Thingiverse

BlueRAHM 3d Printer by rice9300

by Thingiverse

Last crawled date: 3 years ago

UPDATE Feb 16, 2018: Added zipped marlin files configured for BlueRAHM. This configuration uses standard RAMPS 14 connections with 2 exceptions. Second endstop connector used for right side Z endstop and Left side Z motor is connected to Extruder 2.

UPDATE Feb 14, 2018: Added 2 pictures of endstop assemblies. Corrected X endstop part labels.

UPDATE October 28, 2017: Replaced part L1 due to missing face.

UPDATE October 2017: Added improved door: https://www.thingiverse.com/thing:2578498/#files with assembly instructions.

UPDATE September 2017: Added photos of completed units. Will add upgrade for top and door later.

UPDATE July 4, 2017: Revised parts Y2, Z3, Z4 to provide clearance.

UPDATE July 4, 2017: Revised part ZH to allow belt clearance.

UPDATE July 3, 2017: Revised parts Z1, Z2, B5, B8. Improved access to Z rod clamp screw and remove unneeded access hole on B5 and B8.

UPDATE June 28, 2017: Revised parts YA and Z10.

UPDATE June 26, 2017: Designed Z axis extension kit. Thing: 240611. ( https://www.thingiverse.com/thing:2406116)

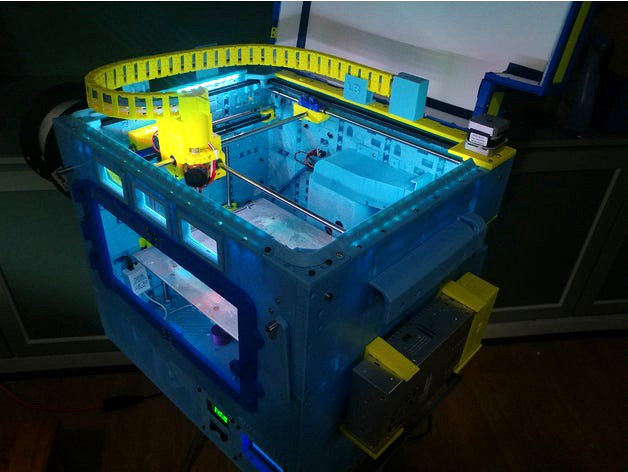

Mostly Printed 3D Printer Optimized to Print ABS. The XY mechanism is of my own devising and as far as I can find it is brand new. It is a combination of ideas taken from the Ultimaker gantry and Richard Horne's Sli3dr Printer but I believe better and simpler than either.

3D Printer Features:

Features Genuine or clone E3D V6 hotend and graphic controller at $350 price point.

Modular construction. Size can be adjusted by adding or removing modules.

More area inside printer is usable as print area compared to many other designs.

All motors outside of build area to allow heated chamber.

Integrated cable management for clean look.

Nearly all parts 3D printed, easily enclosed for printing ABS.

Features horizontal drag chain and low profile cover.

Innovative XY mechanism with excellent accuracy and low parts cost.

XY uses belts and LM8UU bearings.

Can use bowden or direct extruder (this version uses bowden).

Videos: https://www.youtube.com/watch?v=NaFrrTMu-uQ https://www.youtube.com/watch?v=DYeEHxprvno

Orientation of parts and settings for printing is left to the user. Most parts do not require support but a few do. Refer to parts list, included jpeg. The settings I used required about 4kg of ABS. I generally pay about $20 canadian per kg.

Currently a work in progress. More assembly instructions and pictures will follow. Parts for top are not included yet and hardware parts list has not been done. No assembly instructions currently so I suggest you not attempt this printer unless you are handy. Please let me know if you find errors. If you would like to see build instruction videos and hood/enclosure design, let me know. This is a work in progress.

UPDATE Feb 14, 2018: Added 2 pictures of endstop assemblies. Corrected X endstop part labels.

UPDATE October 28, 2017: Replaced part L1 due to missing face.

UPDATE October 2017: Added improved door: https://www.thingiverse.com/thing:2578498/#files with assembly instructions.

UPDATE September 2017: Added photos of completed units. Will add upgrade for top and door later.

UPDATE July 4, 2017: Revised parts Y2, Z3, Z4 to provide clearance.

UPDATE July 4, 2017: Revised part ZH to allow belt clearance.

UPDATE July 3, 2017: Revised parts Z1, Z2, B5, B8. Improved access to Z rod clamp screw and remove unneeded access hole on B5 and B8.

UPDATE June 28, 2017: Revised parts YA and Z10.

UPDATE June 26, 2017: Designed Z axis extension kit. Thing: 240611. ( https://www.thingiverse.com/thing:2406116)

Mostly Printed 3D Printer Optimized to Print ABS. The XY mechanism is of my own devising and as far as I can find it is brand new. It is a combination of ideas taken from the Ultimaker gantry and Richard Horne's Sli3dr Printer but I believe better and simpler than either.

3D Printer Features:

Features Genuine or clone E3D V6 hotend and graphic controller at $350 price point.

Modular construction. Size can be adjusted by adding or removing modules.

More area inside printer is usable as print area compared to many other designs.

All motors outside of build area to allow heated chamber.

Integrated cable management for clean look.

Nearly all parts 3D printed, easily enclosed for printing ABS.

Features horizontal drag chain and low profile cover.

Innovative XY mechanism with excellent accuracy and low parts cost.

XY uses belts and LM8UU bearings.

Can use bowden or direct extruder (this version uses bowden).

Videos: https://www.youtube.com/watch?v=NaFrrTMu-uQ https://www.youtube.com/watch?v=DYeEHxprvno

Orientation of parts and settings for printing is left to the user. Most parts do not require support but a few do. Refer to parts list, included jpeg. The settings I used required about 4kg of ABS. I generally pay about $20 canadian per kg.

Currently a work in progress. More assembly instructions and pictures will follow. Parts for top are not included yet and hardware parts list has not been done. No assembly instructions currently so I suggest you not attempt this printer unless you are handy. Please let me know if you find errors. If you would like to see build instruction videos and hood/enclosure design, let me know. This is a work in progress.

Similar models

thingiverse

free

Mostly Printed 3D Printer Optimized to Print ABS by rice9300

... please let me know if you find errors. if you would like to see build instruction videos and hood/enclosure design, let me know.

thingiverse

free

EndStop Z-axis by Ghost384904

... more throwing off the print.

endstop5 is the newest revision with a larger diameter hole and more clearance between the opening.

thingiverse

free

TrintCore3D by Idegraaf

...u.be/afolpmq_a-8https://youtu.be/5tzniiijzy0https://youtu.be/hyzemayeggi

z-axis is here: http://www.thingiverse.com/thing:1055163

thingiverse

free

Endstop Mounting by dr_delta

...has wrong xy orientation. sry i will correct an update it.

(update 17.09.2017)

i have corrected the orientation, now it works. :)

thingiverse

free

QU-BD Z Endstop - Left Gantry Mod by zcubed

...for those who need it. it has m3 holes to attach it under where the z endstop is located. i use it without an added screw on top.

thingiverse

free

Soap Brush Holder Remix by Greenthunder

...trength. print with support.

feb 16 2020 update:

added single piece bracket that fits a sink with a 42mm thickness between sinks.

grabcad

free

Ender 6 complete cablechain with guide for bowden

... is hard, but you can connect and disconnect the mombers from each other.

if you want to print abs, this parts should be abs too.

thingiverse

free

Sunhokey PRUSA I3 Improved Endstop Holder and Add Power Switch by projectearth7

...this helps others too who has the same or similar 3d printer like mine. updates (june 9, 2015) i...

thingiverse

free

Filament runout sensor for Bowden Bondtech BMG by reggaemanu

...ve added a longer and cutted version for assembly where the z-rod is really near the extruder (like on cr-10 or ender-3 printers)

thingiverse

free

6.5mm glass plate z endstop spacer for Monoprice Dual Extrusion by jdinnis

...d it in cura, and printed it on the monoprice printer in abs. fits great and is just the right size for the 6.5mm plate i added.

Bluerahm

thingiverse

free

BlueRAHM Improved Door With Instructions by rice9300

...mproved door for bluerahm 3d printer including assembly instructions.

bluerahm printer: https://www.thingiverse.com/thing:2387735

thingiverse

free

BlueRAHM Z Axis Extension 100mm. by rice9300

...o pull air from under printer. requires longer z axis rods and about 750g of filament. graphic smart controller bolts to part k4.

Rice9300

thingiverse

free

Hard Drive 3.5" Storage Box. by rice9300

...hard drive 3.5" storage box. by rice9300

thingiverse

storage box for 3.5 inch hard drives.

thingiverse

free

BlueRAHM Improved Door With Instructions by rice9300

...mproved door for bluerahm 3d printer including assembly instructions.

bluerahm printer: https://www.thingiverse.com/thing:2387735

thingiverse

free

Floor spacer for installing laminated flooring. by rice9300

...g laminated flooring. by rice9300

thingiverse

floor spacer for installing laminated flooring to set correct distance from walls.

thingiverse

free

Cyclorama for Green Screen by rice9300

...ell as the tricky center corner pieces. assemble pieces and smooth with drywall mud or similar. rotate as necessary for printing.

thingiverse

free

Compact Terminal Strip With Optional Strain Relief. by rice9300

...mpact terminal strip with optional strain relief. by rice9300

thingiverse

uses 6-32 screws. printed threads. do not over torque.

thingiverse

free

Screw On Lens Cap by rice9300

...w .25mm and fine tune with flowrate if necessary to get a nice fit. screws on easily and stays very secure if printed just right.

thingiverse

free

Cup Washer for 10-32 or close oval or flat screw. by rice9300

...cup washer for 10-32 or close oval or flat screw. by rice9300

thingiverse

cup washer as used on equipment racks.

thingiverse

free

6-32 Nut Pocket by rice9300

...are. insert nut in hex hole and slide under round hole for 6-32 screw. or add 10mmx20.6mmx8mm hole to your object and glue it in.

thingiverse

free

E3D-V6 Printrbot adapter by rice9300

...ts to hotend with 2 4-40 screws. hotend needs to be drilled and tapped to match. shown here with printrbot double drive extruder.

thingiverse

free

Quick and Easy Friction Fit Miniature Wire Splice. by rice9300

...se

friction fit miniature wire splice. assemble tightly with pliers as shown and clip into cover. print larger for larger wires.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.