Thingiverse

BB-8 remix with dummy internals by petropixel

by Thingiverse

Last crawled date: 3 years ago

I was as excited as anyone when I found out they built practical, working BB-8s for the new Star Wars, but I'm not really "$150 toy" excited, and I can't really even justify spending $50 on a used Sphero to cut open, so I decided to build upon the work that's already been done here on Thingiverse. My goal was to build a BB-8 using only printed and hardware store parts that could roll along the floor and keep it's head upright, and spoiler alert: it finally works! https://www.youtube.com/watch?v=bYBuFEJ_PQc

I made some initial modifications to the existing parts, adding holes for 1.75mm filament in the ball halves so it could snapped open and closed (repeatedly) and in the head to make antennas.

The hardware store parts are 19mm ceramic disc magnets (same as the ones for Google Cardboard, left over from that build), 9 7/16" ball bearings (the biggest they carried), 2 8mm OD/3mm ID/4mm wide roller bearings from old spring-loaded extruders (and technically, a hobby store and not a hardware store originally), and 3 #4 x 1/2" screws.

I experimented with 3 different heights for the magnet within the central "stalk". At it's highest, the whole internal assembly just stuck to the head through the ball. At it's lowest, the magnet wasn't close enough to keep the head from just falling off. I've settled for a position right in the middle of those two, but it might be worth printing a version that puts the magnet a millimeter or two higher or lower. It's also possible that this magnets are just too strong for this purpose.

I then thought there might just be too much friction acting on the head, so I split it into two parts and made some room for a pair of roller bearings inside. The head moves better on the ball now, but you still can't roll the ball without it tipping right off.

In experiments with both versions of the head, I found that my internal mechanism seems to stay upright when tilted with no head around, but when I install the head it just gets tippy. I assumed that this means the head is moving the center of gravity too high, so my last idea was to cut open the bottom of the stalk and fill it with pennies. This seems to have only made the movement more sluggish. It may be time to actually do math or reevaluate my approach entirely

The state of BB at this point can be seen here: https://www.youtube.com/watch?v=2JGKrskvX3U

Version 2 replaces 6 of the 7/16" ball bearings with 5 3/4" ones, and incorporates a single #8 x 1" screw. It's more stable and stays upright better, but it still doesn't really "work". I think version 3 will be larger, to cram even more weight inside and maybe give the mechanism more leverage??

Version 3 was basically the same idea scaled up 50% to fit 12 ounces of fishing weight inside. I also added more detail to the head at this time. It didn't really work as well, so I never uploaded the .stls, but it is in the .blend if you really want to try it.

Version 4 kind of works!!!?!?!? I'd been watching James Bruton's full-scale BB-8 builds, not because i thought any of what he was doing would apply to this and just because he does good work, but it turns out the single-axis approach makes a lot of sense. Printing the ball as a "barrel" with two side caps means the internal mechanism can run on a smooth round track instead of running into the seam where the two halves used to join or the roughness at the higher layers. It doesn't balance as quickly as I would like and it doesn't roll at all on smooth surfaces like wood or tile, but it can be pushed or pulled along on carpet and it can be rolled down a reasonably steep ramp without falling over or the head falling off. https://www.youtube.com/watch?v=gLeMTFUNe4I

I've also added opening panels in the side caps in this version, the "pocket" on one side and an arm on the other.

The non-printed part list for this one is 12 1oz fishing weights, 4 19mm ceramic disc magnets, 4 3/4" ball bearings, and 2 #4 x 1/2" screws. I made spaces for some of the 7/16" ball bearings but found that the extra weight up high didn't help.

I think the next version will have a fixed axle at the center rolling on skate bearings.

Version 5 is good enough! It turns out even the cheapest eBay bearings roll more smoothly than ball bearings running in a 3D printed race that I sanded for maybe 15 minutes. Maybe it also helps to have a fixed, defined axis for everything to rotate around. it actually doesn't work nearly as well not that I've painted it, but I'm still satisfied.

The final non-printed parts list is:

10 1oz fishing weights (pictured now)

6 #4 x 1/2" screws

4 19mm ceramic disc magnets

2 608ZZ bearings

2 M8 25mm bolts

2 matching M8 nuts

The cost, even including all of the ball bearings I ended up not using in this final design, is probably less than $20. (If I put a value on the TIME I put into all the previous designs, maybe a bit higher)

I made some initial modifications to the existing parts, adding holes for 1.75mm filament in the ball halves so it could snapped open and closed (repeatedly) and in the head to make antennas.

The hardware store parts are 19mm ceramic disc magnets (same as the ones for Google Cardboard, left over from that build), 9 7/16" ball bearings (the biggest they carried), 2 8mm OD/3mm ID/4mm wide roller bearings from old spring-loaded extruders (and technically, a hobby store and not a hardware store originally), and 3 #4 x 1/2" screws.

I experimented with 3 different heights for the magnet within the central "stalk". At it's highest, the whole internal assembly just stuck to the head through the ball. At it's lowest, the magnet wasn't close enough to keep the head from just falling off. I've settled for a position right in the middle of those two, but it might be worth printing a version that puts the magnet a millimeter or two higher or lower. It's also possible that this magnets are just too strong for this purpose.

I then thought there might just be too much friction acting on the head, so I split it into two parts and made some room for a pair of roller bearings inside. The head moves better on the ball now, but you still can't roll the ball without it tipping right off.

In experiments with both versions of the head, I found that my internal mechanism seems to stay upright when tilted with no head around, but when I install the head it just gets tippy. I assumed that this means the head is moving the center of gravity too high, so my last idea was to cut open the bottom of the stalk and fill it with pennies. This seems to have only made the movement more sluggish. It may be time to actually do math or reevaluate my approach entirely

The state of BB at this point can be seen here: https://www.youtube.com/watch?v=2JGKrskvX3U

Version 2 replaces 6 of the 7/16" ball bearings with 5 3/4" ones, and incorporates a single #8 x 1" screw. It's more stable and stays upright better, but it still doesn't really "work". I think version 3 will be larger, to cram even more weight inside and maybe give the mechanism more leverage??

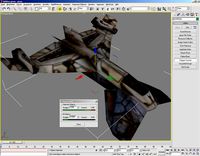

Version 3 was basically the same idea scaled up 50% to fit 12 ounces of fishing weight inside. I also added more detail to the head at this time. It didn't really work as well, so I never uploaded the .stls, but it is in the .blend if you really want to try it.

Version 4 kind of works!!!?!?!? I'd been watching James Bruton's full-scale BB-8 builds, not because i thought any of what he was doing would apply to this and just because he does good work, but it turns out the single-axis approach makes a lot of sense. Printing the ball as a "barrel" with two side caps means the internal mechanism can run on a smooth round track instead of running into the seam where the two halves used to join or the roughness at the higher layers. It doesn't balance as quickly as I would like and it doesn't roll at all on smooth surfaces like wood or tile, but it can be pushed or pulled along on carpet and it can be rolled down a reasonably steep ramp without falling over or the head falling off. https://www.youtube.com/watch?v=gLeMTFUNe4I

I've also added opening panels in the side caps in this version, the "pocket" on one side and an arm on the other.

The non-printed part list for this one is 12 1oz fishing weights, 4 19mm ceramic disc magnets, 4 3/4" ball bearings, and 2 #4 x 1/2" screws. I made spaces for some of the 7/16" ball bearings but found that the extra weight up high didn't help.

I think the next version will have a fixed axle at the center rolling on skate bearings.

Version 5 is good enough! It turns out even the cheapest eBay bearings roll more smoothly than ball bearings running in a 3D printed race that I sanded for maybe 15 minutes. Maybe it also helps to have a fixed, defined axis for everything to rotate around. it actually doesn't work nearly as well not that I've painted it, but I'm still satisfied.

The final non-printed parts list is:

10 1oz fishing weights (pictured now)

6 #4 x 1/2" screws

4 19mm ceramic disc magnets

2 608ZZ bearings

2 M8 25mm bolts

2 matching M8 nuts

The cost, even including all of the ball bearings I ended up not using in this final design, is probably less than $20. (If I put a value on the TIME I put into all the previous designs, maybe a bit higher)

Similar models

thingiverse

free

Ball Bearing w/Steel Balls 5" to 1/2" ID in 1/4" Increments by DanSpangler

...one go

-doesn't require support material

-runs very smooth and quite

-dimension drawings included so you can design your own!

thingiverse

free

Magic Bear by Juusoz

...lso added a logo-less version, but "block supports" and "print thin walls" on the base works the best for me.

thingiverse

free

Ball Bearings by schlem

...shapeways.com/shops/bitforge

check out the "improved ball bearings" for greater precision and maybe even functionality.

thingiverse

free

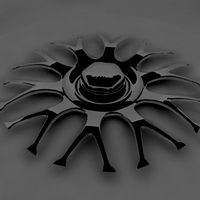

BB-Fidget-Maximus by BBMECH7

...o added one for you folks in metric land ;) 6mm bbs should work perfect in the model labled with "..._6mm"

cheers ! ^_^

thingiverse

free

Vertical Spool Holder with optional Bearing Filament Guide by joechung

...h i haven't tried, but should work totally fine.

net-net is the silky smoothest filament feeding system in the thingiverse ;)

grabcad

free

"Perpetual" Wheel 2

..."perpetual" wheel 2

grabcad

perpetual motion doesn't really work. i'm so sorry...

thingiverse

free

Ybed on rolling bearing by Dimon372

... and quiet.

more details in my blog: http://reprapzone.ru/blog/rolling-bearing-bed.htmlhttp://www.youtube.com/watch?v=4zpaq9tq_1i

thingiverse

free

Mini Spinner "Wiggle" by pete7919

...ith a 0.2. works great as is.

bb tray included so they're not rolling all over the place while you're working with them!

thingiverse

free

Rubbermaid FastTrack like closet upright extension

...ottom uprights in more holes than you normally would as the upright does not provide weight bearing utility (it's not metal!)

thingiverse

free

Ball bearing "ball" by Phdholiday

...fairly narrow to avoid locking.

-the needles need to fill up the bearing, i think ;-)

https://www.youtube.com/watch?v=w00g7utlmx0

Petropixel

thingiverse

free

Stand for petropixel's W16 Engine by MrFozzie

...ith the stand. i used the remixed crankshaft http://www.thingiverse.com/thing:70153 so these are the longer pins i have provided.

thingiverse

free

Bobblehead Windup Walker Cat by petropixel

...icient use of a 5-pack of walker mechanisms, but somewhat more amusing.

now with video!http://www.youtube.com/watch?v=lompq0stg28

thingiverse

free

Mustang Hoonicorn by petropixel

...9;s a ton of reference photos out there for regular notchback mustangs and of this build, so i think it came out fairly accurate.

thingiverse

free

Smart ForTwo by petropixel

...i know what to do with, and one of these waddling around was a fun mental image. judge for yourself https://vine.co/v/hi6r6km16iu

thingiverse

free

Imperial Windup Walker by petropixel

...rt of snowballed out of control from there.

it isn't very good in the snow anymore.http://www.youtube.com/watch?v=yxrs8lshaly

thingiverse

free

Clip-On Darkest Timeline Goatee by petropixel

...k tomorrow, but there's still a chance the new showrunners have ruined it and you'll have an excuse to wear this forever.

thingiverse

free

Modified Sprung Bolt by petropixel

...e space between the springs a bit too much and shortened the bolt too far, but it seems to work well enough to keep the cats out.

thingiverse

free

iPod Touch 5th Gen Bumper for Flexible Filaments by petropixel

...giverse

this is an ipod touch bumper, modified for better fit and printability when printed in flexible filaments like filaflex.

thingiverse

free

Track Day NA by petropixel

... done enough on my previous miata-based models to stitch together one that looks stock except for having a stripped-out interior.

thingiverse

free

Rodin's The Thinker, But With The Thinking Emoji For A Head by petropixel

...ne as a 2d drawing, and it was the first thing that came to mind when i saw the 3d emoji pop up on thingiverse earlier this week.

Dummy

archibase_planet

free

Dummy

...dummy

archibase planet

mannequin dummy

dummy n100111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

women-dummy

...women-dummy

3dexport

just dummy

turbosquid

$10

Dummy

...quid

royalty free 3d model dummy for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1403647)

archive3d

free

Dummy 3D Model

...archive3d

mannequin dummy

dummy n100111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Dummy 3D Model

...d model

archive3d

dummy

dummy 1 n150408 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Dummy 3D Model

...rchive3d

mannequin dummy

dummy n160408 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$30

Target Dummy

...squid

royalty free 3d model target dummy for download as fbx on turbosquid: 3d models for games, architecture, videos. (1437335)

3d_export

$5

jarde-dummy-1snapshot9

...jarde-dummy-1snapshot9

3dexport

jarde-dummy-1.snapshot.9

turbosquid

$130

crash dummy

...

royalty free 3d model crash dummy for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1216074)

3d_export

$20

Dummy 3D Model

... character artists model man woman human wood posable puppet jointed pose humanoid body

dummy 3d model rendersteel 75948 3dexport

Bb

design_connected

$13

BB

...bb

designconnected

poliform bb computer generated 3d model. designed by borghi, matteo.

turbosquid

$5

bbs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

bb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Poliform Bb chair

...poliform bb chair

3ddd

poliform , bb

poliform bb chair

3ddd

$1

bb-8 apple

...bb-8 apple

3ddd

apple

bb-8 apple

turbosquid

$49

BB ROBOT

...urbosquid

royalty free 3d model bb robot for download as max on turbosquid: 3d models for games, architecture, videos. (1556522)

turbosquid

$11

ROBOT BB

...bosquid

royalty free 3d model robot bb for download as blend on turbosquid: 3d models for games, architecture, videos. (1336640)

turbosquid

$4

sofa bb

...turbosquid

royalty free 3d model sofa bb for download as obj on turbosquid: 3d models for games, architecture, videos. (1658053)

3ddd

$1

Quasar Royal BB

... , quasar

светильник royal bb

бренд: quasar

страна:голландия

дизайнер: van vliet edward

3d_export

free

BBS disc

...bbs disc

3dexport

Internals

3ddd

$1

Quorum International

... international

3ddd

florence , quorum international

люстра quorum international florence

3d_export

$5

internal door

...internal door

3dexport

internal door

turbosquid

$40

international

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Lamp International

...ernational

3ddd

lamp international

в файле содержится два светильника от lamp international - люстра арт. 2034/f9 и бра арт. 2026

3ddd

$1

VACCARI INTERNATIONAL

... овальное

производитель vaccari international

серия verona

длина 90, глубина 4,5, высота 70

3ddd

$1

Торшер / Lamp International

...торшер / lamp international

3ddd

lamp international

фабрика lamp international (италия).коллекция siena, арт.3452.

turbosquid

$99

International Soldier

...yalty free 3d model international soldier for download as max on turbosquid: 3d models for games, architecture, videos. (1556764)

turbosquid

$5

Internal door

...id

royalty free 3d model internal door for download as blend on turbosquid: 3d models for games, architecture, videos. (1691264)

3ddd

$1

International Italia 8100

...international italia 8100

3ddd

international italia

люстра lamp international italia 8100 с текстурами и материалами v-ray

turbosquid

$79

International Loadstar

...model international loadstar for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1678922)

Remix

turbosquid

$5

MODA Collection Remix Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

remix yamaha rm1x

...remix yamaha rm1x

3dexport

geometry triangles 15.2k vertices 7.6k pbr no textures 1 materials 1 uv layers yes

3d_ocean

$5

Vray fabric Kvadrat remix green - tileable

...th vray and 3dsmax. high-resolution texture images (2000×2000 px) file included: shader vray 2.40 texture image 3ds max 2011 file

turbosquid

$20

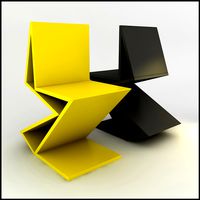

Gerrit Rietveld 1938 Zig Zag Chair Remix

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

multicolored remix parametric table furniture

... fbx, obj, mtl, archive with textures. the model has no glitches. render and materials - vray . without using plugins. good use!

3ddd

$1

Barovier&Toso / Manhattan Remix 7192

... 004293-142405

в коллекции есть люстры 7, 9, 12 рожковые. диаметр соответственный 1000, 1250, 1500 мм.

3ddd

$1

Muuto fiber chair

...grey/grey, dusty green/dusty green, nature/oak, natural white/oak upholstery options remix 183/black, remix 133/grey, remix 643/dusty red leather options black...

3ddd

$1

Barovier&Toso 7190-7195

...7190-7195 3ddd barovier&toso потолочнай люстра фабрики barovier&toso;, коллекция manhattan remix артикул 7190-7195. размеры в inches: 39"...

3d_export

$5

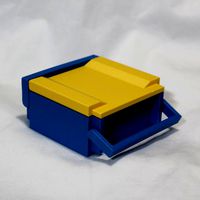

3D Locking Handle Weatherproof Storage Box Container

...handle weatherproof storage box container 3dexport new, improved and remixd! no screws required. print-in-place. weatherproof. parametric. 2 parts. easy...

cg_studio

$49

HTC One Mini 2 Amber Gold3d model

...cell phone mobile cellular super lcd touchscreen touch screen remix amber gold .max .obj .mb .lwo .fbx .c4d .3ds...

8

turbosquid

$6

Rock 8-8

...urbosquid

royalty free 3d model rock 8-8 for download as obj on turbosquid: 3d models for games, architecture, videos. (1659393)

3ddd

$1

Italamp 387/8+8

...italamp 387/8+8

3ddd

italamp

люстра italamp 387/8+8

размеры 92x71h

3ddd

$1

8 марта

...8 марта

3ddd

8 марта

кресло 8 марта

design_connected

$16

No 8

...nected

photo-realistic 3d models of the sibast no 8 armchair from sibast for 3d architectural and interior design presentations.

3d_export

$5

hinge 8

...hinge 8

3dexport

hinge 8

3d_export

$5

iphone 8

...iphone 8

3dexport

iphone 8

turbosquid

$69

iPhone 8 and iPhone 8 Plus

... free 3d model iphone 8 and iphone 8 plus for download as max on turbosquid: 3d models for games, architecture, videos. (1202442)

turbosquid

$12

Calligraphic Digit 8 Number 8

...hic digit 8 number 8 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389341)

3ddd

free

PLANTS 8

...plants 8

3ddd

цветок , горшок

plant 8,,, hope u all like it

3ddd

$1

8 Марта / Amadey

...8 марта / amadey

3ddd

8 марта

8 marta amadey