Thingiverse

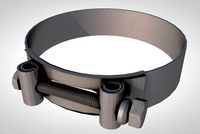

C clamp by Muzeem

by Thingiverse

Last crawled date: 3 years, 4 months ago

A c clamp for 3d printing

Design guidelines for C Clamp

a) Reduce the number and types of parts used in product manufacturing, so that fewer steps and fixtures are required. This approach reduces assembly cost. This approach is referred to as value engineering.

b) Parts to be assembled should have high degree of symmetry or a high degree of asymmetry. They should be designed such that they would not be installed incorrectly. Or such that they do not require locating, aligning, or adjusting.

c) Designs should allow parts to be assembled without obstruction or the lack of a direct line of sight

TENSILE STRESS Due to bolt tightening (for stem and cap screw). Experiments have shown that there exists an initial tension in the stem bolt during tightening and experientially, could be found by the relation

Pi = 1420 d N where: Pi = initial tension in a bolt d =nominal diameter of the bolt

STRESS AREA Area of stem bolt under load engagement situation ;

Stress Area = π/4 (dp+dc) 2 2 Where:

dp= pitch diameter

dc = Core or minor diameter

Compressing Or Crushing Stress On The Threads

This effective stress, has to do with the value of the stress between the threads which combine to transfer the needed force to the work piece under the stem. This stress is obtained by the relation;

fc = P π(d2 - dc 2 )n

where : d = major diameter dc = minor diameter n = number of threads in engagement P = maximum safe axial load

Design guidelines for C Clamp

a) Reduce the number and types of parts used in product manufacturing, so that fewer steps and fixtures are required. This approach reduces assembly cost. This approach is referred to as value engineering.

b) Parts to be assembled should have high degree of symmetry or a high degree of asymmetry. They should be designed such that they would not be installed incorrectly. Or such that they do not require locating, aligning, or adjusting.

c) Designs should allow parts to be assembled without obstruction or the lack of a direct line of sight

TENSILE STRESS Due to bolt tightening (for stem and cap screw). Experiments have shown that there exists an initial tension in the stem bolt during tightening and experientially, could be found by the relation

Pi = 1420 d N where: Pi = initial tension in a bolt d =nominal diameter of the bolt

STRESS AREA Area of stem bolt under load engagement situation ;

Stress Area = π/4 (dp+dc) 2 2 Where:

dp= pitch diameter

dc = Core or minor diameter

Compressing Or Crushing Stress On The Threads

This effective stress, has to do with the value of the stress between the threads which combine to transfer the needed force to the work piece under the stem. This stress is obtained by the relation;

fc = P π(d2 - dc 2 )n

where : d = major diameter dc = minor diameter n = number of threads in engagement P = maximum safe axial load

Similar models

thingiverse

free

Fx impact buttpad with adjustble monopod by puna102

... slide in a m5 nut for the tightening / clamping bolt. it's best to use 100% infill past the m5 nut. should print vertically.

grabcad

free

FEA of Nut and Bolt assembly

...nut and bolt assembly

grabcad

this model shows the stress and displacement of a bracket due to the tightening of a nut and bolt.

thingiverse

free

Syringe Clamp by S3MTech

...ge side also serves as a rotational joint. at the same time it clamps the syringe chamber (18 mm diameter) with a circular clamp.

grabcad

free

TC-331-SS Clamp

...de sta co 331-ss pull action clamp with threaded u-bolt

https://www.amazon.com/331-ss-action-clamp-threaded-u-bolt/dp/b000fmx212

grabcad

free

MTB DH handlebar stem

...

handlebar stem designed for a dh handlebar

31.8mm clamp diameter

28.575mm steerer diameter

approx 100mm extension

8 degree rise

grabcad

free

ShapeOko2 Belt Tensioners

...ension is 4mm hex m5 30mm long

the bolt for the clamp is a 2.5mm hex m3 14mm long

reverse side of clamp 2 locking hex 5mm m3 nuts

grabcad

free

Nut n Bolt assembly

...nut n bolt assembly

grabcad

my first assembly and threading!

3dwarehouse

free

PI

...hematical and physical constants: many formulae from mathematics, science, and engineering involve π. #3d #314 #bram #pi #tánczos

thingiverse

free

C-Clamp 80 mm by 3dprints94

...for the first time. make sure to ease the threaded rod into the clamp. i used 100% infill on the threaded rod to reduce shearing.

grabcad

free

Rod Bolt

...xtends the bolts and puts them under tensile stress, which helps maintain the two components together during tension compression.

Muzeem

thingiverse

free

HyperCube scaled by Muzeem

...hypercube scaled by muzeem

thingiverse

customized hypercube

thingiverse

free

Peristaltic Pump by Muzeem

...peristaltic pump by muzeem

thingiverse

a peristaltic pump with minimum components

thingiverse

free

Friction Hinge by Muzeem

...friction hinge by muzeem

thingiverse

using o-rings in the groove for best performance

thingiverse

free

Filament Recycling machine by Muzeem

...filament recycling machine by muzeem

thingiverse

a filament recycling extruder

thingiverse

free

Piggy Bank Modular by Muzeem

...piggy bank modular by muzeem

thingiverse

a modular secret piggy bank

thingiverse

free

Vaccum Casting Machine by Muzeem

...vaccum casting machine by muzeem

thingiverse

vacuum casting machine for resin casting.

thingiverse

free

CNC 3D printer by Muzeem

...cnc 3d printer by muzeem

thingiverse

a cnc 3d printer for minimum vibrations and best performance.

thingiverse

free

Thumb Wheel by Muzeem

... wheel by muzeem

thingiverse

thumb wheel for bed leveling.

use m3 thread inserts .

infill - 60+

layer height - 0.2

material petg

thingiverse

free

X Endstop Flag by Muzeem

...x endstop flag by muzeem

thingiverse

this is a x endstopper flag design for prusa .

use petg and 100%infill .

thingiverse

free

X - End stop Flag by Muzeem

...x - end stop flag by muzeem

thingiverse

actuating adapter for prusa x endstop.

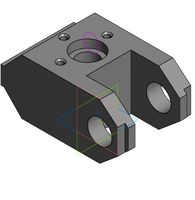

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

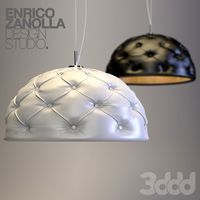

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442049)

turbosquid

$29

clamp

...ty free 3d model clamp for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1442041)

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

C

3ddd

$1

Gustavsberg Skandic 160 c-c

...gustavsberg skandic 160 c-c

3ddd

gustavsberg , смеситель

3dmax 2009

3ddd

$1

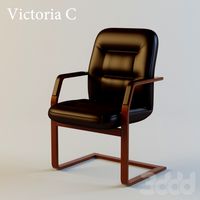

Кресло Victoria C

...кресло victoria c

3ddd

victoria c , стул

victoria c

design_connected

$25

Mobius C

...mobius c

designconnected

zenith mobius c computer generated 3d model. designed by schamburg, marc.

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

molteni & c

turbosquid

$10

Raids house C&C Tiberian sun

... raids house c&c tiberian sun for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1188376)

turbosquid

$10

Civilian Asylum C&C Tiberian sun

...ilian asylum c&c tiberian sun for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1188365)

3ddd

$1

Molteni & C

...molteni & c

3ddd

molteni&c

стул molteni & c

3ddd

free

kamina&c

...kamina&c

3ddd

kamina-c , табурет барашек

sheep chair by kamina-c

design_connected

$29

Extrasoft C

...extrasoft c

designconnected

living divani extrasoft c computer generated 3d model. designed by lissoni, piero.

design_connected

$4

Mono C

...mono c

designconnected

scp mono c tables computer generated 3d model. designed by konstantin grcic.