Thingiverse

Automatic Watch Winder by wepollock

by Thingiverse

Last crawled date: 3 years ago

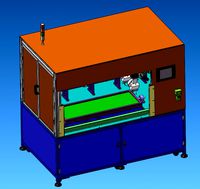

Automatic Watches are great because they do not need batteries; but to wind them you have to wear them! This watch winder is capable of winding three automatic watches so they are set to the correct date and time when you are ready to wear them.

The geometry of the watch winder was driven by the spare parts that I had in inventory including a NEMA 17 motor, an Easy Driver, some bearings, 8mm rod, velcro, 3mm machine screws, Arduino Uno, Relay, Fan (cool the driver) and 2020 from an old 3d printer (I don't have room for).

I am still working on this project (which was more challenging than anticipated) so some elements have been refined, and other elements still need to be tuned and refined.

Challenges Addressed;

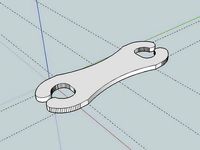

1) To be able to hold watches of various bracelet sizes - the watch holders are spring loaded

2) Noise - I was able to reduce gear noise significantly by having two flange bearings each end shaft. The original design was going to have side bearings to keep the gears compressed. The cantilever design works well with double bearings on each shaft, which eliminates play in the gears.

3) Gearing itself - the original design had stand alone gears - I integrated the gears into the watch holder

4) Where to place the electronics - the electronics were originally in a separate project box; the electronics are now integrated into the unit. The tray was a large single print which covered the extent of my Rostock Max Bed; the majority of the prints were made on a Flashforge creator pro.

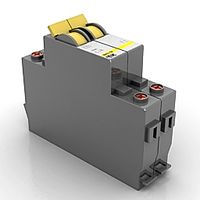

5) Keep the stepper unenergized when idle (added a relay module)

6) Dissipate stepper heat (used a fan and a heat sink)

7) Some watches wind clockwise, some counterclockwise, some unidirectionally (script reverses)

8) Printable with little support (all but electronics tray)

9) Standoffs were originally built into the electronics tray

Closed Concerns

1) Lid for electronics box - three part now enclosed.

Outstanding Concerns

2) Rotary Encoder Programming - If you look at the program you will find that the rotary encoder script has a bug in it. The rotary encoders increment upwards but they don't go down (I am only executing the else part of the statements)

3) Replace some PLA parts with ABS parts for strength.

4) Replace a bad rotary encoder

5) Consider a direct gear reduced motor as opposed to a stepper (I have a 3rpm motor in stock @ 12v)

6) Find the sweet spot between "winding" and "sleeping"

Materials;

8mm rod x 2

5V-One-1-Channel-Relay-Module-Board-Shield

Geeetech-Stepper-Motor-EasyDriver-step-motor-Driver-A3967-Driver-Board-Arduino

ATmega328P CH340G UNO R3 Board

12v power supply 1-2 amps

2020 - 300mm x 3

Female 2.1x5.5mm DC Power Plug Jack Adapter Connector for CCTV

Male Pin Dupont Connector 2.54mm Pitch (used for + - bus)

Dupont Jumper wire

8mm Bore Diameter KFL08 FL08 Pillow Block x 4

KY-040 Rotary Encoder Module x 2

20/20 nuts

compression springs x 9

Various 3mm machine screws

Various 3mm metal screws

The geometry of the watch winder was driven by the spare parts that I had in inventory including a NEMA 17 motor, an Easy Driver, some bearings, 8mm rod, velcro, 3mm machine screws, Arduino Uno, Relay, Fan (cool the driver) and 2020 from an old 3d printer (I don't have room for).

I am still working on this project (which was more challenging than anticipated) so some elements have been refined, and other elements still need to be tuned and refined.

Challenges Addressed;

1) To be able to hold watches of various bracelet sizes - the watch holders are spring loaded

2) Noise - I was able to reduce gear noise significantly by having two flange bearings each end shaft. The original design was going to have side bearings to keep the gears compressed. The cantilever design works well with double bearings on each shaft, which eliminates play in the gears.

3) Gearing itself - the original design had stand alone gears - I integrated the gears into the watch holder

4) Where to place the electronics - the electronics were originally in a separate project box; the electronics are now integrated into the unit. The tray was a large single print which covered the extent of my Rostock Max Bed; the majority of the prints were made on a Flashforge creator pro.

5) Keep the stepper unenergized when idle (added a relay module)

6) Dissipate stepper heat (used a fan and a heat sink)

7) Some watches wind clockwise, some counterclockwise, some unidirectionally (script reverses)

8) Printable with little support (all but electronics tray)

9) Standoffs were originally built into the electronics tray

Closed Concerns

1) Lid for electronics box - three part now enclosed.

Outstanding Concerns

2) Rotary Encoder Programming - If you look at the program you will find that the rotary encoder script has a bug in it. The rotary encoders increment upwards but they don't go down (I am only executing the else part of the statements)

3) Replace some PLA parts with ABS parts for strength.

4) Replace a bad rotary encoder

5) Consider a direct gear reduced motor as opposed to a stepper (I have a 3rpm motor in stock @ 12v)

6) Find the sweet spot between "winding" and "sleeping"

Materials;

8mm rod x 2

5V-One-1-Channel-Relay-Module-Board-Shield

Geeetech-Stepper-Motor-EasyDriver-step-motor-Driver-A3967-Driver-Board-Arduino

ATmega328P CH340G UNO R3 Board

12v power supply 1-2 amps

2020 - 300mm x 3

Female 2.1x5.5mm DC Power Plug Jack Adapter Connector for CCTV

Male Pin Dupont Connector 2.54mm Pitch (used for + - bus)

Dupont Jumper wire

8mm Bore Diameter KFL08 FL08 Pillow Block x 4

KY-040 Rotary Encoder Module x 2

20/20 nuts

compression springs x 9

Various 3mm machine screws

Various 3mm metal screws

Similar models

thingiverse

free

Stepper motor with rotary encoder by shohei

...stepper motor with rotary encoder by shohei

thingiverse

measure position of stepper motor using rotary encoder

thingiverse

free

Prusa I3 Direct Drive Extruder 3mm by alphapilot

...aliexpress.com/item/mk7-bore-8mm-extruder-drive-gear-for-3mm-hobbed-gear-for-makerbot-reprap-mendel-high-quality/32462285369.html

thingiverse

free

Automatic Coil Winding Machine by BenRowland

... then please consider buying me a coffee, it goes towards funding more projects like this:https://www.paypal.me/rowlandtechnology

thingiverse

free

"Doubowden" Double Hobbed Bolt Bowden Extruder Assembly by MatGyver85

...pression springs for idlers. not sure what size exactly.

2 - 8mm x 15mm drill rod (5/16" may work)

1 - nema 17 stepper motor

thingiverse

free

Display holder / rotary encoder / LED switch by killi

...

print the "led_switch_blende.stl" to mount a power switch in the front of your printer. the kdc1-11 just snaps into it

thingiverse

free

Sherline Rotary Table CNC Conversion by kohjbeng

... x m3x10 screws - to secure the mount and shaft couplers to the stepper shaft and worm gear shaft

5) 7 (or possibly less) m3 nuts

grabcad

free

Encoder test stand for 2212 BLDC motor

...r

!!![update]

"motor adaptor" changed to "v3" , .stl and .stp file are available, but .ipt files aren't.

thingiverse

free

Automatic Watch winder by edward57

...in the inner module.

files include parts list and arduino code.

a video link of the winder in action:https://youtu.be/4w7y5nzzleo

thingiverse

free

Turn Table - photo movie image sequencer by linusjarbo

...) threaded rod (1) + nuts

2mmx2cm(2m) + nuts (this is to fasten small spur gear to stepper motor)

3mm (3m) for the stepper mount.

thingiverse

free

Printrbot Full Build Tray by beardface

...; build platform will need to build tray #1 on their own...

(tray a #1 contains: 2 base's, bearing guide & x motor mount)

Wepollock

thingiverse

free

CardCaddy by wepollock

...cardcaddy by wepollock

thingiverse

a simple desktop organizer for business and credit cards.

thingiverse

free

Space Invader Keychain by wepollock

...space invader keychain by wepollock

thingiverse

space invader keychain, nuff said!

thingiverse

free

Interociter aka Interocitor by wepollock

...nterocitor by wepollock

thingiverse

this island earth.. can cal assemble this device?https://www.youtube.com/watch?v=0ggy4fguvii

thingiverse

free

I Love My Dog by wepollock

...i love my dog by wepollock

thingiverse

an "i love my dog" dingus.

thingiverse

free

Red the Robot by wepollock

... inspiration for this little desktop toy; red the robot is singing the "the internationale" hammer and sickle in hand.

thingiverse

free

Toothbrush and Toothpaste Holder by wepollock

...an additional compartment for sundry items. the holes have been sized large enough to accommodate a battery powered tooth brush.

thingiverse

free

Small Parts Storage Box by wepollock

...all parts storage box by wepollock

thingiverse

i needed to store some small parts, here is bunch of small parts boxes i created.

thingiverse

free

Ink Stamp - "Wood Block" by wepollock

...ood block" by wepollock

thingiverse

a 3d printed "stamp" for printing; similar to a "wood block" stamp.

thingiverse

free

Thumb-Twiddler Fidget Device by wepollock

...ngiverse

thumb-twiddler. not every "fidget-spinner" needs ball bearings.

https://www.youtube.com/watch?v=lq4xdavoyhc

thingiverse

free

Desktop Temperature and Humidity by wepollock

...lay.

https://www.ebay.com/itm/digital-cigar-humidor-hygrometer-thermometer-round-black-face-new-/271926824487?hash=item3f501a0e27

Winder

turbosquid

$10

window strap winder (external)

...del window strap winder (external) for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1281687)

3d_export

$14

winder textile special equipment

...s a role of "bridge" connecting the preceding and the following, so it plays an important role in the field of textile.

3d_export

$30

gold pocket watch

...(parented to watch)<br>hour hand (parented to watch)<br>lid (parented to watch)<br>winder (parented to watch)<br>pocketwatch - 2k -<br>diffuse<br>roughness<br>normal - (opengl unity...

3d_export

$30

helmets hats pack lowpoly

...newsboy cap sun cap war guard helmet winter cap winder fold cap<br>fbx-embed texture fbx<br>mb(maya binary)<br>obj<br>blender file only exports without...

3d_export

$32

speed reducer gear box worm helical wpx

...common household uses are washing machines, food blenders and window-winder. reduction drives are also used to decrease the rotational...

thingiverse

free

Side Winder by airdronez

...side winder by airdronez

thingiverse

side winder

thingiverse

free

Earphone winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Earphone Winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Spool Winder by Verohomie

...spool winder by verohomie

thingiverse

spool winder for a cordless drill

thingiverse

free

Cable Winder by kazsoft

...cable winder by kazsoft

thingiverse

just a simple cable winder.

Automatic

archibase_planet

free

Automat

...automat

archibase planet

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$17

Automatic wire bending machine wire automatic bending machine

...atic wire bending machine wire automatic bending machine

3dexport

automatic wire bending machine, wire automatic bending machine

archive3d

free

Automat 3D Model

...ive3d

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$20

Design of automatic laminator

...design of automatic laminator

3dexport

design of automatic laminator

3d_export

$6

Automatic soldering machine

...automatic soldering machine

3dexport

automatic soldering machine

turbosquid

$20

automatic rifle

...id

royalty free 3d model automatic rifle for download as fbx on turbosquid: 3d models for games, architecture, videos. (1163137)

turbosquid

$9

automatic gun

...yalty free 3d model automatic gun for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1226948)

turbosquid

$5

Automatic Knife

...lty free 3d model automatic knife for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1378253)

turbosquid

$15

Automatic Stamp

...d model automatic stamp for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1569569)

turbosquid

$1

flashlight for automat

...flashlight for automat for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1314717)

Watch

3d_ocean

$4

Watch

...watch

3docean

accessory watch

just ordinary watch

archibase_planet

free

Watch

...se planet

watch wristwatch wristlet watch wrist-watch

watch gucci n121213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wrist-watch wristwatch

watch n280114 - 3d model (*.3ds) for interior 3d visualization.

3d_export

free

Watch

...watch

3dexport

watch

archibase_planet

free

Watch

...watch

archibase planet

wrist-watch wrist watch wristwatch

watch n061110 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wrist-watch wristwatch

watch n011212 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...watch

archibase planet

watch wristwatch wrist watch

watch bulova n170211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

watch

...watch

3dexport

black watch

archibase_planet

free

Watch

...chibase planet

watch wrist-watch wristwatch

watch orient titanium n090713 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Watch

...net

wrist watch watch wristwatch clock

watch casio g-shock wristwatches n260111 - 3d model (*.3ds) for interior 3d visualization.