Thingiverse

Carburetor spacer for Briggs and Stratton Sno/Gard 62000 (Snowblower Hako 6009H) by szalat

by Thingiverse

Last crawled date: 3 years ago

I have a Hako Snowblower with fairly rare Briggs and Stratton Sno/gard 62000 two cycle engine. Bought for cheap with carburetor problem. My attempt to overhaul original carburettor failed. Original diaphragm set for this carburetor costs about 100$! I've tried to make DIY diaphragms but no luck.

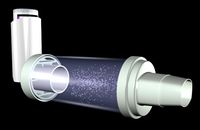

Finally I have decided to go with stock universal diaphragm carburetor for brush cutter. Here is a link to ebay (just for example, random seller)

Biggest problem with this carburettor was that it is a bit different. Wrong bolt spacing, wrong throat diameter, and worse of all - it needs to be mounted in position 90 degrees different from original carburetor and impulse channel is on surface of engine/carburettor.

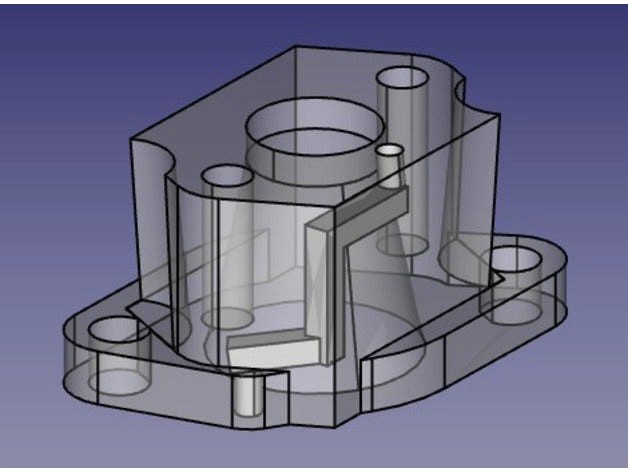

I've took old carburetor, old carburetor spacer, new carburetor and a caliper and start drawing in FreeCAD. This is what I've designed. Most challenging was impulse channel design.

Printed in PET-G. Sanded inside surface then covered it in epoxy glue (for fuel resistance) then inserted upper bolts (M5 afair) with epoxy. It is designed to put between old carburetor spacer and new carburetor. Fits well, engine works like a charm, PET-G doesn't melt or deform (yes it does, see UPDATE 2).

One thing I did not manage is engine governor (see update below). Original carburetor has metal throttle valve that turns without applying virtually any force. New carburetor has different construction - it has throttle in form of drilled cylinder and internal spring (that is essential for carburetor, cannot throw it out). This makes turning throttle fairly heavy and governor has no strength to overpass its resistance. Governor is not working right now (see update below).

UPDATE

Just updated project files for another carburetor from chainsaw (Walbro WT series) that has brass round plate as a throttle that turns without effort. Not tested yet but seems like it should work with original governor.

króciec-gaznika-odsniezarki-v4-gaźnik-pilarki.stl - spacer for chainsaw carburetor

króciec-gaznika-odsniezarki-v4-gaźnik-pilarki-kółko.stl - lever (wheel-form) for chainsaw carburetor

króciec-gaznika-odsniezarki-v4-gaźnik-pilarki-nakrywka.stl - anti-garbage protective cap for chainsaw carburetor. It is bolted on top of the carburetor and protects against falling small particles or parts inside of a carb throat. It is near identical to cap from original carburetor. It should also work with brush cutter carburetor.

Interesting fact: many snow blowers doesn't have air filter. Seems like in snowy winter conditions there is no dust floating everywhere.

UPDATE 2

Ended up with this part machined by hand and MIG welded from scrap metal parts. There was no problem with softening PETG when engine was running. During work engine is cooled efficiently by its fan and flow of air/fuel mixture. It softens just after engine was running few minutes and stopped. Seems that internal heat comes out from engine mixture channel and mounting bolts. It rises temperature of bottom part of the printed carburetor spacer making it soft and deforming.

In conclusion:

part invention and testing process was very simplified by CAD and 3d printing. Although printed carburetor spacer itself was not suitable for real life work, it has proven that concept realisation is just working. Then it was very simple to make such part from metal knowing shapes, dimensions and angles.

Finally I have decided to go with stock universal diaphragm carburetor for brush cutter. Here is a link to ebay (just for example, random seller)

Biggest problem with this carburettor was that it is a bit different. Wrong bolt spacing, wrong throat diameter, and worse of all - it needs to be mounted in position 90 degrees different from original carburetor and impulse channel is on surface of engine/carburettor.

I've took old carburetor, old carburetor spacer, new carburetor and a caliper and start drawing in FreeCAD. This is what I've designed. Most challenging was impulse channel design.

Printed in PET-G. Sanded inside surface then covered it in epoxy glue (for fuel resistance) then inserted upper bolts (M5 afair) with epoxy. It is designed to put between old carburetor spacer and new carburetor. Fits well, engine works like a charm, PET-G doesn't melt or deform (yes it does, see UPDATE 2).

One thing I did not manage is engine governor (see update below). Original carburetor has metal throttle valve that turns without applying virtually any force. New carburetor has different construction - it has throttle in form of drilled cylinder and internal spring (that is essential for carburetor, cannot throw it out). This makes turning throttle fairly heavy and governor has no strength to overpass its resistance. Governor is not working right now (see update below).

UPDATE

Just updated project files for another carburetor from chainsaw (Walbro WT series) that has brass round plate as a throttle that turns without effort. Not tested yet but seems like it should work with original governor.

króciec-gaznika-odsniezarki-v4-gaźnik-pilarki.stl - spacer for chainsaw carburetor

króciec-gaznika-odsniezarki-v4-gaźnik-pilarki-kółko.stl - lever (wheel-form) for chainsaw carburetor

króciec-gaznika-odsniezarki-v4-gaźnik-pilarki-nakrywka.stl - anti-garbage protective cap for chainsaw carburetor. It is bolted on top of the carburetor and protects against falling small particles or parts inside of a carb throat. It is near identical to cap from original carburetor. It should also work with brush cutter carburetor.

Interesting fact: many snow blowers doesn't have air filter. Seems like in snowy winter conditions there is no dust floating everywhere.

UPDATE 2

Ended up with this part machined by hand and MIG welded from scrap metal parts. There was no problem with softening PETG when engine was running. During work engine is cooled efficiently by its fan and flow of air/fuel mixture. It softens just after engine was running few minutes and stopped. Seems that internal heat comes out from engine mixture channel and mounting bolts. It rises temperature of bottom part of the printed carburetor spacer making it soft and deforming.

In conclusion:

part invention and testing process was very simplified by CAD and 3d printing. Although printed carburetor spacer itself was not suitable for real life work, it has proven that concept realisation is just working. Then it was very simple to make such part from metal knowing shapes, dimensions and angles.

Similar models

thingiverse

free

Briggs Stratton Carburetor adapter by kebekwa

...briggs stratton carburetor adapter by kebekwa

thingiverse

just my design of a carburetor adapter for briggs stratton to mikuni

thingiverse

free

Briggs & Stratton Throttle Knob by TasteOfChaoZ

... knob by tasteofchaoz

thingiverse

simple throttle knob for modern briggs & stratton engines like the rs-, cr- and xr-series.

thingiverse

free

Briggs and Stratton Engine Snow Blower Choke Knob

...for my snowblower with briggs and stratton engine. the fit is quite tight and will require a decent amount of pressure to put on.

thingiverse

free

Engine Key Briggs & Stratton # 794696 by elhalpern

...

a second version has been uploaded that does not have the support feature for those with resin or sintering printers. 1/27/2020

thingiverse

free

Briggs and Stratton Quantum Air Filter Knob by ctrlrst

...ratton quantum air filter knob by ctrlrst

thingiverse

air filter knob for briggs and stratton quantum, original screw/bolt used.

thingiverse

free

Snowblower skid for Briggs & Stratton Model #1696619 by Mister_Ko

... way should point down as well as 2mm wear indicators.

i suggest these be printed with 100% infill to account for eventual wear.

grabcad

free

Engine Briggs & Stratton 10hp

...engine briggs & stratton 10hp

grabcad

engine briggs & stratton 10hp

grabcad

free

briggs stratton 10 hp engine

...briggs stratton 10 hp engine

grabcad

parts assembled for briggs 10 hp engine

thingiverse

free

Customized - Lawn Mower Gasket by cakes

.../maxpower-14111-carburetor-briggs-stratton/dp/b006e1ee88/ref=pd_sim_86_4?_encoding=utf8&psc=1&refrid=e24tn8005sxz9vjzk7q9

cg_trader

$14

Briggs Stratton XR550 Engine - Motor

...briggs stratton xr550 engine - motor

cg trader

briggs & stratton xr550 engine

Szalat

thingiverse

free

Filament spool holder by szalat by szalat

...giverse.com/thing:498247 but it is made to better fit with "x3d corexy printer" http://www.thingiverse.com/thing:730199

thingiverse

free

Bottle cutter by szalat by szalat

...is needs a little work on project.

one observation: when making "bottle bands" you must pull the band a little upwards.

thingiverse

free

Gopro Hero 2 lens cap with HERO2 tag by szalat

...g by szalat

thingiverse

model made with freecad/linux.

printed with pla and it fits good on bare lens (without waterproof case).

thingiverse

free

Dell DA-2 PSU clamp by szalat

...ing dell da-2 psu inside enclosure of x3d corexy printer but i think it can be used for other printers with wooden box.

screws m3

thingiverse

free

Soldering iron tip cleaner, steel wire container by szalat

...dering-solder-iron-tip-cleaner-cleaning-steel-wire-with-stand-set-soldering-iron-stand/32580430800.html

you need only steel wire.

thingiverse

free

Uchwyt zamka Velux/ Velux striking plate by szalat

...lds window in place so rubber gasket is watertight.

update after 10 months

after 10 months it is still in good working condition.

thingiverse

free

3D Printer light with LED strip for X3D CoreXY by szalat

...ews, but i've fix it to the printer case just with two strips double sided self-adhesive tesa tape.

made with freecad, linux.

thingiverse

free

Filament (1.75 mm) end sensor microswitch by szalat

...nd freecad source file for editing.

in the picture is earlier version, but it does not differ much from the attached newer files.

thingiverse

free

Bowden Central Carriage for "X3D CoreXY by Unix" by szalat

... advice: only use bowden feed extruder if you for some reason really need it. direct is better in spite of his downside (weight).

thingiverse

free

28BYJ-48 stepper motor to NEMA 17 adapter by szalat

... drive more current than this motor can handle it will heat up quickly and burn or melt this adapter and possibly other elements.

62000

3d_export

$5

Perch 3D Model

...3d model 3dexport fish perch perch 3d model luckbird 62000 ...

3d_export

$49

snowman

...ma , mb big snowman: 18000 overall vertex count: 62000 textures: color,...

3ddd

$1

john lewis sebastian 7 light drop ceiling light

...john lewis , sebastian стек не свернут вес модели 62000 полигонов текстуры не требуются...

3ddd

free

Закуска

...штоф и рюмка с водкой, тарелка, вилка и маслёнка. 62000 ...

3ddd

$1

REGENBOGEN люстра хоф

...коричневого, зеленого и оранжевого светильника кол полигонов люстры - 62000 ...

3dfindit

free

62000 Precision Adjuster

...62000 precision adjuster

3dfind.it

catalog: wixroyd

3d_sky

free

Shop

...shop 3dsky bench traditional pub bench (andythornton). 1200h615h1000 62000 ...

3d_sky

free

Porada / Cheri

...porada / cheri 3dsky bench 62000 polygons length: 118 cm width: 41.6 cm height: 71...

3d_sky

free

Appetizer

...and a glass of vodka, plate, fork and oiler. 62000 ...

3d_sky

free

john lewis sebastian 7 light drop ceiling light

...john lewis sebastian weight stack is not collapsed model 62000 polygons texture does not require...

Hako

design_connected

$11

Hako Library

...hako library

designconnected

ligne roset hako library computer generated 3d model. designed by boisselier, philippe.

turbosquid

$90

Hako Cazador

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Euromissile HAKO

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$89

Scion Hako coupe concept 2008

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

hako by musuka

...hako by musuka

thingiverse

thingiverse

free

hako by musuka

...hako by musuka

thingiverse

lust up 2014.7.17.

3dfindit

free

Hako Bar

...hako bar

3dfind.it

catalog: 101 copenhagen

3dfindit

free

Hako Bench

...hako bench

3dfind.it

catalog: 101 copenhagen

3dfindit

free

Hako console

...hako console

3dfind.it

catalog: 101 copenhagen

thingiverse

free

HAKO - V490 lettering by Falcais

...hako - v490 lettering by falcais

thingiverse

hako - v490 lettering for the hood.

Sno

turbosquid

$90

Tucker Sno-Cat

...e 3d model tucker sno-cat for download as sldas, ige, and obj on turbosquid: 3d models for games, architecture, videos. (1635504)

thingiverse

free

Sno*Jet Hood Vent by copperdog626

...se

i needed a hood vent for my 73' sno*jet star jet 433. the first picture is the new one and the second is the old one.

thingiverse

free

SNO-T Sextant index shade bracket by brettpim

... a shallow mark in the same place on top and bottom.

for more information about the sno-t sextant see william morris' website

thingiverse

free

Sno-Tek by Ariens Snowblower Skid Shoes

...be sure to measure your mounts if trying to use this in a different application or resize appropriately to adapt to other models.

thingiverse

free

SNO-T Sextant index shade bracket by brettpim

...om to mark where the notch is on the original piece.

for more information about the sno-t sextant see william morris' website

thingiverse

free

Improved Snoopy Sno Cone Machine Locking Cap by jsc

... as it uses a different mechanism. my design is a faithful reproduction of the original, but with the locking direction reversed.

thingiverse

free

sno explorer, tracked rc vehicle

..., hence the motors should have sufficient torque.

the coil springs have an outer diameter of 10 mm and a wire diameter of 0.8 mm.

thingiverse

free

snowflake 4

...snowflake 4

thingiverse

a flake of sno

thingiverse

free

Sno Brūm Ice Scraper Attachment by bmemike

...9;s handle and accommodate the special triangular-holed cap. you will need 3 zip ties to keep it permanently attached during use.

thingiverse

free

Snoopy Sno Cone Machine Replacement Locking Cap by CodeCreations

...3mm hole on the handle. stick a piece of filament through it to help keep the parts together securely and make it easier to turn.

Snowblower

thingiverse

free

Custom Snowblower Wheel by madwrench

...custom snowblower wheel by madwrench

thingiverse

just some bling wheels for my snowblower.

thingiverse

free

Husqvarna snowblower key

... but the keys for snowblowers are pretty much universal.

i also haven't printed one yet as i'm waiting for more filiment.

thingiverse

free

N scale Tractor with snowblower by Areg7

...n scale tractor with snowblower by areg7

thingiverse

n scale tractor with snowblower

thingiverse

free

Snowblower Ski by te_3D

...snowblower ski by te_3d

thingiverse

fits the big red snow blowers

thingiverse

free

Snowblower Ignition Key by roboto

...a plastic ignition key for a mtd yardmachines snowblower 24 inch 2 stage. it may also fit other brands with same 4 cycle engines.

thingiverse

free

Batteriecase for Snowblower by Uzzi

...batteriecase for snowblower by uzzi

thingiverse

this is a battery protector for a snow blower sg 110 from china.

thingiverse

free

v formed snowblower 1/32 tracktor by jan1cato

...v formed snowblower 1/32 tracktor by jan1cato

thingiverse

!!!! untested !!!!

v formed snowblower for 1 32 scale tracktors

thingiverse

free

Snowblower Part by homeautomationguru

...wblower model number i built it for, but i'm posting for people to be able to follow along with the steps in the above posts.

thingiverse

free

MTD Snowblower Key

...with my settings, it prints in about 8 minutes.

i suggest printing extra hot and with 4 walls so that it has plenty of strength.

thingiverse

free

SNOWMOBILE/ SNOWBLOWER PULL CORD HANDLE by camaroboy383

...art handle designed for snowmobiles, but can be used on snowblowers as well... print on its side in abs with 100% infill... enjoy

Stratton

turbosquid

$25

Stratton Chair

...uid

royalty free 3d model stratton chair for download as max on turbosquid: 3d models for games, architecture, videos. (1223827)

turbosquid

$1

Briggs & Stratton Lawnmower Wheel

...tton lawnmower wheel for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1233718)

3d_export

$5

stratton home decor plant box collection

...on home decor plant box collection

3dexport

stratton home decor plant box collection sansevieria dieffenbachia dracaena aloevera

turbosquid

$1

Briggs & Stratton Lawnmower Wheel Concept

...nmower wheel concept for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1233719)

3ddd

$1

Crate and Barrel Set-01

...лампа-newbury table lamp рамки для фотографий-benson 8x10 picture frame, stratton 5x7 picture frame...

thingiverse

free

Briggs Stratton Carburetor adapter by kebekwa

...briggs stratton carburetor adapter by kebekwa

thingiverse

just my design of a carburetor adapter for briggs stratton to mikuni

thingiverse

free

Briggs & Stratton Throttle Knob by TasteOfChaoZ

... knob by tasteofchaoz

thingiverse

simple throttle knob for modern briggs & stratton engines like the rs-, cr- and xr-series.

3d_sky

free

Stratton Pendant Light By Tech Lighting

...sky

tech lighting

model large clearhttp://www.techlighting.com/products/fixtures/line-voltage-pendants/stratton-pendant

thingiverse

free

Briggs and Stratton Quantum Air Filter Knob by ctrlrst

...ratton quantum air filter knob by ctrlrst

thingiverse

air filter knob for briggs and stratton quantum, original screw/bolt used.

thingiverse

free

Briggs & Stratton InStart battery alternative by Suxel

...e battery to be used with a instart briggs & stratton lawnmower engine.

visit my website myprojectcorner.com for more details

Briggs

3ddd

$1

L'arte Luce BRIGG

...ый светильник

серия-brigg

производитель-l'arte luce

страна:италия

стиль:классика

материал:бронза

диаметр 250мм

высота 210мм

turbosquid

$100

Briggs- Army Soldier with skeleton

...riggs- army soldier with skeleton for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1523217)

turbosquid

$1

Briggs & Stratton Lawnmower Wheel

...tton lawnmower wheel for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1233718)

3ddd

$1

L'Arte Luce / Brigg L13501.86

...86

3ddd

l13501.86 , l\'arte luce

larteluce светильник подвесной brigg l13501.86

turbosquid

$1

Briggs & Stratton Lawnmower Wheel Concept

...nmower wheel concept for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1233719)

turbosquid

$15

Briggs Multi Light Ceiling Semi Flush Light

...iggs multi light ceiling semi flush light for download as max on turbosquid: 3d models for games, architecture, videos. (1449872)

3ddd

free

Люстра L'arte Luce

... brigg

серия-brigg

производитель-l'arte luce

страна:италия

стиль:классика

материал:бронза

диаметр 740mm

высота 400mm

3ddd

$1

Люстра L'arte Luce

...c

серия-brigg

производитель-l'arte luce

страна:италия

стиль:классика

материал:бронза

длина 1760mm

ширина 250mm

высота 400mm

3ddd

$1

Бра

...ерия-brigg

производитель-l'arte luce

страна:италия

стиль:классика

материал:бронза

ширина-270 mm

выступ-250 mm

высота-340 mm

3dbaza

$3

BRIGGS CHANDELIER by Eurofase (113633)

...briggs chandelier by eurofase (113633)

3dbaza

briggs by eurofase chandelier 3d model

Carburetor

turbosquid

$37

carburetor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$60

Carburetor 3D Model

...etor 3d model

3dexport

carburetor motorcycle car vehicle fuel atomize mikuni 7cc bike

carburetor 3d model blacks3d 89649 3dexport

3d_ocean

$9

Moped carburetor

...is exported in fbx and obj formats with materials applied and is fully subdivideable. for more car/motorcycle-related stuff ch...

3d_export

$39

Carburetor 3D Model

...nic detailled detail engine car vehicle auto animation animated motor fuel throttle

carburetor 3d model cesar_vonc 12002 3dexport

3d_export

$25

Moped carburetor 3D Model

...arb moped two stroke engine fuel puch maxi petrol injection feed motorcycle

moped carburetor 3d model dragosburian 80983 3dexport

3d_export

free

Carburetor FREE model

...odel

3dexport

carburetor created in blender. i upload two files a fbx and a blend file. you can edit the blend file if you want.

turbosquid

$99

Downdraught Single Bore Carburetor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$300

LSX-LS7 Carburetor intake manifold

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$39

holley dominator carburetor

... in this model, please do not hesitate to contact us, we are looking forward to continuously dealing with you.<br>markos 3d

3d_export

$5

Piaggio Ciao Sport Filter Adapter Two Verisons

...3dexport a new aftermarket design adapter for piaggio ciao/si carburetor. fits a 42mm sport filter. ready to print. step...

Gard

3d_export

free

avant garde f134

...avant garde f134

3dexport

avant garde f134

3ddd

free

AVANT- GARDE

...avant- garde

3ddd

dix heures dix

современный торшер

dix heures dix - avant-garde

дизайн fabrice berrux

3d_export

free

Sconce in avant-garde style

...sconce in avant-garde style

3dexport

this sconce is perfect for avant-garde interiors

turbosquid

$30

gard 5.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Elven Swords With No Gard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Avant Garde Arm Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Avant-garde-lounge-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Avant garde bar chair 3D Model

...rt

avant-garde bar club cafe furniture designer interior modern vray plastic

avant garde bar chair 3d model em.en. 90364 3dexport

turbosquid

$6

Gard Flydal Rorgemoen Design Stool

... model gard flydal rorgemoen design stool for download as max on turbosquid: 3d models for games, architecture, videos. (1217584)

3d_export

$15

Avant garde high bar table 3D Model

...ant-garde bar club cafe furniture designer interior modern vray plastic

avant garde high bar table 3d model em.en. 95198 3dexport

Spacer

turbosquid

$55

Spacer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

grendizer & double spacer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Hex Spacers M3 Male-Female

... spacers m3 male-female

3dexport

hex spacers m3 male-female with length from 5mm to 60mm for printed circuit boards. step files.

3d_export

$5

industrial lift - spacer crane

...crane<br>- 500 kg<br>- render 3ds max 2020 and corona renderer.<br>- formats: max 2020, max 2017, obj, fbx, stp

3d_export

$5

spacer hanging light

...lampshades: any total number of lamps: 6 polys: 18 546 verts: 19 045 https://imperiumloft.ru/lyustry-175/ev_a048924-eurosvet.html

turbosquid

$5

Industrial lift Spacer crane Renaissance construction

...naissance construction for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1571898)

3d_export

$7

industrial lift - spacer crane renaissance construction

...ction<br>- 750 kg<br>- render 3ds max 2020 and corona renderer.<br>- formats: max 2020, max 2017, obj, fbx, stp

3d_export

$10

Spacer Sliding Wardrobe 1200 Hanger

...painter available for all software<br>ue4. ue5. blender. maya. 3d max. unity. c4d.<br>formats: .obj .gltf .fbx .blend

3d_export

$5

Hockey puck 3D Model

...hockey puck 3d model 3dexport hockey puck spacer washer disk shim hockey puck 3d model gizmo_fbi 28754...

3d_export

$5

Front 30mm Lift Kit for 1996-2004 Nissan Pathfinder and 1997-2003 Infiniti QX4

...terrano r50, regulus 1997-2003 infiniti qx4 - front strut spacer ...