Thingiverse

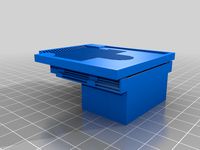

Chirpy's Cheapy Hotend by cae2100

by Thingiverse

Last crawled date: 2 years, 12 months ago

Im sorry or all of the reading, but here's my hotend.

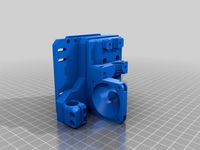

My hotend is built from a piece of oak dowel rod that I had laying around, a 3mm OD, 2mm ID ptfe tube that I got on ebay for really cheap, a piece of a heatsink from a power supply (solid aluminum block), a 1 inch piece of a 6mm bolt with a 3mm hole drilled through it, and a welding MIG tip. Most of this can be found in your garage, the trash, or at walmart, lol. The rest of what you need is just generic hotend parts from wherever you normally get them.

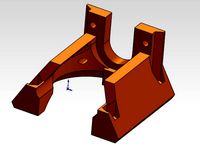

As Ive shown in the drawings, the thermal break is 32mm long with a 2mm hole drilled longways through it. Then drill a hole 3mm though it till 3mm from the end, and a 5mm hole 14mm into the piece of wood so it matches the drawing above, then just use a drill bit and turn it with your fingers to taper off the top. I then used my 1/4th inch hole cleaner tool, but you can just use a 1/4th inch or 6mm die to cut threads into the dowel rod so it fits in well.

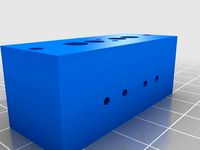

The heater block is just a 10mmx20mmx16.5mm aluminum block that was cut from the heatsink with a 6mm hole drilled through the side/end for the heater element, a threaded m6 or 1/4th inch hole, and a 3mm hole, threaded for a screw in thermistor, but you can just put the thermistor in the hole instead.

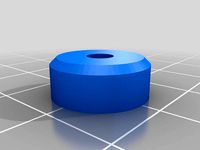

The metal tube that connects the heater block and everything together, that's just a 1/4th inch(6mm) stainless steel bolt that I cut off the head so it's just a hollow bolt with a 3mm 1/8th inch hole through the middle of it. It's around a 1 inch (25.4mm) long. I also put a simple washer and a nut on the bolt, then screwed it in so it locked everything tight against the thermal break(oak piece)

The tip is threaded and the original threads of the MIG tip is cut off, the threads of the tip will go 5mm(half way into the heater block) and stick out around 7.5mm, just use a hammer and file to smooth down the nozzle like you see in wildseyed's hotend. I drilled mine 2mm till almost 1mm from the end of the tip, almost to the very tip of the nozzle. Then I drilled 3mm into around 2mm from the opening so it goes from 3mm hole, to 2mm hole, then the end of the nozzle.

Lastly, you need to run the 3mm OD, 2mm ID ptfe tubing as far as it will go into the hollow bolt and thermal break, then cut it off a hair over 2mm from the end of the bolt so it overhangs just slightly. This is so that when you put it together, it'll self seal itself up and wont leak.

I put the nozzle in first and tightened it up, then put the bolt attached inside of the oak rod in, and tighten it up, it'll seal it up. Just use some PTFE plumbers tape on the threads going into the heater block so you never have to worry about any leaks.

Ive only used this hotend with PLA, and it works perfectly with that, but I cant see any issues why it wouldnt work with ABS also.

Ive been using this hotend on my homemade prusa i2, and it's performed perfectly since it's been built. Before anyone asks about max temps and such, truth is, Im not sure what it would be but probably is around 240s or so due to the ptfe in it.

EDIT: here's a video of the printer running with the hotend:https://www.youtube.com/watch?v=c5UHJzLdNJk

My hotend is built from a piece of oak dowel rod that I had laying around, a 3mm OD, 2mm ID ptfe tube that I got on ebay for really cheap, a piece of a heatsink from a power supply (solid aluminum block), a 1 inch piece of a 6mm bolt with a 3mm hole drilled through it, and a welding MIG tip. Most of this can be found in your garage, the trash, or at walmart, lol. The rest of what you need is just generic hotend parts from wherever you normally get them.

As Ive shown in the drawings, the thermal break is 32mm long with a 2mm hole drilled longways through it. Then drill a hole 3mm though it till 3mm from the end, and a 5mm hole 14mm into the piece of wood so it matches the drawing above, then just use a drill bit and turn it with your fingers to taper off the top. I then used my 1/4th inch hole cleaner tool, but you can just use a 1/4th inch or 6mm die to cut threads into the dowel rod so it fits in well.

The heater block is just a 10mmx20mmx16.5mm aluminum block that was cut from the heatsink with a 6mm hole drilled through the side/end for the heater element, a threaded m6 or 1/4th inch hole, and a 3mm hole, threaded for a screw in thermistor, but you can just put the thermistor in the hole instead.

The metal tube that connects the heater block and everything together, that's just a 1/4th inch(6mm) stainless steel bolt that I cut off the head so it's just a hollow bolt with a 3mm 1/8th inch hole through the middle of it. It's around a 1 inch (25.4mm) long. I also put a simple washer and a nut on the bolt, then screwed it in so it locked everything tight against the thermal break(oak piece)

The tip is threaded and the original threads of the MIG tip is cut off, the threads of the tip will go 5mm(half way into the heater block) and stick out around 7.5mm, just use a hammer and file to smooth down the nozzle like you see in wildseyed's hotend. I drilled mine 2mm till almost 1mm from the end of the tip, almost to the very tip of the nozzle. Then I drilled 3mm into around 2mm from the opening so it goes from 3mm hole, to 2mm hole, then the end of the nozzle.

Lastly, you need to run the 3mm OD, 2mm ID ptfe tubing as far as it will go into the hollow bolt and thermal break, then cut it off a hair over 2mm from the end of the bolt so it overhangs just slightly. This is so that when you put it together, it'll self seal itself up and wont leak.

I put the nozzle in first and tightened it up, then put the bolt attached inside of the oak rod in, and tighten it up, it'll seal it up. Just use some PTFE plumbers tape on the threads going into the heater block so you never have to worry about any leaks.

Ive only used this hotend with PLA, and it works perfectly with that, but I cant see any issues why it wouldnt work with ABS also.

Ive been using this hotend on my homemade prusa i2, and it's performed perfectly since it's been built. Before anyone asks about max temps and such, truth is, Im not sure what it would be but probably is around 240s or so due to the ptfe in it.

EDIT: here's a video of the printer running with the hotend:https://www.youtube.com/watch?v=c5UHJzLdNJk

Similar models

thingiverse

free

Mighty Mite Table Saw Fence by cae2100

...rcuit boards, to help keep the cuts straight.

for the handle, i used this printed at 96%:http://www.thingiverse.com/thing:11405

thingiverse

free

BQ Hotend DIY by maot1985

...lex kk396 connectors. i attached a kk396 header to the original heater cartridge cable in order to use the original hotend again.

thingiverse

free

Cooling duct for plexi anet A8 clone by kulek

...with hot filament dripping from the nozzle with cooler on, it's spinning clockwise.

this printer is anet made from 6mm plexi.

thingiverse

free

mk10 red hotend mount for prusa i3 cr-10 by netpipe

...at tube.

if the 1/8 x 3/4 inch bolts dont fit in the red hotend just thread them in there with a square bit and drill with force.

thingiverse

free

Rope Cutter by SomePerson7979

...f that. just pull the rope through the hole, wrap it around the bottom and in to the blade groove. wiggle a bit and it's cut.

thingiverse

free

E3D Direct Mount for Wanhao Di3 by abitidi

...d inserts to put it all together because that's what i had on hand. i may add a version with encapsulated nuts in the future.

thingiverse

free

DrillAndFile DIY Hot End by Stemer114

... that is, 6 more to go.

the detailed documentation for the hot end is available at http://reprap.org/wiki/drillandfile_hot_end

thingiverse

free

2 fan duct for larger J Head nozzles by McSquid

...dn't end up in the right place so i needed to drill new ones 6mm to the right but this should work for most people out there.

thingiverse

free

Extruder for Geared stepper motor 1:50 with Ceramic Hotend Chess from 2engineers by capitaenz

... feedback from edwyn:

"put a piece of ptfe btween the nozzle and ceramic part."

i'll try it when i have time again.

thingiverse

free

hybrid PTFE/wood insulator by whosawhatsis

...tter insulator than ptfe/peek, this may be a viable alternative, and the material costs should be lower than existing insulators.

Chirpy

thingiverse

free

Chirpy's CNC by cae2100

...ts above added into the file, it's just a rough doodle that serves it's purpose just to see what the full cnc looks like.

thingiverse

free

T&C Grinder Patterns/Parts

...build that im doing on youtube under the name "chirpy#39;s tinkerings". ill add more patterns and blueprints as the...

grabcad

free

chirpy’s head stone

...one

grabcad

i made this for my sons bird when it passed on,, then cut it in plastic and now its in the yard covered with flowers

Cheapy

thingiverse

free

3A buck converter case by evilbender

...by evilbender thingiverse quick and dirty case for the cheapy 3a buck...

thingiverse

free

Dial Gauge Holder by UechiMike

...m to aid in leveling. using this i was able to square the platform within 0.025 mm (0.001") - which is close enough for me.

thingiverse

free

UNI-T UT120C Case

...the ut120c to be a really good all around cheapy meter for the basics around the lab and on...

thingiverse

free

closet rod holder, 1-3/8'' (35mm)

...another closet rod holder. the existing ones were just cheapy plastic, so i made these in solidworks, and printed...

thingiverse

free

Flashlight holder for Pistol by JustinSpanier

...project. i modeled it to hold one of those cheapy flashlights that you get at harbor freight, since i...

thingiverse

free

Armadillo pen or toothbrush holder by harddrv1

...item mostly for looks. will hold only 1 standard cheapy electric tooth brush or 1 large pen (may hold...

thingiverse

free

CR10v2 Y Carriage Linear Rail Adapters by Jmpr_Lite

...clean and lube the rails before installing. materials: 2x cheapy 450mm mgn12h rails. 4x m5 12mm screws and used...

thingiverse

free

Nerdtacular EDC Pocket Caddy by ednegari

...ll upright in your front pocket.

designed in tinkercad: https://www.tinkercad.com/things/ambhttxowt2-nerdtacular-edc-pocket-caddy

thingiverse

free

Quick and Simple LIPO Voltage Tester by AndyGadget

... of the cheapie chinese led voltmeters and just designed the 3d printed housing and added the test prongs. (print other way up!)

Cae2100

thingiverse

free

crucible by cae2100

...crucible by cae2100

thingiverse

basic crucible shapes

thingiverse

free

Robotnik Logo by cae2100

...robotnik logo by cae2100

thingiverse

its just robotnik logo from sonic the hedgehog games.

thingiverse

free

nuclear storage container by cae2100

...rse

it's just a container for storing stuff in, looks great if printed in fluorescent filament and used around a blacklight.

thingiverse

free

fixed Robot_arm_MG995_micro_v2 for mg955 servo base by cae2100

...fixed robot_arm_mg995_micro_v2 for mg955 servo base by cae2100

thingiverse

fixed robot_arm_mg995_micro_v2 for mg955 servo base

thingiverse

free

Gingery Lathe addons by cae2100

...se

these are the addons for the basic gingery lathe including face plate, 2 jaw chuck parts, 4 jaw chuck parts, and steady rest.

thingiverse

free

7/16 rod holders by cae2100

...7/16 rod holders by cae2100

thingiverse

end pieces to bolt down a piece of 7/16 smooth rod for a basic cnc.

thingiverse

free

12v rotary tool mount by cae2100

...t by cae2100

thingiverse

mounts for this for use on desktop cnc:http://www.harborfreight.com/80-piece-rotary-tool-kit-97626.html

thingiverse

free

7/16 bearing by cae2100

...ne, just for temporary bearings to hold everything together. ill probably recast them in hdpe later on, but they work good as is.

thingiverse

free

Die Filer Patterns by cae2100

...casting, print die_filer and die_filer(r) for the two halves, they have a 5/16 hole or 8mm hole in the pattern for locating pins.

thingiverse

free

Angles by cae2100

...u need.

i made these for drawing cut lines on angle iron to make drafts on ingot trays for metal casting so they come out easily.

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.