Thingiverse

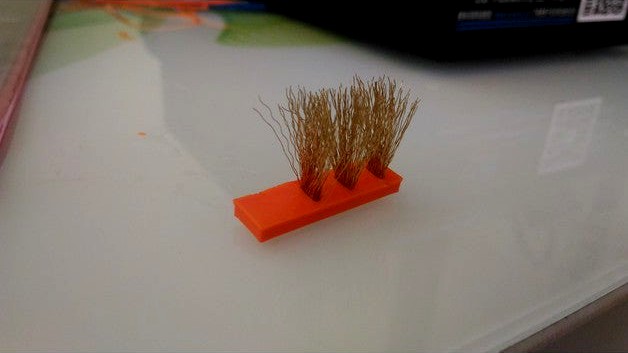

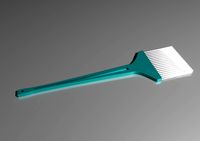

Brush for cleaning Nozzle with the Start G-Code by 3jcube

by Thingiverse

Last crawled date: 3 years ago

My way to clean the Nozzle before each print For the CR10 printers and all like

Here is my story...

The printer came with a concave glass like many of you and of course the solution is to replace it.

So I went to the local mirror store and asked the man to cut a piece 300X300 mm like what is known about the dimensions of the printer

He suggested to chamfer the edges for safety and I agreed

When I returned home I put the mirror on the heated bed plate

I found that it came short and after some measurements I discovered the mistake I had made

First the heated bed plate dimensions are 310X310 mm.

Second process of chamfering the edges took approximately 3 mm from each side.

The total becomes about 15 mm short.

Of course, it is not big problem, because I do not think I will print anything with a diameter bigger than 290 mm and the clamps hold the mirror well.

After a while I noticed that in many printers there is a system to clean the nozzle before each print.

And even many have made copies of these systems on their printers if you do some search on youtube you will find some like

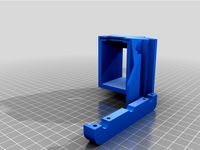

So I thought to take advantage of this extra space of the plate next to the mirror and do a system to cleaning the nozzle with a metal brush.

and this was the product of that idea.

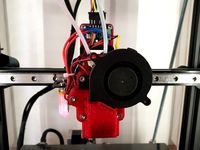

Of course, as you will notice in the videos I have integrated two techniques to achieve the best results using the metal brush and also do some extra extrusion.

The extrusion code is custumized code taken from DIY3DTech YouTube Channel

" Creality CR10 - GCode to Clean Nozzle Before Printing "

The attached code can be replaced by the printers start G-code and you should find the exact numbers to be placed in the code, depending on where the brush is placed on your plate.

Of course, a very important point must be taken. The brush must be at least 80 mm away from the front of the plate in order not to obstruct the bed leveling

I hope you find it useful

and as usual feel free to customize and change what it takes to have a successful nozzle cleaning

And Please be careful about anything you do and if you do not have enough experience, do not risk anything

I'm not responsible for any problem or error you get

Do it at your own risk.

I used superglue to paste it to the plate

I'm using cura 3.4.1

you will find the start g-code under

Preferences -> Printers -> Machine settings -> Start G-Code

please take a copy of your original start g-code in case you want to go back.

This is the code you see it working in the video " Attempt no.4 "

I'm Sorry about children's voices in the background ;-)

https://youtu.be/uxPJLbfihL4

M82 ;absolute extrusion mode

M117 Clean ; Indicate nozzle clean in progress on LCD

M107 ; Turn layer fan off

G21 ; Set to metric [change to G20 if you want Imperial]

G90 ; Force coordinates to be absolute relative to the origin

G28 ;Home

G92 E0 ; Reset extruder to [0] zero end of cleaning run

G1 E-3 F500 ; Retract filiment by 3 mm to reduce string effect

G1 Z5 F4000 ;Move up 5mm to good position so the nozell hit the tip of brush;

G1 Y83 F4000 ;Move back to the first line of brush

G1 X10 F4000 ;Move side to do the first wipe

G1 Y91 F4000 ;Move back to the 2nd line of brush

G1 X0 F4000 ;Move side to do the 2nd wipe

G1 Y98 F4000 ;Move back to the 3ed line of brush

G1 X10 F4000 ;Move side to do the 3ed wipe

G1 Z25 E-3 F500 ;Move up 25mm to safety ; Retract filiment by 3 mm to reduce string effect

G4 P5000 ;stop for 5seconds to do extra manual cleaning if needed

; the coming code is doing some extrusion to cleaning nozel this is custumized code taken from

; DIY3DTech YouTube Channel " Creality CR10 - GCode to Clean Nozzle Before Printing! "

G1 X10 Y137 F4000 ; Move in 10mm from edge 40mm back to privent hiting the brush

G1 Z0.15 F4000 ;[z] 0.15mm close to heated bed

G92 E0 ; Set extruder to [0] zero

G1 Y237 E20 F500 ; Extrude 20mm filiment along Y axis to prime and clean the nozzle

G92 E0 ; Reset extruder to [0] zero end of cleaning run

G1 E-3 F500 ; Retract filiment by 3 mm to reduce string effect

G1 Z5 F4000 ; Move over and rise to safe Z height

M117 Printing ; Indicate Printing in progress on LCD

Here is my story...

The printer came with a concave glass like many of you and of course the solution is to replace it.

So I went to the local mirror store and asked the man to cut a piece 300X300 mm like what is known about the dimensions of the printer

He suggested to chamfer the edges for safety and I agreed

When I returned home I put the mirror on the heated bed plate

I found that it came short and after some measurements I discovered the mistake I had made

First the heated bed plate dimensions are 310X310 mm.

Second process of chamfering the edges took approximately 3 mm from each side.

The total becomes about 15 mm short.

Of course, it is not big problem, because I do not think I will print anything with a diameter bigger than 290 mm and the clamps hold the mirror well.

After a while I noticed that in many printers there is a system to clean the nozzle before each print.

And even many have made copies of these systems on their printers if you do some search on youtube you will find some like

So I thought to take advantage of this extra space of the plate next to the mirror and do a system to cleaning the nozzle with a metal brush.

and this was the product of that idea.

Of course, as you will notice in the videos I have integrated two techniques to achieve the best results using the metal brush and also do some extra extrusion.

The extrusion code is custumized code taken from DIY3DTech YouTube Channel

" Creality CR10 - GCode to Clean Nozzle Before Printing "

The attached code can be replaced by the printers start G-code and you should find the exact numbers to be placed in the code, depending on where the brush is placed on your plate.

Of course, a very important point must be taken. The brush must be at least 80 mm away from the front of the plate in order not to obstruct the bed leveling

I hope you find it useful

and as usual feel free to customize and change what it takes to have a successful nozzle cleaning

And Please be careful about anything you do and if you do not have enough experience, do not risk anything

I'm not responsible for any problem or error you get

Do it at your own risk.

I used superglue to paste it to the plate

I'm using cura 3.4.1

you will find the start g-code under

Preferences -> Printers -> Machine settings -> Start G-Code

please take a copy of your original start g-code in case you want to go back.

This is the code you see it working in the video " Attempt no.4 "

I'm Sorry about children's voices in the background ;-)

https://youtu.be/uxPJLbfihL4

M82 ;absolute extrusion mode

M117 Clean ; Indicate nozzle clean in progress on LCD

M107 ; Turn layer fan off

G21 ; Set to metric [change to G20 if you want Imperial]

G90 ; Force coordinates to be absolute relative to the origin

G28 ;Home

G92 E0 ; Reset extruder to [0] zero end of cleaning run

G1 E-3 F500 ; Retract filiment by 3 mm to reduce string effect

G1 Z5 F4000 ;Move up 5mm to good position so the nozell hit the tip of brush;

G1 Y83 F4000 ;Move back to the first line of brush

G1 X10 F4000 ;Move side to do the first wipe

G1 Y91 F4000 ;Move back to the 2nd line of brush

G1 X0 F4000 ;Move side to do the 2nd wipe

G1 Y98 F4000 ;Move back to the 3ed line of brush

G1 X10 F4000 ;Move side to do the 3ed wipe

G1 Z25 E-3 F500 ;Move up 25mm to safety ; Retract filiment by 3 mm to reduce string effect

G4 P5000 ;stop for 5seconds to do extra manual cleaning if needed

; the coming code is doing some extrusion to cleaning nozel this is custumized code taken from

; DIY3DTech YouTube Channel " Creality CR10 - GCode to Clean Nozzle Before Printing! "

G1 X10 Y137 F4000 ; Move in 10mm from edge 40mm back to privent hiting the brush

G1 Z0.15 F4000 ;[z] 0.15mm close to heated bed

G92 E0 ; Set extruder to [0] zero

G1 Y237 E20 F500 ; Extrude 20mm filiment along Y axis to prime and clean the nozzle

G92 E0 ; Reset extruder to [0] zero end of cleaning run

G1 E-3 F500 ; Retract filiment by 3 mm to reduce string effect

G1 Z5 F4000 ; Move over and rise to safe Z height

M117 Printing ; Indicate Printing in progress on LCD

Similar models

thingiverse

free

Custom start Gcode by monopriceman

... a priming/wiping line to the rear)

g0 z3

g0 y0

g0 z0

g1 x-1;(move a little closer to the print area)

g1 e15 f250;(small retract)

thingiverse

free

SVO2 Purge Bucket and GCODE by RedSquirrelHobbies

... positioning on

g1 z-1 f1000 ; lower nozzle by 1mm

g90 ; absolute positioning on

m400 ; wait for finish

thingiverse

free

Anet A8 Filament Scraper by DasEimer

... z0

g29 /autolevel

g1 z2 x-20 f9000

g1 y2 f9000

g92 e0

g1 e25 f500 /extrude 25mm

g4 s1

g1 x0 f2000 /wipe

g92 e0

g1 f9000

m117

thingiverse

free

Purge Bucket for A10M (cleaned up) by carterlewellyn

... e0 ;reset extruder positioning

g1 e-2 f5000 ;retract filament to resting spot

g92 e0 ;reset extruder positioning

i hope it helps

thingiverse

free

ANET A8 Nozzle Filament Wiper - Cleaner - Updated by andy_spoo

...

g1 y50 f3000 ; move out of the way of wiper

g;; 1 x10 y10 f3000; back to 'near' front left

g92 e0; zero extruder

; *****

thingiverse

free

Bukito Purge box

...ing code for use with purge box

g28 ;home

g1 z.1 f6000 ;move the platform down .1mm

;prime the extruder

g92 e0

g1 f200 e10

g92 e0

thingiverse

free

A20M A10M BigMac MKII 5015 Blower

...

g1 e70 f3000

g92 e0

g1 e30 f200

g92 e0

g4 s3

g0 f10000

; end extruder 2

g92 e0

g1 e-5 f6000

g1 x-10.5 f8000

g1 e-70 f3000

g92 e0

thingiverse

free

Ender 3/Pro Ender5/Pro Bed Nozzle Brush by blindley125

...1 z10.0 f3000 ; move z axis up little to prevent scratching of heat bed

g1 x8 y20 z0.3 f5000.0 ; move over to prevent blob squish

thingiverse

free

Geeetech A10t Purge Bucket with removable bucket by 123TaDa

...ipe

g0 x0 f2000 ; return

m211 s1 ; turn on soft stops once more

g1 e-0.5 ; try to prevent pips

g92 e0

; start extruder script end

thingiverse

free

Geeetech i3 Pro B extruder wiper by Damien68

...0 ;zero the extruded length

g1 f200 e3 ;extrude 3mm of feed stock

g92 e0 ;zero the extruded length again

g1 f9000

m117 printing ;

3Jcube

thingiverse

free

Soldering Tip cleaner + Fan Holder by 3jcube

...soldering tip cleaner + fan holder by 3jcube

thingiverse

under writing

https://www.thingiverse.com/thing:1725308

thingiverse

free

box files tool by 3jcube

...ple box for file-tools

the clips need some changes to fit perfectily

i uplowaded the orijinal max file feel free to customize it

thingiverse

free

Aquarium cave ( thin walls ) by 3jcube

... prim with 4-5 lines

ps:

i'm using cura slicer and i printed mine with uniform scaling by 75% on x an y and left it 100% on z

thingiverse

free

creality cr10 sd card cover by 3jcube

...der-adapter-car-gps-mobile/32721250427.html?spm=a2g0s.9042311.0.0.98ce4c4dragstp

so i did this remix

the 3dsmax file version 2016

thingiverse

free

Yet another belt tension for the MPCNC ( 10mm belt + 2 Bearing ) by 3jcube

...place i used 10mm m3 bolts.

its need support for printing so if you don't like work with supports this thing is not for you.

Brush

3d_export

free

brush

...brush

3dexport

brush

3d_export

free

brush

...brush

3dexport

it is brush

archibase_planet

free

Brush

...brush

archibase planet

brush toilet brush sanitary ware

brush - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Brush

...rush

archibase planet

rack brush cleaner toilet brush sanitary ware

brush - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Brush

...brush

archibase planet

brushes

brush - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Brush

...brush

archibase planet

?oilet brush sanitary ware

brush - 3d model (*.gsm+*.3ds) for interior 3d visualization.

design_connected

$11

Brushes

...brushes

designconnected

smallaccents brushes computer generated 3d model.

turbosquid

$1

Brush

...rush

turbosquid

royalty free 3d model brush for download as on turbosquid: 3d models for games, architecture, videos. (1391784)

3d_export

$5

brush

...brush

3dexport

comb

turbosquid

$10

Brush

...squid

royalty free 3d model brush for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1191257)

Code

turbosquid

$1

Code

...code

turbosquid

royalty free 3d model code for download as on turbosquid: 3d models for games, architecture, videos. (1293119)

3ddd

$1

банкетка code

...e , банкетка , капитоне

производитель

3d_export

$5

Code lock

...code lock

3dexport

realistic hight-poly model of code lock with high quality pbr textures (4096x4096). rendering in v-ray.

3d_export

$5

Code lock

...code lock

3dexport

realistic hight-poly model of code lock with high quality pbr textures (4096x4096). rendering in v-ray.

turbosquid

$10

Code Lock

...

royalty free 3d model code lock for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1368816)

turbosquid

$30

Code: MRN

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

DV home / CODE

...dv home / code

3ddd

dv home

итальянская фабрика dv home / стул code

3ddd

free

Blastation, Code 27

...ddd

blastation , code 27

диван фабрики blastation. размер 2700х950 h1100. 135 883 polys.

turbosquid

$10

Code Sofa, ENNE

...id

royalty free 3d model code sofa, enne for download as max on turbosquid: 3d models for games, architecture, videos. (1192986)

turbosquid

free

Armani Sport Code

...e 3d model armani sport code for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1204039)

Nozzle

3d_export

$5

nozzle

...nozzle

3dexport

3d_export

$49

fuel nozzles

...fuel nozzles

3dexport

fuel nozzles 3d model. include max, obj, fbx files.

archive3d

free

Nozzle 3D Model

...archive3d

nozzle hair-drier ware

nozzle - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$25

Pirouette Nozzle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Fuel Nozzle

...model fuel nozzle for download as c4d, fbx, obj, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1672732)

3d_export

$10

laval airjet nozzle

...laval airjet nozzle

3dexport

a simple modified laval nozzle (airjet shooter) for sorting purposes.

3d_export

$36

Gas nozzle 3D Model

... 3d model

3dexport

gas pump nozzle dispenser filling station petrol fuel spout tank gun

gas nozzle 3d model tartino 1945 3dexport

turbosquid

$39

Rocket nozzle, supressor.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$12

Oil Nozzle Gun3d model

...zle gun

.max .obj .jpg .fbx .dxf .3ds - oil nozzle gun 3d model, royalty free license available, instant download after purchase.

3d_export

$29

Fuel Pump Nozzle 3D Model

...l nozzle pump fuel fueling hose station photoreal detailed textures materials

fuel pump nozzle 3d model guidovrola 47129 3dexport

G

3ddd

free

G. Moscatelli

...алка

вешалка 25 / 26 / 27коллекция: belle heleneбренд: g. moscatelliстрана: италияразмеры: высота - 190 / 195; диаметр - 50 / 60.

3ddd

$1

G Plan Vintage

...g plan vintage

3ddd

винтаж , g plan

g plan vintage armchair

turbosquid

free

G protein

...otein

turbosquid

free 3d model g protein for download as c4d on turbosquid: 3d models for games, architecture, videos. (1309660)

turbosquid

$14

Fence G

...turbosquid

royalty free 3d model fence g for download as fbx on turbosquid: 3d models for games, architecture, videos. (1310122)

turbosquid

$7

G for Gun

...rbosquid

royalty free 3d model g for gun for download as max on turbosquid: 3d models for games, architecture, videos. (1685215)

turbosquid

$5

G Ring

...

turbosquid

royalty free 3d model g ring for download as stl on turbosquid: 3d models for games, architecture, videos. (1285079)

turbosquid

$5

Letter G

...urbosquid

royalty free 3d model letter g for download as max on turbosquid: 3d models for games, architecture, videos. (1408463)

turbosquid

$5

Letter g

...urbosquid

royalty free 3d model letter g for download as max on turbosquid: 3d models for games, architecture, videos. (1408408)

3ddd

$1

Infiniti / G-Chair

...infiniti / g-chair

3ddd

infiniti

www.infinitidesign.it/ita/g-chair.php

3ddd

$1

кресло G-68

...кресло g-68

3ddd

кресло

кресло руководителя g-68

Start

turbosquid

$50

The starting post

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Starting Block

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

car start

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$100

start race motocross

...start race motocross

3dexport

start race motocross

3d_ocean

$2

Two Start Buttons

...cording for easy navigation – modeled from an image file can be used for different matters - great to start presantations in a...

turbosquid

$10

Kitchen Start Time

...

royalty free 3d model kitchen start time for download as max on turbosquid: 3d models for games, architecture, videos. (1502055)

turbosquid

$35

Start Finish CheckPoint

...tart finish checkpoint for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1652558)

turbosquid

$41

Stairs Post Starting

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$79

The starting post "Leon"

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$80

Horses start-cages3d model

...del

cgstudio

.3ds .c4d .dxf .obj - horses start-cages 3d model, royalty free license available, instant download after purchase.

Cleaning

turbosquid

$29

Clean Bow

...osquid

royalty free 3d model clean bow for download as blend on turbosquid: 3d models for games, architecture, videos. (1257234)

turbosquid

$25

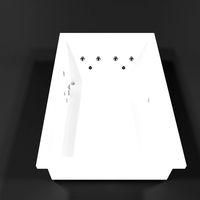

Jacuzzi Clean

...quid

royalty free 3d model jacuzzi clean for download as max on turbosquid: 3d models for games, architecture, videos. (1461249)

turbosquid

$1

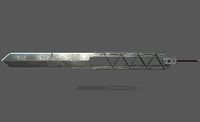

Zanbato - Clean

...ree 3d model zanbato - clean for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328531)

turbosquid

$10

Cleaning Products

...model cleaning products for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1559247)

turbosquid

$25

cleaning kit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Cleaning pads

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

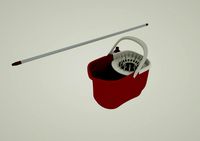

Cleaning Bucket

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

cleaning bucket

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cleaning robot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cleaning Equipment

...ng equipment for download as max, 3ds, dae, dxf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1693554)