Thingiverse

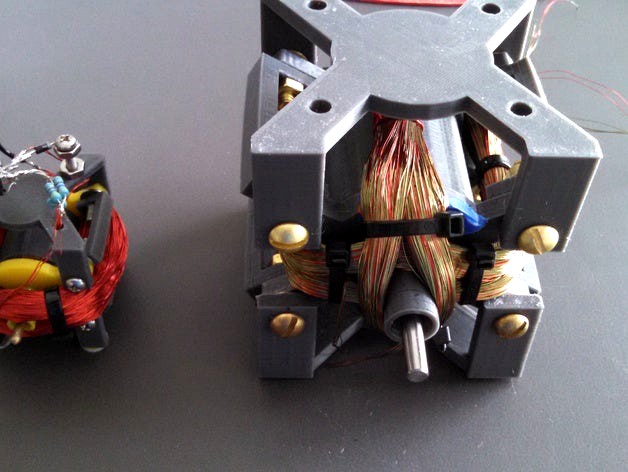

Bedini Style Window Motor by Cotton80

by Thingiverse

Last crawled date: 3 years ago

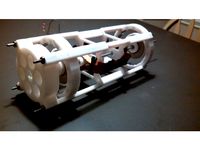

This Thing represents two models which are a basis for studying radiant or flyback energy. They are a compact design. The difference between the two designs is in the ends that hold the bearings. You will see that one has three brace tabs and the other has four. This assist with the coil placement on both models. Here are three links to videos to explain each.

The original designs and applications for these motors should be credited to John Bedini and Ron Cole. The Bedini SSG Circuit can be used to pulse this motor. It is a good one to start out with. This company provides a great kit that can be used with this motor: http://teslagenx.com/kits/tx-sg4tub.html?category=kits|pcb

https://www.youtube.com/watch?v=ZYheabS5WBUhttps://www.youtube.com/watch?v=1r3-KltRWEUhttps://www.youtube.com/watch?v=EqtP2-h8jm8

There are several options for pulsing these machines. I would recommend that you study circuits by John Bedini. A search through the internet yields loads of free information. Also, Energyscienceforum.com is a place where this research is explored and shared by like-minded individuals. Disclaimer: Do not operate these machines if you do not have experience with electrical, electronics, and mechanical systems. Catastrophic failure of parts at high rpm can cause injury, death, or destruction of property. Operate at your own risk.

Parts List: Qty:

Magnets- 2" X 1/2" X 1/4" N 42 Neodymium Magnets 6

Sourced from www.magnet4less.com nsnsns arrangement

Bearings- 1/4" X 3/4" X 7/32" R4A Open Ball Bearings 2

Sourced from VXB Bearings (can be upgraded for better performance)

Shaft- 6" X 1/4" linear motion hardened steel 1

Sourced from VXB Bearings (can be upgraded to non-magnetic material)

Brass bolts and nuts Sourced from Lowe's 6 or 8 depending on model

1/4" - 20 X 1 round slotted brass bolts 1/4" - 20 Brass Hex Nuts

Brass is essential due to non-magnetic properties

It's your choice on the wire and batteries. I explain what I use in the videos. A fine tuned window motor this size can run in the micro amp range. I have run mine between .75 amps (2800 rpm's with the two flywheels) down to between 15 - 20 milliamps (470 rpm's). If you are looking to recover flyback energy you will need to tune your device with techniques discovered in your research for maximum results.

https://www.youtube.com/watch?v=frWQ8Kben5Q

This video is an update with the mounting bracket.

08/07/2016 video update with a 50% scale modelhttps://www.youtube.com/watch?v=VkFXT_C94RA

Details and parts for this model can be found on this thread: http://www.energyscienceforum.com/showthread.php?t=3380

video update as of 08/07/2016: https://www.youtube.com/watch?v=b95PVtz1xQc

video update as of 08/18/2016: https://www.youtube.com/watch?v=Fm88KIe_vec

Also update on information at: http://www.energyscienceforum.com/showthread.php?t=3380&page=3&p=23865#post23865

update 08/19/2016: A 3 to 1 rubber band pulley system was added as well as a .25" square magnet trigger wheel for reed or hall switching. The trigger magnet disc can be used in place of the small pulley. Be extra careful when drilling these out with .25" drill bit;) for the shaft.

update 08/28/2016: A 7 to 3 to 1 rubber band pulley system was added as well as a .25" square magnet trigger shaft for capacitor discharge.

update 09/06/2016: The rotor was updated to include bearing standoffs on both sides. You must use support on the bottom.

update 04/08/2017: reed switch holder for large reed switch. http://www.surplus-electronics-sales.com/index.php?main_page=product_info&products_id=299

The original designs and applications for these motors should be credited to John Bedini and Ron Cole. The Bedini SSG Circuit can be used to pulse this motor. It is a good one to start out with. This company provides a great kit that can be used with this motor: http://teslagenx.com/kits/tx-sg4tub.html?category=kits|pcb

https://www.youtube.com/watch?v=ZYheabS5WBUhttps://www.youtube.com/watch?v=1r3-KltRWEUhttps://www.youtube.com/watch?v=EqtP2-h8jm8

There are several options for pulsing these machines. I would recommend that you study circuits by John Bedini. A search through the internet yields loads of free information. Also, Energyscienceforum.com is a place where this research is explored and shared by like-minded individuals. Disclaimer: Do not operate these machines if you do not have experience with electrical, electronics, and mechanical systems. Catastrophic failure of parts at high rpm can cause injury, death, or destruction of property. Operate at your own risk.

Parts List: Qty:

Magnets- 2" X 1/2" X 1/4" N 42 Neodymium Magnets 6

Sourced from www.magnet4less.com nsnsns arrangement

Bearings- 1/4" X 3/4" X 7/32" R4A Open Ball Bearings 2

Sourced from VXB Bearings (can be upgraded for better performance)

Shaft- 6" X 1/4" linear motion hardened steel 1

Sourced from VXB Bearings (can be upgraded to non-magnetic material)

Brass bolts and nuts Sourced from Lowe's 6 or 8 depending on model

1/4" - 20 X 1 round slotted brass bolts 1/4" - 20 Brass Hex Nuts

Brass is essential due to non-magnetic properties

It's your choice on the wire and batteries. I explain what I use in the videos. A fine tuned window motor this size can run in the micro amp range. I have run mine between .75 amps (2800 rpm's with the two flywheels) down to between 15 - 20 milliamps (470 rpm's). If you are looking to recover flyback energy you will need to tune your device with techniques discovered in your research for maximum results.

https://www.youtube.com/watch?v=frWQ8Kben5Q

This video is an update with the mounting bracket.

08/07/2016 video update with a 50% scale modelhttps://www.youtube.com/watch?v=VkFXT_C94RA

Details and parts for this model can be found on this thread: http://www.energyscienceforum.com/showthread.php?t=3380

video update as of 08/07/2016: https://www.youtube.com/watch?v=b95PVtz1xQc

video update as of 08/18/2016: https://www.youtube.com/watch?v=Fm88KIe_vec

Also update on information at: http://www.energyscienceforum.com/showthread.php?t=3380&page=3&p=23865#post23865

update 08/19/2016: A 3 to 1 rubber band pulley system was added as well as a .25" square magnet trigger wheel for reed or hall switching. The trigger magnet disc can be used in place of the small pulley. Be extra careful when drilling these out with .25" drill bit;) for the shaft.

update 08/28/2016: A 7 to 3 to 1 rubber band pulley system was added as well as a .25" square magnet trigger shaft for capacitor discharge.

update 09/06/2016: The rotor was updated to include bearing standoffs on both sides. You must use support on the bottom.

update 04/08/2017: reed switch holder for large reed switch. http://www.surplus-electronics-sales.com/index.php?main_page=product_info&products_id=299

Similar models

thingiverse

free

DIY Belt Conveyor Parts by workpiles

...3.motor case

4.tensioner

details :https://www.youtube.com/watch?v=pqj7nqns0x8http://workpiles.com/2016/08/ccb9-diy-belt_conveyor/

thingiverse

free

free energy - magnetic motor 6 by Zdenek_Preisner

...ree energy - magnetic motor 6 by zdenek_preisner

thingiverse

4 * bearings 624 2rs cx

https://www.youtube.com/watch?v=ywzgovyqny8

thingiverse

free

free energy - magnetic motor 4 by Zdenek_Preisner

...ree energy - magnetic motor 4 by zdenek_preisner

thingiverse

5 * bearings 624 2rs cx

https://www.youtube.com/watch?v=hxoq6lycovg

thingiverse

free

IRON MAN by ardiwu

...pen close video..https://www.youtube.com/watch?v=h2xnvjrauni

motor: mg995

iron man case : http://www.thingiverse.com/thing:260152

thingiverse

free

Bedini/Cole Window Motor with a Jefimenko electrostatic motor twist by Cotton80

... perfectly. the large round hole can be used for your power cord from a wall-wart or battery pack. there will be more to come;)

thingiverse

free

AD Moore Dirod driven by Bedini/Cole Window Motor by Cotton80

...://www.youtube.com/watch?v=xctr_gmc3ja

motor used to drive this electrostatic generator: http://www.thingiverse.com/thing:1676878

thingiverse

free

Pulse Motor(s) for Zero Back emf Experiment by Cotton80

.... you will need to use support on the coil piece and rotor. with the adapter horizontally stacking multiple motors are possible.

thingiverse

free

Shooting Car Toy Launcher by gsyan

...e.com/watch?v=pcluyfkd8v0

https://www.youtube.com/watch?v=gxquox1zvbi

update:

2017.04.01 trigger updated, make it more sensitive.

thingiverse

free

Magnetically Levitated Bedini/Cole Window Pulse Motor by Cotton80

...45

https://www.youtube.com/watch?v=p0tj8u7_qmi

the rotor was redesigned so that the magnets are no longer exposed on the outside.

thingiverse

free

free energy - magnetic motor 5 by Zdenek_Preisner

...ee energy - magnetic motor 5 by zdenek_preisner

thingiverse

2 * bearings 624 2rs cx

https://www.youtube.com/watch?v=sidh7bb3cao

Bedini

thingiverse

free

Bedini rotor by Syngenta

...ni are in my library. the holes are perfect for 20mm 6mm thick ring magnets.the cover is put onto the magnets for safety reasons.

thingiverse

free

ReDesign3DP Bedini Motor V1 by redesign3dp

...redesign3dp bedini motor v1 by redesign3dp

thingiverse

redesigned bedini motor

thingiverse

free

Bedini Rotor round by Syngenta

...ngenta

thingiverse

this is the round version of my bedini rotor. magnets with 20mm diameter and 7mm in depth fit into the holes.

thingiverse

free

Bedini rotor by Syngenta

...dermagnet-200-x-200-x-30-mm-n45-nickel-m3-senkloch::511.html

(german shop)

coils and other rotors for a bedini are in my library.

thingiverse

free

Optical Tachometer for Bedini 3-pole Kit by liquidbuddha

...istor, with 5mm led plastic holders (both from radio shack). there is a small channel for wires, for the back side led or sensor.

thingiverse

free

Let's make your own Bedini Motor by arnoldkorea

...e spindle)

1 x m3 bolt (m3x50)

8 x m3 bolt (m3x20)

12 x m3 nut

make your own bedini motor circuit and play with fun !!

thingiverse

free

Bedini SSG Solderless Circuit by Cotton80

...elp reduce print time and still remains functional.

i also added a stencil for those who may want to put your circuit on a board.

thingiverse

free

Bedini-Type 6-Pole Magnet Motor by Syrus54

...the size to fit the application.

item is not for sale, royalty free.

[ do not sell nor re-distribute my work ]

you're welcome

thingiverse

free

electric coil by Syngenta

...by syngenta thingiverse this coil is perfect for a bedini pulse motor, the little hole is perfect for 2mm...

thingiverse

free

Bedini SG style motor (mechanical components) by MrCadillacsts

...tl will be glued to the lower side of the mounting plate.

add your bedini circuit and start the motor!!

have fun with this kit!!!

Cotton80

thingiverse

free

Electronic Symbol Stencils (Basic) by Cotton80

...your pencils. this is two basic stencils to assist with drawing your electronic circuit schematic. they are .8mm thick. enjoy!

thingiverse

free

Bracket 3-Point by Cotton80

... to whatever dimensions you like.

disclaimer: use this part in your build at your own risk. load test have not been performed.

thingiverse

free

Toggle Switch Mounts (2 or 4) by Cotton80

... in one side for wire access.

also not pictured is 4 mounting holes for 6-32 bolts. they will need to be at least 1.5" long.

thingiverse

free

Bracket 90 Degree L by Cotton80

...able tops, securing chair seats

disclaimer: use this part in your creation at your own risk. load test have not been performed.

thingiverse

free

Bedini SSG Solderless Circuit by Cotton80

...elp reduce print time and still remains functional.

i also added a stencil for those who may want to put your circuit on a board.

thingiverse

free

Coupler for 1" Aluminum Square Tube (3-Way) by Cotton80

... support for the two horizontal tube sections.

disclaimer: use this object at your own risk. load test have not been performed.

thingiverse

free

Bearing Hub for PMSM by Cotton80

...en working with electrical equipment, especially when working with capacitors. do not attempt without good electrical knowledge.

thingiverse

free

Magnet Stator for a Mini Windmill Style Generator by Cotton80

...ill bit through the piece to ensure a good fit.

this thing can be scaled up to 200% to fit a 1/2" shaft and 1" magnets.

thingiverse

free

3/4" Rod Holder by Cotton80

...on top to make a light weight shelf. you can use the keyhole hangers to hang pictures in the open instead of directly on a wall.

thingiverse

free

Spur Gears: 1 to 2 Ratio for 1/4" or 8mm shaft by Cotton80

...an easy fit.

the large gear has 28t and the small gear has 14t.

added on 02/05/2017: gears together for 1/4" & 8mm shaft

Window

thingiverse

free

Window

...window

thingiverse

window

thingiverse

free

Window holder (To tilt a window.) by capitaenz

...window holder (to tilt a window.) by capitaenz

thingiverse

to keep a window open / to tilt a window.

thingiverse

free

Window Handle

...window handle

thingiverse

window handle to use with sliding windows, can be glued to the window.

thingiverse

free

WINDOW by leonk

...window by leonk

thingiverse

window

thingiverse

free

WINDOW by leonk

...window by leonk

thingiverse

window

thingiverse

free

Window by chill2s

...window by chill2s

thingiverse

just a window.

thingiverse

free

Window bracket

...window bracket

thingiverse

windows bracket

thingiverse

free

Window keep / Window Jam / Window Stop / Fensterstopper by BigMacintosh85

... thing so that my windows won't slam when it's windy outside. i hope it will help some people to protect their windows :)

thingiverse

free

Window short holder (ajar window) by AndroVet

...window short holder (ajar window) by androvet

thingiverse

window short holder (ajar window) - the most used provisions.

thingiverse

free

Window stopper wedge for tilted windows

...ng shut on a windy day

-keep pets that try to climb though the window (and fail) from getting pinched to death in the window side

Style

thingiverse

free

bracelet styles by aramisi

...bracelet styles by aramisi

thingiverse

bracelet styles

thingiverse

free

Style Builiding by nagato

...style builiding by nagato

thingiverse

style builiding

thingiverse

free

House Style by nagato

...house style by nagato

thingiverse

house style

thingiverse

free

Styling CORRIDOR by NANCHI

...styling corridor by nanchi

thingiverse

styling corridor

thingiverse

free

Sword Samurai Style

...sword samurai style

thingiverse

samurai style sword.

thingiverse

free

L89 Style Hood

...l89 style hood

thingiverse

1/25th scale l89 style hood

thingiverse

free

Fillamentum swatch style

...fillamentum swatch style

thingiverse

fillamentum swatch style: https://fillamentum.com/collections/samples_swatches

thingiverse

free

graffiti style by atze_peng

...graffiti style by atze_peng

thingiverse

hip hop dont stop!

3d graffiti style _ mebes

thingiverse

free

DECORATION STYLE CODING

...decoration style coding

thingiverse

a decoration in the style of coding > _

(no bicolor file)

blog : bit.ly/leofactory

thingiverse

free

MWO Style Thorn

...mwo style thorn

thingiverse

a work in progress on the thorn in an mwo style. version 3 coming soon!

Motor

thingiverse

free

Motor test

...motor test

thingiverse

motor stand for test rc motors

thingiverse

free

Motor Halter Conrad Motor by Kortie

...motor halter conrad motor by kortie

thingiverse

motor halterung für tamiya trucks 1:14 in verbindung conrad motor

thingiverse

free

motor mount for 550 brushed motor by lijingwei

...motor mount for 550 brushed motor by lijingwei

thingiverse

motor mount for 550 brushed motor

thingiverse

free

Motor Guard for 2306 Motors by Simongotnews

...motor guard for 2306 motors by simongotnews

thingiverse

should work with the most common motors in 2306 standarts.

thingiverse

free

Motor mount

...motor mount

thingiverse

motor mount

thingiverse

free

ZMR250 Motor protector for 1806 Motor by king_draki

...otector for 1806 motor by king_draki

thingiverse

nice an light motor protector for 1806 motors.

m2.5 max.

12 -16 mm motor mount.

thingiverse

free

Motor Mounts for YoYo Motors by drmcland

...line following and or semi autonomous robots using these motors.

the image above is the bottom of a self balancing robot.

enjoy

thingiverse

free

Motor base

...motor base

thingiverse

base do motor regulavel

thingiverse

free

Motor Estrella

...motor estrella

thingiverse

motor estrella 6 cilindros.

thingiverse

free

Motor fitting

...motor fitting

thingiverse

wrap's around motor