Thingiverse

Carbon Fibre Tube Quadcopter - Kraken Pod by MantleQuads

by Thingiverse

Last crawled date: 3 years ago

UPDATE: Both V1 tube frames have been broken due to the carbon tubes not being properly secured and reinforced. I am working on a second revision that will use two small carbon plates to reinforce the arms, rather than relying on a big blob of epoxy.

Inspired by the Bexamous tube frame: https://imgur.com/a/hEevI

Final frame weights:

5" 200 size - 43g with a 2mm Kraken pod (31g without)

6" 230 size - 55g with a 3mm Kraken pod (34g without)

To make a frame you will need:

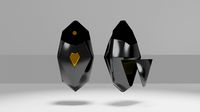

4x 10mm_tube_16mm_mount (the part the motors mount on to)

1x 10mm_tube_Kraken template (this part is used as a template for drilling the board and pod holes and filing the notch)

10mm OD, 8mm ID carbon fibre tube, length of your choosing. I get mine here: http://www.ebay.com.au/itm/1Pc-Roll-Wrapped-Carbon-Fiber-Tube-3K-8mm-x-10mm-X-500mm-For-Multicopter-DIY-/131665162489?hash=item1ea7daf0f9:g:i3MAAOSwNphWXWZJ

Epoxy, I used 5 minute epoxy.

Optionally, a Kraken pod, I find the 3mm pod to be indestructible but the thinner pods are much lighter. I'm currently working on my own TPU pod that will fit a 50x50mm mounting pattern. https://boltrc.com.au/index.php?id_product=162&controller=product&search_query=kraken+pod&results=15

How to put it all together: (Repeat steps 1,2,3,4. You will need to make two tubes)

NOTE: Carbon fibre dust is not good, avoid using rotary tools such as a dremel tool because it will throw dust in the air. A drill, hacksaw and a file are all that will be needed for the build and are all safe to use as long as the carbon is kept wet. I cut and drill my carbon outside spraying the tool and carbon tube with water frequently.

Tools:

Hacksaw

Drill

File

Water proof fine sanding paper (optional)

Measure

Measure a section of carbon tube, wrap the area to be cut with masking tape. For reference, I use two 250mm long tubes for a 6" and 220mm for a 5", both fitting a Kraken pod.

Cut

Cut the tubing as desired with a hacksaw, keeping the tube and saw wet so no carbon particles escape. You may have to roll the tube around to make the cut. If the end of the tube is left rough or uneven wet the sand paper and smooth out the tip of the carbon tube.

Drilling

Slide the template block on to a tube, lining the middle of the notch up with the centre of the tube. Place a motor mount on each end of the tube, ensuring that the end of the tube is level with the end of the motor mount. Ensure that both mounts and the template are correctly placed, you don't want misaligned holes. Drill a small pilot hole through all holes on one side of the tube, I use a 1/16 size bit. Repeat on the other side and follow up with a larger drill bit to widen the original holes so that they can all fit a M3 bolt. (Using a pilot hole minimises splitting of the carbon.) Wet the tube and drill bits as required.

Filing

For this task I use a 4mm wide file that is about 200mm long. Wet the notch and file and begin to wear at the exposed carbon in the notch with the side of the file. remove all carbon from the notch and attempt to make the edges as smooth and straight as possible.

Assembly

Remove the template and place all motor mounts on the ends of each tube, lined up with the holes. Notch the two carbon pieces together and check they will fit smoothly and correctly. Begin to mix the epoxy. (I use a broken prop for this, actually very good for scooping up a little bit of epoxy and applying it.) Coat the edges of the exposed notch on each tube with epoxy, Apply epoxy to the gap between arms at the centre of the frame as well as the top and bottom of where the notches meet. (Bexamous' guide has pictures detailing this process and shows how much epoxy should be used) To make sure the frame comes out straight I like to flip it over so the mounting surface of the motor mounts is upside down, then I screw on a Kraken pod to make sure it holds a good X shape. Allow the epoxy to cure for at least about 12 hours, preferably in a warm dry place.

Inspired by the Bexamous tube frame: https://imgur.com/a/hEevI

Final frame weights:

5" 200 size - 43g with a 2mm Kraken pod (31g without)

6" 230 size - 55g with a 3mm Kraken pod (34g without)

To make a frame you will need:

4x 10mm_tube_16mm_mount (the part the motors mount on to)

1x 10mm_tube_Kraken template (this part is used as a template for drilling the board and pod holes and filing the notch)

10mm OD, 8mm ID carbon fibre tube, length of your choosing. I get mine here: http://www.ebay.com.au/itm/1Pc-Roll-Wrapped-Carbon-Fiber-Tube-3K-8mm-x-10mm-X-500mm-For-Multicopter-DIY-/131665162489?hash=item1ea7daf0f9:g:i3MAAOSwNphWXWZJ

Epoxy, I used 5 minute epoxy.

Optionally, a Kraken pod, I find the 3mm pod to be indestructible but the thinner pods are much lighter. I'm currently working on my own TPU pod that will fit a 50x50mm mounting pattern. https://boltrc.com.au/index.php?id_product=162&controller=product&search_query=kraken+pod&results=15

How to put it all together: (Repeat steps 1,2,3,4. You will need to make two tubes)

NOTE: Carbon fibre dust is not good, avoid using rotary tools such as a dremel tool because it will throw dust in the air. A drill, hacksaw and a file are all that will be needed for the build and are all safe to use as long as the carbon is kept wet. I cut and drill my carbon outside spraying the tool and carbon tube with water frequently.

Tools:

Hacksaw

Drill

File

Water proof fine sanding paper (optional)

Measure

Measure a section of carbon tube, wrap the area to be cut with masking tape. For reference, I use two 250mm long tubes for a 6" and 220mm for a 5", both fitting a Kraken pod.

Cut

Cut the tubing as desired with a hacksaw, keeping the tube and saw wet so no carbon particles escape. You may have to roll the tube around to make the cut. If the end of the tube is left rough or uneven wet the sand paper and smooth out the tip of the carbon tube.

Drilling

Slide the template block on to a tube, lining the middle of the notch up with the centre of the tube. Place a motor mount on each end of the tube, ensuring that the end of the tube is level with the end of the motor mount. Ensure that both mounts and the template are correctly placed, you don't want misaligned holes. Drill a small pilot hole through all holes on one side of the tube, I use a 1/16 size bit. Repeat on the other side and follow up with a larger drill bit to widen the original holes so that they can all fit a M3 bolt. (Using a pilot hole minimises splitting of the carbon.) Wet the tube and drill bits as required.

Filing

For this task I use a 4mm wide file that is about 200mm long. Wet the notch and file and begin to wear at the exposed carbon in the notch with the side of the file. remove all carbon from the notch and attempt to make the edges as smooth and straight as possible.

Assembly

Remove the template and place all motor mounts on the ends of each tube, lined up with the holes. Notch the two carbon pieces together and check they will fit smoothly and correctly. Begin to mix the epoxy. (I use a broken prop for this, actually very good for scooping up a little bit of epoxy and applying it.) Coat the edges of the exposed notch on each tube with epoxy, Apply epoxy to the gap between arms at the centre of the frame as well as the top and bottom of where the notches meet. (Bexamous' guide has pictures detailing this process and shows how much epoxy should be used) To make sure the frame comes out straight I like to flip it over so the mounting surface of the motor mounts is upside down, then I screw on a Kraken pod to make sure it holds a good X shape. Allow the epoxy to cure for at least about 12 hours, preferably in a warm dry place.

Similar models

thingiverse

free

T-Bit by sebWW2

....asp?idproduct=80945

before drilling two holes per carbon tube i put in the tubes to make sure t-bit and tube line up perfectly.

thingiverse

free

4mm bowden tube end holder by apell

...h with the 4mm drill bit, then it may or may not hold the tube properly in place.

use m4x8mm screws for mounting to 2020 profile.

thingiverse

free

Tubequad

...ly, and will be for 12x12 mounting pattern. the carbon tube, frame, and motor mounts were glued together using a two part epoxy..

thingiverse

free

CARBON TUBE QUADCOPTER FRAME 10MM by giek2000

...for 10mm tube too. because props overlap you could make a 5" 170 racer.

comes with 19mm, 16mm, and 12mm spaced motor mounts.

thingiverse

free

Thrust bench by Tiktiki

...ght to get a good reading.

printable motor mounts:http://www.thingiverse.com/thing:723234http://www.thingiverse.com/thing:1459883

thingiverse

free

Cutting template for slots in half inch tube by bshephard

...a hose clamp so i made a pair of these to use as a template and to hold the pipe in the vice while i cut the slots with a hacksaw

thingiverse

free

Domino by R87Mavric

...angular domino keys after gluing templates on keys.

fill holes with epoxy glue and liquid dye to desired color.

polish and enjoy!

grabcad

free

drill bit

...drill bit

grabcad

drill bits are cutting tools used to create cylindrical holes

thingiverse

free

reprapguru Y plate replacement by ToddCarr

...ad to make two holes on the end slightly larger to keep the heatbed alignment but all in all it is fine.

i used 1.5 mm aluminum.

grabcad

free

Drill Bit

...drill bit

grabcad

drill bits are cutting tools used to remove material to create holes.

Mantlequads

thingiverse

free

Locust 6" by MantleQuads

... long as credit is given to the original design. please contact me if you are interested in using any of my designs commercially.

thingiverse

free

BOLT210 Race Runcam 3 40 degree mount by MantleQuads

...rips of velcro tape on the top of the mount and bottom of the rc3 to make sure the camera won't eject easily in a hard crash.

thingiverse

free

Reverie by MantleQuads

... long as credit is given to the original design. please contact me if you are interested in using any of my designs commercially.

thingiverse

free

Locust 4" by MantleQuads

... long as credit is given to the original design. please contact me if you are interested in using any of my designs commercially.

thingiverse

free

Locust 5" by MantleQuads

... long as credit is given to the original design. please contact me if you are interested in using any of my designs commercially.

thingiverse

free

Jackal 5" by MantleQuads

... long as credit is given to the original design. please contact me if you are interested in using any of my designs commercially.

Kraken

turbosquid

$10

Kraken

...oyalty free 3d model kraken for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1401448)

3d_export

$5

rum kraken

...rum kraken

3dexport

3d model rum "kraken"

3d_export

$5

razer kraken

...razer kraken

3dexport

razer kraken headphones, modeled in cinema 4d, render in corona

turbosquid

$3

Mighty Hammer Kraken

...ree 3d model mighty hammer kraken for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1611798)

turbosquid

$35

Octopus/Kraken pearl

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Kraken two-handed sword

...kraken two-handed sword

3dexport

heavy two-handed sword. the height of the sword is 1.5 meters

3d_ocean

$20

Monster Creature - Clawler

...3docean alien creature melee fighter monster monster creature – kraken shell clawler head – from 1,538 to 1,572mil poly...

3d_ocean

$3

Square Scales Seamless Texture

...scales seamless texture 3docean aqua cartoon creature fin fish kraken mermaid merman monster ocean octopus scales scaly sea sea...

3d_export

$5

ancient sea chest for a game project low-poly

...other things. on top of the chest is a kraken with ruby stones for eyes. the chest is static....

thingiverse

free

Kraken by Kush

...r making the tinkercad tutorial for the kraken. here is the link to it:https://www.tinkercad.com/quests/adueoggzo9p-lesson-kraken

Fibre

turbosquid

$39

Natural fibre carry Bags

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$24

Crinoline Chair With Armrests and Polyethylene Fibre

...hair with armrests and polyethylene fibre for download as max on turbosquid: 3d models for games, architecture, videos. (1390035)

turbosquid

$49

Futuristic Carbon Fibre Panels (PBR)

...istic carbon fibre panels (pbr) for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1212926)

3ddd

$1

Resident "FIBRE LIGHT - BOTTLE"

... fibre light , bottle

led. подвесной светильник из ультратонкого углеволокна.

turbosquid

$10

Fibre-reinforced plastic rebar factory

... plastic rebar factory for download as mat, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1297054)

turbosquid

$45

Carbon fibre floor standing speakers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Cedrimartini Ufo Glass-fibre Pendant Lamp

...cedrimartini ufo glass-fibre pendant lamp for download as max on turbosquid: 3d models for games, architecture, videos. (1386392)

3ddd

$1

Покрытие "Fibres de Cotex" (часть 1)

...uot; ткани. покрытие скрывает дефекты стен, не впитывает запахи, не выгорает, обеспечивает дополнительную тепло- и звукоизоляцию.

3ddd

$1

Покрытие "Fibres de Cotex" (часть 2)

...uot; ткани. покрытие скрывает дефекты стен, не впитывает запахи, не выгорает, обеспечивает дополнительную тепло- и звукоизоляцию.

3ddd

$1

Zanotta Undercover Sofa

...polyester fibre. removable quilted cover with heat bound polyester fibre in fabric or...

Quadcopter

3d_export

$5

quadcopter

...quadcopter

3dexport

futuristic quadcopter design.<br>original design davidflo 77

turbosquid

$19

quadcopter

...lty free 3d model quadcopter for download as max, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1591426)

turbosquid

$25

QuadCopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Quadcopter 3D Model

...quadcopter 3d model

3dexport

quadcopter studio shaders

quadcopter 3d model vortex333 93968 3dexport

3d_export

$5

Quadcopter 3D Model

...quadcopter 3d model

3dexport

quadcopter aircraft helicopter

quadcopter 3d model greatghost 94019 3dexport

3d_export

$18

passenger quadcopter

... a multicopter is an aircraft built according to a helicopter scheme, with three or more rotors. previews rendered with redshift.

turbosquid

$159

Quadcopter Animated.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Drone Quadcopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Drone Quadcopter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$29

Quadcopter

...

questions about the continuation of the collection or the model can be asked here:<br>https://www.artstation.com/evgen_beg

Pod

design_connected

$13

Pod

...pod

designconnected

niche modern pod computer generated 3d model. designed by pyles, jeremy.

3d_export

$5

engine pod

...engine pod

3dexport

engine pod

turbosquid

$80

POD

...pod

turbosquid

royalty free 3d model pod for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1234976)

3ddd

$1

Pod 325

...pod 325

3ddd

пуф

pod 325

turbosquid

$4

PODS

...oyalty free 3d model pods for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1563118)

3d_export

$5

coworking pods

...coworking pods

3dexport

private pods for workspaces, offices

3ddd

$1

Pod Meeting

...pod meeting

3ddd

pod meeting , martela

146cm x 205cm

design_connected

$16

Pod 325

...pod 325

designconnected

department pod 325 computer generated 3d model.

3d_ocean

$5

Ariel Power Pod

...model ariel power pod ariel power pod, modeled in cinema 4d r14 and all materials are included. if you like it, please rate this

3ddd

$1

POD 325

...pod 325

3ddd

кресло мешок

кресло мешок pod 325, room 21 85x50x100cm.

Carbon

3d_ocean

$2

Carbon Textures

...usty shiny tga tileable

a pack of 5 carbon textures. tileable. 512×512 pixel sized. jpg , tga image format given. stay connected

design_connected

$16

Carbon Chair

...carbon chair

designconnected

moooi carbon chair chairs computer generated 3d model. designed by marcel wanders.

3ddd

$1

Carbon touring desk

... tonino lamborghini casa , стол

tonino lamborghini casa carbon touring desk

turbosquid

$1

carbonic acid

...id

royalty free 3d model carbonic acid for download as blend on turbosquid: 3d models for games, architecture, videos. (1517834)

design_connected

$7

Carbon Shagreen Box

...carbon shagreen box

designconnected

carbon shagreen box computer generated 3d model.

turbosquid

$90

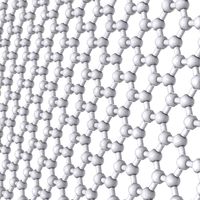

Carbon NanoSheet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$90

Carbon Nanotube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

carbon nanosheet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$38

Carbon Planet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Carbon dioxide

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Tube

archibase_planet

free

Tube

...tube

archibase planet

paint tube stationery

tube - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

free

tube

...tube

turbosquid

free 3d model tube for download as c4d on turbosquid: 3d models for games, architecture, videos. (1378271)

archibase_planet

free

Tube

...tube

archibase planet

mascara cosmetics make-up

tube 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

Tube pants

...tube pants

3dexport

tube pants

3d_export

free

Tube

...tube

3dexport

turbosquid

free

TUBE

...

free 3d model tube for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1672199)

turbosquid

$29

tube

...lty free 3d model tube for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442047)

3ddd

$1

perfume tube

...perfume tube

3ddd

тюбик

perfume tube, тюбик

3ddd

$1

Olivieri Tube

...olivieri tube

3ddd

olivieri

кровать olivieri tube

turbosquid

$22

Tube

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.