Thingiverse

Brushless R/C Racing Hovercraft - For 200x200 printer by Apru

by Thingiverse

Last crawled date: 3 years, 1 month ago

Some playing around on a small frozen pondhttps://www.youtube.com/watch?v=GtGw097Tzy4

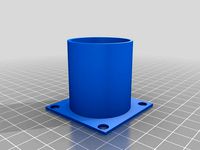

Edit Dec 21, 2017: I added a new lift duct design. The normal duct is designed to cancel out the motor torque of a clock wise rotating propeller. You can mirror it in your slicer if you have a counter clockwise propeller rotation direction. Additionally, a safety grate has been added which screws to the top of the duct and protects peoples fingers. A grate for the thrust duct is forthcoming.

This is a remix of the original to hovercraft to fit on a 200 x 200 printer. I added reinforcements at the joints of the upper and lower hulls to make sure the seam was strong. I used Welders contact adhesive available on Amazon. Other adhesives such as Goop or E6000 available at Walmart, Lowes, Home Depot would work too. CA/Superglue will work but it's a brittle glue when cured. You want the adhesive to be somewhat flexible but strong or the joint may fail.

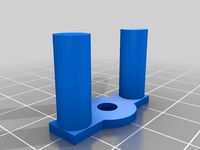

Print the thrust duct and rudders with 1 perimeter and low infill - like 15% or so. They need to be light. I recommend using a brim to keep the thrust duct stuck to the build platform. Tall and thin objects like the legs of the thrust duct tend to have large thermal stress distributions causing them to warp and pull off the bed. a 5mm brim solved my problems. The thrust duct requires the use of supports.

I recommend printing in PETG or ABS. PLA will be brittle. ABS may cause problems with warping and printing large pieces without an enclosure. PETG is a good mix of strength and printing ease.

I printed the skirt ring successfully in one piece on my 200 x 200 Makerfarm I3V 8inch printer.

I used pieces of 1.8mm filament as alignment pins. They also act to strengthen the joint.

I am experimenting with a new thrust duct remix design to decrease weight (lower the CG) while increasing durability.

I would also recommend getting the skirt parameters correct using a trash bag, however, use of nylon ripstop material (parachute fabric) is ideal as it's tough, light weight, abrasion resistant and a much better material than a trash bag.

Further remixed parts are coming as I work on the design iterations.

Edit Dec 21, 2017: I added a new lift duct design. The normal duct is designed to cancel out the motor torque of a clock wise rotating propeller. You can mirror it in your slicer if you have a counter clockwise propeller rotation direction. Additionally, a safety grate has been added which screws to the top of the duct and protects peoples fingers. A grate for the thrust duct is forthcoming.

This is a remix of the original to hovercraft to fit on a 200 x 200 printer. I added reinforcements at the joints of the upper and lower hulls to make sure the seam was strong. I used Welders contact adhesive available on Amazon. Other adhesives such as Goop or E6000 available at Walmart, Lowes, Home Depot would work too. CA/Superglue will work but it's a brittle glue when cured. You want the adhesive to be somewhat flexible but strong or the joint may fail.

Print the thrust duct and rudders with 1 perimeter and low infill - like 15% or so. They need to be light. I recommend using a brim to keep the thrust duct stuck to the build platform. Tall and thin objects like the legs of the thrust duct tend to have large thermal stress distributions causing them to warp and pull off the bed. a 5mm brim solved my problems. The thrust duct requires the use of supports.

I recommend printing in PETG or ABS. PLA will be brittle. ABS may cause problems with warping and printing large pieces without an enclosure. PETG is a good mix of strength and printing ease.

I printed the skirt ring successfully in one piece on my 200 x 200 Makerfarm I3V 8inch printer.

I used pieces of 1.8mm filament as alignment pins. They also act to strengthen the joint.

I am experimenting with a new thrust duct remix design to decrease weight (lower the CG) while increasing durability.

I would also recommend getting the skirt parameters correct using a trash bag, however, use of nylon ripstop material (parachute fabric) is ideal as it's tough, light weight, abrasion resistant and a much better material than a trash bag.

Further remixed parts are coming as I work on the design iterations.

Similar models

thingiverse

free

hovercraft Mk2 by Churchillww1

...f using fins

its more aerodynamic

the skirt frame is attached to the body

i have not made this yet but i will update it when i do

thingiverse

free

Sovol SV01 Lateral Fan Duct Remix by Genesis5226

...ential future updates from problems that may arise.

recommend using petg filament to prevent warping or disfiguration during use.

thingiverse

free

MarvinMarvin

...tle help with supports on the skirt pieces. i recommend cura tree support, but the more pedestrian supports will do the job too.

thingiverse

free

MinV2 Ender 3 40mm Duct fan remix

... of the stock cooling fan. i would use petg to keep things from warping or melting. will post make images after i get it printed.

thingiverse

free

Printo H2 Trash bin by ja2ja1

...inter with closed box cover.

trash bin is useful for any left overs from, skirts, brims, rafts, supports, pieces of filament etc.

thingiverse

free

Android logo by umer801

...ality.i am using anet et4 pro printer with settings 25% infill. you can also brim or skirt. i use brim to stick my print to bed.

thingiverse

free

Brushless R/C Racing Hovercraft by kodaknix

...ct can be printed as one so i put the files for them in here to.https://www.youtube.com/watch?v=hch_sxtejds&feature=youtu.be

thingiverse

free

Hovercraft by Churchillww1

...t where one of the slots on one side of the body didn't prints this is now fixed. this was only for the updated body sections

thingiverse

free

Sovol SV01 Cooling Fan Duct

...fan duct

thingiverse

i got this from cr10s pro cooling fan and modify it to fit sovol printer. use petg or abs to avoid warping.

thingiverse

free

Car Bag Holder by jaymigibbs42

...ing in petg (like i printed these) or in abs to prevent them melting in your car especially since they will be attached to metal.

Apru

thingiverse

free

SSN774 Virginia Class Submarine by Apru

...ssn774 virginia class submarine by apru

thingiverse

ssn774 virginia class submarine

thingiverse

free

ZMR Slim LED Light Bar and Antenna Base by Apru

...zmr slim led light bar and antenna base by apru

thingiverse

zmr slim led light bar and antenna base for frsky rx

thingiverse

free

Defiant Wings Defiant 28 Parts by Apru

... these parts with minimum top/bottom layers and lowish infill. i used 2 top/bottom, 2 perimieters, .2 layer height and 30 infill.

thingiverse

free

Z-UP-Unsupported Angle Tester by igr3gs by Apru

...r by igr3gs by apru

thingiverse

i rotated this to z-up. i figured others may need it too. some slicers can't rotate objects.

thingiverse

free

Tear Drop Petzval Aperture by Apru

...tear drop filter. i'm sure she's not alone and others may want one.

send me a note if you want custom shapes.

enjoy.

thingiverse

free

Defiant Wings Defiant42 Nutless Motor Mount by Apru

...petg, abs or nylon. using pla will likely result in failure due to motor heat conducting into the screws and softening the mount.

thingiverse

free

3DR Simple Ramps 1.4 Mount by Apru

...older here:

http://www.thingiverse.com/thing:255702

the mount has 6 mounting holes allowing you some flexibility in mounting.

thingiverse

free

3DR Simple Spool Mount with Underneath Mounting Holes by Apru

...for this as i type. i will create that thing and link to it here as well.

the mounting holes can be used for anything, really.

thingiverse

free

SSN688 Los Angeles Class Submarine by Apru

...g:287026 as a propeller. i merged the tailcone with the propeller and printed them as one piece.

the model was created in sw2013.

thingiverse

free

3DR Simple J-Head End Effector by Apru

...p screws

3 m3 nuts

1 m5 nut

1 push fit pneumatic bushing for 4mm od tube, 5mm thread

tridprinting j-head (at least the peek body)

Hovercraft

thingiverse

free

Hovercraft by seansylvester1

...hovercraft by seansylvester1

thingiverse

hovercraft for science olympiad

thingiverse

free

Savannah Hovercraft

...savannah hovercraft

thingiverse

all in one savannah hovercraft

thingiverse

free

HOVERCRAFT by papo2110

...hovercraft by papo2110

thingiverse

hovercraft

https://www.youtube.com/watch?v=zt8meeqsma4&t=351s

thingiverse

free

Clan Hovercraft by smight

...clan hovercraft by smight

thingiverse

clan hovercraft

thingiverse

free

Hovercraft by _MSA_

...by _msa_

thingiverse

hovercraft

this thing was designed to be easy to print and for small kids: without sharp edges and durable.

thingiverse

free

Lightning Attack Hovercraft

...lightning attack hovercraft

thingiverse

lightning attack hovercraft

thingiverse

free

Gabriel reconnaissance hovercraft

...gabriel reconnaissance hovercraft

thingiverse

gabriel reconnaissance hovercraft

thingiverse

free

Battletech Saladin Hovercraft

...base of the savannah master hovercraft. i was looking for a saladin hovercraft and i could not find one i wanted to use. enjoy.

thingiverse

free

Hovercraft by Mowzes

...eetles, honeycomb patterns made by bees and the web of a spider, all to make the most of the total performance of the hovercraft.

thingiverse

free

Hovercraft Prop by ExcellentEngineering

...ring

thingiverse

this is a propeller for a hovercraft it works and fit with no modifications needed https://youtu.be/7dupvxxerx4

200X200

thingiverse

free

200x200 Vesamount by JohnneBe84

...200x200 vesamount by johnnebe84

thingiverse

thingiverse

free

OpenAstroTracker Part14 200x200 bed

...openastrotracker part14 200x200 bed

thingiverse

a shorter part 14 if you're printing on a 200x200 print bed.

thingiverse

free

test size 20x20 and 200x200 by olo2000pm

...test size 20x20 and 200x200 by olo2000pm

thingiverse

test size 20x20 and 200x200

thingiverse

free

Smartrap v0.4 200x200 build plate by flow

...smartrap v0.4 200x200 build plate by flow

thingiverse

smartrap v0.4 200x200 build plate

thingiverse

free

Calibrazione piano 200x200 by ModelQuartier

...calibrazione piano 200x200 by modelquartier

thingiverse

stampare a 0,1mm di layer

thingiverse

free

Calibration squares for 200x200 mm bed by just_a_normal_cool_username

...ed by just_a_normal_cool_username

thingiverse

calibration squares for calibrating your 3d printer. designed for 200x200 mm beds.

thingiverse

free

Surgical Mask Strap Remix (ENHANCE) 200x200 by danielggarcia

... 200x200 by danielggarcia

thingiverse

adaptation of surgical mask strap remix (enhance) for 200x200 bed.

original work by mrbulp

thingiverse

free

Big Bullzeye Clock - Pieces cut for 200x200 build plate by gwschuster

...ild plate by gwschuster

thingiverse

these are pieces that are too big for a 200x200 build plate cut to fit - super glue together

thingiverse

free

HD Receiver Vesa 200x200 Holder by matthesjimte

...hd receiver vesa 200x200 holder by matthesjimte

thingiverse

holder for hd receiver with 170x40mm size and vesa 200x200mm

thingiverse

free

Prusa i3 200x200 Build Tray by Joe_Murphy

...prusa i3 200x200 build tray by joe_murphy

thingiverse

print prusa i3 in one 200x200mm tray. missing extruder.

Brushless

thingiverse

free

Tyro 79 brushless key

...tyro 79 brushless key

thingiverse

tyro 79 brushless key

thingiverse

free

Propeller antirotation brushless lock

...propeller antirotation brushless lock

thingiverse

propeller antirotation brushless lock

thingiverse

free

Brushless motor holder by NukeCraft

...brushless motor holder by nukecraft

thingiverse

brushless motor holder for bl3650

thingiverse

free

Brushless motor mount by robotbuilders

...brushless motor mount by robotbuilders

thingiverse

replacement mount for brushless motor.

thingiverse

free

Brushless motor mount by TarsVH

...brushless motor mount by tarsvh

thingiverse

a mount for a 2830 size brushless motor

thingiverse

free

Softmount for brushless 28x18.5 by Maketron

...softmount for brushless 28x18.5 by maketron

thingiverse

softmount or silentblock for brushless 28x18.5 and washer m3

thingiverse

free

Fixe câbles Brushless by KZR

...fixe câbles brushless by kzr

thingiverse

fix cable pour combo brushless 3 cables

thingiverse

free

brushless motor protector by cahittt

...brushless motor protector by cahittt

thingiverse

you need such a solution to protect your brushless motor

thingiverse

free

Motor Brushless by LittleGroundhog

...motor brushless by littlegroundhog

thingiverse

project ba2

thingiverse

free

BRUSHLESS MOTOR PLIERS by giek2000

...brushless motor pliers by giek2000

thingiverse

brushless motor grip / pliers for 2205 motors. print with flexible material.

Racing

thingiverse

free

Gazoo Racing

...gazoo racing

thingiverse

gazoo racing logo keychain

thingiverse

free

racing flag by Euklid

...racing flag by euklid

thingiverse

racing flag

thingiverse

free

ktm racing by ray46

...ktm racing by ray46

thingiverse

ktm racing keychain

thingiverse

free

Race Car by _jordiegriffo_

...race car by _jordiegriffo_

thingiverse

toy race car

thingiverse

free

TM Racing by Markbina

...tm racing by markbina

thingiverse

tm racing

keychains

thingiverse

free

micro race drone

...micro race drone

thingiverse

micro race drone

thingiverse

free

racing drone by Devon3DP

...racing drone by devon3dp

thingiverse

racing drone for 3 cell.

thingiverse

free

Race Car by EnviteDesign

...race car by envitedesign

thingiverse

its a car that i turn into a race car

thingiverse

free

Award for the winner of Race 2014 (Kart race of my family) by Flightcache

...ngiverse

award for the winner of race 2014 (kart race of my family)

designed with autodesk inventor 2014.

printed in pla 0.2 mm.

thingiverse

free

Escudo Racing Club by Conde88

...escudo racing club by conde88

thingiverse

escudo racing club

R

thingiverse

free

R R dice by Mocha22

...r r dice by mocha22

thingiverse

xxx

thingiverse

free

Tranmere R

...tranmere r

thingiverse

tranmere r

thingiverse

free

R by MalW

...r by malw

thingiverse

otcr letter r

thingiverse

free

iRobot(R) Mirra(R) compatible propeller by mren

...ra(r) pool robot.

trademarks are owned by the respective owners.

this part is a ground up design.

not affiliated with irobot (r).

thingiverse

free

Letra R by Xbertus

...letra r by xbertus

thingiverse

letra r

thingiverse

free

3d R by Syzguru11

...3d r by syzguru11

thingiverse

3d r

thingiverse

free

Letter R by rortiz11

...letter r by rortiz11

thingiverse

letter r

thingiverse

free

Part R by ZainK

...part r by zaink

thingiverse

part r

thingiverse

free

Cosinus(r) by MoyMaker

...cosinus(r) by moymaker

thingiverse

this implements z=cos(r)

where r=sqrt(x^2+y^2).

thingiverse

free

unown R abecedario

...unown r abecedario

thingiverse

unown r abecedario

C

thingiverse

free

C

...c

thingiverse

c

thingiverse

free

Connector cage C&C by niewiem

...connector cage c&c by niewiem

thingiverse

the connector is used to connect c&c modular cages

thingiverse

free

C by celena

...c by celena

thingiverse

c

thingiverse

free

c by DIonno18

...c by dionno18

thingiverse

c

thingiverse

free

C&C Generals Particle Cannon by kayjay123

...c&c generals particle cannon by kayjay123

thingiverse

c&c generals particle cannon

thingiverse

free

c by MalW

...c by malw

thingiverse

otcr letter c

thingiverse

free

C&C Tiberian Dawn - Nod units by blackrice000

...na units][?]

update:

2017/9/15: upload apc, artillery, buggy, stealthtank, apache, flametank, lighttank

2018/4/15: upload c-130

thingiverse

free

Connector cage C&C v2 by niewiem

...connector cage c&c v2 by niewiem

thingiverse

the connector is used to connect c&c modular cages v2

thingiverse

free

LVOA-C

...lvoa-c

thingiverse

replica of the lova-c ar

thingiverse

free

C&C Tiberian Dawn - GDI units by blackrice000

...;c general - gla units][?]

[c&c general - usa units][?]

[c&c general - china units][?]

official website :renegade x home

Printer

thingiverse

free

printer by riegel

...printer by riegel

thingiverse

printer

thingiverse

free

Printer by elnuvoldesign

...printer by elnuvoldesign

thingiverse

printer

thingiverse

free

3D Printer of a 3D printer by wacko

...3d printer of a 3d printer by wacko

thingiverse

a 3d print of the new low costs ready to print, 3d printer from www.pp3dp.com

thingiverse

free

Printer case light (X3D printer) by arekm

...printer case light (x3d printer) by arekm

thingiverse

printer case light.

thingiverse

free

Printer Knob by arthurTW

...printer knob by arthurtw

thingiverse

printer knob for delta 3d printer

thingiverse

free

3d printer part for Irapid printer by esadesad

...use damage to your printer. this solution fixes the platform of the printer with magnets and allows more precise printing models.

thingiverse

free

printer parts by kmoore22

...printer parts by kmoore22

thingiverse

printer parts for montevallo build your own 3d printer course

thingiverse

free

3D PRINTER by juju68

...3d printer by juju68

thingiverse

3d printer

thingiverse

free

Light on the printer by umitakin

...light on the printer by umitakin

thingiverse

light on the printer

thingiverse

free

Calibrate the printer by olo2000pm

...calibrate the printer by olo2000pm

thingiverse

calibrate the printer