Thingiverse

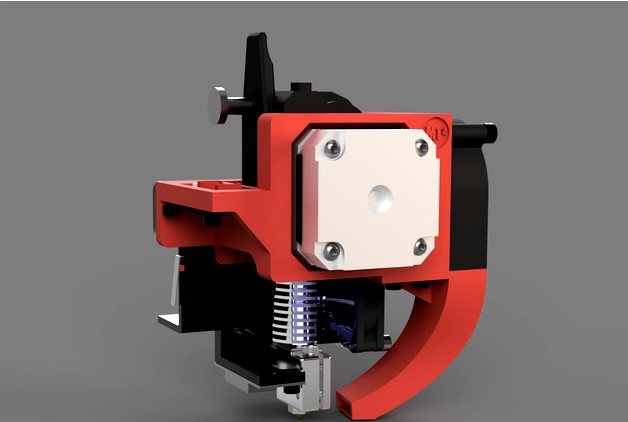

Anycubic Chiron Direct Drive - BMG by MT2

by Thingiverse

Last crawled date: 4 years, 1 month ago

Objectives

I developed this light'ish weight direct drive extrusion system with the objective of matching or reducing the form factor of the stock print head assembly. I do a lot of sequential printing so I wanted minimal bulk around the nozzle. I also wanted nozzle height to replicate stock so there would be no need to change nozzle home position or Z height. Auto bed leveling is excatly the same as stock. I also wanted easy access to the fans, heatsink, and particularly the nozzle so that I could easily swap larger orificed nozzles taking advantage of the E3D Volcano hotend and the printer's massive format.

Parts

Dual drive extruder from Bondtech or the cost effective Trianglelab Dual Drive Extruder.

24v Volcano hotend from E3D or the Trianglelab Volcano Hotend. Be sure to get some larger nozzles for faster prints.

Slim style Nema 17 stepper motor like this one. You coud attempt to use the original extruder stepper motor but it is very heavy and the 3:1 gear ratio of the BMG style extruder doesn't need much torque. Less weight, less ringing.

24v 5015 Blower Fan for the part cooler.

I'm a big fan of Trianglelab because they ship fast and quality is very good.

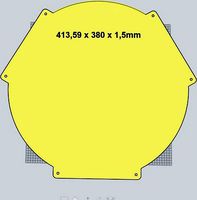

By the way, if you are having issues with adhesion on the Ultrabase, definitely going with an adhesive PEI sheet like this massive 405x405 PEI bed surface and say goodbye to warping. I also much prefer the smoother print quality on the bottom of the part.

Nuts & Bolts

You'll be able to reuse most of the original M3 screws from the old hotend assembly but you will need M3 nuts and some longer M3's as well as 2 x M4 screws for the part cooler fan. I highly recommend getting a metric screw/nut set like this one because let's face it, the 3d printing addiction will take hold if it hasn't already and you'll always need various size screws.

Printing Tips

You can use PLA, PETG, etc. Plastic does not come in contact with anything hot. I recommend at least 20% infill and 3+ perimeters and top/bottom layers. More perimeters provide stronger holes for threading. As always, make sure your printer is dimensionally accurate to ensure correct tolerances.

Miscellaneous

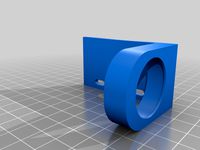

Print Head Wiring Harness

The robot arm cable guide thingy had to go. It wasn't worth designing around and I actually think it negatively impacts print quality. See the print files for a cable guide that is used to keep the cable in a neutral postion that minimizes drag or weight on the print head assembly.

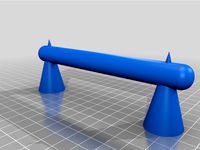

Filament Routing

I see a lot of direct drive systems that retain the Bowden tube for filament routing. This takes away one of the key benefits of a direct drive system which is easy filament loading and better yet... hot swapping filament while the printer is running. I suppose you could do it still with the PTFE tube but definitely not as easily. Check out the filament guide in the files list for an alternative routing strategy. Also allows you to get rid of the crappy metal arm that holds the filament roll. I also think that a heavy roll of filament moving and shaking on the frame of the printer impacts print quality.

X Axis Endstop

This needs to be flipped upside down to accomodate the extruder chassis.

I developed this light'ish weight direct drive extrusion system with the objective of matching or reducing the form factor of the stock print head assembly. I do a lot of sequential printing so I wanted minimal bulk around the nozzle. I also wanted nozzle height to replicate stock so there would be no need to change nozzle home position or Z height. Auto bed leveling is excatly the same as stock. I also wanted easy access to the fans, heatsink, and particularly the nozzle so that I could easily swap larger orificed nozzles taking advantage of the E3D Volcano hotend and the printer's massive format.

Parts

Dual drive extruder from Bondtech or the cost effective Trianglelab Dual Drive Extruder.

24v Volcano hotend from E3D or the Trianglelab Volcano Hotend. Be sure to get some larger nozzles for faster prints.

Slim style Nema 17 stepper motor like this one. You coud attempt to use the original extruder stepper motor but it is very heavy and the 3:1 gear ratio of the BMG style extruder doesn't need much torque. Less weight, less ringing.

24v 5015 Blower Fan for the part cooler.

I'm a big fan of Trianglelab because they ship fast and quality is very good.

By the way, if you are having issues with adhesion on the Ultrabase, definitely going with an adhesive PEI sheet like this massive 405x405 PEI bed surface and say goodbye to warping. I also much prefer the smoother print quality on the bottom of the part.

Nuts & Bolts

You'll be able to reuse most of the original M3 screws from the old hotend assembly but you will need M3 nuts and some longer M3's as well as 2 x M4 screws for the part cooler fan. I highly recommend getting a metric screw/nut set like this one because let's face it, the 3d printing addiction will take hold if it hasn't already and you'll always need various size screws.

Printing Tips

You can use PLA, PETG, etc. Plastic does not come in contact with anything hot. I recommend at least 20% infill and 3+ perimeters and top/bottom layers. More perimeters provide stronger holes for threading. As always, make sure your printer is dimensionally accurate to ensure correct tolerances.

Miscellaneous

Print Head Wiring Harness

The robot arm cable guide thingy had to go. It wasn't worth designing around and I actually think it negatively impacts print quality. See the print files for a cable guide that is used to keep the cable in a neutral postion that minimizes drag or weight on the print head assembly.

Filament Routing

I see a lot of direct drive systems that retain the Bowden tube for filament routing. This takes away one of the key benefits of a direct drive system which is easy filament loading and better yet... hot swapping filament while the printer is running. I suppose you could do it still with the PTFE tube but definitely not as easily. Check out the filament guide in the files list for an alternative routing strategy. Also allows you to get rid of the crappy metal arm that holds the filament roll. I also think that a heavy roll of filament moving and shaking on the frame of the printer impacts print quality.

X Axis Endstop

This needs to be flipped upside down to accomodate the extruder chassis.

Similar models

thingiverse

free

Ender 5 Bondtech BMG direct drive mount - HeroMe compatible

...to connect the extruder and the hotend, around 5cm should work, but please do not take it as granted and take measure yourself :)

thingiverse

free

Cable clip for Trianglelab BMG Dual Drive extruder by jk_printer

... ender 3 and 3 pro using a bmg-style dual drive extruder (trianglelab bmg clone). requires no screws or changes to the assembly.

thingiverse

free

Ender 3 BMG E3D V6 Volcano Direct Drive with BLTouch by Simon3105

... is still in testing phase and i'm very new to designing models in fusion360. so please have mercy on me if it's ugly ;-;

thingiverse

free

Compact Direct drive For Ender-3 by Modif93

...: -34mm y : 6.5mm

used -0.823mm for z axis, but it differs by nozzle kinds and assembly

(i use trianglelab hardened steel nozzle)

thingiverse

free

Ender 3 BMG V6 Volcano Direct Drive with BLTouch by Simon3105

... something equal. pla will melt obvioulsy because it is close to the hotend, but also the extruder stepper motor gets really hot.

thingiverse

free

Volcano Fan nozzle for mk2s by paeppi

...e fan nozzle for the mk2s extruder if you change it to a e3d volcano hotend.

print it in this direction, so no support is needed.

thingiverse

free

Ender 5 Upgrade - Direct Drive - BMG

...(i will create a list of them later).

3.6 - swiss cr10 hotend from trianglelab.. stock hotend will fit to hero plus ver6 funduct.

thingiverse

free

CL260 Hotend Cable Guide by a69291954

... cable guide by a69291954

thingiverse

guide for hotend cables for a cl260 printer

needs

1x m3 screw (10mm or longer)

1x m3 nut

thingiverse

free

BMG aero wind cooling duct by Laserdroid

...y laserdroid

thingiverse

remix of bmg areo fan duct for the volcano hotend

mounted on mellow wind bmg type direct drive extruder

thingiverse

free

MGN9H BMG Volcano V6 mount with level sensor by jatson

....

the fanduct not held by screws, you will need to stick it in position according to your setup.

i'm using it for my anet e10

Mt2

3ddd

$1

диван

...диван 3ddd driade mt2 sofa ron arad...

thingiverse

free

MT2 WALL HOLDER

...mt2 wall holder

thingiverse

wall holder for mt2 tools. slightly tilted to improve ergonomy.

3dfindit

free

B40-MT2

...b40-mt2

3dfind.it

catalog: walter uhl technische mikroskopie

thingiverse

free

Plug MT2 by kinedryl

...plug mt2 by kinedryl

thingiverse

.

thingiverse

free

Threaded Container by MT2

...threaded container by mt2

thingiverse

originally posted on instagram.

3dfindit

free

AXICOM MT2 SENSITIVE

...axicom mt2 sensitive

3dfind.it

catalog: te connectivity

thingiverse

free

Morse MT2 tool holder narrow

...morse mt2 tool holder narrow

thingiverse

make a wall holder for mt2 tools

thingiverse

free

Morse MT2 tool holder wide

...morse mt2 tool holder wide

thingiverse

yet another mt2 holder that is slightly wider

thingiverse

free

MT2 Morse Taper desktop holder for mini lathe

...mt2 morse taper desktop holder for mini lathe

thingiverse

mt2 morse taper desktop holder for mini lathe

thingiverse

free

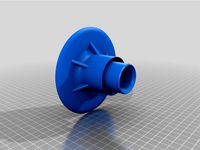

6mm Sprinkler Nozzle by MT2

...kler nozzle by mt2

thingiverse

nozzle for large impact sprinklers. improved spray in my opinion. originally posted on instagram.

Chiron

turbosquid

$20

Bugatti Chiron

...osquid

royalty free 3d model bugatti chiron for download as on turbosquid: 3d models for games, architecture, videos. (1672037)

turbosquid

$49

Bugati Chiron

...d

royalty free 3d model bugatti chiron for download as blend on turbosquid: 3d models for games, architecture, videos. (1568696)

3d_export

$5

Bugatti Chiron

...een sold. as of january 2022, some of these sold vehicles still need to be physically manufactured and delivered to their owners.

turbosquid

$25

bugati chiron

... model bugati chiron for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1258877)

3d_export

$12

rim for bugatti chiron gt

...rim for bugatti chiron gt

3dexport

this rim is made for the bugatti chiron gt.

3d_export

$7

bugatti chiron armchair

...15 obj leave me comment if you have any question or if you have any opinions or suggestions about this model. thank you very much

turbosquid

$160

Bugatti Chiron 3d model

...oyalty free 3d model bugatti chiron 3d model for download as on turbosquid: 3d models for games, architecture, videos. (1433781)

cg_studio

$199

Bugatti Chiron 20173d model

...or

.obj .max .lwo .fbx .c4d .3ds - bugatti chiron 2017 3d model, royalty free license available, instant download after purchase.

3d_export

$5

bugatti chiron 2017 bugatti machine car

...bugatti chiron 2017 bugatti machine car

3dexport

car bugatti chiron 2017 3d model

turbosquid

$39

Bugatti Chiron wheel 4

...l 4 for download as ma, 3ds, max, lwo, obj, xsi, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1383533)

Bmg

turbosquid

$3

.50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

.50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

50 BMG Cartridge

...e 3d model 50 bmg cartridge for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1303035)

turbosquid

$30

Sniper 50 bmg

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cal 50 BMG

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$25

.50 BMG Cartridge3d model

...odel

cgstudio

.3ds .max .obj .wrl - .50 bmg cartridge 3d model, royalty free license available, instant download after purchase.

3d_export

$5

50 caliber BMG round 3D Model

...d 3d model

3dexport

50cal caliber 50 round bullet bmg cartridge browning rifle

50 caliber bmg round 3d model csw92 27660 3dexport

3d_export

$22

.50 BMG Cartridge 3D Model

...ectile rifle round pistol cartridge m2 hb 127x99mm nato browning barrett m82a1

.50 bmg cartridge 3d model plutonius 8091 3dexport

turbosquid

free

LAR Grizzly .50 BMG Sniper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

cartrige m50 bmg

...aterials are logically named<br>the main format is in 3ds max 2009.<br>satisfcation garranteed..<br>thank you !

Anycubic

thingiverse

free

anycubic filament holder

...anycubic filament holder

thingiverse

anycubic filament holder

thingiverse

free

Cableholder Anycubic Mega

...cableholder anycubic mega

thingiverse

cableholder anycubic mega

thingiverse

free

AnyCubic Toolholder by WildManPrinting

...anycubic toolholder by wildmanprinting

thingiverse

anycubic i3 mega toolholder that clips on the side of the spool a-frame.

thingiverse

free

AnyCubic Funnel by phana007

...anycubic funnel by phana007

thingiverse

funnel for anycubic resin and also a reducer for a normal soda bottle.

thingiverse

free

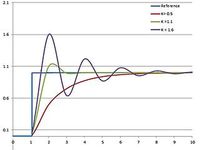

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

anycubic mega i3

...anycubic mega i3

thingiverse

anycubic i3 mega/mega s led 30mm 10-14v 6500k

thingiverse

free

Handle for anycubic by cruiser7

...handle for anycubic by cruiser7

thingiverse

its easier to handle the cover of the anycubic mono x and wash&care

thingiverse

free

anycubic predator Printbed by Lihyon

...anycubic predator printbed by lihyon

thingiverse

anycubic predator printbed

thingiverse

free

Anycubic Predator Triggers by marcelcountry

...anycubic predator triggers by marcelcountry

thingiverse

anycubic predator triggers

thingiverse

free

support anycubic cable by sarpdental

...support anycubic cable by sarpdental

thingiverse

support anycubic cable

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)