3dExport

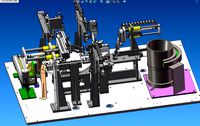

automobile valve assembly machine

by 3dExport

Last crawled date: 1 year, 10 months ago

this equipment is the first automatic assembly machine for automobile valve, throttle valve and slide valve switch in china. the bus runs fast and can assemble 800-1000 valve products per hour. the equipment is divided into two machines. first, the product is pre installed. the other machine is the final assembly machine. the second two machines can complete more than ten parts assembly, the operation mode of the equipment is turntable type, which is composed of 10 station and 12 station turntable respectively. the pre installed machine platform is 12 station turntable. first of all, all accessories are manually put into the vibration plate for feeding, feeding and distribution. the vibration plate is customized by different production shapes, so it can be seen from the picture that the size of the vibration plate is large or small, which is also due to the product specification if the size is different, then the material is fed and divided after feeding from the vibration plate. here, the feeding is unified by the direct vibration. the direct vibration also works with the vibration. the material distribution mechanism is different, the product shape is different, and the material distribution method is also different. here, the material distribution is pushed from the bottom to the top, pushed from the left, and the stepper motor rotates to find the position for material separation and comparison for difficult material distribution, we adopt ccd visual positioning method, so the structure in this line basically contains the structure and practice commonly used by the automation equipment. therefore, each station corresponds to different product assembly. after material separation, the product is directly clamped into the turntable by the manipulator for assembly. one station rotates to the next station to complete all accessories pre installation in turn after these actions, the blanking manipulator picks up the semi-finished products and puts them into the conveyor belt, from which the machine is transported to another machine. when the inductor in the conveyor belt detects the entry of the products, it starts to clamp the semi-finished products to the rotating plate in the general assembly platform for the overall assembly of the products. the turntable is distributed by 10 stations, and each station is assembled with one kind of accessories until all the accessories are assembled, from the blanking machine to the blanking box, the above is all the operation principle and operation process of the equipment. due to the large number of equipment positions, the detailed structure and function realization still need to open the drawing for research after downloading. because the drawing is relatively large, the download will be decompressed with 700bm, so select the place where the network is relatively fast to avoid interruption, and the drawing is very complete. all structures are complete it can be seen clearly that it is a very good work for learning reference structure. of course, it can also be used to make similar products. it can be transformed into another different device with only a small change. this is the most valuable analysis and research equipment in the automation industry at present. welcome to download and learn actively. at the same time, thank you for your support and attention.

Similar models

3d_export

$15

20 sets of vibrating plate direct vibration feeding mechanism

...oading and distribution structure of oil nozzle vibration plate, bearing vibration plate and conveyor belt distribution structure

3d_export

$27

automatic assembly equipment for motor parts

...f this set of drawings is very complex and has great learning value. i hope you will download it. don't miss the opportunity.

3d_export

$20

optical fiber head assembly machine network signal plug assembly equipment

...ve positioning accuracy: ≤± 0.02 mm control communication mode: manual disc programming mode: touch screen parameter modification

cg_trader

$29

Motor automatic assembly production line

...eyor belt, and the clamping manipulator will perform the clamping and assembly. after completion, the fixture will work in a loop

cg_trader

$55

The rotary plate feeding and unloading device

... plate feeding machine or other feeding mechanism, the feeding of circular products can be directly applied

institutions include:

cg_trader

$5

Printer accessories bearing automatic assembly machine

... industry industrial manufacture assembly mechanic components electrical printer bearing industrial machine electrical components

cg_trader

$19

Cam assembly machine

... plate. the main sources of power are cylinders and motors. cam mechanism, high production efficiency, stable equipment operation

cg_trader

$9

A vibrating disc for piping products

...tubes, round products all can use this kind of similar structure if you like,you can paypal for you to...

cg_trader

$29

Fully automatic bulb assembly production line

...ture assembly mechanic components electrical bulb test feed dispensing load unload rivet industrial machine electrical components

cg_trader

$82

Small product packaging machine

...the packaging department, through the ratchet mechanism will be a piece of product packaging, blanking

the mechanism consists of:

Automobile

turbosquid

$29

Automobile Differential

... free 3d model automobile differential 3d for download as iam on turbosquid: 3d models for games, architecture, videos. (1296581)

turbosquid

$7

Automobile Rim

...model automobile rim for download as 3ds, obj, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1458083)

turbosquid

$14

Automobile Tires

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

automobile wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Automobile part

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

injection mold for automobile lamp

...injection mold for automobile lamp

3dexport

injection mold for automobile lamp

turbosquid

$32

Automobile Rim RH

...y free 3d model automobile rim rh for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1424732)

turbosquid

$15

Automobile disc (rim)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Corradon Car Automobile

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$21

welding fixture for automobile body

...ile welding line. we must design welding line suitable for automobile and strive to improve the design and manufacturing ability.

Valve

3d_export

$5

Valve

...valve

3dexport

diverter valve

3d_export

$5

valve

...valve

3dexport

this is a 3d model of a valve available in all formats.

3d_export

free

valve

...valve

3dexport

simple valve 3d model, more free models here:

3d_export

$20

gate valve

...gate valve

3dexport

gate valve

3d_export

$10

stop valve

...stop valve

3dexport

stop valve

3d_export

$5

ball valve

...ball valve

3dexport

ball valve

turbosquid

$14

Valve

...e

turbosquid

royalty free 3d model valve for download as c4d on turbosquid: 3d models for games, architecture, videos. (1217741)

3ddd

$1

valve 02

...valve 02

3ddd

клапан

water valve

3ddd

$1

Valve 01

...valve 01

3ddd

клапан

water valve

turbosquid

$19

Valve

...royalty free 3d model valve for download as ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1425806)

Assembly

3d_export

$7

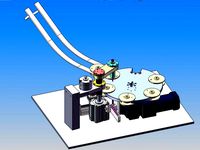

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

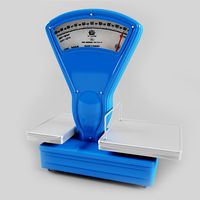

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.