Thingiverse

Cherry Pi III by AndyCart

by Thingiverse

Last crawled date: 3 years ago

Update 19/08/2014

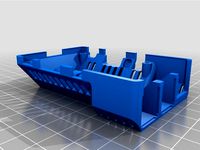

Added improved filament spool holder and disc and also a wiring grommet for where the cable bundle from the hot end and extruder stepper pass through the Z tower extrusion. The hole in the extrusion should be drilled 180mm from the base of the Z tower stepper mount. This allows full travel on the Z carriage with the 225mm rods (tube length) that I use with the 8mm drilled ball bearing and spring/string retention system. I normally drill two 5mm holes adjacent to each other and file the bridge between them out to form an oval. I've also added some detailed assembly images and a drawing that shows where the T nuts in the lower base are required.

Update 08/08/2014

I've changed the design of the delta rods. Instead of using magnets I am now using 8mm stainless ball bearings drilled with a 4mm diameter, 4mm deep hole. They are sold for some sort of use in photography. Readily available on ebay. The effector and rod carrier designs have been changed so that they have 8mm sockets to accept the 8mm balls. The whole thing is locked together with Spectra line (100lb) and springs. I used 85mm, fairly strong ones. A little silicone grease before assembly should stop any wear. I've uploaded the amended .stl files and some images of how I assembled it all. There is also a write up in my thread on the Reprap forum. It really does make a rock solid, backlash free connection between the effectors and the towers. There is absolutely no play at the nozzle and I've been able to up 'quality' print speeds considerably.

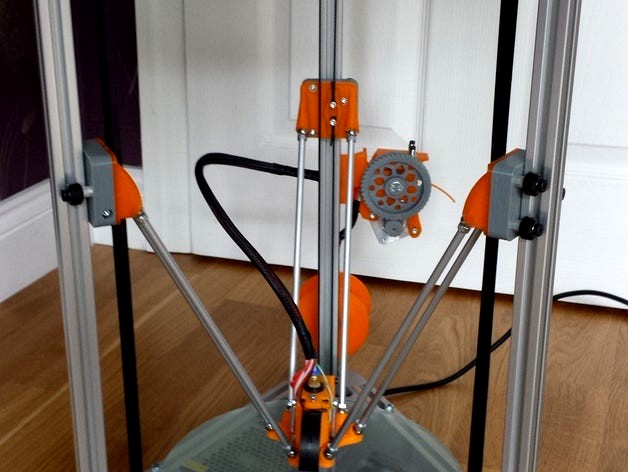

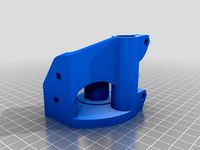

Anyone that has followed my previous designs has probably been expecting this :-) I've now got to a point where my Cherry Pi printer is at iteration three and I'm really happy with it. Version III incorporates mini V wheels for the carriages and a hot end Z probe for auto levelling and calibration. I use Rich Cattell's Marlin fork which enables all that. I have managed to substantially reduce the number of parts required and, due to the v wheels leaving the rear face of the extrusion free, been able to mount te extruder to the Z tower which results in a relatively short Bowden tube to the extruder. I have renamed the plastic parts to incorporate details of the quantity required and the settings and materials I used to print mine (P=perimeter, B=bottom layers, T=top layers). I've also switched to using a centrifugal fan as I feel it gives greater airflow. It's also easier to incorporate into the Z probe hot end design. The print areTa is around 190mm x 190mm x 250mm. I print at 100mm/s infill, 60mm/s outer perimeter, 70mm/s inner perimeter and 200mm/s travel. Acceleration is 3000 throughout and XY Jerk is 20. It would probably go higher but I'm happy at that and it doesn't seem to stress the machine too much.

BOM

Plastic parts as required

3 x 2020 Bosch/Rexroth Extrusion @ 600mm

9 x 2020 Bosch/Rexroth Extrusion @ 250mm

6 x 16mm x 5mm x 4mm flanged bearings

9 x Open Builds Mini V Wheel Kits

12 x 10mm spherical neodymium magnets

6 x 6mm aluminium tube (with 5mm ID, I drilled mine to this) @ 225mm

12 x M5 8mm SHCS machined with a 10mm ball end mill to form cup for magnet (rod ends)

4M GT2 belt

3 x GT2 pulleys

4 x 13mm x 6mm x 7mm micro switches

4 x NEMA 17 stepper motors

1 x Arduino Mega 2560

1 x RAMPS 1.4

1 x RRD Smart LCD Display

4 x 4988 stepper drivers

12V 5A PSU

Mains lead

1 x 50mm brushless centrifugal fan

250mm diameter glass/mirror build plate

J Head (Bowden type)

0.5M 4mm OD 2mm ID PTFE tube

2 x 1/8 NPT 4mm pneumatic fittings

5 x 608 bearings (extruder and spool holder)

100mm M8 threaded rod (spool holder)

M8 60mm hobbed bolt (hobbed at 25mm)

3 x M8 nut

8 x M8 washers

2 x M3 50mm SHCS (extruder clamp)

2 x compression springs to suit above

2 x tension springs to suit effector/hot end hinge

8 x M3 nut

3 x M5 45mm SHCS (top idlers)

3 x M5 nut

6 x M5 washer

18 x M3 8mm SHCS (stepper fixing, effector)

2 x M3 30mm SHCS (effector/hot end hinge & fan mount)

3 x M3 25mm SHCS (carriage adjuster)

2 x M3 15mm SHCS (effector springs)

61 M5 T-Nuts (i use these http://www.thingiverse.com/thing:28788)

61 M5 8mm SHCS

Apologies if I missed anything but I think it's mainly all there. Let me know.

Enjoy

Added improved filament spool holder and disc and also a wiring grommet for where the cable bundle from the hot end and extruder stepper pass through the Z tower extrusion. The hole in the extrusion should be drilled 180mm from the base of the Z tower stepper mount. This allows full travel on the Z carriage with the 225mm rods (tube length) that I use with the 8mm drilled ball bearing and spring/string retention system. I normally drill two 5mm holes adjacent to each other and file the bridge between them out to form an oval. I've also added some detailed assembly images and a drawing that shows where the T nuts in the lower base are required.

Update 08/08/2014

I've changed the design of the delta rods. Instead of using magnets I am now using 8mm stainless ball bearings drilled with a 4mm diameter, 4mm deep hole. They are sold for some sort of use in photography. Readily available on ebay. The effector and rod carrier designs have been changed so that they have 8mm sockets to accept the 8mm balls. The whole thing is locked together with Spectra line (100lb) and springs. I used 85mm, fairly strong ones. A little silicone grease before assembly should stop any wear. I've uploaded the amended .stl files and some images of how I assembled it all. There is also a write up in my thread on the Reprap forum. It really does make a rock solid, backlash free connection between the effectors and the towers. There is absolutely no play at the nozzle and I've been able to up 'quality' print speeds considerably.

Anyone that has followed my previous designs has probably been expecting this :-) I've now got to a point where my Cherry Pi printer is at iteration three and I'm really happy with it. Version III incorporates mini V wheels for the carriages and a hot end Z probe for auto levelling and calibration. I use Rich Cattell's Marlin fork which enables all that. I have managed to substantially reduce the number of parts required and, due to the v wheels leaving the rear face of the extrusion free, been able to mount te extruder to the Z tower which results in a relatively short Bowden tube to the extruder. I have renamed the plastic parts to incorporate details of the quantity required and the settings and materials I used to print mine (P=perimeter, B=bottom layers, T=top layers). I've also switched to using a centrifugal fan as I feel it gives greater airflow. It's also easier to incorporate into the Z probe hot end design. The print areTa is around 190mm x 190mm x 250mm. I print at 100mm/s infill, 60mm/s outer perimeter, 70mm/s inner perimeter and 200mm/s travel. Acceleration is 3000 throughout and XY Jerk is 20. It would probably go higher but I'm happy at that and it doesn't seem to stress the machine too much.

BOM

Plastic parts as required

3 x 2020 Bosch/Rexroth Extrusion @ 600mm

9 x 2020 Bosch/Rexroth Extrusion @ 250mm

6 x 16mm x 5mm x 4mm flanged bearings

9 x Open Builds Mini V Wheel Kits

12 x 10mm spherical neodymium magnets

6 x 6mm aluminium tube (with 5mm ID, I drilled mine to this) @ 225mm

12 x M5 8mm SHCS machined with a 10mm ball end mill to form cup for magnet (rod ends)

4M GT2 belt

3 x GT2 pulleys

4 x 13mm x 6mm x 7mm micro switches

4 x NEMA 17 stepper motors

1 x Arduino Mega 2560

1 x RAMPS 1.4

1 x RRD Smart LCD Display

4 x 4988 stepper drivers

12V 5A PSU

Mains lead

1 x 50mm brushless centrifugal fan

250mm diameter glass/mirror build plate

J Head (Bowden type)

0.5M 4mm OD 2mm ID PTFE tube

2 x 1/8 NPT 4mm pneumatic fittings

5 x 608 bearings (extruder and spool holder)

100mm M8 threaded rod (spool holder)

M8 60mm hobbed bolt (hobbed at 25mm)

3 x M8 nut

8 x M8 washers

2 x M3 50mm SHCS (extruder clamp)

2 x compression springs to suit above

2 x tension springs to suit effector/hot end hinge

8 x M3 nut

3 x M5 45mm SHCS (top idlers)

3 x M5 nut

6 x M5 washer

18 x M3 8mm SHCS (stepper fixing, effector)

2 x M3 30mm SHCS (effector/hot end hinge & fan mount)

3 x M3 25mm SHCS (carriage adjuster)

2 x M3 15mm SHCS (effector springs)

61 M5 T-Nuts (i use these http://www.thingiverse.com/thing:28788)

61 M5 8mm SHCS

Apologies if I missed anything but I think it's mainly all there. Let me know.

Enjoy

Similar models

thingiverse

free

Cherry Pi Delta 3D Printer by AndyCart

...the idler bearing belt guides - they disintegrated on me! i've posted a modified design on the 'files' section

andy

thingiverse

free

Mendel rotated geared extruder by JBFromOZ

...x .035) springs x 2 from century springs or similar 8mm trinity labs hob x 1 m3 nut x...

thingiverse

free

One Z-Motor / Filament holder solution for Prusa i3 Rework by WieMi

...t)

360mm m8 threaded rod (middle)

2x 380mm m8 threaded rod (right)

11x m3 nut

8x m3 - 8mm grub screw

8x m8 nut

5x 688zz bearing

thingiverse

free

East3D gecko Z bearing rod brace by delukart

...a m3 screw to lock the 608-zz bearing in place .

i didn't lock the bearing in place with the m3 screw. it dont need it realy.

thingiverse

free

Printable Z-Stage for Makerbot / Cupcake CNC by Iwo

...tamins):

* 2x precision rods, 8mm, >270mm long

* 3x linear bearings, 8mm / 15mm outside, 24mm high

* 45mm 12v fan

thingiverse

free

X-ends for holding 20x20 extrusion nuts/lm8uus by Simonious

...z-nut with spring pair - should fit m8 or similar i'm using it on acme 1/4" rods in the...

thingiverse

free

XY_Plotter by modelatolyesi

...

1x ball-pen spring.

electronics:

arduino uno

cnc shield.

2x a4988 stepper driver.

9g. servo.

4x micro switch.

extension cables.

thingiverse

free

Mini drill press with led light by pierrot93300

...aded shaft

3 lm8uu

6 nuts m8

6 nuts m3

6 screws m3*16mm

1 heatsink 28mm

1 switch on/off

36pcs m3*5mm hex screw (hw005) (optional)

thingiverse

free

Plane Blade and Chisel Sharpening Sled by fauxhican - Metric Remix

...e idea from 3dm4rk's remix, thanks).

2 - m8 x 30mm countersunk allen bolt.

2 - m8 lock nuts.

2 - 608rs (sealed) ball bearing.

thingiverse

free

Articulated arm by mroc

...figured it'd be fun to try to make something similar by 3d printing. i made three different versions with...

Andycart

thingiverse

free

Cherry Pi IIIS by AndyCart

... springs.

check out the forum post for full instructions and help with the build

http://forums.reprap.org/read.php?178,361141

thingiverse

free

Low Friction Spool Holder by AndyCart

...pool sizes. it allows very easy feeding of filament to the extruder with virtually no friction and swapping spools takes seconds.

thingiverse

free

Bug Bot by AndyCart

...t. total build cost is around £25.00

there's a video of him doing his thing here http://youtu.be/ogso3zanqsa

enjoy

andy

thingiverse

free

Andycart / Maso effector for Cherry Pi III 10mm ball bearing for E3D V6 Hotend by Zzyzxx71

...9;s fan.

i do not know if this will work with the e3d v5, i believe andy's oriignal effector was designed for it's use.

thingiverse

free

PrntQB V2 by AndyCart

... the completed machine here http://youtu.be/_oyftjf3l34.

i've added a better quality video here :-http://youtu.be/qpjg7uqw8mi

thingiverse

free

Cherry Pi IIIS Heated Bed Mount by AndyCart

...between the mount and the bed to help insulate the mount. the mount is printed in abs and i use 0.3mm layer height and 33% infill

thingiverse

free

Big Bullseye Clock by AndyCart

...asy winding. thanks to goofy for the idea for that. there's a video of the clock running here :-

https://youtu.be/l88bo01-u7i

thingiverse

free

Cherry Pi II by AndyCart

... nuts used throughout (http://www.thingiverse.com/thing:28788)

low friction spool mount

(http://www.thingiverse.com/thing:235925)

thingiverse

free

Core XY PrntQB by AndyCart

...ng for delta like speeds with cartesian precision. we'll see :-)

i am now waiting for the rest of the parts to ship.

andy

thingiverse

free

3dr spring socket arms by ekaggrat

...by ekaggrat thingiverse this is a modification to use andycart#39;s cherry pi spring socket joint idea in the...

Iii

3d_export

$17

JetRanger III

...jetranger iii

3dexport

jetranger iii

3ddd

$1

Jarron III

...jarron iii

3ddd

jarron iii

decorative glass vase

cg_studio

$139

Panzer III - PzKpfw III - Ausf.G3d model

....3ds .c4d .lwo .obj - panzer iii - pzkpfw iii - ausf.g 3d model, royalty free license available, instant download after purchase.

cg_studio

$139

StuG III - Sturmgeschutz III - Ausf.D3d model

....c4d .lwo .obj - stug iii - sturmgeschutz iii - ausf.d 3d model, royalty free license available, instant download after purchase.

3ddd

free

Velashape III

... syneron , candela

velashape iii — аппарат для лечения целлюлита

3d_ocean

$8

Inoplanet III

...inoplanet iii

3docean

3ds arman3dg games inoplanet low max poly trees

inoplanet iii

design_connected

$16

Richard III

...richard iii

designconnected

baleri italia richard iii armchairs computer generated 3d model. designed by philippe starck.

3d_export

$199

cinderella iii

...cinderella iii

3dexport

3d_export

$119

lara iii

...lara iii

3dexport

3ddd

$1

Towel Collection III

...towel collection iii

3ddd

полотенце

towel collection iii

Cherry

3ddd

$1

Cherry

...cherry

3ddd

cherry

люстра cherry

archibase_planet

free

Cherry

...cherry

archibase planet

cherry cherries berry

cherry n010808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Cherries

...cherries archibase planet cherries cherry berry food cherries n010812 - 3d model (*.gsm+*.3ds) for...

3d_ocean

$5

cherry

...ation food fruit fruits kitchen realistic red table

cherry cherries fruit fruits table decoration bowl kitchen food realistic red

3ddd

$1

Cherry

...cherry

3ddd

бра cherry

3ddd

$1

cherry

...cherry

3ddd

вишня

plate with cherries for tableware use

3d_export

free

cherry

...cherry

3dexport

cherry lowpoly<br>for fruits and vegetables collecion

3d_ocean

$20

Cherries

...cherries 3docean 3ds max architecture cherries cherry choice fruit deco decoration fruit fruits mental ray realistic...

3d_export

$25

Cherry

...ss what version your 3d program is. preview images are rendered blender cycles formats are: blander 3ds max maya cinema4d obj fbx

3d_export

$8

cherry

...cherry

3dexport

Pi

design_connected

$11

Pi

...pi

designconnected

ligne roset pi chairs computer generated 3d model. designed by thibault desombre.

3d_export

$5

raspberry pi

...raspberry pi

3dexport

carcasa para la raspberry pi

turbosquid

$18

pied

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люста emme pi light

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

бра классическое emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

3ddd

$1

Emme Pi Light

...emme pi light

3ddd

emme pi light

design_connected

$16

Pi-Air

...pi-air

designconnected

living divani pi-air lounge chairs computer generated 3d model. designed by harry & camila.

3d_ocean

$15

Manneken Pis

...picting a naked little boy urinating into a fountain’s basin. (wikipedia) the model was sculpted in blender 2.70a rendered wit...

3ddd

$1

Emme pi light

...emme pi light

3ddd

emme pi light

люстра классическая фирма: emme pi light

артикул: 3595/5/cot/12/wh