Thingiverse

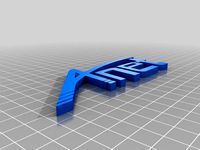

Anet A8 Z Endstop Fine Tuner by klownius

by Thingiverse

Last crawled date: 3 years ago

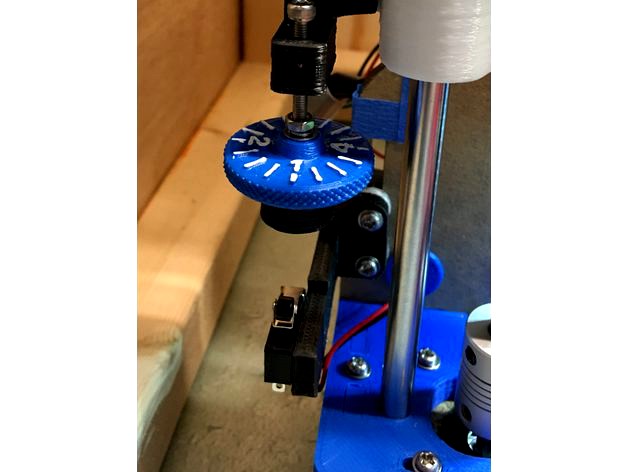

This is an amalgamation of several different mods that I used to create the Z Finely Adjustable Endstop that I needed. Basically, I purchased an autolevel sensor, but I didn't want to mess up my printer updating the firmware to get the sensor to work. I have heard good stories and horror stories.

With this mod, I really don't need an autolevel. I adjusted all four bed screws using A4 paper to get it level initially (one time). Before every print, I just make sure both carriages on the Z threaded rod are at the same height, and then I adjust the nozzle height with this mod using an A4 paper in the middle to check its height. Turn the dial to raise or lower, and home the Z Axis. Do this until the A4 paper has some resistance but not a lot of resistance. When I mess with the bed to install a mod or something, I have to re-do the four bed screws, but that is it.

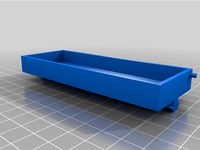

I printed the barrel fatty part with the hole side up. I printed the top endstop part with supports.

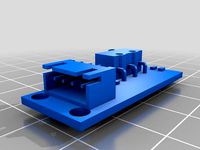

This mod does go over a chain mod, this one specifically:

http://www.thingiverse.com/thing:1905344

If using a different one, please check to make sure this will fit over it. Also, you might need some spacers/washers behind the bottom part depending on your mod situation.

Hardware needed extra (reuse the endstop switch screws and the bolts and nuts the standard Z endstop uses):

4 x M3 Nuts

3 x M3 Washer

1 x M3 Lock Washer

1 x 40mm long (or longer) M3 Screw (any type head)

2 x M3 Screw (longer screws to fit through this mod, the chain, the carriage, and into the motor)

? x Washer/Spacers (as need be)

Need to know how to melt a nut into PLA/ABS. Screw an M3 nut to the very end of a long M3 screw. Use a lighter to heat up the nut for about 22 to 30 seconds (in the BLUE part of the flame - it can get a black coating if using the orange part). Line the nut up over the plastic part, and using the nut into the PLA/ABS with the hole centered. Push until the nut is all the way in, and it is flat (not tilted). Carefully unscrew the bolt, and let it cool in there.

Construction:

Print one of each of the parts. Melt a nut into the bottom of the thumb wheel (side without numbers). Melt another nut into the fatty endstop cap (the side with the hole).

Slide a nut into the Z endstop top part (the little slot there). Screw the 40mm or longer bolt almost all the way in to that nut on the Z endstop top part (look at the picture to see orientation).

Screw an M3 nut onto the 40mm or longer bolt, followed by a lock washer, followed by a regular washer. Screw on the thumb wheel so the numbers are facing the Z endstop top, and do it ways up the bolt. Finally screw on the end cap fatty part all the way onto the bolt so that it is tight without moving (hand tightening is good enough).

Now, screw the thumbwheel down towards the fatty endcap until it is solidly against it, pretty tight (hand tightening is good enough). Push the washer and lock washer down on top of the thumb wheel. Finally, screw the M3 screw all the way down until it is down solid (use a wrench to tighten, but not over tighten).

Now, you should be able to turn the thumbwheel clockwise or counterclockwise so that the screw head near the slotty nut goes up or down. It should turn fairly easily. Vibration doesn't really change it, and I level it between prints, anyway, so there is no real need to lock it down.

Unlike the other mod this was based off of, do NOT remove the switch arm - it provides a necessary function. When the nozzle head is too close to the bed, you turn the dial so that it pushes the switch arm down a little more (it will bend slightly, and that's fine). When the Z axis is homed, the nozzle will now be raised slight higher. Without the arm, it's not possible to screw it down any more to raise the nozzle - not so good.

Install the top part of the mod as seen in the picture. Install the bottom part of the mod by replacing the current Z endstop and brackets. Be sure that the fatty top part hits the bottom switch end square on. Adjust or use washers/spacers on the bottom part until it does so.

Make sure the carriage isn't over the heated bed when you try leveling initially. Move the thumb wheel until there is about the same amount of bolt space above and below the slotty nut. Set the bottom part to pretty much the bottom. Try homing the Z axis only (again, not over the bed) until it looks like the nozzle is at least 1mm above the bed. THEN and only THEN, try leveling over the bed using an A4 piece of paper.

There it is!

I would like to thank alexan9er and cd1701 for their awesome mods. Without people like them, this mod would not have been possible!

With this mod, I really don't need an autolevel. I adjusted all four bed screws using A4 paper to get it level initially (one time). Before every print, I just make sure both carriages on the Z threaded rod are at the same height, and then I adjust the nozzle height with this mod using an A4 paper in the middle to check its height. Turn the dial to raise or lower, and home the Z Axis. Do this until the A4 paper has some resistance but not a lot of resistance. When I mess with the bed to install a mod or something, I have to re-do the four bed screws, but that is it.

I printed the barrel fatty part with the hole side up. I printed the top endstop part with supports.

This mod does go over a chain mod, this one specifically:

http://www.thingiverse.com/thing:1905344

If using a different one, please check to make sure this will fit over it. Also, you might need some spacers/washers behind the bottom part depending on your mod situation.

Hardware needed extra (reuse the endstop switch screws and the bolts and nuts the standard Z endstop uses):

4 x M3 Nuts

3 x M3 Washer

1 x M3 Lock Washer

1 x 40mm long (or longer) M3 Screw (any type head)

2 x M3 Screw (longer screws to fit through this mod, the chain, the carriage, and into the motor)

? x Washer/Spacers (as need be)

Need to know how to melt a nut into PLA/ABS. Screw an M3 nut to the very end of a long M3 screw. Use a lighter to heat up the nut for about 22 to 30 seconds (in the BLUE part of the flame - it can get a black coating if using the orange part). Line the nut up over the plastic part, and using the nut into the PLA/ABS with the hole centered. Push until the nut is all the way in, and it is flat (not tilted). Carefully unscrew the bolt, and let it cool in there.

Construction:

Print one of each of the parts. Melt a nut into the bottom of the thumb wheel (side without numbers). Melt another nut into the fatty endstop cap (the side with the hole).

Slide a nut into the Z endstop top part (the little slot there). Screw the 40mm or longer bolt almost all the way in to that nut on the Z endstop top part (look at the picture to see orientation).

Screw an M3 nut onto the 40mm or longer bolt, followed by a lock washer, followed by a regular washer. Screw on the thumb wheel so the numbers are facing the Z endstop top, and do it ways up the bolt. Finally screw on the end cap fatty part all the way onto the bolt so that it is tight without moving (hand tightening is good enough).

Now, screw the thumbwheel down towards the fatty endcap until it is solidly against it, pretty tight (hand tightening is good enough). Push the washer and lock washer down on top of the thumb wheel. Finally, screw the M3 screw all the way down until it is down solid (use a wrench to tighten, but not over tighten).

Now, you should be able to turn the thumbwheel clockwise or counterclockwise so that the screw head near the slotty nut goes up or down. It should turn fairly easily. Vibration doesn't really change it, and I level it between prints, anyway, so there is no real need to lock it down.

Unlike the other mod this was based off of, do NOT remove the switch arm - it provides a necessary function. When the nozzle head is too close to the bed, you turn the dial so that it pushes the switch arm down a little more (it will bend slightly, and that's fine). When the Z axis is homed, the nozzle will now be raised slight higher. Without the arm, it's not possible to screw it down any more to raise the nozzle - not so good.

Install the top part of the mod as seen in the picture. Install the bottom part of the mod by replacing the current Z endstop and brackets. Be sure that the fatty top part hits the bottom switch end square on. Adjust or use washers/spacers on the bottom part until it does so.

Make sure the carriage isn't over the heated bed when you try leveling initially. Move the thumb wheel until there is about the same amount of bolt space above and below the slotty nut. Set the bottom part to pretty much the bottom. Try homing the Z axis only (again, not over the bed) until it looks like the nozzle is at least 1mm above the bed. THEN and only THEN, try leveling over the bed using an A4 piece of paper.

There it is!

I would like to thank alexan9er and cd1701 for their awesome mods. Without people like them, this mod would not have been possible!

Similar models

thingiverse

free

Hictop i3 Z Top Bearing Guide by chaoren

...olt in place with proper allen wrench and use a wrench to tighten jam nut down to the z top to prevent the bolt from backing off.

thingiverse

free

Monoprice MP Select Mini Z Axis Adjustable Endstop by divide

...o keep the spring from binding on the head of the screw.

reused:

limit switch m2 screws and nuts

x carriage shield plastic screw

thingiverse

free

Prusa Z Adjuster by lazzymonk

...2 nyloc nuts.

needs about 10mm overhang of the x axis smooth rods.

the blue thumb wheel is http://www.thingiverse.com/thing:29782

thingiverse

free

Anet A8 Z Axis End Stop Adjuster by FredGenius

...a knob to make adjusting easier.

you will need:

2x m3x18mm screws

2x m3 nuts

2x m3x25mm screws

1x m5x40mm hex bolt

1x m5 half nut

thingiverse

free

Tevo Black Widow - Z Endstop Adjustable by bdwalker1

... as well)

m3 washer

m3 thumb screw nut

parts for attaching mount to printer:

m4x8 screw (x2)

m4 washer (x2)

m4 drop-in t-nut (x2)

thingiverse

free

Z-Motor holder with precision Z-Axis calibration for Velleman K8200 / 3Drag by akkenoth

...m3 nut and 4x m3 washer to mount microswitch to plate

to mount z endstop screw block you can use original screw, washers and nut.

thingiverse

free

print bed thumb wheel by tanasibob

...lt with a washer to seat it properly... make this one of your first mods, you will not be sorry (if you dont have auto leveling.)

thingiverse

free

Ender 3 Adjustable Z Endstop Cryo by cryogen

...ing part of the bolt use the lock washed and nut to secure the bolt in the knob.

i use petg for long-term use of the item.

enjoy.

thingiverse

free

Folger Tech 2020 Prusa i3 Robust Adjustable Z Endstop by QuadBert

...spring), and through the square block and nut on the sensor mount part, then on out the top. put a washer and nylock nut on top.

thingiverse

free

Folger Tech Cloner Adjustable Z Endstop Mount by djcdude95

...ustment. much better than the stock design.

flip the top part so it is flat side down. (doesnt matter much which flat side it is)

Klownius

thingiverse

free

Spinner Star Sturdier by klownius

...how i roll...

thanks to m4jin and l1terally for doing what they do!

original thumb screw:http://www.thingiverse.com/thing:2274261

thingiverse

free

Anet A8 Heated Bed Handle by klownius

...e out over a greater area on the plastic thus reducing the pressure (defined as force/area) and lowering the chance for cracking.

thingiverse

free

Anet A8 9mm 6 Turn Spring Washers by klownius

...m/152247887255?_trksid=p2057872.m2749.l2649&sspagename=strk%3amebidx%3ait

customizer:http://www.thingiverse.com/thing:1804488

thingiverse

free

Anet A8 Y Axis Motor Mount Replacement by klownius

...naltered.

here is a link to the motor gaskets so that you know what i am talking about:http://www.makergeeks.com/ne17stga4pa.html

thingiverse

free

Anet A8 Improved Y-Belt Tensioner Bar by klownius

...is. all credit please to audiogod and freemark!

http://www.thingiverse.com/thing:2306072http://www.thingiverse.com/thing:1683085

thingiverse

free

Anet A8 Corner Brace Bottom Right Frame (Minimalistic) by klownius

...e.

see other side:http://www.thingiverse.com/thing:2105996

see upper braces by electrico:http://www.thingiverse.com/thing:1672959

thingiverse

free

Anet A8 Generic Spool Holder by klownius

... asked about it. it's built entirely of hardware store parts. i don't think any of the rods were specially cut, either.

thingiverse

free

Solder Fume Extractor (Minimalistic) by klownius

...o work, but i decided to use a brim. good old brim, nothing beats that. except a raft.

thanks:

thanks to zeebly for the design!

thingiverse

free

Anet A8 Corner Brace Bottom Left Frame (Minimalistic) by klownius

...e.

see other side:http://www.thingiverse.com/thing:2105106

see upper braces by electrico:http://www.thingiverse.com/thing:1672959

Tuner

archibase_planet

free

Tuner

...tuner

archibase planet

tuner

tuner - 3d model for interior 3d visualization.

3d_ocean

$16

Tuner

...here just for render of presentation. all formats includes tuner only. this is audio tuner and this is my own design. this tun...

turbosquid

$15

tuner

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Tuner 3D Model

...tuner 3d model

archive3d

tuner

tuner - 3d model for interior 3d visualization.

archive3d

free

Tuner 3D Model

...deo equipment

tuner digital bbk n250616 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$29

Shift Tuner

...osquid

royalty free 3d model shift tuner for download as fbx on turbosquid: 3d models for games, architecture, videos. (1236363)

turbosquid

$65

Tuner Card

...ty free 3d model tuner card for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1299311)

turbosquid

$39

Radio Tuner

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Guitar Tuner

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Shift Tuner red

...id

royalty free 3d model shift tuner red for download as fbx on turbosquid: 3d models for games, architecture, videos. (1486834)

Endstop

thingiverse

free

Endstop-holder for endstop v1.2 by albiuz

...endstop-holder for endstop v1.2 by albiuz

thingiverse

endstop-holder designed for mech endstop v1.2

thingiverse

free

Endstop by 3dboxpro

...endstop by 3dboxpro

thingiverse

endstop

thingiverse

free

Endstop by 1sPiRe

...endstop by 1spire

thingiverse

endstop model for conceptions

thingiverse

free

Endstop holder for Opto or Mechanical endstops by LulzBot

... endstops by lulzbot

thingiverse

these are the standard 1.0 prusa endstops with an added mounting hole for mechanical endstops.

thingiverse

free

Endstop Holder by onurhamdiuzun

...endstop holder by onurhamdiuzun

thingiverse

endstop holder for makerbot endstop and other endstops

thingiverse

free

Endstop Cover

...endstop cover

thingiverse

cover for endstop boards for makerbot design.

thingiverse

free

Endstop Mount for optical Endstops by Whitehawk2000

...whitehawk2000

thingiverse

use two 20mm m3 screws and nuts to screw the endstop onto the mount and just clip it onto the 8mm rod.

thingiverse

free

C-beam endstop mount for Makerbot type endstops

...c-beam endstop mount for makerbot type endstops

thingiverse

c-beam endstop mount for makerbot type endstop boards.

thingiverse

free

Endstop Mount for MakerBot Mecanical Endstop. by nka

...v-slots carriage.

endstop is screw with m3 (8mm) tapped hole and the endstop hold on the extrusion using a m5 (8mm) and t-nuts.

thingiverse

free

ENDSTOP 10mm by desert500

...endstop 10mm by desert500

thingiverse

endstop

A8

turbosquid

$47

Car A8

...

turbosquid

royalty free 3d model car a8 for download as max on turbosquid: 3d models for games, architecture, videos. (1196060)

turbosquid

$50

Audi A8

...yalty free 3d model audi a8 for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1580187)

turbosquid

$15

Audi A8

...lty free 3d model audi a8 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1387519)

turbosquid

$500

Audi A8

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

audi a8 cars car

audi a8 3d model ma 20351 3dexport

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

3d model of audi a8

audi a8 3d model badyaka 12136 3dexport

3d_ocean

$89

Audi A8 2010

...usiness car car class class f f german german luxury luxury s s s8 s8 sedan sedan vehicle vehicle

new audi a8 2010 detaled model.

turbosquid

$39

A8 2018

...a8 2018 for download as 3ds, obj, wrl, c4d, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1345349)

turbosquid

free

audi a8 l

...rbosquid

royalty free 3d model audi a8 l for download as obj on turbosquid: 3d models for games, architecture, videos. (1663016)

3d_ocean

$45

Audi A8 restyled

...our door vehicle was created in blender3d 2.62.realistic renderings were created with yafaray 0.1.2 realistic plugin.rendering...

Anet

thingiverse

free

Anet by derbodesign

...anet by derbodesign

thingiverse

logo anet

thingiverse

free

Anet e10 , Anet v1.0 by jonathan_943D

...anet e10 , anet v1.0 by jonathan_943d

thingiverse

soporte de ventilador de 80mm, para controladora anet v1.0

thingiverse

free

Anet A8 Anet AM8 Y belt holder

...anet a8 anet am8 y belt holder

thingiverse

anet a8 anet am8 y belt holder

thingiverse

free

Anet A8 Probe Bracket for anet sensor by chelrix

...anet a8 probe bracket for anet sensor by chelrix

thingiverse

anet a8 probe bracket for anet official sensor and marlin firmware

thingiverse

free

Anet logo by JUST3D_PRNTNG

...anet logo by just3d_prntng

thingiverse

anet logo

thingiverse

free

Fan nozzle for Anet A8 with original Anet levelsensor by peteruhlmann

...et levelsensor by peteruhlmann

thingiverse

here is an improved fan nozzle for the anet a8 with original level sensor from anet.

thingiverse

free

Anet Et4 Box

...anet et4 box

thingiverse

tool box for anet et4

thingiverse

free

Anet Logo by Superflex_Plastic_Fantastic

...anet logo by superflex_plastic_fantastic

thingiverse

anet logo to incorporate into designs.

thingiverse

free

Box for Anet ET4

...box for anet et4

thingiverse

this is a simple box for tool of anet et4

thingiverse

free

Anet V1.0 Board Kühlung (80mm Lüfter) / Anet A8 by MadCre8

...anet v1.0 board kühlung (80mm lüfter) / anet a8 by madcre8

thingiverse

anet v1.0 board kühlung (80mm lüfter) / anet a8

Fine

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps

торшер fine art

3ddd

$1

Fine Art_Chandelier

...fine art_chandelier

3ddd

fine art lamps

fine art_chandelier, crystal enchantment

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps

люстра и бра fine art

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps

люстра для бильярда fine art

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps

торшер и бра fine art

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps , сша

бра fine art lamps (сша)

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps , сша

люстра fine art lamps (сша)

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps , сша

настольная лампа fine art lamps (сша)

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps

светильники fine art

люстра и бра 750640

3ddd

$1

Fine Art

...fine art

3ddd

fine art lamps

светильники фирмы fine art

бра 429850

торшер 452230

люстра 429540

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)