little to allow some overlap at the back of the machine and a bit better gap-coverage with the fan at the front of the machine.

I generally engrave thin wood so the curtain in this case rides about 4mm above the actual CNC surface.

to provide some basic protection for nearby eyes whilst engraving. As stated in the Fan Mount thing I believe the X-Z carriage for all the machines listed are the same so it should fit them - the pictures here are on my 3018 and most were taken during engraving.

NOTE I am NOT an eye doctor, engineer, optics specialist, safety expert, etc. - in fact I'm not that bright at all so if you somehow find a way whilst using this device to damage your eyesight, hearing, libido, etc. with your laser engraver I am not responsible! My engraver is on a desk adjoining my main work area and this thing keeps casual glances and passing family from getting the full impact of reflected laser energy. Always wear your safety glasses when dealing with lasers! All that being said the curtain appears safe to view the laser through but it doesn't cover all areas of exposure 100%.

The one tricky bit on this build will be finding the material to block the light. I'm using some "Welders Curtain" that I managed to acquire from the machine shop where I work, normally the "curtain" comes in large (4', 6', etc.) panels which when attached to a frame can be used to block the light from a welder at work. I failed to find any supplier of smaller pieces of this material so if you know a welder and can get some great, otherwise this may not be for you. There are probably other materials that could be used that I'm unaware of, there is a 1mm allowance for thickness in the curtain holder designs to accommodate the "curtain".

I wanted to be able to pop this item on and off when needed so I didn't want to use hardware, I've created some spring clips on the parts - safe to say that despite my best efforts prints this small will always be fragile and these clips are no exception(!). You're more likely to break them when assembling/disassembling the frame, once they are in place on the machine the forces from the CNC moving will not harm them, and even if you break a piece or two off the overall effect of all the clips will (probably) keep it attached just fine.

There is a picture with a rough template for the curtain material, note this was my first attempt and if/when I cut a new one I will extend forward and backward a little to allow some overlap at the back of the machine and a bit better gap-coverage with the fan at the front of the machine.

I generally engrave thin wood so the curtain in this case rides about 4mm above the actual CNC surface.

Similar models

thingiverse

free

CNC Fan Mount for laser engraving ( 1610 / 3018 / 2418 ) by SnitDesigns

...g:2984605

if you need to adapt to flexible ducting of a different dimension i recommend:https://www.thingiverse.com/thing:1015874

thingiverse

free

CNC 3018 Pro Cable Tidy Set | Remixed for 10mm Bakelite sides by moose9999456456465

...ame.

i printed without supports - even the 'foot' on the 10mmx60mm clip was fine.

many thanks to les for the great thing!

thingiverse

free

CNC 3018 - Laser Holder

...nc-router-adjustable-speed-spindle-motor-wood-engraving-machine-milling-engraver-p-1463876.html?rmmds=search&cur_warehouse=cn

thingiverse

free

CNC 3018 Pro Circuit Board Box

...protective box with cooling fan mounting for cronos and similar cnc/laser electronics board which have mounting holes 90mm x...

grabcad

free

Laser Rotary Attachment for K40

... k40 cutting/engraving machine. almost all parts are made with 3d printer. all notification you will find in 2d assembly drawing.

thingiverse

free

diy laser engraver from cd-rom cnc by Danissimo

...rint them) you dont need the detail "crutch", maybe.

my laser is the cheapest laser on aliexpress https://goo.gl/qzcju5

thingiverse

free

CNC 3018 Milling Bits Holder by 3DanielW

...this upgrade part for the "woodpecker cnc 3018" and similar engraving machines (1610, 2418) is designed to add a...

thingiverse

free

CNC 3018 Tool Head Cable Grips by 3DanielW

...these upgrade parts for the "woodpecker cnc 3018" and similar engraving machines (1610, 2418) are designed to secure the...

thingiverse

free

Mini Laser Engraver Upgrade Parts by profhankd

...ation of your laser. i'm just describing what i did to my machine in an attempt to reduce the risk and improve functionality.

grabcad

free

CNC Laser

...cnc laser

grabcad

cnc laser engraving machine with a working area of 0.5x0.5 m

Snitdesigns

thingiverse

free

Cable Holder - 20mm surface by SnitDesigns

...ally the same as the 16mm cable holder (aside from fitting a 20mm surface), modified slightly to fit my wife's bedside table.

thingiverse

free

Cable Holder - 16mm surface by SnitDesigns

...16mm), as shown it fits over a molded edge on wood furniture and holds standard small usb charging cables. designed in tinkercad.

thingiverse

free

4 Port USB 3.0 Powered Hub Mount by SnitDesigns

...ld your usb hub securely in any orientation

see also my 7 port usb 3.0 powered hub mounthttps://www.thingiverse.com/thing:4870605

thingiverse

free

7 Port USB 3.0 Powered Hub Mount by SnitDesigns

...d your usb hub securely in any orientation.

see also my 4 port usb 3.0 powered hub mounthttps://www.thingiverse.com/thing:4872448

thingiverse

free

Ikea LINNMON cable holder by SnitDesigns

...hold hdmi, ethernet, power cables, etc. so i designed this on tinkercad.

it fits ikea linnmon and/or any other 34mm desktop/shelf

thingiverse

free

Anet A8 Circular Extruder Fan - lowered (various lengths) by SnitDesigns

... else can use it.

these fans will likely collide with any clips you may have around the edge of your heatbed so plan accordingly.

thingiverse

free

CNC Fan Mount for laser engraving ( 1610 / 3018 / 2418 ) by SnitDesigns

...g:2984605

if you need to adapt to flexible ducting of a different dimension i recommend:https://www.thingiverse.com/thing:1015874

2418

3d_export

$15

Living room 3D Model

...living room drawing bookcase living room 3d model slimerrr2007 2418 ...

3d_export

$7

Bug low poly

...include: maya 2014, 3d max 2014, obj, fbx<br>faces: 1284<br>tris: 2418lt;br>verts: 1214<br>hope u like it,<br>thank...

3d_export

$8

european family house with underground garage

...with underground garage 3dexport contains 2 lod levels<br>(lod0)<br>5966 vertices<br>9149 triangles<br>(lod1)<br>2418 vertices<br>2994 triangles<br>edge loop based topology, unnecessary loops removed/connected<br>performance packed...

3d_export

free

9 knots

...of 8 (abok 420, 520, 570)<br>7 true love (abok 2418<br>8 overhand (abok 4, 514)<br>9 bow (abok 1212, 2403,...

3d_export

$17

Medieval Sawmill Mechanism

...-roughness -ao polycount -verts: 2154(lod0),1751(lod1),1546(lod2),1220(lod3). -edges: 4479(lod0),4101(lod1),3602(lod2),2785(lod3). -faces: 2393 (lod0),2418lod1),2124(lod2),1633(lod3). -tris: 4172 (lod0),3366(lod1),2956(lod2),2304(lod3). file formats: -fbx(binary) 2019 -fbx(ascii) 2019...

3d_export

$10

Circular Saw

...-normal (directx) -color -roughness -ao polycount -verts: 1160(lod0),1040(lod1),940(lod2),760(lod3). -edges: 2418lod0),2178(lod1),1994(lod2),1618(lod3). -faces: 1260 (lod0),1140(lod1),1056(lod2),860(lod3). -tris: 2316 (lod0),2076(lod1),1876(lod2),1516(lod3). file formats: -fbx(binary)...

3d_export

$12

Blueberry Crate Box

...color<br>- roughness<br>- ao<br>polycount( blueberry crate box)<br>- verts: 3942(lod0),2804(lod1),1582(lod2),906(lod3).<br>- edges: 10987(lod0),7925(lod1),4339(lod2),2418lod3).<br>- faces: 7102 (lod0),5178(lod1),2814(lod2),1570(lod3).<br>- tris: 7599(lod0),5338(lod1),2954(lod2),1636(lod3).<br>file formats: -fbx(binary) 2019 -fbx(ascii)...

3d_export

$29

Sawmill Mechanism with Storage

...polycount (sawmill mechanism) -verts: 2154(lod0),1751(lod1),1546(lod2),1220(lod3). -edges: 4479(lod0),4101(lod1),3602(lod2),2785(lod3). -faces: 2393 (lod0),2418lod1),2124(lod2),1633(lod3). -tris: 4172 (lod0),3366(lod1),2956(lod2),2304(lod3). polycount (3 standart logs and 3...

3d_export

$40

Sawmill and Warehouse

...polycount (sawmill mechanism) -verts: 2154(lod0),1751(lod1),1546(lod2),1220(lod3). -edges: 4479(lod0),4101(lod1),3602(lod2),2785(lod3). -faces: 2393 (lod0),2418lod1),2124(lod2),1633(lod3). -tris: 4172 (lod0),3366(lod1),2956(lod2),2304(lod3). polycount (3 standart logs and 3...

3d_export

$79

Sawmill and Lumberjack Set

...polycount (sawmill mechanism) verts: 2154(lod0),1751(lod1),1546(lod2),1220(lod3). edges: 4479(lod0),4101(lod1),3602(lod2),2785(lod3). faces: 2393 (lod0),2418lod1),2124(lod2),1633(lod3). tris: 4172 (lod0),3366(lod1),2956(lod2),2304(lod3). file formats: -fbx(binary) 2019 -fbx(ascii) 2019...

1610

turbosquid

$15

human-1610

...turbosquid

royalty free 3d model human-1610 for download as on turbosquid: 3d models for games, architecture, videos. (1146353)

design_connected

$11

MI T-1610

...mi t-1610

designconnected

horgenglarus mi t-1610 computer generated 3d model.

3ddd

free

Vermont Castings Defiant NC 1610

...

модель: defiant nc 1610

описание: дровяная печь / камин

сайт:http://www.vermontcastings.com/products.asp?model=defiant

3d_export

$8

bracelet lock 1610 mm

...ach others and then enjoy your bracelet. i don't recommend to rescale this model, order to create the lock same as your wish.

3ddd

$1

Best / Quadra

...quadra 3ddd best , вытяжка вытяжка пристенная best quadra. 1610 полигонов. wall mounted range hood best quadra. 1610 polygons....

3ddd

$1

Двери Barausse

...двери barausse 3ddd двери , barausse двери barausse 1610 burano pu 1610 burano vu материалы corona и vray...

3ddd

$1

Двери Barausse

...двери barausse 3ddd двери , barausse двери barausse 1610 burano ppp 1610 burano vpp материалы corona и vray...

3ddd

$1

Двери Barausse

...двери barausse 3ddd двери , barausse двери barausse 1610 burano pp 1610 burano vp материалы corona и vray...

3ddd

$1

Camelgroup / Firenze Day

...firenze day 3ddd camel group , комод комод: 107bfc.01fd (l.1610 p.630 h.1050) производитель: camelgroup (италия) коллекция : firenze day...

3ddd

$1

Lexington Dakota

...lexington dakota 3ddd lexington lexington dakota chair item: 161011 dimensions: 29½w x 35d x 41h in. inside width:...

3018

3d_export

$5

Cartoon Black Bus Car

...triangulated for the game engine. total number of polygons: 3018 ...

thingiverse

free

CNC 3018 by Assomer

...cnc 3018 by assomer

thingiverse

accessoire pour cnc diy 3018

3dfindit

free

3017, 3018

...3017, 3018

3dfind.it

catalog: 80/20

thingiverse

free

aspiration 3018

...rse

support pour brosse aspiration fraiseuse 3018

la brosse fait 69x43 mm

brosse ancien aspirateur je ne connais plus la marque

thingiverse

free

CNC 3018 rod mount

...cnc 3018 rod mount

thingiverse

rod mount for cnc 3018.

thingiverse

free

Outillage CNC 3018 Pro

...outillage cnc 3018 pro

thingiverse

ranger vos principaux outils cnc 3018 pro

thingiverse

free

CNC 3018 Calibrator by digital_technology_factory

...cnc 3018 calibrator by digital_technology_factory

thingiverse

this is a part to calibrate the rods of the z axis of the cnc 3018

thingiverse

free

CNC 3018 Dremel Mount

...d.com/custlink/vvdv4y6oc6https://amzn.to/2bjkmil

dremel 3000https://amzn.to/36bt4f9

(affiliate links! if you want to support me.)

thingiverse

free

CNC 3018 Clamp protection

...lamp protection

thingiverse

designed to protect the aluminium of the cnc 3018 and protect the wood

with a little power it fits.

thingiverse

free

CNC 3018 tools organizer

...cnc 3018 tools organizer

thingiverse

this is a tools organizer for my cnc 3018 that i designed.

feel free to use.

Engraving

turbosquid

$8

Engraved Sword

...alty free 3d model engraved sword for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1168563)

turbosquid

$10

Engraved tiger

...ree 3d model engraved tiger for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1298214)

turbosquid

$1

Engraver(General)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Seax Knife Engraved

...model seax knife engraved for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1497294)

3d_export

$5

scary monster engraving

...nal engraving for 3d printing will give your environment an exotic look! it will look great if you paint it in the color of stone

turbosquid

$59

Emerald Engraving Ring

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Runes Engraving Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Decoration Engraved table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Viking helmet with engraved

...met with engraved for download as c4d, 3ds, dxf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1618783)

turbosquid

$5

Engraved coffee cup

...ved coffee cup for download as blend, dae, fbx, obj, and gltf on turbosquid: 3d models for games, architecture, videos. (1713648)

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Eye

3ddd

$1

Best / Eye Eye

...пристенная best eye eye.

1660 полигонов.

wall mounted range hood best eye eye.

1660 polygons.

file: max 2010, 2012; fbx; obj.

3d_export

$5

eyes

...eyes

3dexport

eyes

3d_ocean

$5

3D EYE

...ocean

body cornia dynamic eye eye eyes human human eye iris nurbs eye organ

detailed eye . purchase and use it for any purpose ..

3d_ocean

$5

3d Eye

...3d eye

3docean

3d eye eyes

this is 3d eye model

3d_export

$5

Human eye

...human eye

3dexport

human eye, iris, eyeball, eye anatomy

turbosquid

free

Eye

...eye

turbosquid

free 3d model eye for download as c4d on turbosquid: 3d models for games, architecture, videos. (1429061)

turbosquid

free

Eyes

...eyes

turbosquid

free 3d model eyes for download as blend on turbosquid: 3d models for games, architecture, videos. (1153269)

turbosquid

$25

eye

...e

turbosquid

royalty free 3d model eye for download as blend on turbosquid: 3d models for games, architecture, videos. (1371896)

turbosquid

$10

Eye

...eye

turbosquid

royalty free 3d model eye for download as c4d on turbosquid: 3d models for games, architecture, videos. (1303492)

turbosquid

$5

Eye

...e

turbosquid

royalty free 3d model eye for download as blend on turbosquid: 3d models for games, architecture, videos. (1343488)

Protection

archibase_planet

free

Protection

...protection

archibase planet

protection

protection - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$10

Protective shelter

...protective shelter

3dexport

military protective cover for laser and soldier

3d_export

free

protective helmet

...protective helmet

3dexport

this is a helmet to protect the standard human head. in the archive there are textures.

3d_export

$5

Protected Diamonds

...protected diamonds

3dexport

two textured diamonds protected by a fictitious-style pedestal and a glass

turbosquid

$28

Mask helmet protection scifi futuristic protection

... scifi futuristic protection for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1551702)

archive3d

free

Protection 3D Model

...d model

archive3d

protection

protection - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

protected pressure gauge

...protected pressure gauge

3dexport

protected pressure gauge

turbosquid

$150

protection character

... model protection character for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366331)

3d_export

$5

mask medical protection

...mask medical protection

3dexport

medical protection equipment 3d model

3d_export

$6

face protect mask

...

a face protect mask is a personal protective equipment to from potentially infectious materials. file formats: sldprt, step, stl

Cnc

3d_export

$35

Cnc

...cnc

3dexport

the cnc machine is unfinished

3d_export

$10

cnc router

...cnc router

3dexport

prototipe cnc router

3d_export

$10

cnc machine

...cnc machine

3dexport

cnc machine model with individual model files with assembly

3d_export

$5

Cnc 3D Model

...cnc 3d model

3dexport

cnc

cnc 3d model csiszar 61289 3dexport

turbosquid

$10

cnc bedroom

...osquid

royalty free 3d model cnc bedroom for download as max on turbosquid: 3d models for games, architecture, videos. (1494981)

turbosquid

$9

cnc(wood)

...rbosquid

royalty free 3d model cnc(wood) for download as max on turbosquid: 3d models for games, architecture, videos. (1189189)

turbosquid

$1

CNC Frame

...rbosquid

royalty free 3d model cnc frame for download as stl on turbosquid: 3d models for games, architecture, videos. (1371706)

turbosquid

free

cnc table

...rbosquid

royalty free 3d model cnc table for download as max on turbosquid: 3d models for games, architecture, videos. (1500926)

turbosquid

$30

CNC Lathe

...

royalty free 3d model cnc lathe for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1284634)

turbosquid

$25

CNC Machine

...

royalty free 3d model cnc machine for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1307199)