Thingiverse

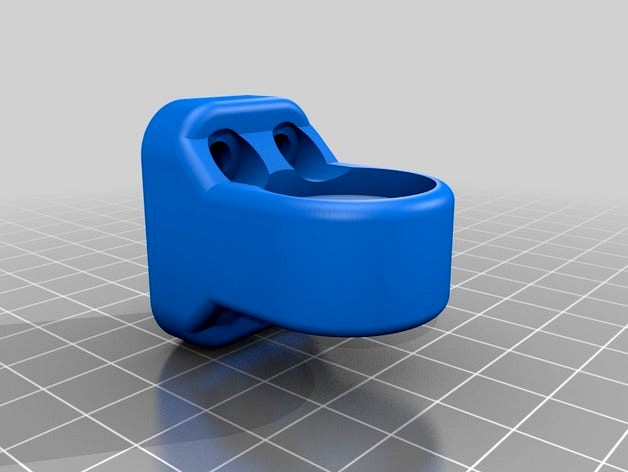

Anet A8 Y Axis Leadscrew Conversion by 3DPrintVids

by Thingiverse

Last crawled date: 3 years ago

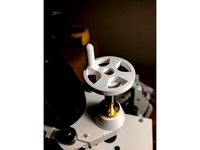

25/03/2018 UPDATE: Well, thats it, it's done, all the parts are designed, the drill holes templated, and it works, firmware change instructions are below... The only thing that may change is the addition of some frame bracing in the middle where i have cut out the centre, just need to do some cable tidying then it'll be time for a test print...

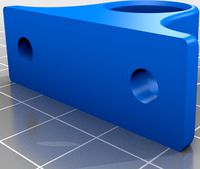

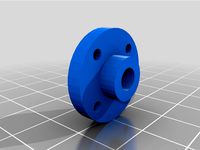

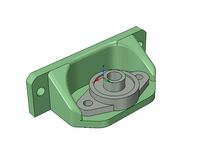

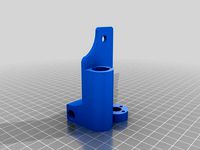

This is an Y Axis Leadscrew conversion for the popular Anet A8 3D Printer...

The plan is to run a bearing supported leadscrew with the Y axis motor mounted on the front.

Parts:

4 x M4 x 16 mm - For Lead Screw Nut Holder to Carriage

2 x M5 x 25 mm - For Front Bearing To Adapter Plate

2 x M5 x 20 mm - For Rear Bearing To Rear Frame

4 x M3 x 40 mm - For Stepper Motor

2 x M3 x 30 mm - To Affix Adapter To Base Board

1 x Leadscrew 8 x 400mm

2 x 8mm Bearings

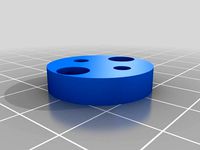

1 x 8mm Anti Backlash Nut

Cable Extension JST-XT 4 Pin OR Cable/Solder/Heatshrink.

You will need to modify your firmware/speeds:

M92 Y400.00 - Set Steps Per MM to 400

M203 Y40.00 - Set Max Feedrate to 40 units/s

M201 Y100 - Set Max Acceleration to 100

M500 - Save Settings

M501 - Recall Saved Settings to check they are correct...

With a lead screw you can no longer pull the bed forwards, so if like me you want the printer to move the build plate to the front at the end of the print...

Add this to your end of print code box in your slicer/controller software - This moves the bed to the forward position but with no overhang...

G90 ;absolute positioning

G1 Y175;

M84 ;steppers off

Please leave any comments/suggestions below...

Watch these and other items being printed live on my new YouTube channel: Please Like & Subscribe... http://bit.ly/2FNOORr

Check out my new Facebook Page: http://fb.me/3DPrintChannel

This is an Y Axis Leadscrew conversion for the popular Anet A8 3D Printer...

The plan is to run a bearing supported leadscrew with the Y axis motor mounted on the front.

Parts:

4 x M4 x 16 mm - For Lead Screw Nut Holder to Carriage

2 x M5 x 25 mm - For Front Bearing To Adapter Plate

2 x M5 x 20 mm - For Rear Bearing To Rear Frame

4 x M3 x 40 mm - For Stepper Motor

2 x M3 x 30 mm - To Affix Adapter To Base Board

1 x Leadscrew 8 x 400mm

2 x 8mm Bearings

1 x 8mm Anti Backlash Nut

Cable Extension JST-XT 4 Pin OR Cable/Solder/Heatshrink.

You will need to modify your firmware/speeds:

M92 Y400.00 - Set Steps Per MM to 400

M203 Y40.00 - Set Max Feedrate to 40 units/s

M201 Y100 - Set Max Acceleration to 100

M500 - Save Settings

M501 - Recall Saved Settings to check they are correct...

With a lead screw you can no longer pull the bed forwards, so if like me you want the printer to move the build plate to the front at the end of the print...

Add this to your end of print code box in your slicer/controller software - This moves the bed to the forward position but with no overhang...

G90 ;absolute positioning

G1 Y175;

M84 ;steppers off

Please leave any comments/suggestions below...

Watch these and other items being printed live on my new YouTube channel: Please Like & Subscribe... http://bit.ly/2FNOORr

Check out my new Facebook Page: http://fb.me/3DPrintChannel

Similar models

thingiverse

free

Anet A8 E3D Extruder Carriage and X Axis Leadscrew Conversion by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

Prusa MK3 Leadscrew Nut Adapter by b3n3d1k7

...itionally, 2 8mm long m3 screws and nuts for attaching the leadscrew nut to the adapter.

printed and tested - works great so far.

thingiverse

free

Prusa Steel X axis with tensioner and 8mm leadscrew support by fedewolfie

...ner and a m5 screw and nut for the toothed idler, i use a cheap aliexpress toothed idler with a m5 bore.

prints without supports.

thingiverse

free

Anet A8 Rear Brace with Y axis end stop by 3DMagicm

...thingiverse

rear brace for added support and stability for anet a8. also includes the y-axis end stop and stepper motor mount.

thingiverse

free

Anet A8 Plus z-axis synchronizer by toxic049

... gt2 gear

2 12mm diameter 6mm high bearings

2 605z 8mm bearings

6 m5 x 40 mm bolts

modifications:

move both z axis motors up 10mm

thingiverse

free

Anet A8 x-axis v-weel update by Lancerevo21

...te by lancerevo21

thingiverse

3x v-weel

4 x baring 10x5x4

5x m5 x 25 + nuts

6 x m3 nuts

2x m4 nuts

2x m4 x40 screw

12x m5 spacer

thingiverse

free

AM8 RAMPS Y axis endtop mount and target by PapaJohn88

...h

2 x m5 x 10mm screws

2 x m5 square nuts

printer:

anet a8

rafts:

no

supports:

no

resolution:

0.2 (i printed at .12)

infill:

20%

thingiverse

free

Y LM8UU Bearing Mount Anet A8 by Vali24

...ngs, no noises.

you need:

4x y bearing mount

8x m3 nut

8x m3 screw

it's remixed from https://www.thingiverse.com/thing:710913

thingiverse

free

Anet A8 Y-axis stepper mount with bearing

...anet a8 y-axis stepper mount with bearing

thingiverse

you need one bearing 625.

...not tested yet.

thingiverse

free

Cart X-axis Anet A8 by Giovanni1965

...mm v-slot pulleys with 5 mm hole, four m5 nuts, four m5 screws 20 mm long, eight m4 nuts, six 10 mm m4 screws, 2 40 mm m4 screws.

3Dprintvids

thingiverse

free

Anet A8 Extruder Button by 3DPrintVids

...tvids

thingiverse

i know there is a hundred of them out there already, but this is my take on an extruder button for an anet a8

thingiverse

free

Extruder Nozzle Spanner Keyring by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

DIY Night Vision Spotter by 3DPrintVids

...king about for ages, the battery is a 3s 2200mah lipo from one of my rc planes and the screws etc all came out of my parts bin...

thingiverse

free

100mm Encoder Wheel 8T 3mm 5mm by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

100mm Encoder Wheel 16T 3mm 5mm by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

100mm Encoder Wheel 64T 3mm 5mm by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

100mm Encoder Wheel 32T 3mm 5mm by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

100mm Encoder Wheel 4T 3mm 5mm by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

thingiverse

free

Anet A8 Shelf Frame Support by 3DPrintVids

...youtube channel: please like & subscribe... http://bit.ly/2fnoorr

check out my new facebook page: http://fb.me/3dprintchannel

Leadscrew

thingiverse

free

Leadscrew Support by The_Custom_Side

...w support for 8mm leadscrew.

printed in 0.25mm petg

requires bearing (16mm od, 8mm id).

no supports, no rafts, 20% gyroid infill.

thingiverse

free

Hook for M8 Leadscrew

...hook for m8 leadscrew

thingiverse

hook which holds on m8 leadscrew without pressure on the screw

thingiverse

free

X Idler Leadscrew by GOO2014

...x idler leadscrew by goo2014

thingiverse

x idler leadscrew

thingiverse

free

10mm Leadscrew Knob by carboncopy101

...10mm leadscrew knob by carboncopy101

thingiverse

this is a knob for a 10mm leadscrew for manual turning. enjoy.

thingiverse

free

nut for m5 leadscrew by mbzn

...nut for m5 leadscrew by mbzn

thingiverse

created to use as a nut for m5 threaded bar in place of a leadscrew

thingiverse

free

8mm Leadscrew Crank by dakahler

...igned for the cyclone pcb, but can be used on any 8mm leadscrew.

the captive nut for the set screw is designed to be heat-staked.

thingiverse

free

Z leadscrew support for KFL08 by bajmar

...z leadscrew support for kfl08 by bajmar

thingiverse

z leadscrew support for kfl08

thingiverse

free

X-Axis Leadscrew Idler by brisinger

...x-axis leadscrew idler by brisinger

thingiverse

x-axis leadscrew idler

thingiverse

free

Leadscrew Adapter by PhoenixZip

...rew, and it does not fit our lorei printers.

this adapter allows use of holes that are 16mm apart to our (roughly) 11.85mm holes.

thingiverse

free

Trintcore z-axis modified leadscrew by grubeludouche

... modified leadscrew by grubeludouche

thingiverse

this is a mod to fit a t8 pitch leadscrew, replacing the original m8 leadscrew.

A8

turbosquid

$47

Car A8

...

turbosquid

royalty free 3d model car a8 for download as max on turbosquid: 3d models for games, architecture, videos. (1196060)

turbosquid

$50

Audi A8

...yalty free 3d model audi a8 for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1580187)

turbosquid

$15

Audi A8

...lty free 3d model audi a8 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1387519)

turbosquid

$500

Audi A8

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

audi a8 cars car

audi a8 3d model ma 20351 3dexport

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

3d model of audi a8

audi a8 3d model badyaka 12136 3dexport

3d_ocean

$89

Audi A8 2010

...usiness car car class class f f german german luxury luxury s s s8 s8 sedan sedan vehicle vehicle

new audi a8 2010 detaled model.

turbosquid

$39

A8 2018

...a8 2018 for download as 3ds, obj, wrl, c4d, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1345349)

turbosquid

free

audi a8 l

...rbosquid

royalty free 3d model audi a8 l for download as obj on turbosquid: 3d models for games, architecture, videos. (1663016)

3d_ocean

$45

Audi A8 restyled

...our door vehicle was created in blender3d 2.62.realistic renderings were created with yafaray 0.1.2 realistic plugin.rendering...

Anet

thingiverse

free

Anet by derbodesign

...anet by derbodesign

thingiverse

logo anet

thingiverse

free

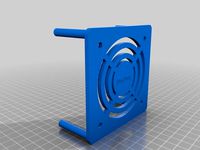

Anet e10 , Anet v1.0 by jonathan_943D

...anet e10 , anet v1.0 by jonathan_943d

thingiverse

soporte de ventilador de 80mm, para controladora anet v1.0

thingiverse

free

Anet A8 Anet AM8 Y belt holder

...anet a8 anet am8 y belt holder

thingiverse

anet a8 anet am8 y belt holder

thingiverse

free

Anet A8 Probe Bracket for anet sensor by chelrix

...anet a8 probe bracket for anet sensor by chelrix

thingiverse

anet a8 probe bracket for anet official sensor and marlin firmware

thingiverse

free

Anet logo by JUST3D_PRNTNG

...anet logo by just3d_prntng

thingiverse

anet logo

thingiverse

free

Fan nozzle for Anet A8 with original Anet levelsensor by peteruhlmann

...et levelsensor by peteruhlmann

thingiverse

here is an improved fan nozzle for the anet a8 with original level sensor from anet.

thingiverse

free

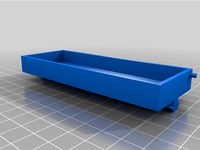

Anet Et4 Box

...anet et4 box

thingiverse

tool box for anet et4

thingiverse

free

Anet Logo by Superflex_Plastic_Fantastic

...anet logo by superflex_plastic_fantastic

thingiverse

anet logo to incorporate into designs.

thingiverse

free

Box for Anet ET4

...box for anet et4

thingiverse

this is a simple box for tool of anet et4

thingiverse

free

Anet V1.0 Board Kühlung (80mm Lüfter) / Anet A8 by MadCre8

...anet v1.0 board kühlung (80mm lüfter) / anet a8 by madcre8

thingiverse

anet v1.0 board kühlung (80mm lüfter) / anet a8

Conversion

3ddd

$1

Conversation Seat

...шетка

the conversation seat made in englandhttp://www.squintlimited.com/products/the_conversation_seat/gold

+ max 2011

3d_export

$10

Converse 3D Model

...converse 3d model

3dexport

converse shoe pc unix mac

converse 3d model electropainter17075 38067 3dexport

turbosquid

$100

converse-shoe

...quid

royalty free 3d model converse-shoe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1398427)

turbosquid

$10

Conversation Furniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Converse Allstars

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Conversation Club Chair

...conversation club chair

designconnected

donghia conversation club chair chairs computer generated 3d model. designed by n/a.

design_connected

$27

Hemicycle Conversation Chair

...rsation chair

designconnected

ligne roset hemicycle conversation chair computer generated 3d model. designed by nigro, philippe.

3d_export

$24

Converse keds 3D Model

...converse keds 3d model

3dexport

converse all star ked shoe clothes sports

converse keds 3d model vermi1ion 26201 3dexport

3ddd

$1

Converse All-Star Shoes

...converse all-star shoes

3ddd

кеды , обувь

converse all-star shoes

design_connected

$18

CONVERSE Jack Purcell Sneakers

...converse jack purcell sneakers

designconnected

converse jack purcell sneakers computer generated 3d model.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Y

turbosquid

$1

Tetera y Galletas y Caf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Смеситель Y-CON

...смеситель y-con

3ddd

смеситель , y-con

смеситель y-con

3ddd

$1

Y-Chair

...y-chair

3ddd

tom dixon

y-chair designed by tom dixon,

3ds max + obj, corona

3ddd

$1

Y Chair compilation

....net/products/us/y-chair-sled-base

y chair swivel basehttp://www.tomdixon.net/products/us/y-chair-swivel-base

turbosquid

$190

Y-8

...y-8

turbosquid

royalty free 3d model y-8 for download as max on turbosquid: 3d models for games, architecture, videos. (1658891)

turbosquid

$7

Bench Y

...turbosquid

royalty free 3d model bench y for download as obj on turbosquid: 3d models for games, architecture, videos. (1488746)

turbosquid

$15

bonePile Y

...oyalty free 3d model bonepile y for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546374)

turbosquid

$7

Y for Yarn

...d

royalty free 3d model y for yarn model for download as max on turbosquid: 3d models for games, architecture, videos. (1699732)

turbosquid

$2

FONT Y

...quid

royalty free 3d model font y for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549457)

3ddd

$1

WOOD-y

...wood-y

3ddd

wooden guy