3dExport

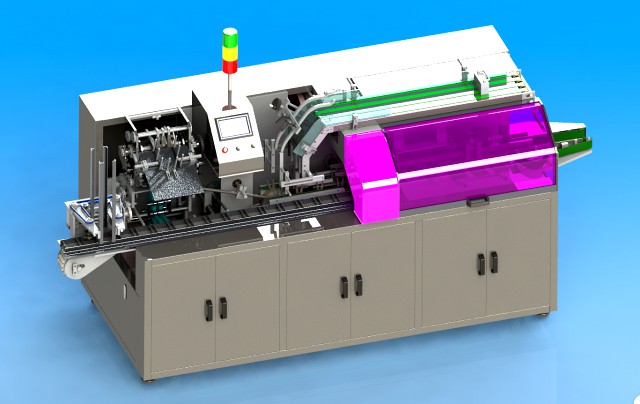

automatic high speed cartoning machine packaging machine

by 3dExport

Last crawled date: 1 year, 9 months ago

automatic high speed cartoning machine continuous cartoning machine

working principle the feeding of automatic cartoning machine is generally divided into three entrances: manual entrance, medicine bottle inlet and machine package box inlet. the whole process from feeding to final packaging and forming can be roughly divided into four stages: the carton is fixed by a guide rail clamp and opened by a push plate. at the same time, there will be two forward moving clips rising from below, blocking the side of the carton from the front and rear direction, so that the box is opened at a right angle and moved forward to the filling area. after filling in the filling area, the mechanism of the machine will fold the ears into the left and right guide rails, and then close the cover. before closing the cover, the mechanism will bend the plug of the carton first, and then a push plate will push the box cover to bend, so that the tongue can be inserted into the box and the lock catch is fastened. the closing action is a key action, which is closely related to the carton structure and the accuracy of machine adjustment. drawing of full automatic high-speed box loading machine (full cam type), with two motors to realize dozens of action cycles, instructions, products are automatically put into the box together: including solidworks 2015 stp xt format, this product is suitable for packaging of pharmaceutical aluminum plastic plate, round bottle, foreign bottle, cosmetics, auto parts, toothpaste, office supplies, poker and other similar items. it can open the carton automatically, pack and seal the box. the machine uses plc to control the photoelectric monitoring of all parts of the action, automatically reject the unqualified items in operation. in case of any abnormality, it can automatically stop the machine and display the reasons, so as to eliminate the fault in time. the machine can be used alone, or linked with the blister packaging machine and its thermosol device or other equipment to form a complete set of production line. main performance and structure features: 1. automatic opening (suction) box, folding instruction manual, blanking, feeding, marking batch number, sealing box, testing and scraping, etc., with stable operation and low noise. 2. plc and man-machine interface automatic control operating system, stepless frequency conversion speed regulation, high degree of automation, easy to understand operation. 3, using international famous brand electrical components, stable and reliable performance. 4, automatic stop function of mechanical overload is adopted to ensure the safety of human and machine. 5, automatically remove the packaging products that are short of packaging materials or instructions, so as to ensure the quality of packaging products. 6, with the functions of fault display, alarm and finished product counting, it is easy to maintain and deal with faults. 7. various automatic feeders and conveying mechanisms can be designed according to customer requirements. 8. hot melt adhesive machine can be used. hot melt glue spraying sealing or hot melt glue brushing device can be designed. 9. it can be connected with aluminum plastic packaging machine, pillow type packaging machine, filling machine, soap making machine, code spraying machine (or supervision code system), labeling machine, online weighing instrument, 3d packaging machine, heat shrinkable packaging machine, strapping machine and other production lines. main technical parameters power supply: ac380v three-phase five wire system power supply 50 hz total power 2.5 kw production capacity main engine running speed: 50-120 boxes / min gas consumption: 20 m3 / h (pressure 0.5-0.8 mpa)

working principle the feeding of automatic cartoning machine is generally divided into three entrances: manual entrance, medicine bottle inlet and machine package box inlet. the whole process from feeding to final packaging and forming can be roughly divided into four stages: the carton is fixed by a guide rail clamp and opened by a push plate. at the same time, there will be two forward moving clips rising from below, blocking the side of the carton from the front and rear direction, so that the box is opened at a right angle and moved forward to the filling area. after filling in the filling area, the mechanism of the machine will fold the ears into the left and right guide rails, and then close the cover. before closing the cover, the mechanism will bend the plug of the carton first, and then a push plate will push the box cover to bend, so that the tongue can be inserted into the box and the lock catch is fastened. the closing action is a key action, which is closely related to the carton structure and the accuracy of machine adjustment. drawing of full automatic high-speed box loading machine (full cam type), with two motors to realize dozens of action cycles, instructions, products are automatically put into the box together: including solidworks 2015 stp xt format, this product is suitable for packaging of pharmaceutical aluminum plastic plate, round bottle, foreign bottle, cosmetics, auto parts, toothpaste, office supplies, poker and other similar items. it can open the carton automatically, pack and seal the box. the machine uses plc to control the photoelectric monitoring of all parts of the action, automatically reject the unqualified items in operation. in case of any abnormality, it can automatically stop the machine and display the reasons, so as to eliminate the fault in time. the machine can be used alone, or linked with the blister packaging machine and its thermosol device or other equipment to form a complete set of production line. main performance and structure features: 1. automatic opening (suction) box, folding instruction manual, blanking, feeding, marking batch number, sealing box, testing and scraping, etc., with stable operation and low noise. 2. plc and man-machine interface automatic control operating system, stepless frequency conversion speed regulation, high degree of automation, easy to understand operation. 3, using international famous brand electrical components, stable and reliable performance. 4, automatic stop function of mechanical overload is adopted to ensure the safety of human and machine. 5, automatically remove the packaging products that are short of packaging materials or instructions, so as to ensure the quality of packaging products. 6, with the functions of fault display, alarm and finished product counting, it is easy to maintain and deal with faults. 7. various automatic feeders and conveying mechanisms can be designed according to customer requirements. 8. hot melt adhesive machine can be used. hot melt glue spraying sealing or hot melt glue brushing device can be designed. 9. it can be connected with aluminum plastic packaging machine, pillow type packaging machine, filling machine, soap making machine, code spraying machine (or supervision code system), labeling machine, online weighing instrument, 3d packaging machine, heat shrinkable packaging machine, strapping machine and other production lines. main technical parameters power supply: ac380v three-phase five wire system power supply 50 hz total power 2.5 kw production capacity main engine running speed: 50-120 boxes / min gas consumption: 20 m3 / h (pressure 0.5-0.8 mpa)

Similar models

cg_trader

$69

Automatic high-speed cartoning machine

...cosmetics, auto parts, toothpaste, office supplies, poker, etc. and similar items. it can automatically open the carton and pack...

3d_export

$28

automatic packing line medicine bottle cosmetics toothpaste mask

...sing the lid is a key action, which is closely related to the structure of the carton and the accuracy of the machine adjustment.

grabcad

free

Automatic high speed canning machine

...ts server operating speed: 50-120 boxes/min gas consumption: 20 cubic meters/hour (pressure 0. 5-0.8 mpa) weight : about 1.2 tons

grabcad

free

industrial 3D model Automatic high speed canning machine

...ts server operating speed: 50-120 boxes/min gas consumption: 20 cubic meters/hour (pressure 0. 5-0.8 mpa) weight : about 1.2 tons

cg_trader

$16

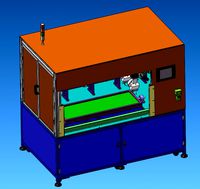

3D Design of Automatic Paper Box Filling and Opening Machine

... box sealing detection function. packaging package box models sorting filling machine automatically industrial industrial machine

3d_export

$20

automatic bottled beverage production line

...ttention. for you to create your own beverage filling machine way, so that your product is better than the industry in appearance

grabcad

free

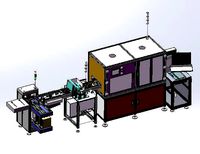

in line Cartoning machine and packaging

...orming from cardboard sheets and then filling the product according to the number of contents per box and then tied automatically

grabcad

free

Full-automatic L-shaped sealing and cutting heat shrinkable packaging machine

...storage platform make the whole machine really realize high-speed and unmanned automatic operation. worth learning and reference.

grabcad

free

Fully automatic vertical sealing and cutting machine

...storage platform make the whole machine really realize high-speed and unmanned automatic operation. worth learning and reference.

3d_export

$15

automatic bottle arrangement filling and sealing handling and stacking line

...nal model of automatic bottle arranging, filling, sealing, labeling, origami sealing, carton automatic handling and stacking line

Cartoning

archibase_planet

free

Carton

...carton

archibase planet

carton cardboard box box

carton box n090211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$2

Carton

...y free 3d model carton for download as 3ds, max, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1193748)

turbosquid

$3

Carton

...3d model carton for download as blend, obj, dae, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1677880)

3d_export

$6

milk carton

...milk carton

3dexport

3d_export

$25

carton packing machinesolidworks

...carton packing machinesolidworks

3dexport

carton packing machine(solidworks)

archive3d

free

Carton 3D Model

...on cardboard box box

carton box n090211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Carton-Animals

...uid

royalty free 3d model carton-animals for download as max on turbosquid: 3d models for games, architecture, videos. (1344404)

turbosquid

$20

carton cannon

...yalty free 3d model carton cannon for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1617978)

turbosquid

$21

Juice Carton

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$18

Milk-Carton

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Automatic

archibase_planet

free

Automat

...automat

archibase planet

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$17

Automatic wire bending machine wire automatic bending machine

...atic wire bending machine wire automatic bending machine

3dexport

automatic wire bending machine, wire automatic bending machine

archive3d

free

Automat 3D Model

...ive3d

automat equipment

automat n190510 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$20

Design of automatic laminator

...design of automatic laminator

3dexport

design of automatic laminator

3d_export

$6

Automatic soldering machine

...automatic soldering machine

3dexport

automatic soldering machine

turbosquid

$20

automatic rifle

...id

royalty free 3d model automatic rifle for download as fbx on turbosquid: 3d models for games, architecture, videos. (1163137)

turbosquid

$9

automatic gun

...yalty free 3d model automatic gun for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1226948)

turbosquid

$5

Automatic Knife

...lty free 3d model automatic knife for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1378253)

turbosquid

$1

flashlight for automat

...flashlight for automat for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1314717)

3d_export

$20

automatic pcb loading and unloading dispensing test automatic line

...ment structure is very complex. it is a very practical equipment for smt industry. the equipment is mature application equipment.

Speed

turbosquid

$50

speed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

speed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

speed

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Speed Camera

...model is separate and named appropriately. this is perfect for any type of scene from a road side, architectural or motorway s...

turbosquid

$25

Speed Buggy

...urbosquid

royalty free 3d model speed buggy for download as on turbosquid: 3d models for games, architecture, videos. (1209512)

turbosquid

$4

Speed Sign

...turbosquid

royalty free 3d model speed sign for download as on turbosquid: 3d models for games, architecture, videos. (1251518)

3d_export

$10

variable speed bicycle

...variable speed bicycle

3dexport

variable speed bicycle

3d_export

$5

High - speed aircraft

...high - speed aircraft

3dexport

high speed plane

turbosquid

$5

Speed bag

...y free 3d model speed bag for download as blend, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1577878)

turbosquid

$9

Speed Bump

... 3d model speed bump for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1551854)

Packaging

archibase_planet

free

Package

...package

archibase planet

cat food package

package n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package dog food petfood

package 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package dog food petfood

package 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package paper bag screw

package n050313 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package cat food dry cat food

package 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Package

...package

archibase planet

package cat food dry cat food

package 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Packaging Box

...packaging box

3docean

3dmodel box packaging packaging box

simple packaging box

turbosquid

$1

packaging

...osquid

royalty free 3d model packaging for download as blend on turbosquid: 3d models for games, architecture, videos. (1304457)

3ddd

free

package

...package

3ddd

банка

packing design

3d_export

$5

package design

...package design 3dexport box packaging ...

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

High

3d_export

$15

ironman high

...ironman high

3dexport

ironman high poly

turbosquid

$49

High Heel Girl (High Poly)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

High Heel Girl (High Poly)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

High Heel Girl (High Poly)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

High Heel Girl (High Poly)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

High heel girl (High Poly)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Cantu High

...cantu high

designconnected

linbrasil cantu high computer generated 3d model. designed by rodrigues, sergio.

design_connected

$16

Ribbon High

...ribbon high

designconnected

cappellini ribbon high bar stools computer generated 3d model. designed by nendo.

design_connected

$16

Koja high

...koja high

designconnected

blå station koja high computer generated 3d model. designed by mattson, fredrik.

design_connected

$11

Garry High

...garry high

designconnected

ligne roset garry high computer generated 3d model. designed by jourdan, eric.