Thingiverse

Case for D300VS by mosb1000

by Thingiverse

Last crawled date: 3 years ago

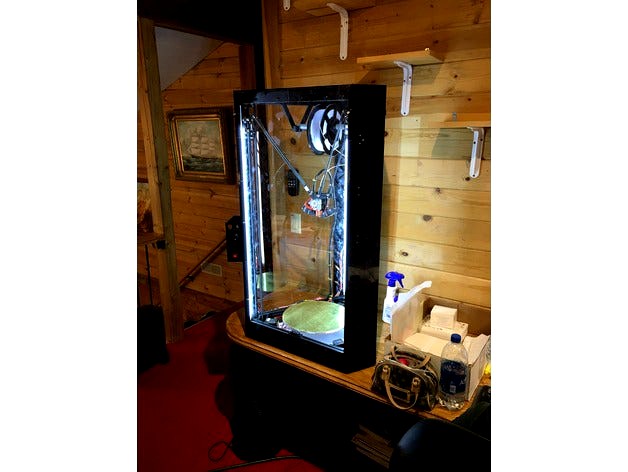

These are the STLs for a case I printed for my D300 VS.

It has a few problems:

1) the front plexi-glass is too close to the print bed to allow my Titan Aero to come all the way to the front of the bed.

2) the PSU mount I printed doesn't leave adequate room for the wiring, so I haven't included it in the files

3) I haven't designed a handle to open the doors yet

4) the doors slide up in single sections, so it takes a lot of space vertically.

5) the door latching mechanism isn't great, you hold the panels up by tightening screws into them

6) the screw holes are a little snug

7) there isn't quite enough room for the corner brackets, so the bottom doesn't come together snuggly

I printed it in PETG. If I decide to redo it, I will print it in ABS, which will be easy now that I have a good case! The pieces are printed with the larger, flat sides down. It may be possible to print them vertically so that you can put more than on piece on the bed at a time. If I redo it, it will be designed to print vertically.

This case moves the controller outside the case, to allow better cooling. The plexiglass is 2-3mm thickness polystyrene purchased from home depot in 2'x4' sheets. The case should be assembled first, then the plexiglass should be cut to measure. I used 3mm plastic insulated panels for the top and bottom.

The air inside the case gets up to around 40ºC when the heat bead is set at 100ºC. Additional ventilation is not needed, because the heat conducts through the plexiglass panels. For higher temperatures, you would need to replace some of the plexiglass sides with insulated panels, or add a chamber heater.

The diffusors should be printed in clear, translucent, or white filament. The lighting requires about 5m of LED light strips. It is important to print the diffusors with no perimeters (solid infill only) so that they hold together well. Also, for best results the solid infill should have at least 4 directions (0º, 45º, 90º, and 135º, for example) otherwise the light will make star pattern instead of being fully diffused. I installed a dimmer switch, and white lights, but I think it would be cool to get multi-color lights and a color controller. You definitely have to be good with a soldering iron if you are assembling the strips yourself. Otherwise, you could buy 6 pre-terminated 1m strips and cut them to the correct length.

I have worked out a lot of design improvements, so if you are interested in printing this, let me know and if there is enough interest I will do an improved version.

It has a few problems:

1) the front plexi-glass is too close to the print bed to allow my Titan Aero to come all the way to the front of the bed.

2) the PSU mount I printed doesn't leave adequate room for the wiring, so I haven't included it in the files

3) I haven't designed a handle to open the doors yet

4) the doors slide up in single sections, so it takes a lot of space vertically.

5) the door latching mechanism isn't great, you hold the panels up by tightening screws into them

6) the screw holes are a little snug

7) there isn't quite enough room for the corner brackets, so the bottom doesn't come together snuggly

I printed it in PETG. If I decide to redo it, I will print it in ABS, which will be easy now that I have a good case! The pieces are printed with the larger, flat sides down. It may be possible to print them vertically so that you can put more than on piece on the bed at a time. If I redo it, it will be designed to print vertically.

This case moves the controller outside the case, to allow better cooling. The plexiglass is 2-3mm thickness polystyrene purchased from home depot in 2'x4' sheets. The case should be assembled first, then the plexiglass should be cut to measure. I used 3mm plastic insulated panels for the top and bottom.

The air inside the case gets up to around 40ºC when the heat bead is set at 100ºC. Additional ventilation is not needed, because the heat conducts through the plexiglass panels. For higher temperatures, you would need to replace some of the plexiglass sides with insulated panels, or add a chamber heater.

The diffusors should be printed in clear, translucent, or white filament. The lighting requires about 5m of LED light strips. It is important to print the diffusors with no perimeters (solid infill only) so that they hold together well. Also, for best results the solid infill should have at least 4 directions (0º, 45º, 90º, and 135º, for example) otherwise the light will make star pattern instead of being fully diffused. I installed a dimmer switch, and white lights, but I think it would be cool to get multi-color lights and a color controller. You definitely have to be good with a soldering iron if you are assembling the strips yourself. Otherwise, you could buy 6 pre-terminated 1m strips and cut them to the correct length.

I have worked out a lot of design improvements, so if you are interested in printing this, let me know and if there is enough interest I will do an improved version.

Similar models

thingiverse

free

uBITX EF01 case panels by dmbaty

...here: https://www.banggood.com/electronic-plastic-shell-cartridge-handle-project-case-desk-instrument-200x175x70mm-p-1035473.html

thingiverse

free

Imperial Symbol Filament Spool by CabDesign3d

.... you will need to print 2 of them, and they should snap together. i have not printed them yet, so i haven't done a fit test.

thingiverse

free

Command Strip LED Strip Hanger by kpdudek2

... and well supported.

i included the solidworks file in case the .125" channel doesn't fit the light strip you are using.

thingiverse

free

Snapmaker A350 Drawer, elongated by MakerIggs

...rs yet, but if they don't fit, i'll likely redo them. i have printed this twice successfully to fit 2 different machines.

thingiverse

free

Customizable pocket reading lamp using mobile phones light by ngfelixl

...;ll need to adjust at least your phone settings. if you have suggestions for improvement, let me know.

happy printing and cheers!

thingiverse

free

dji box by shaydock88

...uld fit. i haven't received my case yet so haven't tried. i got some wires , the sticks and memory card storage in there.

thingiverse

free

High Voltage Insulator by BTNZ

... probably isn't an option for me so i deigned the half one so it can be printed on its side and sandwiched together.

enjoy...

thingiverse

free

Heated Bed Lift Kit for bed insulation - Longer LK1 / Alfawise U20 U30 by candre23

...r your own device.

everything prints without supports as provided, though the block and pin could definitely benefit from a brim.

thingiverse

free

Iphone 7/8 Cases by AGBale

...s by agbale

thingiverse

i haven't actually printed either of these yet. should work, i just haven't gotten around to it.

thingiverse

free

LED Strip Clamps (#6 Screw) (Single and Dual Row) by QuadeHale

...lamps down properly. this will cause an issue if you try and print them flat with no support as there won't be a first layer.

Mosb1000

thingiverse

free

Tea Dispenser by mosb1000

...t 0.2mm layer height on a 0.4mm nozzle. two shells and 3 top and bottom layers, 25% infill. fan set to max cooling past layer 10.

thingiverse

free

Knobs for 2001 Chevrolet Stereo by mosb1000

...lace. you will have to remove the metal retainers which will be left over from your original knobs, if they cracked and fell off.

thingiverse

free

Teebeutelspender teabag dispenser

...each other. the original tea bag dispenser is from mosb1000 ...

D300Vs

thingiverse

free

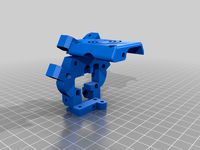

E3D Hemera delta mount (D300VS/D300VS+)

...rest is as the original. print upside down with support. and don't look at my wiring, it was only mounted for a short test ;)

thingiverse

free

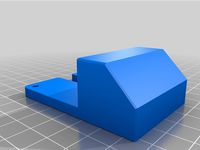

D300vs cable guide by stavrosg

...ade one for my cr-10, adapted it for my delta ,an ultibots d300vs+

added a 60mm taller version that handled my 450mm delta better

thingiverse

free

D300VS+ Dust Covers by Lucidwolf

...vertical slot based delta printers.

this is part of my upgrades to the ultibots d300vs+ https://www.thingiverse.com/thing:3089764

thingiverse

free

D300VS+ Modifications by Lucidwolf

...printers speed limit.

like most printers this is a work in progress.

still need to design and print

1.) led holders

2.) enclosure

thingiverse

free

D300VS Directed Airflow Part Cooler by hardrocker

...mm blower fans with no changes required for the wiring. the design requires (6) m3x25mm screws and (6) m3 nuts for installation.

thingiverse

free

D300VS Thickened Barbell Carriages

...them to work.

another good mod would be to move the tensioning mechanism over to the side with the two wheels for more stability.

thingiverse

free

UltiBots D300VS Filament Guide by SublimeLayers

...imelayers

thingiverse

this is a filament guide that helps prevent filament from unspooling when the printer homes after a print.

thingiverse

free

55mm Magball Carriage & Effector for D300VS+

... of the effector in order to allow easier access to the titan aero (or titan extruder.) this makes assembly and cleaning easier.

thingiverse

free

UltiBots D300VS 3D Printer by Verohomie

...

d300vs bom is located here https://docs.google.com/spreadsheets/d/13qilrma5xjv6fmad4rimuzotkzjiyf5niunzzmn20gm/edit?usp=sharing

thingiverse

free

Tusk Fan for D300VS+ magball edition

...erse.com/thing:2223113/ effector :)

source here https://www.sublimelayers.com/2017/10/tusk-part-cooling-for-titan-aero-and.html

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.