Thingiverse

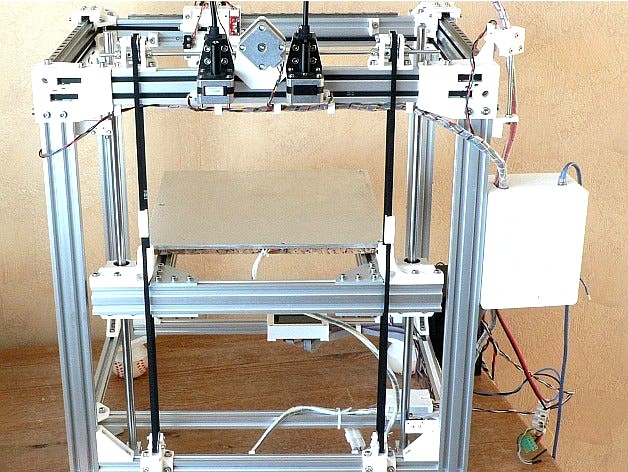

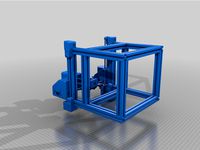

Bed_Hoist_for_a_3D_Printer_ (D-Bot, Core_XY) by printingSome

by Thingiverse

Last crawled date: 3 years ago

Edit (11-08-19): today published Bed Hoist for a 3D Printer - Final Version,https://www.thingiverse.com/thing:3732450

Edit (14-02-19): today published Bed_Hoist_for_a_3DPrinter (D-Bot, CoreXY)-_Version_2, www.thingiverse.com/thing:3427719.

That version 2 supersedes this one, because it is simpler: 1 belt, simpler parts.

No solution for the 2 mm-wave-error yet, though.

For a time I worked with one hoist and belt in this first version and that went ok, even somewhat better than with 2 belts.

So if you already have made version 1, perhaps you can leave version 2 for what it is and try it with 1 bed hoist: just move one hoist to the middle, uncouple the other one and look how that goes. ;-)

But if you are new to this concept or want to try other worm gears, forget version 1 and go for version 2.

A system for Z-axis movement with hoist action.

I looked for a way to replace the lead screws with something else and found that I needed only 1 motor with a 20:1 worm gear to hoist and lower my bed, which weighs some 4.5kg together with its support frame.

The motor action is brought via a ø5mm rod to 2 sets of timing pulleys to 2 of the usual GT2 belts.Pulleys without teeth are used to force the belt over as much of the teeth as possible.

All supported by ball bearings, 2 of them flanged to prevent sideways movement.

The Gt2 belts are captured with a remix of a nice thing I saw, among others, called "Separate GT2 belt tensioner" by MrArrow1961, https://www.thingiverse.com/thing:910725.

A bit more difficult to print than the usual solution, but easier to finetune belt tension and to place/remove the belt with it.

I made this thing so I can use it with my D-Bot_Linear_Z-guide, https://www.thingiverse.com/thing:2779260, but it is independent of it.

However, trying it in a system with wheels for the Z-axis gave me insurmountable problems, because without the support of the lead screws the bed angled so much downwards that this could not be compensated for with the usual bed supports.Just too much play in those wheel systems, whatever I tried with 3 of 4 wheels. So be warned. ;-)

No such problem with the linear Z-guides.

All in all I found this thing much simpler and quieter than the lead screw configurations I tried.

As accurate also, I think. Compared to the loads they are made for, I feel this load won't stretch the belts so as to give wrong printing heights.Somewhere (can't find it any more) I even saw a pre-load advised by the manufacturer of some 2kg, so that should be ok.

Though, of course, it doesn't harm to check once in a while when height is of an essence with your print..

For materials, assembling specifics, more images and more rationales, see the"Notes.pdf¨ in the "Thing Files".

The nimble motor support and motor are very present in the pictures, alas (because it has nothing to do with this thing), but to dismantle the whole thing etc. only to make a picture without it was a bit too much trouble for my liking. ;-)

Edit (03-04-18) Added Stringsupport.stl and holes for strings to hoist -> Hoist-v!.stl. I have not yet printed them, but that should not be a problem.

Changed Notes again accordingly -> Notes-v1c.pdf

Edit (04-04-18) Sorry, there was a problem, Stringsupport-v1.stl should work...

Edit (05-04-18) Added Stringsupport_XL.stl, for those who need a bit more room for their weight and a small change to normal stringsupport -> Stringsupport-v1a

Edit (15-04-18) Updated a picture

Edit (31-07-18) I am going for an improvement, proposed by ZaKote, (thanks, ZaKote :-) ), see comments, and will replace the threaded rod (+nuts, etc) with a ø5mm rod with shaft collars. Changed the text above and the notes: Notes-v2.pdf accordingly. The pictures have to wait until it becomes reality. ;-)

Edit (16-09-18) Had at first a bit of a problem finding a good rod, so I added a url of a seller who delivered ito the Notes -> Notes-v2a.pdf. Finally made the first prints with the ø5mm rod and indeed the result was much better. I thought at first that the problem (see comments) was completely gone, but then I saw there still was a bit of same same, though much less (wonder what the cause of that is...).

Edit (09-10-18) replaced pictures.

Edit (07-11-18) Replaced counterweight system with belts with adjustable belt tensioners. Version1 of the hoist is still perfectly usable, but those holes for strings are superfluous so I went back to the old hoist.

Adapted Notes -> v3a. Photo's will follow.

Edit (08-11-18) added photos. This improvement does nothing for the 2mm wave (see comments), but I'm waiting for another GT2 pulley, hopefully of a better quality...

Edit (29-11-18) correction in Notes : 8x GT2 idler pulleys 20 without teeth, ø3mm bore, belt width 6mm -> v3c. Thanks ZaKote

Edit (14-02-19): today published Bed_Hoist_for_a_3DPrinter (D-Bot, CoreXY)-_Version_2, www.thingiverse.com/thing:3427719.

That version 2 supersedes this one, because it is simpler: 1 belt, simpler parts.

No solution for the 2 mm-wave-error yet, though.

For a time I worked with one hoist and belt in this first version and that went ok, even somewhat better than with 2 belts.

So if you already have made version 1, perhaps you can leave version 2 for what it is and try it with 1 bed hoist: just move one hoist to the middle, uncouple the other one and look how that goes. ;-)

But if you are new to this concept or want to try other worm gears, forget version 1 and go for version 2.

A system for Z-axis movement with hoist action.

I looked for a way to replace the lead screws with something else and found that I needed only 1 motor with a 20:1 worm gear to hoist and lower my bed, which weighs some 4.5kg together with its support frame.

The motor action is brought via a ø5mm rod to 2 sets of timing pulleys to 2 of the usual GT2 belts.Pulleys without teeth are used to force the belt over as much of the teeth as possible.

All supported by ball bearings, 2 of them flanged to prevent sideways movement.

The Gt2 belts are captured with a remix of a nice thing I saw, among others, called "Separate GT2 belt tensioner" by MrArrow1961, https://www.thingiverse.com/thing:910725.

A bit more difficult to print than the usual solution, but easier to finetune belt tension and to place/remove the belt with it.

I made this thing so I can use it with my D-Bot_Linear_Z-guide, https://www.thingiverse.com/thing:2779260, but it is independent of it.

However, trying it in a system with wheels for the Z-axis gave me insurmountable problems, because without the support of the lead screws the bed angled so much downwards that this could not be compensated for with the usual bed supports.Just too much play in those wheel systems, whatever I tried with 3 of 4 wheels. So be warned. ;-)

No such problem with the linear Z-guides.

All in all I found this thing much simpler and quieter than the lead screw configurations I tried.

As accurate also, I think. Compared to the loads they are made for, I feel this load won't stretch the belts so as to give wrong printing heights.Somewhere (can't find it any more) I even saw a pre-load advised by the manufacturer of some 2kg, so that should be ok.

Though, of course, it doesn't harm to check once in a while when height is of an essence with your print..

For materials, assembling specifics, more images and more rationales, see the"Notes.pdf¨ in the "Thing Files".

The nimble motor support and motor are very present in the pictures, alas (because it has nothing to do with this thing), but to dismantle the whole thing etc. only to make a picture without it was a bit too much trouble for my liking. ;-)

Edit (03-04-18) Added Stringsupport.stl and holes for strings to hoist -> Hoist-v!.stl. I have not yet printed them, but that should not be a problem.

Changed Notes again accordingly -> Notes-v1c.pdf

Edit (04-04-18) Sorry, there was a problem, Stringsupport-v1.stl should work...

Edit (05-04-18) Added Stringsupport_XL.stl, for those who need a bit more room for their weight and a small change to normal stringsupport -> Stringsupport-v1a

Edit (15-04-18) Updated a picture

Edit (31-07-18) I am going for an improvement, proposed by ZaKote, (thanks, ZaKote :-) ), see comments, and will replace the threaded rod (+nuts, etc) with a ø5mm rod with shaft collars. Changed the text above and the notes: Notes-v2.pdf accordingly. The pictures have to wait until it becomes reality. ;-)

Edit (16-09-18) Had at first a bit of a problem finding a good rod, so I added a url of a seller who delivered ito the Notes -> Notes-v2a.pdf. Finally made the first prints with the ø5mm rod and indeed the result was much better. I thought at first that the problem (see comments) was completely gone, but then I saw there still was a bit of same same, though much less (wonder what the cause of that is...).

Edit (09-10-18) replaced pictures.

Edit (07-11-18) Replaced counterweight system with belts with adjustable belt tensioners. Version1 of the hoist is still perfectly usable, but those holes for strings are superfluous so I went back to the old hoist.

Adapted Notes -> v3a. Photo's will follow.

Edit (08-11-18) added photos. This improvement does nothing for the 2mm wave (see comments), but I'm waiting for another GT2 pulley, hopefully of a better quality...

Edit (29-11-18) correction in Notes : 8x GT2 idler pulleys 20 without teeth, ø3mm bore, belt width 6mm -> v3c. Thanks ZaKote

Similar models

thingiverse

free

Tronxy x5s single Z motor conversion by napo7

...the threaded rod version, but it can be cheaper and easier to source than leadscrew...

next version to come : with idler pulleys

thingiverse

free

ANET A8 Improved X-Axis tensioner - remix for asymmetric GT2 pulley by taconite

...e stl-file was broken --> reupload

update 03/11/18 - added a knob for the tensioner: https://www.thingiverse.com/thing:2821938

thingiverse

free

K8200 GT2 Y-Belt Tensioner replacement by raby

...t tensioner replacement by raby

thingiverse

an easier way to fasten the y-belt, designed for a gt2 belt and 20 teeth gt2 pulley.

thingiverse

free

GT2 Belt Conversion for Felix 2.0 Printer by seaton

...pdate: i mistakenly uploaded an earlier version of the stl where the belt was a bit slack, the current version is the correct one

thingiverse

free

Sunhokey S-508 - Y carriage GT2 belt holder by RRA

...ore it'll probably be simpler & fit better with the current m5 screws.

v2: with prusa's square belt dents instead...

thingiverse

free

Simple GT2 Belt Tensioner by frankvdh

...o insert between belt and frame one way than the other.

[edit] slightly enlarged the frame to make it stronger after i broke one.

thingiverse

free

Anet A8 X-axis GT2 pulley holder by TheGooNie

...https://www.thingiverse.com/thing:2196516 and for my luck the designer has also uploaded a "cad" (blender) file for it.

thingiverse

free

TWO TREES SAPPHIRE PRO Belt Tensioner by Mr_Helpmann

...egrees is the maximum setting.

needed parts:

2 x pulley 16 teeth(13mm) rbs12567 gt2

2 x screw countersunk m3x14

4 x screw m3x10

thingiverse

free

Anet A6 2017 Y-Belt tensioner holder for belt holder (and for GT2 pulley with teeth) by Samoth47

...ersion for the backplate to be adapted with this new version because it's not exactly a perfect fit at 100% and 90% (for me).

thingiverse

free

X carriage with belt tensioner by xavan

...mm for this one.

a more stable system: for the pulley-based one, the idler pulley is "floating" and fixed for this one.

Printingsome

thingiverse

free

Back_Leadscrew_Bracket by printingSome

... another look at the earlier version and decided that is was way to difficult to print and these things are also easier to mount.

thingiverse

free

camera hot shoe to keep on by printingSome

..., before i could get to the battery or the sd-card.

not any more. with this gadget i can get to both without disturbing anything.

thingiverse

free

Ball_Foot for D-Bot by printingSome

...tennis balls, good damping, little swaying. i attached them after gluing the harder part of pieces of velcro (the hooks) inside.

thingiverse

free

ATX PSU mount by printingSome

...hings under the bottom are supports for some tie-wraps or such.

the thin stiles in the bottom-holes should afterwards be removed.

thingiverse

free

y-axis min/max endstop for Prusa i3 Hesine by printingSome

...i have.

it can serve as well as a min. endstop mount.

warning: check whether you want to miss a couple of mm in the y direction.

thingiverse

free

x-axis endstop for Prusa i3 Hesine by printingSome

...ning this, but i now prefer and use "x-axis min/max endstop for microswitch", https://www.thingiverse.com/thing:1683535

thingiverse

free

y-axis belt tensioner (Prusa i3 Hesine) by printingSome

...ed it all in one go, but for the little round thing, which i reprinted with a layer height of 0.1mm. it looked a lot better then.

thingiverse

free

Open Cable Chain Reversed by printingSome

...hole bunch wrapped up could also use a little support (perhaps the same rubber band ;-) ).

please give me your thoughts. thanks.

thingiverse

free

3-extruder base with LCD controller stand by printingSome

...ings get straight on to the extruder-house.

the lcd controller-box is from http://www.thingiverse.com/thing:1116163, with thanks.

thingiverse

free

Glass bed XY corner clamp variation by printingSome

...quot; i put between the glass and the aluminium.)

i fits nicely on my prusa i3 hesine bed and i enjoy the absence of the clamps.

Hoist

3ddd

$1

Hoist

...hoist

3ddd

тренажер

fitness equipment

3d_ocean

$20

Hoist Crane

...hoist crane

3docean

crane industrial lift loader machine outdoor work

3d model crane hoist

turbosquid

$10

Hoist 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Hoist 1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

тренажер Hoist PTS Ensemble

...тренажер hoist pts ensemble

3ddd

тренажер

hoist pts ensemble

turbosquid

$60

Material Hoist Construction

...free 3d model material hoist construction for download as max on turbosquid: 3d models for games, architecture, videos. (1375181)

turbosquid

$20

HOIST WAY FAN

...quid

royalty free 3d model hoist way fan for download as max on turbosquid: 3d models for games, architecture, videos. (1259868)

3d_export

$10

Crane Hoist Podem 3D Model

...crane hoist podem 3d model

3dexport

crane loader lift work machine hoist

crane hoist podem 3d model genkot27 68607 3dexport

3d_ocean

$20

Crane Hoist Stahl ST50

...crane hoist stahl st50

3docean

crane industrial lift loader machine outoor work

3d model crane hoist stahl st50

3d_export

$10

Chain hoist lifting beam 3D Model

...chain hoist lifting beam 3d model

3dexport

chain hoist lifting beam

chain hoist lifting beam 3d model flash 53891 3dexport

Xy

3ddd

$1

Вешалка напольная XY-027

...а штанги: 171 см

диаметр основания: 38 смhttp://mebelshopos.ru/aksessuary-ofisnye/veshalka-napolnaya-xy-027-detail.html

turbosquid

$9

XY Rectangular Dining Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

holly hunt xy bench

...eight: 17.75 in

width: 45 in, 26 in

depth: 18 in

больше превьюhttps://www.behance.net/gallery/24983999/bench-3d-model?

3ddd

$1

pillows bed 2

...pillows bed 2 3ddd подушка , круглая dimensions: xy ...

3ddd

$1

Honeycomb Floor

...паркет parquet with metalic honeycomb floor demensions 500x500 cm xy multitexture +...

3d_export

$7

positioning screw mechanism

...and lead screw, constitute a double displacement adjustable mechanism, xy axis double position adjustable positioning.<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$9

positioning mechanism of heavy-duty platform

...activity -- ball mechanism activity ---- drive heavy load xy axis movement -- positioning completed<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$180

optical fiber laser marking machines assembly

...fiber laser marking machine<br>automatic loading and unloading laser marking machine<br>xy platform adjustable laser marking machine<br>laser marking machine used with...

thingiverse

free

XY ROBOT by ymtlab

...xy robot by ymtlab

thingiverse

xy robot

thingiverse

free

tavola xy

...tavola xy

thingiverse

piccola tavola xy da abbinbare volendo al supporto microscopio. https://www.thingiverse.com/thing:4114462

Bot

turbosquid

$19

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Bot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

scanner bot

...scanner bot

3dexport

cool scanner bot who scans for fixing things...

3d_ocean

$9

Apc Bot

...n bot games toys

an all-purpose-constructo-bot. for cartoon purposes. the model is not rigged. please use vray adv for rendering.

3d_export

$75

Bot 3D Model

...bot 3d model

3dexport

robot bot man kiborg character

bot 3d model evgen 19504 3dexport

turbosquid

free

Eye Bot

...eye bot

turbosquid

free 3d model eye bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1514059)

turbosquid

$29

Gorill-bot

...bosquid

royalty free 3d model gorill-bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1239456)

turbosquid

$25

Lamp Bot

...bosquid

royalty free 3d model lamp bot for download as blend on turbosquid: 3d models for games, architecture, videos. (1230121)

turbosquid

$10

Spectre Bot

...osquid

royalty free 3d model spectre bot for download as fbx on turbosquid: 3d models for games, architecture, videos. (1616378)

turbosquid

$8

Ultra Bot

...urbosquid

royalty free 3d model ultra bot for download as ma on turbosquid: 3d models for games, architecture, videos. (1330752)

Core

3ddd

$1

Skandiform Core

...skandiform core

3ddd

skandiform

кресло фирмы skandiform, модель core.

габаритные размеры (шхвхг): 530х700х510 мм

turbosquid

$8

Chandelier CORE

...id

royalty free 3d model chandelier core for download as max on turbosquid: 3d models for games, architecture, videos. (1673910)

turbosquid

free

Planet Core

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Samsung Galaxy Core 2

...samsung galaxy core 2

3ddd

телефон

samsung galaxy core 2

turbosquid

$10

cable 2 core

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

cable 1 core

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кондиционер ICE CORE

...кондиционер ice core

3ddd

кондиционер

37 000 полигонов

turbosquid

$65

Insulated Multi Core Cable

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Samsung Galaxy Core Advance

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Samsung Galaxy Core II

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

free

bed

...bed

3ddd

bed , постельное белье

bed

3ddd

$1

Bed

...bed

3ddd

bed , постельное белье , постель

bed

3d_export

$7

bed adairs bed

...rs bed

3dexport

bed adairs bed in modern style. if you want a smoother surface, please turn on turbosmooth in the modifier list.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.