Thingiverse

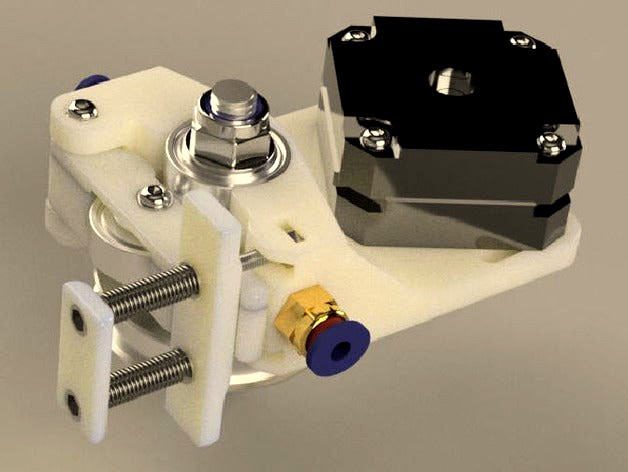

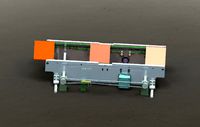

Belted Extruder V2. for 1.75mm Bowden by dintid

by Thingiverse

Last crawled date: 3 years ago

New edition now available: Belted Extruder v.3 for 1.75

This is my finished Belted Extruder (V2) for 1.75mm filament.

I have worked hard to make it wotk with flexibles as well. There is less than 1mm room between idler and filament-outlet hole when filament is loaded.

I have not tested it with flexible though, as I do not have any 1.75 flexibles on hand.

You do not have to open idler to load filament, which makes it very easy to change filament!This is replacement remix of my previous Universal Belted Extruder - Bowden and Direct, which I will no longer work on.

You can view it in 3D on Autodesk Fusion 360 site.

I removed the embedded version here as it really killed some phones and tablets.

Details

I use a 60-GT2 aluminium pulley to avoid inaccuracies and avoid wear and tear of printed gear. You can use a 80 tooth printed gear if you absolutely want higher gearing than 1:3.75

I use a 16-GT2 aluminium pulley for my small gear.

Gear ratio: 1:3.75

Silent running due to belt operation

Belt needed 168-172

A Nema 17 motor

Belt is tightened by tilting the motor

Strongly advice you to buy Hobbed Bolt from E3D

Push-Fitting used is 1/8 BSP (9,7-9.9 mm) or M6. Look at file names. The one without Push-Fitting size specifications is 1/8 BSP.

With 32 microstepping and normal 1.8 degree Nema, the steps are about 1100mm/s filament, so ultra high definition and high torque

Updates

Added a version for M6 Push-Fitting. I have made m6 threadding for the fittings. Tested fine at 0.2mm layer height.

This is my finished Belted Extruder (V2) for 1.75mm filament.

I have worked hard to make it wotk with flexibles as well. There is less than 1mm room between idler and filament-outlet hole when filament is loaded.

I have not tested it with flexible though, as I do not have any 1.75 flexibles on hand.

You do not have to open idler to load filament, which makes it very easy to change filament!This is replacement remix of my previous Universal Belted Extruder - Bowden and Direct, which I will no longer work on.

You can view it in 3D on Autodesk Fusion 360 site.

I removed the embedded version here as it really killed some phones and tablets.

Details

I use a 60-GT2 aluminium pulley to avoid inaccuracies and avoid wear and tear of printed gear. You can use a 80 tooth printed gear if you absolutely want higher gearing than 1:3.75

I use a 16-GT2 aluminium pulley for my small gear.

Gear ratio: 1:3.75

Silent running due to belt operation

Belt needed 168-172

A Nema 17 motor

Belt is tightened by tilting the motor

Strongly advice you to buy Hobbed Bolt from E3D

Push-Fitting used is 1/8 BSP (9,7-9.9 mm) or M6. Look at file names. The one without Push-Fitting size specifications is 1/8 BSP.

With 32 microstepping and normal 1.8 degree Nema, the steps are about 1100mm/s filament, so ultra high definition and high torque

Updates

Added a version for M6 Push-Fitting. I have made m6 threadding for the fittings. Tested fine at 0.2mm layer height.

Similar models

thingiverse

free

Belted Extruder v.3 for 1.75 by dintid

...ofcourse use bigger motors, but i rather like this model for it's compact size and great accuracy.

i found it on german ebay.

thingiverse

free

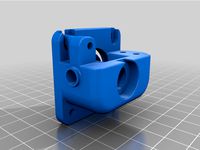

Universal Belted Extruder - Bowden and Direct by dintid

...er:

2x m3 50mm or longer screws

2x 1cm or longer springs, matching the long screws.

4x m3 spacers for the long screws and springs

thingiverse

free

Bowden extruder funnel for 1.75mm filaments by nmaggioni

...be fed more easily, sliding automagically into the bsp fitting and then into the bowden tube. it's made for 1.75mm filaments.

thingiverse

free

Belted Extruder V.3 for 2.85mm by dintid

...- can be found for cheap on aliexpress and similar - buy extras as they do wear down eventually....

thingiverse

free

Bowden extruder by louis2

...ament. it use an m10 pneumatic fitting for more reliability and an easier filament insertion. can be used with flexible filament.

thingiverse

free

Yet Bondtech Bowden Extruder - Geared with Belt

... be printed in the orientation they are in when loading the files.

designed to be printed with 0.2mm layer or a division here of.

thingiverse

free

Compact Bowden Extruder, 1.75mm Filament for MK7 Drive Gear V2 by Hiselrya

...lament for mk7 drive gear v2 by hiselrya

thingiverse

a remix of the, compact bowden extruder, 1.75mm filament for mk7 drive gear

thingiverse

free

Compact Bowden Extruder MK8 drive gear IR gate by sailorpete

...lity is limited due to the two bsp fittings.

-1.75mm filaments

(more photos to follow)

update 1:

added a panel mount flush option

thingiverse

free

Compact Bowden Extruder For CR-10 by Tijnv

...with a small diameter drive gear. and when doing that you have to be able to change the extruder steps in your printers firmware.

thingiverse

free

Compact Bowden Extruder, direct drive 1.75mm (Flexible Filament inlay) 4mm Tube, M5 pushfit by sobo84

...ment. works great for me.

maybe you have to cut it a little bit.

idler:

i glued anwasher with epoxid on it. it is just perfect!

Dintid

thingiverse

free

Mini Screwdriver Holder by dintid

...verse

needed a shorter handle for my multiple small bits, and made this one.

they are made for bits with a cross-section of 4mm.

thingiverse

free

xBot Chamber Heater Fanduct by dintid

...xbot chamber heater fanduct by dintid

thingiverse

chamber heater fan duct for use with my xbot 3d printer design.

thingiverse

free

Long Slider for Push Drill with Adjustable Chuck by dintid

...h adjustable chuck by dintid

thingiverse

i wanted a longer slider than available on the clever push drill with adjustable chuck.

thingiverse

free

Ultimaker 2 Motor Spacer by dintid

...tep file from ultimaker 2 github repository. i have also put up the original step file.

please correct me if the licens is wrong!

thingiverse

free

Tantillus (Ultius) XY Endstop Holders by dintid

...erse

after designing the tantillus compact ultimaker slider adapters i needed some new endstop holders to use, so here they are.

thingiverse

free

Spoolholder for xBot and Ultimakers 2/3 by dintid

...holder i designed for my xbot-medium 3d printer project.

it is designed to use standard 1kg spools with a width of up to 70-75mm.

thingiverse

free

xBot Door Hinges by dintid

...3 10mm screws.

more information:

you can read more about the xbot 3d printer on my blog betrue3d.dk (opens my blog in new window)

thingiverse

free

Dremel mount by dintid

...d the dremel using a couple of zip-ties.

you can use all the adjustment stuff from the source as i retained all his nice options.

thingiverse

free

Nema 17 motor mount bracket by dintid

...r mount bracket

needed a bracket for my universal belted extruder

bom

5x m3 nuts.

4x m3 8mm screws..

1x m3 15mm screw, or longer.

thingiverse

free

BLTouch mount - generic by dintid

...h as well, as it can be usefull :)

if you want to read more about my printer, you should go to my blog at:https://www.betrue3d.dk

75Mm

cg_studio

$79

75mm Pak 97/383d model

...rld ww2 wwii

.obj .jpg .max .fbx .3ds - 75mm pak 97/38 3d model, royalty free license available, instant download after purchase.

3d_export

$79

75mm Pak 97-38 3D Model

... pak tank war weapon world

75mm pak 97-38 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl graverino 108478 3dexport

3d_ocean

$79

75mm Pak 97/38

...el originally created with 3ds max and rendered with vray the model is easy to modify, the main parts can be easily moved as i...

cg_studio

$149

M4A3 Sherman - 75mm - Mid production3d model

... .c4d .lwo .obj - m4a3 sherman - 75mm - mid production 3d model, royalty free license available, instant download after purchase.

cg_studio

$139

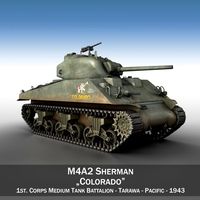

M4A2 Sherman - Colorado3d model

...m4a2 sherman colorado tank us marine corps pacific theatre 75mm m3 l/40 gun .c4d .obj .lwo .fbx .3ds -...

cg_studio

$139

M4A2 Sherman - Destroyer3d model

...m4a2 sherman destroyer tank us marine corps pacific theatre 75mm m3 l/40 gun .c4d .obj .lwo .fbx .3ds -...

cg_studio

$65

Pak 403d model

...pak 403d model cgstudio gun ww2 75mm artillery world war wwii 1943 army 1945 anti tank...

cg_studio

$125

Anti tank guns ww23d model

...anti tank guns ww23d model cgstudio gun ww2 75mm artillery wwii army 1945 antitank projectile weapon shell case...

3ddd

free

Indian vase

...311742 размеры: длинна маленькой вазы - 460mm, ширина - 75mm высота - 130mm длинна большой вазы - 600mm, ширина...

3d_export

$7

facemaskearloopweldingmachine

...the welding of one-time plane mask ear belt with 75mm standard ear band spacing. if you want to weld...

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Belted

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

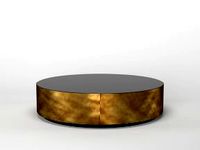

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

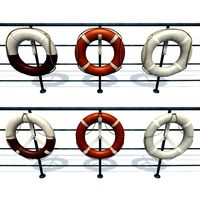

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)