Thingiverse

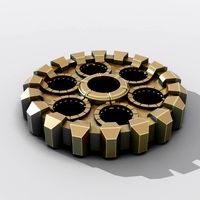

CGS (Conrad Gear System) Extruder; yet anther metal gear extruder by Louis_Cypher

by Thingiverse

Last crawled date: 3 years ago

User alocinb asked me to publish this one, so here we go

Purpose

I designed this since the Gregs Wade was too bulky for my liking and I liked the idea of having a metal gear.

Use

3mm filament. Intended for sparkcube but not limited to (uses standard gregs flange)

Design Concept

The extruder uses standard metal gears available at www.conrad.de namely a 12 teath gearwheel and a 60 teeth gearwheel. The 60teeth gearwheel runs a cut down (to 35mm) standard M5x50 screw driving the MK8 gear. The axle is carried by two 625 bearings.

There is an option to mount a 40x40 fan to the back to cool down PLA via the channel running towards the hotend

BOM

MK8 gear

1x screw M5x50 (needs to have a shaft)

4x screw M3x12 (length depends on your motor)

2x 625 bearings

M5 x50 or similar with shaft long enough to fit the gears (25-35mm) or a piece of 5mm smooth rod

Fan+ screws (optional)

Threaded rod M4 plus nuts for the idler

Two springs for the idler

Tools

No special tools needed. You have to drill the gears to fit 5mm screws

Options

There are two versions of the body. One having an attachment for the sparkcube limit switch and one without

Experiences/ does it work

I used it for about half a year and >5kg of filament and liked it. I changed to 1.75mm filament and hence now use a direct extruder (to be uploaded)

Purpose

I designed this since the Gregs Wade was too bulky for my liking and I liked the idea of having a metal gear.

Use

3mm filament. Intended for sparkcube but not limited to (uses standard gregs flange)

Design Concept

The extruder uses standard metal gears available at www.conrad.de namely a 12 teath gearwheel and a 60 teeth gearwheel. The 60teeth gearwheel runs a cut down (to 35mm) standard M5x50 screw driving the MK8 gear. The axle is carried by two 625 bearings.

There is an option to mount a 40x40 fan to the back to cool down PLA via the channel running towards the hotend

BOM

MK8 gear

1x screw M5x50 (needs to have a shaft)

4x screw M3x12 (length depends on your motor)

2x 625 bearings

M5 x50 or similar with shaft long enough to fit the gears (25-35mm) or a piece of 5mm smooth rod

Fan+ screws (optional)

Threaded rod M4 plus nuts for the idler

Two springs for the idler

Tools

No special tools needed. You have to drill the gears to fit 5mm screws

Options

There are two versions of the body. One having an attachment for the sparkcube limit switch and one without

Experiences/ does it work

I used it for about half a year and >5kg of filament and liked it. I changed to 1.75mm filament and hence now use a direct extruder (to be uploaded)

Similar models

thingiverse

free

Hypercube evolution XY idler with 5mm shaft by andreilx

...store.

another option would be to use part of a metal drill rod.

the shaft is only pressed into the bore. no need to use a screw.

thingiverse

free

7:32 Compact Geared Extruder Nema17 and 14 by ryannining

...haft bearing

1x 624 for idler.

1xm4 nut

to make tensior, i use steel from peg to clamphttps://www.youtube.com/watch?v=-7bpu9pbq18

thingiverse

free

NSTT Extruder by Paciente8159

...gure the e steps/mm to about 440. test it and adjust.

enjoy your new geared extruder. the printing quality on this is worth it!!!

thingiverse

free

Nema 17 1:4 Planetary Geared Extruder by ryannining

...nt setting notes.

bearing use 625

for clipping the idler to the body, use metal peg like on the photo, or you can use other clip.

thingiverse

free

C Extruder for MK8 gear and J-head by LordM

...ou can use the same bearings, spring and tension screws.

the plate is flexible having oval holes to be fixed on the x-carriage.

thingiverse

free

Idler for Direct-drive extruder, easy pull desing ( 695z Bearing ) by Portillo

...se a round pcb spacer with the desire size. other option is cut some rod you have, like a 5mm drill to 10mm length.

best regards.

thingiverse

free

Extruder / Bowden - 3mm filament by dinizhobby

...zhobby

thingiverse

extruder for bowden filament 3mm

you need mk8 driver gear and one bearing 6x13x5 and shaft 6mm with screw m4

thingiverse

free

Eventorbot Wade / Greg Extruder Parts by kkronyak

...may not be perfect but they work and i am open to suggestions to improve them. i hope some eventorbot owners find these helpful!

thingiverse

free

inverted bulldog extruder with mk8 drive gear with filament guide by justsomeone

...lock to use m3x16 screws.(in my setup 3mm thickness steel plate is between with main block and the stepper)

i hope u may like it.

thingiverse

free

Greg's Wade Strengthened Extruder Idler 3mm filament by DjDemonD

... extruder as the x carriage moves from left to right. the filament guide hole is a little more generous also, to reduce friction.

Anther

thingiverse

free

KUGOO G2 PRO anther by lifeapi

...kugoo g2 pro anther by lifeapi

thingiverse

kugoo g2 pro anther/duster

thingiverse

free

WW2 plane by invis_camodude

...ww2 plane by invis_camodude thingiverse anther plane to my gallery don't worry there will be...

thingiverse

free

Honeycomb Spinner (No Bearings) by AdamRW17

...honeycomb spinner (no bearings) by adamrw17 thingiverse anther spinner that requires no additional hardware, just print, assemble...

thingiverse

free

W5501 Weistek VAT Cover by fificap

...v2 file as the original one was mixed with anther ...

thingiverse

free

Extruder signal. by Yojimbojpr

...extruder signal. by yojimbojpr thingiverse anther stupid little thing. is a signal to see the...

thingiverse

free

MPCNC Endstop Mount (for 25 mm tube)

...mount (for 25 mm tube) thingiverse this is just anther microswitch mount for mpcnc endstops. it is designed for...

thingiverse

free

Ninebot by Segway KickScooter ES2 by ukrutko

...16х10х1 / шайба 16х10х1 shim 16х10х07 / шайба 16х10х07 anther of shock absorber / пыльник оси амортизатора sleeve snubber...

thingiverse

free

Aquarium Magnetic Scraper by danzig483

...with diameter 8mm and high 5mm, if you use anther size of magnetics you have cad file for future...

thingiverse

free

Slimer Buddha by SavageRodent

...slimer buddha by savagerodent thingiverse yeah anther one! printing note: on account of some slapdash modeling...

Cypher

3d_export

$6

Cypher

...cypher

3dexport

squish dumpling avatars of the valorant agents.

3d_export

$15

car rim sevenk sk-cypher

... 2021 + v-ray 5.0 materials<br>3ds max 2018 + v-ray 3.6 materials<br>ue4.25 asset + materials<br>3d print ready

3d_export

$5

Bill chipper

...bill chipper 3dexport bill cipher (or bill cypher as you like) is the antagonist in the animated...

thingiverse

free

Bill cypher by ghostlegend15

...bill cypher by ghostlegend15

thingiverse

this is a medallion of a painting i did of bill cypher.

thingiverse

free

Cypher Camera by TheSeakerDC

...cypher camera by theseakerdc

thingiverse

hello

thingiverse

free

bill cypher shelf by ghostlegend15

...bill cypher shelf by ghostlegend15

thingiverse

thingiverse

free

Asylum Research Cypher AFM by vipqualitypost

...itypost

thingiverse

just a small scale model of an asylum research cypher afm. print with backpack facing down for best results.

thingiverse

free

Cypher From Valorant by SixgunG

...youtube.com/channel/ucr9onv8c2gvu1usqtrlumhq

thanks to markusplus for extracting the game file. make sure to check out his page.

thingiverse

free

Cypher of the Monks Clock Pyramid Clock by Extkits

...ock takes some practice, but is relatively easy.

details are here https://extkits.co.uk/resources/cotmres/cotm-reading-the-clock/

thingiverse

free

Evermore Cypher Ring by WeGeekTogether

...evermore cypher ring by wegeektogether

thingiverse

a decoder ring based off the rune language found in the evermore theme park.

Conrad

design_connected

$16

Conrad Armchair

...conrad armchair

designconnected

alberta conrad armchair computer generated 3d model.

design_connected

$13

Conrad Bench

...conrad bench

designconnected

alberta conrad bench computer generated 3d model.

design_connected

$27

Conrad Sofa 260

...conrad sofa 260

designconnected

alberta conrad sofa 260 computer generated 3d model.

3ddd

$1

Posters CONRAD KNUTSEN

... надпись , музыка

набор иллюстраций conrad knutsen

3ddd

free

Подвесной светильник Conrad

...подвесной светильник conrad

3ddd

conrad

высота: 1300 мм.

диаметр: 400 мм.

материал: сталь/steel

turbosquid

$10

Conrad Plus Lampadario

...alty free 3d model conrad plus lampadario for download as max on turbosquid: 3d models for games, architecture, videos. (1284544)

turbosquid

free

Conrad Dine Chair

...

royalty free 3d model conrad dine chair for download as max on turbosquid: 3d models for games, architecture, videos. (1160545)

3d_export

$10

Armchair 005 conrad 3D Model

...hair 005 conrad 3d model

3dexport

armchair chair sofa vray conrad furniture

armchair 005 conrad 3d model artline3d 21821 3dexport

3d_export

$10

fendi casa conrad

...fendi casa conrad

3dexport

fendi casa conrad<br>formats: 3d max 2014<br>3d max 2017<br>obj rar

3ddd

$1

Lexington_Conrad Chair&Conrad Ottoman

... пуф

lexington

tower place

conrad chair

size:33½w x 40½d x 36h in

conrad ottoman

size:28½w x 22½d x 19½h in.

Louis

3ddd

free

Louis Louis bed

...ф , зеркало

кровать фирмы stanley furniture коллекция louis louis. снята с производства.

3ddd

$1

Louis

... riva , капитоне

классическое кресло фабрики louis артикул lov-10-snw68_l.

3ddd

free

LOUIS

...i , louis

louis

ulivi

king size bed

cm 196x233xh.105

matress

cm 180x200

polys: 98 1210

3ddd

$1

Louis Drawer

...louis drawer

3ddd

louis

тумба компании louis

3ddd

$1

Saint Louis

...saint louis

3ddd

saint louis , капитоне

saint louis

3ddd

$1

Louis XVI

...louis xvi

3ddd

louis xvi

louis xvi classic chair

3ddd

$1

Loui Jover

... газета , балерина , picture

работы loui jover

3ddd

free

Louis vuitton

...louis vuitton

3ddd

сумка

сумка louis vuitton

3ddd

free

Кресло Louis armchair

...кресло louis armchair

3ddd

louis

кресло louis armchair

3ddd

$1

Louis Philip

... текстуры, форматы fbx, obj, присутствуют. ссылка:http://www.eichholtz.com/dining-chair-louis-philip-0112002999114.aspx

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$9

Gear

...gear

turbosquid

royalty free 3d model gear for download as on turbosquid: 3d models for games, architecture, videos. (1712328)

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport

Metal

3d_ocean

$10

Metal Barrel

...metal barrel

3docean

barrel barrels metal metal barrel wood barrel

metal barrel

turbosquid

$14

Metals

...als

turbosquid

royalty free 3d model metals for download as on turbosquid: 3d models for games, architecture, videos. (1486252)

3d_ocean

$18

Metal Furniture

...metal furniture

3docean

design desk indoor industrial metal metal furniture restoration table

metal furniture 3d model

3d_export

$5

metal table

...metal table

3dexport

metal table.blend

3d_export

$5

Metal Shelf

...metal shelf

3dexport

metal shelf

3d_export

free

metal detector

...metal detector

3dexport

metal detector

3ddd

$1

metal lux

...metal lux

3ddd

dedalo , metal lux

люстра и бра metal lux коллекция dedalo.

3ddd

$1

bonded metal

...bonded metal

3ddd

https://www.forms-surfaces.com/bonded-metal

boded tiled metal

3ddd

$1

Metal

...metal

3ddd

1280-1024 бесшовный 8-)

3d_export

$5

cgaxis metal

...cgaxis metal

3dexport

notebook cgaxis metal

Cgs

turbosquid

$38

Cg Woman

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

CHD2551GI-CG

...0 ммhttp://www.visualcomfortlightinglights.com/product/visual-comfort-e-f-chapman-oslo-sconces-chd2551gi-cg.html?page=1

3ddd

free

Gaggenau CG 290

...b , варочная панель

gaggenau cg 290 model.

cooking hob, with unwrapped texture for logo.

turbosquid

$20

CG Rooster Character

...

royalty free 3d model cg rooster character for download as on turbosquid: 3d models for games, architecture, videos. (1675178)

turbosquid

$60

CG robot -Xtruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

CG Tron Logo

...el cg tron logo for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1279589)

3ddd

$1

CG 50-2902

...cg 50-2902

3ddd

christopher guy

max 12, vray

3ddd

$1

8535/18 CG XU

...8535/18 cg xu

3ddd

люстра артикул 8535/18 cg xu

высота:60см

диаметр:90см

turbosquid

$30

CG Celestial model

...er guy - celestial 3d model for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1565785)

3d_export

$40

CG egg 3D Model

...cg egg 3d model

3dexport

egg food eat lighting render realistic

cg egg 3d model jac 36193 3dexport