Thingiverse

Bre In Space! MakerBot Mars Base. by latigerlilly

by Thingiverse

Last crawled date: 4 years, 6 months ago

Introduction

This Mars mission proposal is unique because it has several firsts. I used my search-fu until my face turned blue but have not seen any other Mars mission proposal in the universe that contains the following unique points. First, why are all the Mars colonization proposals fixated on the necessity of sending up big, athletic males to Mars? Cost estimates range from 1 to 1.5 million dollars per pound of human sent to Mars for a colonization mission. Therefore, it would be cost efficient to only send up petite females with canisters of cryogenic preserved sperm. Second, why are all other proposals locked in the paradigm of hydroponic farming? Hydroponic farming is not space nor weight efficient. The nutrition produced per cubic meter by hydroponic farming is much less than that produced by microbial culture. Growing spirulina would produce the maximum amount of nutrition per cubic meter. Doing so would slash mission cost further. Finally, why do we need to shield the colonists from radiation with heavy lead shielding or a meteor on the trip to Mars? Lead is very heavy and therefore expensive to send into space. Redirecting a meteor is very expensive as it would mean additional launches at 75 to 150 million dollars per launch. There are genes that allow certain organisms to resist the effects of radiation damage better than others of the same species. We should select our spirulina and astronauts for radiation resistance and not worry too much about shielding. Shielding from radiation should be minimal on the trip to Mars to further slash mission costs and make a womaned trip to Mars affordable. A trip to Mars has been technologically feasible since the Apollo Moon mission in 1969. However, nobody has been to Mars because it wasn't affordable nor profitable. My proposal will not only make a Mars colony financially possible, it will turn Mars into a profitable cash cow that will attract other colonization missions and rapid human development on Mars. I invite you to suddenly find yourself enjoying this outline for humanity's biggest step into the 21st century!

3D Printing

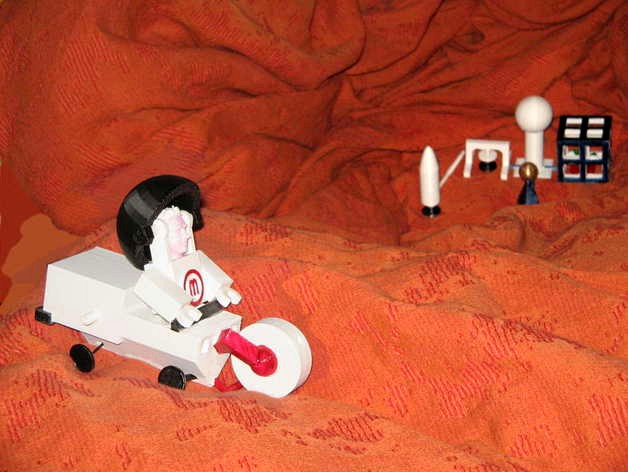

This 3D printing project is unique because it has several firsts. I used my search-fu until I was googly-eyed but could not spy any other 3d print file on Thingiverse that has the following unique features. First, others on Thigiverse have made ball and socket joints that need to be assembled. However, assembling a ball and socket joint by pushing the ball into the socket is a logical fallacy. If the ball can be easily pushed into the socket, won't it just as easily fall out of the socket? My brave Bre the makernaut {8} has a ball and socket joint that is printed already assembled. No human assembly is required and it is impossible to disassemble this ball and socket joint. Not only that, this printed ball and socket joint can hold its position as it is pose-able. Another first achievement in this project is the first 3d printed mechanical device that is printed in more than one color. There are other 3d printed objects on Thingiverse that are mechanical devices with printed moving parts, but they are printed in just one color. There are also gorgeous multi-color prints on Thingiverse that take advantage of the Replicator's dual print nozzles, but they are not printed pre-assembled mechanical devices. My Mars buggy {7} is printed with rolling wheels in two different colors all in one print with no human assembly. 3D printing the Mars colony without human labor before the colonists arrive is the key to low mission cost because you don't have to purchase additional launches for all the infrastructure necessary for a Mars colony. I want to showcase 3d printing technology by pushing FDM technology to its limits with this project. If you'll notice, it has seemingly impossible shapes with lots of spheres and overhangs, but my Little Replicator That Could handled it all with aplomb. You might be surprised to find that my project has inspired you to design more adventurously. Arriba!

Preparation for Launch

Several years prior to the first launch, the marketing department will seek corporate sponsors for the Mars colonization mission. The Apollo landing on the moon attracted more viewers than the Superbowl. The last Superbowl made close to $300 million in ad revenue. By selling product placement advertising for a reality show of the trip to Mars, at least $720 million of ad revenue could be milked from the trip to Mars. This reality show is immune to viewers fast forwarding through the ads by viewing a recording of the reality show because there are no commercial breaks since all advertising is done by product placement. For example, a certain cola company could pay $10 million for our two makernauts to drink all of their beverages from a cup with their product's name on it. They would only wear a certain brand of shoes for another $10 million, etc. The Mars reality show is only aired quarterly to avoid the public getting bored of seeing the makernauts doing routine tasks week after week. Planned leaks of exaggerated perils or drama will have the public clamoring for the next episode. Additional merchandising deals and makernaut product endorsements would conservatively put the total revenue estimate to over $1 billion.

By limiting the cost of the Mars mission to less than $250 million, the entity that orchestrates this would net a profit of at least $750 million from the trip to Mars.

First Launch

Several years before launching our two makernauts, we will launch 1000 microchips, solar panels, seeds, frozen sperm, spirulina, a 3D Printer {9} and a robot to Mars. Upon arrival, the 3D Printer will be used to print more 3D Printers and robots. This army of 3d printers and robots will be used to construct the Mars base prior to the arrival of its human inhabitants. Although the RepRap project has so far been unable to 3D Print another 3D Printer, it is hampered by patents that prevent them from printing in metal. They could not utilize this technology in their open source project because that would be a patent infringement. However, the technology already exists to print high quality metal parts with DMLS. By licensing DMLS technology, we should be able to fabricate everything that our makernauts need on Mars using Martian materials with the 1000 microchips, seeds, solar panels, frozen sperm, and spirulina that we will send to Mars.

The Martian soil is rich with iron oxide. That is why Mars is red. Martian craters are rich in rare earth elements. Using an automated robotic rotary digger {2}, we could extract this iron and rare earth elements to produce stainless steel alloys for our DMLS 3d printer to produce metal items such as more 3d printers that can print using other materials. A rotary digger design is much better than a backhoe digger design because a backhoe design requires a human operator or complex artificial intelligence while a rotary digger only requires a very simple microcontroller algorithm and simplicity means lower cost. The big wheel in front of the vehicle spins with scoops that scoop up Martian soil when the vehicle moves forward, driving into the side of the interior of a crater. The spinning wheel then deposits the soil on a conveyer belt that feeds a set of processes separating the soil into all the necessary raw materials; hydrogen, oxygen, water, silica, clay, iron oxides, rare earth elements, etc. The automated rotary digger then drives to a storage tank and a nozzle on the right hand side of the vehicle connects to the storage tank. Finally, the digger transfers all the raw materials for storage into the storage tank {5}.

The Martian soil is rich in clay and silica. 3D printers could be used to make buildings out of glass and concrete using silica and clay. The Martain clay soil is rich in aluminum, calcium, silicon, and iron oxides. The Marian polar soil contains frozen water. These elements of water, aluminum, calcium, silicon, and iron oxide could be chemically manipulated to make cement. Cement and Martian aggregate (sand and small pebbles) could be used to make concrete. This concrete can be used to 3d print buildings {1}.

Martain buildings are fantastically shaped in order to attract space tourists. This will be a cash cow for our Mars colony. By 3d printing a building into an existing structure such as a plateau or rock hill, these buildings become an indestructible part of Mars. In contrast, any habitation pods and inflatable structures sent to Mars from earth will be blown away by the next Martian dust storm like a trailer park in an Oklahoma tornado. Sending structures to Mars instead of fabricating them on Mars will also increase launch costs.

The automated robotic rotary digger {2} could extract frozen water from the Martian soil and by use of solar cell powered electrolysis, oxygen and hydrogen could be extracted from the water. This could be used to fuel a rocket {6} or to power a buggy {7} with hydrogen fuel cells. The Mars colony will be placed in a sweet spot that is just north enough to have frozen water containing permafrost inches below the surface but just south enough to have at least 4 hours of sun exposure a day for the solar cells to operate. About 1.9% of the Martian atmosphere is nitrogen. Oxygen extracted from water with nitrogen extracted from the atmosphere could be combined to make breathable air. Breathable air, water, hydrogen, and oxygen could be stored in a large community storage tank {5} with a plumbing and enclosed road system connecting all buildings on the Mars colony to this storage tank. Using an enclosed road system to connect buildings minimizes the times makernauts and space tourists have to use an airlock. This is crucial because every time someone uses an airlock, precious breathable air is lost.

A microbial culture of spirulina will be grown in a 3d printed greenhouse {3} along with a backup crop of plants {4} such as soy, flax, wheat, and kale. The plants and spirulina will be chosen based on radiation resistance. Varieties of plants growing wild near Chernobyl will be cultivated. Due to a near zero hunting and gathering pressure, the exclusion zone area near Chernobyl which is 1000x more radioactive than what is considered safe has become a wildlife preserve of radiation resistant wildlife. Wild plants growing near Chernobyl have genes for radiation resistance . Also, spirulina contains all the nutrients a human would need to survive.

Second Launch

The Mars One project estimates their Mars mission cost to be roughly $6 billion. However, this is because they are sending up enough infrastructure for 16 astronauts. Half of these astronauts are average to athletic size men. There is no need to send men up to Mars for a reproducing colony if we send women to Mars with canisters of frozen sperm. Canisters of frozen sperm not only reduce launch weight over sending an actual man, but also increases genetic variability essential to avoid inbreeding commonly associated with small populations. By sending up a 500 mL canister with sperm samples from 500 men, you can have the genetic variation of 500 different men without having to send 500 men to Mars. By only sending up 2 petite women weighing less than 100 lbs each and 3d printing the infrastructure on Mars instead of sending it from earth, total mission cost would be slashed to a total of only $250 million comprising of 2 launches.

Radiation shielding for a spaceship to Mars would be prohibitively expensive due to the weight of sufficiently heavy shielding. Therefore, one of the criteria for makernaut selection would be to choose people who possess the genes for radiation resistance. Because somehumans possess genes for radiation resistance.

Continuing Mission

Due to Mar's gravity being 1/3 that of earth, it would be cheaper to send space vehicles such as Earth satellites into space from Mars than Earth. Our two makernauts would build and launch a heavily radiation shielded orbiter that is designed to orbit the sun with a trajectory that intersects Earth and Mars. This would allow space tourists to travel to Mars cheaply without the use of rockets to propel them to Mars. They would only need rockets to escape the Earth's gravity. Also, the components of Earth satellites could be 3d printed on Mars and launched to this orbiter. These components would be assembled into an Earth satellite during the journey to Earth. Mars would become a center of space vehicle production, launching, and space tourism.

Also, much like how old England had allowed its colonies to become tax free economic development zones, Mars could become a tax haven. Martian banks could make Mars the 21st century Switzerland.

Finally, for countries without any endogenous rare earth element sources, Mars could be a method by which they could secure themselves a strategic rare earth element supply.

Parts List

3d Printed Martian Building - building.stl

automated robotic rotary digger -

digger.stl

diggerUPDATED.stl

greenhouse - greenhouse.stl

food plant - tree.stl

storage tank - storagetank.stl

rocket

R1 - rocketDEa.stl , rocketDEb.stl

R2 - rocket.stl

buggy

R1 - r1buggyle.stl , r1buggyre.stl

R2 - r2buggy.stl

makernaut (aka astronaut)

R1 - helmet.stl

makernautR1DEa.stl

makernautR1DEci.stl , makernautR1DEcii.stl

makernautR1pos.stl

R2 - helmet.stl , makernautR2a.stl

3d printer

R1 - 3dprinter2DEa (repaired).stl , 3dprinter2DEb.stl

R2 - 3dprinter3.stl

Update 6/13/14

To remove the Automated Robotic Rotary Digger and the Buggy from the print platform, cool the platform to room temperature, then reheat it. Wearing gloves to protect you from the heat, use a razor blade to remove the wheels from the print platform. Do not pry it off the platform with your hands or the axle will break. Use dental floss and a rubber spatula to remove the rest of the items from the print platform. Print the items at slow 30 mm/s print and 30 mm/s travel speeds with dual shells and 20% fill. Lower percent fill, higher speeds, and less shells will cause unsightly surface holes and broken axles.

I had entered "Polhemus Scan of Bre Pettis" as a source file in my original entry on 6/12/14, but it mysteriously did not show up in my entry. So, I re-entered it.

Update 6/14/14

I improved the automated robotic rotary digger so that the front digging wheel is more likely to turn in a less well calibrated 3d printer. I made the front digging wheel's tolerances looser. This file is diggerUPDATED.stl .

Initial energy needs on Mars and during the trip to Mars will be met with solar panels sent from Earth. Increasing energy needs of the immediate future on the Martian colony will be met with 3d printed wind powered generators 3d printed on Mars. Energy needs farther into the future on Mars will be generated by printed solar cells using organic semiconducting inks. The organic chemical groups used as building blocks to produce these inks come from microbial cultures grown on Mars that metabolizes sunlight, water, trace elements, and carbon dioxide concentrated from the Martian atmosphere.

Update 6/15/14

Improved buggy with looser tolerances so that it'll print on a 3d printer that is not calibrated with as much precision and accuracy. New improved buggy files are r1buggyleUPDATED.stl , r1buggyreUPDATED.stl , and r2buggyUPDATED.stl .

This Mars mission proposal is unique because it has several firsts. I used my search-fu until my face turned blue but have not seen any other Mars mission proposal in the universe that contains the following unique points. First, why are all the Mars colonization proposals fixated on the necessity of sending up big, athletic males to Mars? Cost estimates range from 1 to 1.5 million dollars per pound of human sent to Mars for a colonization mission. Therefore, it would be cost efficient to only send up petite females with canisters of cryogenic preserved sperm. Second, why are all other proposals locked in the paradigm of hydroponic farming? Hydroponic farming is not space nor weight efficient. The nutrition produced per cubic meter by hydroponic farming is much less than that produced by microbial culture. Growing spirulina would produce the maximum amount of nutrition per cubic meter. Doing so would slash mission cost further. Finally, why do we need to shield the colonists from radiation with heavy lead shielding or a meteor on the trip to Mars? Lead is very heavy and therefore expensive to send into space. Redirecting a meteor is very expensive as it would mean additional launches at 75 to 150 million dollars per launch. There are genes that allow certain organisms to resist the effects of radiation damage better than others of the same species. We should select our spirulina and astronauts for radiation resistance and not worry too much about shielding. Shielding from radiation should be minimal on the trip to Mars to further slash mission costs and make a womaned trip to Mars affordable. A trip to Mars has been technologically feasible since the Apollo Moon mission in 1969. However, nobody has been to Mars because it wasn't affordable nor profitable. My proposal will not only make a Mars colony financially possible, it will turn Mars into a profitable cash cow that will attract other colonization missions and rapid human development on Mars. I invite you to suddenly find yourself enjoying this outline for humanity's biggest step into the 21st century!

3D Printing

This 3D printing project is unique because it has several firsts. I used my search-fu until I was googly-eyed but could not spy any other 3d print file on Thingiverse that has the following unique features. First, others on Thigiverse have made ball and socket joints that need to be assembled. However, assembling a ball and socket joint by pushing the ball into the socket is a logical fallacy. If the ball can be easily pushed into the socket, won't it just as easily fall out of the socket? My brave Bre the makernaut {8} has a ball and socket joint that is printed already assembled. No human assembly is required and it is impossible to disassemble this ball and socket joint. Not only that, this printed ball and socket joint can hold its position as it is pose-able. Another first achievement in this project is the first 3d printed mechanical device that is printed in more than one color. There are other 3d printed objects on Thingiverse that are mechanical devices with printed moving parts, but they are printed in just one color. There are also gorgeous multi-color prints on Thingiverse that take advantage of the Replicator's dual print nozzles, but they are not printed pre-assembled mechanical devices. My Mars buggy {7} is printed with rolling wheels in two different colors all in one print with no human assembly. 3D printing the Mars colony without human labor before the colonists arrive is the key to low mission cost because you don't have to purchase additional launches for all the infrastructure necessary for a Mars colony. I want to showcase 3d printing technology by pushing FDM technology to its limits with this project. If you'll notice, it has seemingly impossible shapes with lots of spheres and overhangs, but my Little Replicator That Could handled it all with aplomb. You might be surprised to find that my project has inspired you to design more adventurously. Arriba!

Preparation for Launch

Several years prior to the first launch, the marketing department will seek corporate sponsors for the Mars colonization mission. The Apollo landing on the moon attracted more viewers than the Superbowl. The last Superbowl made close to $300 million in ad revenue. By selling product placement advertising for a reality show of the trip to Mars, at least $720 million of ad revenue could be milked from the trip to Mars. This reality show is immune to viewers fast forwarding through the ads by viewing a recording of the reality show because there are no commercial breaks since all advertising is done by product placement. For example, a certain cola company could pay $10 million for our two makernauts to drink all of their beverages from a cup with their product's name on it. They would only wear a certain brand of shoes for another $10 million, etc. The Mars reality show is only aired quarterly to avoid the public getting bored of seeing the makernauts doing routine tasks week after week. Planned leaks of exaggerated perils or drama will have the public clamoring for the next episode. Additional merchandising deals and makernaut product endorsements would conservatively put the total revenue estimate to over $1 billion.

By limiting the cost of the Mars mission to less than $250 million, the entity that orchestrates this would net a profit of at least $750 million from the trip to Mars.

First Launch

Several years before launching our two makernauts, we will launch 1000 microchips, solar panels, seeds, frozen sperm, spirulina, a 3D Printer {9} and a robot to Mars. Upon arrival, the 3D Printer will be used to print more 3D Printers and robots. This army of 3d printers and robots will be used to construct the Mars base prior to the arrival of its human inhabitants. Although the RepRap project has so far been unable to 3D Print another 3D Printer, it is hampered by patents that prevent them from printing in metal. They could not utilize this technology in their open source project because that would be a patent infringement. However, the technology already exists to print high quality metal parts with DMLS. By licensing DMLS technology, we should be able to fabricate everything that our makernauts need on Mars using Martian materials with the 1000 microchips, seeds, solar panels, frozen sperm, and spirulina that we will send to Mars.

The Martian soil is rich with iron oxide. That is why Mars is red. Martian craters are rich in rare earth elements. Using an automated robotic rotary digger {2}, we could extract this iron and rare earth elements to produce stainless steel alloys for our DMLS 3d printer to produce metal items such as more 3d printers that can print using other materials. A rotary digger design is much better than a backhoe digger design because a backhoe design requires a human operator or complex artificial intelligence while a rotary digger only requires a very simple microcontroller algorithm and simplicity means lower cost. The big wheel in front of the vehicle spins with scoops that scoop up Martian soil when the vehicle moves forward, driving into the side of the interior of a crater. The spinning wheel then deposits the soil on a conveyer belt that feeds a set of processes separating the soil into all the necessary raw materials; hydrogen, oxygen, water, silica, clay, iron oxides, rare earth elements, etc. The automated rotary digger then drives to a storage tank and a nozzle on the right hand side of the vehicle connects to the storage tank. Finally, the digger transfers all the raw materials for storage into the storage tank {5}.

The Martian soil is rich in clay and silica. 3D printers could be used to make buildings out of glass and concrete using silica and clay. The Martain clay soil is rich in aluminum, calcium, silicon, and iron oxides. The Marian polar soil contains frozen water. These elements of water, aluminum, calcium, silicon, and iron oxide could be chemically manipulated to make cement. Cement and Martian aggregate (sand and small pebbles) could be used to make concrete. This concrete can be used to 3d print buildings {1}.

Martain buildings are fantastically shaped in order to attract space tourists. This will be a cash cow for our Mars colony. By 3d printing a building into an existing structure such as a plateau or rock hill, these buildings become an indestructible part of Mars. In contrast, any habitation pods and inflatable structures sent to Mars from earth will be blown away by the next Martian dust storm like a trailer park in an Oklahoma tornado. Sending structures to Mars instead of fabricating them on Mars will also increase launch costs.

The automated robotic rotary digger {2} could extract frozen water from the Martian soil and by use of solar cell powered electrolysis, oxygen and hydrogen could be extracted from the water. This could be used to fuel a rocket {6} or to power a buggy {7} with hydrogen fuel cells. The Mars colony will be placed in a sweet spot that is just north enough to have frozen water containing permafrost inches below the surface but just south enough to have at least 4 hours of sun exposure a day for the solar cells to operate. About 1.9% of the Martian atmosphere is nitrogen. Oxygen extracted from water with nitrogen extracted from the atmosphere could be combined to make breathable air. Breathable air, water, hydrogen, and oxygen could be stored in a large community storage tank {5} with a plumbing and enclosed road system connecting all buildings on the Mars colony to this storage tank. Using an enclosed road system to connect buildings minimizes the times makernauts and space tourists have to use an airlock. This is crucial because every time someone uses an airlock, precious breathable air is lost.

A microbial culture of spirulina will be grown in a 3d printed greenhouse {3} along with a backup crop of plants {4} such as soy, flax, wheat, and kale. The plants and spirulina will be chosen based on radiation resistance. Varieties of plants growing wild near Chernobyl will be cultivated. Due to a near zero hunting and gathering pressure, the exclusion zone area near Chernobyl which is 1000x more radioactive than what is considered safe has become a wildlife preserve of radiation resistant wildlife. Wild plants growing near Chernobyl have genes for radiation resistance . Also, spirulina contains all the nutrients a human would need to survive.

Second Launch

The Mars One project estimates their Mars mission cost to be roughly $6 billion. However, this is because they are sending up enough infrastructure for 16 astronauts. Half of these astronauts are average to athletic size men. There is no need to send men up to Mars for a reproducing colony if we send women to Mars with canisters of frozen sperm. Canisters of frozen sperm not only reduce launch weight over sending an actual man, but also increases genetic variability essential to avoid inbreeding commonly associated with small populations. By sending up a 500 mL canister with sperm samples from 500 men, you can have the genetic variation of 500 different men without having to send 500 men to Mars. By only sending up 2 petite women weighing less than 100 lbs each and 3d printing the infrastructure on Mars instead of sending it from earth, total mission cost would be slashed to a total of only $250 million comprising of 2 launches.

Radiation shielding for a spaceship to Mars would be prohibitively expensive due to the weight of sufficiently heavy shielding. Therefore, one of the criteria for makernaut selection would be to choose people who possess the genes for radiation resistance. Because somehumans possess genes for radiation resistance.

Continuing Mission

Due to Mar's gravity being 1/3 that of earth, it would be cheaper to send space vehicles such as Earth satellites into space from Mars than Earth. Our two makernauts would build and launch a heavily radiation shielded orbiter that is designed to orbit the sun with a trajectory that intersects Earth and Mars. This would allow space tourists to travel to Mars cheaply without the use of rockets to propel them to Mars. They would only need rockets to escape the Earth's gravity. Also, the components of Earth satellites could be 3d printed on Mars and launched to this orbiter. These components would be assembled into an Earth satellite during the journey to Earth. Mars would become a center of space vehicle production, launching, and space tourism.

Also, much like how old England had allowed its colonies to become tax free economic development zones, Mars could become a tax haven. Martian banks could make Mars the 21st century Switzerland.

Finally, for countries without any endogenous rare earth element sources, Mars could be a method by which they could secure themselves a strategic rare earth element supply.

Parts List

3d Printed Martian Building - building.stl

automated robotic rotary digger -

digger.stl

diggerUPDATED.stl

greenhouse - greenhouse.stl

food plant - tree.stl

storage tank - storagetank.stl

rocket

R1 - rocketDEa.stl , rocketDEb.stl

R2 - rocket.stl

buggy

R1 - r1buggyle.stl , r1buggyre.stl

R2 - r2buggy.stl

makernaut (aka astronaut)

R1 - helmet.stl

makernautR1DEa.stl

makernautR1DEci.stl , makernautR1DEcii.stl

makernautR1pos.stl

R2 - helmet.stl , makernautR2a.stl

3d printer

R1 - 3dprinter2DEa (repaired).stl , 3dprinter2DEb.stl

R2 - 3dprinter3.stl

Update 6/13/14

To remove the Automated Robotic Rotary Digger and the Buggy from the print platform, cool the platform to room temperature, then reheat it. Wearing gloves to protect you from the heat, use a razor blade to remove the wheels from the print platform. Do not pry it off the platform with your hands or the axle will break. Use dental floss and a rubber spatula to remove the rest of the items from the print platform. Print the items at slow 30 mm/s print and 30 mm/s travel speeds with dual shells and 20% fill. Lower percent fill, higher speeds, and less shells will cause unsightly surface holes and broken axles.

I had entered "Polhemus Scan of Bre Pettis" as a source file in my original entry on 6/12/14, but it mysteriously did not show up in my entry. So, I re-entered it.

Update 6/14/14

I improved the automated robotic rotary digger so that the front digging wheel is more likely to turn in a less well calibrated 3d printer. I made the front digging wheel's tolerances looser. This file is diggerUPDATED.stl .

Initial energy needs on Mars and during the trip to Mars will be met with solar panels sent from Earth. Increasing energy needs of the immediate future on the Martian colony will be met with 3d printed wind powered generators 3d printed on Mars. Energy needs farther into the future on Mars will be generated by printed solar cells using organic semiconducting inks. The organic chemical groups used as building blocks to produce these inks come from microbial cultures grown on Mars that metabolizes sunlight, water, trace elements, and carbon dioxide concentrated from the Martian atmosphere.

Update 6/15/14

Improved buggy with looser tolerances so that it'll print on a 3d printer that is not calibrated with as much precision and accuracy. New improved buggy files are r1buggyleUPDATED.stl , r1buggyreUPDATED.stl , and r2buggyUPDATED.stl .