3dExport

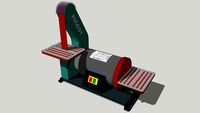

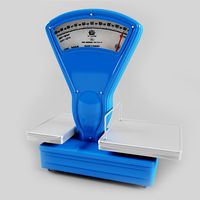

belt grinder sander buffer edge polishing machine

by 3dExport

Last crawled date: 1 year, 10 months ago

- modeled and textured in autodesk inventor. the model contains the most popular formats:

1. autodesk inventor *.ipt *.iam *.ipn *.idw *.dwg (native)

2. solidworks: *.sldprt *.slddrw *.sldasm

3. 3ds max: *.max

4. rhinoceros: *.3dm

5. sketchup: *.skp

6. blender: *.blend

7. autocad: *.dwg

8. collada file type: *.dae

9. stereolithography: *.stl

10. lightwave: *.lwo

11. acis: *.sat (nurbs)

12. iges: *.iges *.igs (nurbs)

13. step: *.step *.stp (nurbs)

14. 3ds max all ver.: *.3ds (multi format)

15. wavefront obj: *.obj *.mtl (multi format)

16. fbx: *.fbx (multi format)

- each file was checked for opening and full content by the model.

- the 3d model was created on real base. its created accurately, in real units of measurement, qualitatively and maximally close to the original.

- renders are made in luxion keyshot

- we provide 3d model cheap price but with good quality

- if you need any other formats we are more than happy to make them for you. contact me for any question :)

sincerely your, surf3d

more information about 3d models :

belt grinding is an abrasive machining process used on metals and other materials. it is typically used as a finishing process in industry. a belt, coated in abrasive material, is run over the surface to be processed in order to remove material or produce the desired finish.[1][2]

belt grinding is a versatile process suitable for all kinds of different applications. there are three different applications of the belt grinding technology:[3]

finishing: surface roughness, removal of micro burrs, cosmetic finishes, polishing

deburring: radiusing, burr removal, edge breaking

stock removal: high stock removal, cleaning (e.g. of corrosion), eliminating mill or tool marks, dimensioning

a belt sander or strip sander is a sander used in shaping and finishing wood and other materials.[1] it consists of an electric motor that turns a pair of drums on which a continuous loop of sandpaper is mounted. belt sanders may be handheld and moved over the material, or stationary (fixed), where the material is moved to the sanding belt. stationary belt sanders are sometimes mounted on a work bench, in which case they are called bench sanders. stationary belt sanders are often combined with a disc sander.

belt sanders can have a very aggressive action on wood and are normally used only for the beginning stages of the sanding process, or used to rapidly remove material. sometimes they are also used for removing paints or finishes from wood. fitted with fine grit sand paper, a belt sander can be used to achieve a completely smooth surface.

stationary belt sanders are used for removing non-ferrous metals, such as aluminum. non-ferrous metals tend to clog grinding wheels, quickly making them useless for grinding soft metals. because the small grooves in the sandpaper are opened up as they go around the arc of the drive wheel, belt sanders are less prone to clogging.

belt sanders can vary in size from the small handheld unit shown in the illustration to units wide enough to sand a full 1.2 by 2.5 m (4-by-8 foot sheet) of plywood in a manufacturing plant. some belt sanders can be as large as 1.2 by 0.7 metres (3 ft 11 in 2 ft 4 in). sanding wood produces a large amount of sawdust. therefore, belt sanders employed in woodworking are usually equipped with some type of dust collection system. it may be as simple as a cloth filter bag attached to a portable sander or a large vacuum system to suck dust particles away into a cen

1. autodesk inventor *.ipt *.iam *.ipn *.idw *.dwg (native)

2. solidworks: *.sldprt *.slddrw *.sldasm

3. 3ds max: *.max

4. rhinoceros: *.3dm

5. sketchup: *.skp

6. blender: *.blend

7. autocad: *.dwg

8. collada file type: *.dae

9. stereolithography: *.stl

10. lightwave: *.lwo

11. acis: *.sat (nurbs)

12. iges: *.iges *.igs (nurbs)

13. step: *.step *.stp (nurbs)

14. 3ds max all ver.: *.3ds (multi format)

15. wavefront obj: *.obj *.mtl (multi format)

16. fbx: *.fbx (multi format)

- each file was checked for opening and full content by the model.

- the 3d model was created on real base. its created accurately, in real units of measurement, qualitatively and maximally close to the original.

- renders are made in luxion keyshot

- we provide 3d model cheap price but with good quality

- if you need any other formats we are more than happy to make them for you. contact me for any question :)

sincerely your, surf3d

more information about 3d models :

belt grinding is an abrasive machining process used on metals and other materials. it is typically used as a finishing process in industry. a belt, coated in abrasive material, is run over the surface to be processed in order to remove material or produce the desired finish.[1][2]

belt grinding is a versatile process suitable for all kinds of different applications. there are three different applications of the belt grinding technology:[3]

finishing: surface roughness, removal of micro burrs, cosmetic finishes, polishing

deburring: radiusing, burr removal, edge breaking

stock removal: high stock removal, cleaning (e.g. of corrosion), eliminating mill or tool marks, dimensioning

a belt sander or strip sander is a sander used in shaping and finishing wood and other materials.[1] it consists of an electric motor that turns a pair of drums on which a continuous loop of sandpaper is mounted. belt sanders may be handheld and moved over the material, or stationary (fixed), where the material is moved to the sanding belt. stationary belt sanders are sometimes mounted on a work bench, in which case they are called bench sanders. stationary belt sanders are often combined with a disc sander.

belt sanders can have a very aggressive action on wood and are normally used only for the beginning stages of the sanding process, or used to rapidly remove material. sometimes they are also used for removing paints or finishes from wood. fitted with fine grit sand paper, a belt sander can be used to achieve a completely smooth surface.

stationary belt sanders are used for removing non-ferrous metals, such as aluminum. non-ferrous metals tend to clog grinding wheels, quickly making them useless for grinding soft metals. because the small grooves in the sandpaper are opened up as they go around the arc of the drive wheel, belt sanders are less prone to clogging.

belt sanders can vary in size from the small handheld unit shown in the illustration to units wide enough to sand a full 1.2 by 2.5 m (4-by-8 foot sheet) of plywood in a manufacturing plant. some belt sanders can be as large as 1.2 by 0.7 metres (3 ft 11 in 2 ft 4 in). sanding wood produces a large amount of sawdust. therefore, belt sanders employed in woodworking are usually equipped with some type of dust collection system. it may be as simple as a cloth filter bag attached to a portable sander or a large vacuum system to suck dust particles away into a cen

Similar models

grabcad

free

BELT SANDER-BELT PRESS

...ation of belt pressing unit into a std belt sander for cheap inaccurate surface grinding process(for aesthetic surface finishing)

cg_trader

$5

hand-held sanding machine

...able woodworking machine. in the process of wood-made furniture, the hand-held sanding machine play an important role in the end.

grabcad

free

Eccentric Sander

...er

grabcad

eccentric sander for sanding wood, metal, plaster, concrete and stone. abrasive 125mm

cyclonic suction collector box.

thingiverse

free

Belt Sander by Kris3DK

...belt sander by kris3dk

thingiverse

remix to use the sander handheld with drill as power.

3dwarehouse

free

Ponceuse à bande stationnaire combinée (belt grinder)

...l #meuler #meuleuse #métal #outils #poncer #ponceuse #sander #sanding #stationary #stationnaire #tape #tools #travail #wood #work

3d_export

$60

the synchronous belt sander

...r the purchase.<br>designed with solidworks 2017, render with photoview 360<br>**************************************

thingiverse

free

Wall bracket for abrasive belt sanders or limes by patric123

... patric123

thingiverse

wall bracket for abrasive belt sanders or limes

support mural pour bandes abrasives de ponceuses ou limes

cg_trader

$10

Disk sander Grind abrasive machine Clean

...g trader

3d model disk sander grind abrasive machine clean , formats include obj, fbx, stl, blend, ready for 3d animation and ot

grabcad

free

Auto Rotary Sand Blasting

...across that surface at high speeds; the effect is similar to that of using sandpaper, but provides a more...

grabcad

free

Sanding Machine

...per and a mechanism for quickly moving it contained within the housing with a means for holding it or fixing it to the workbench.

Buffer

turbosquid

$9

Damper, buffer, absorber

...ty free 3d model damper, buffer, absorber for download as obj on turbosquid: 3d models for games, architecture, videos. (1648319)

turbosquid

$20

Buffer Poser Prop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Tillig 07950. Buffer stop without track

... 07950. buffer stop without track for download as max and dwg on turbosquid: 3d models for games, architecture, videos. (1286875)

turbosquid

$25

TIGHT BUFFER Cable TB DQ-LINE TB006 62.5-125.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

cold counter chiller

...chiller 3ddd холодильник marine mess area used chiller for buffer ...

archibase_planet

free

Subbuffer

...subbuffer

archibase planet

subbuffer speacers audio

sub buffer media - 3d model for interior 3d visualization.

3ddd

free

барашки

...барашки мех hair and fur. p.s в hairs вместо buffer поставьте mr...

archive3d

free

Subbuffer 3D Model

...l

archive3d

subbuffer speacers audio

sub buffer media - 3d model for interior 3d visualization.

3ddd

$1

Пушистый пуф Furlicious

...fbx модель без меха. для визуализации необходимо переключить с buffer на mr prim в разделе...

Sander

turbosquid

$9

Sander

...uid

royalty free 3d model sander for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607159)

3ddd

free

Sander Mulder Josephine

...sander mulder josephine

3ddd

sander mulder

http://www.sandermulder.com/josephine.html

3ddd

free

Sander Mulder Pandora

...sander mulder pandora

3ddd

sander mulder

http://www.sandermulder.com/pandora.html

3ddd

free

Sander Mulder - Sputnik

...нальный столик от sander mulder

модель - sputnik

ссылка на сайт производителя:http://www.sandermulder.com/sputnik.html

turbosquid

$30

Disc Sander

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$98

Tablet sander

...let sander for download as 3ds, max, ige, obj, fbx, and sldas on turbosquid: 3d models for games, architecture, videos. (1424774)

turbosquid

$17

Sander Wall Mirror

... free 3d model sander wall mirror for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1202867)

turbosquid

$60

The synchronous belt sander

...elt sander for download as 3ds, max, ige, obj, fbx, and sldas on turbosquid: 3d models for games, architecture, videos. (1424296)

3ddd

free

Sander Wall Mirror

...l mirror

3ddd

канат , веревка , морской

зеркало

3ddd

$1

Riley Sanders — Dowel Lamp

...riley sanders — dowel lamp

3ddd

дизайнерский светильник от riley sanders.

используется как на столе так и на полу.

Grinder

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

archibase_planet

free

Coffee grinder

... planet

coffee-grinder coffee grinder kitchen ware

coffee grinder n030510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$1

Grinder

...turbosquid

royalty free 3d model grinder for download as c4d on turbosquid: 3d models for games, architecture, videos. (1408552)

turbosquid

$10

Grinder

...

royalty free 3d model grinder for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1568436)

turbosquid

$25

Grinder

...yalty free 3d model grinder for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1508433)

turbosquid

$5

Grinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Grinder

... 3d model grinder for download as c4d, obj, fbx, dae, and 3ds on turbosquid: 3d models for games, architecture, videos. (1603976)

3d_ocean

$14

Meat grinders

...eat grinders

3docean

kitchen meat grinders tools

this is little meat grinders with an old design, 1960-1980, made in 3ds max 2008

archibase_planet

free

Coffee grinder

...ase planet

coffee-grinder kitchen equipment

coffee grinder gipfel n270810 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Grinder 3D Model

...

coffee-grinder grinder

grinder n120108 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Polishing

archibase_planet

free

Nail polish

...ail polish

archibase planet

nail varnish nail polish enamel

nail polish n250212 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$1

nail polish

...osquid

royalty free 3d model nail polish for download as max on turbosquid: 3d models for games, architecture, videos. (1598166)

turbosquid

$9

Nail Polish

...royalty free 3d model nail polish for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1297984)

turbosquid

$100

Polish MiG29

... free 3d model polish mig29 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1387984)

turbosquid

$90

Polish Train

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

METAL POLISH

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Nail Polish

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

NAIL POLISH

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Polished Sword

...el polished sword for download as 3ds, obj, x, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1205634)

turbosquid

free

Polished Knife

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Belt

turbosquid

$9

Belt conveyor belt

...t conveyor belt for download as 3ds, ige, obj, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1226546)

3d_export

$6

belt

...d then comes off and fastens at the front of the seat. version: 2015 units: millimetres x-form: yes polys: 120 950 verts: 163 944

3d_export

$7

belt grinder

...belt grinder

3dexport

belt grinder

3d_export

$5

Belt conveyor

...belt conveyor

3dexport

belt conveyor

3ddd

$1

column belt

...column belt

3ddd

колонна

column belt

turbosquid

$5

Belt

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Leather Belt

...ather belt is created in 3dsmax 2011 and rendered with vray 1.5 and it has all the texture included with the multiple obj format.

3d_ocean

$5

Belt Ring

...belt ring

3docean

belt jewelry ring

belt ring 3d model. total weight 3.5 gram & 1.1 stone size. 3dm and obj file format.

design_connected

$11

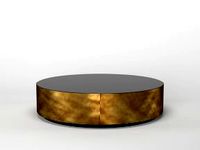

Belt Round

...belt round

designconnected

meridiani belt round computer generated 3d model. designed by parisio, andrea.

design_connected

$11

Belt Oval

...belt oval

designconnected

meridiani belt oval computer generated 3d model. designed by parisio, andrea.

Edge

3ddd

free

EDGE

... часы

светильник edge

дизайнер: моторный александрhttp://www.djournal.com.ua/?p=2483

3ddd

$1

Edge

...edge

3ddd

edge

кухня-моноблок, без плинтуса, подвешивается на стену.

3ddd

$1

кровать EDGE

...кровать edge

3ddd

edge

кровать и тумбочки от компании edge

полигоны: 181 253

3ddd

free

EDGE светильник

...edge светильник

3ddd

edge , подвес

производитель польша

материал метал

3ddd

$1

Artemide Edge

...artemide edge

3ddd

artemide

люстра artemide edge. сделана по фото.

design_connected

free

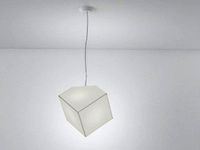

Edge pendant

...edge pendant

designconnected

free 3d model of edge pendant by fabbian designed by baldereschi, alessandra.

3ddd

$1

EDGE CHANDELIER

...lier фирмы holly hunt. официальный сайт:https://www.hollyhunt.com/showproduct.aspx?productid=3103&manufacturerid;=1

design_connected

$7

Edge 30

...edge 30

designconnected

artemide edge 30 computer generated 3d model. designed by mendini, alessandro.

3ddd

$1

Edge Seat

... банкетка

om website: beltafrajumar.com

designer: jacob pringiers

formats: 3ds, c4d, fbx, obj

3ddd

$1

бра Fabbian Edge

... edge

бра fabbian, модель edge, артикулы d77 d01 15 и edge d 77 d03 15. маленькое бра сделано более корректно

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.