Thingiverse

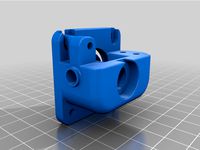

ANET A8 | Customizable E3D v6 Carriage / Bowden Mount by TNS

by Thingiverse

Last crawled date: 3 years ago

Hi Thingiverse-Community!

UPDATE March 27th: Added option for parameterizable sensor holder in CUSTOMIZER.

I was not satisfied with the stock hotend / extruder setup of the ANET A8! I had a couple of issues with the old one and I didn't like the following things:

Accessibility of the extruder motor was bad (unmount fan with cooling plate)

It was hard to actually watch the nozzle during print due to a clustered design with lots of components attached to the 'print-head'

High print speeds went along with more inaccurate results, due to the heavy 'print-head' with the extruder motor

The design is inspired / based on the design by Jubaleth (http://www.thingiverse.com/thing:2002778).

Features of this mount:

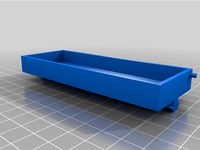

Slim, light and modular design

Unobstructed view on nozzle / as few things as possible in front of nozzle (cooling fan moved to left side, leveling sensor on back)

Equipped with several slots for zip ties for a proper cable management

Cooling fan in (nearly) same distance to the nozzle as before -> you have good chances to still use your current cooling duct

Fully compatible with x-axis cable chain (http://www.thingiverse.com/thing:2105040)

Customizable sensor holder (optional in customizer interface) - Attention: this sensor mount may interfere with other components (e.g. a cable chain), I still recommend the rear sensor holder (see links below)

Pick your version / file:

CarriageV2_3__63mm_AnetA8_E3Dv6_Mount.stl - For hotends with a total height of ~63mm (top to nozzle tip - measure without push-fit), eg. original E3Dv6

CarriageV2_3__74mm_AnetA8_E3Dv6_Mount.stl - For hotends with a total height of ~74mm (top to nozzle tip - measure without push-fit)

Use the CUSTOMIZER! - Just set your personal preferences and export your custom carriage! (Caution: settings in 'expert' tab are not foolproof and may need firmware adaptations (other then them in this description)!)

DISCLAIMER: There are several variations of hotends out there, I tried to adapt this carriage to the most of them! Nevertheless, in some cases the fan position might be slightly off. You can use the 'expert-fine-tuning' in the CUSTOMIZER to fine tune the position of the fan holder to suite you personal needs or to fit your beloved fan duct! (I used the same coordinate system orientation as the printer in order to make those adjustment parameters as easy graspable as possible.)

Modular extensions and recommended addons:

Bowden extruder motor mount (Anet A8 stock parts) or improved bowden extruder (non-stock parts)

Rear bed leveling sensor mount or rear sensor mount V2 (screw- and customizable)

Belt holder (by Simhopp)

Hotend cooling mount for the E3D v6 clones (by anthonywob)

Mistral 2 fan duct (by Leo) - rotate your heater block in a way that the shorter end points towards the fan

Firmware Adaptation:

Due to a changed nozzle position it is recommended to change the following parameter in your configuration.h file:#define X_MIN_POS -10NOTE: If this parameter is not changed, all prints will be shifted around 1 cm to the right.

If you added a sensor holder, you also have to adapt the probe position in the firmware correspondingly!

Why should I switch to a bowden setup?

A bowden setup has the benefit of moving the (heavy) extruder motor away from the moving carriage. Therefore the printer is able to accelerate way faster due to the reduced weight of the carriage. Based on this fact, the printer is able to achieve higher speeds without getting inaccurate results.

Why do you exchange the stock hotend with a E3D v6 styled one?

In order to avoid jams or clogges it is crucial to have a hot nozzle, but still a cold shaft! Compared to the stock version, E3D v6 styled nozzles provide a large cooling surface which will keep the shaft super cool without any effort!

Things you will need in order to switch to this setup:

E3Dv6 / E3D clone

Teflon tube and pneumatic couplers

UPDATE March 27th: Added option for parameterizable sensor holder in CUSTOMIZER.

I was not satisfied with the stock hotend / extruder setup of the ANET A8! I had a couple of issues with the old one and I didn't like the following things:

Accessibility of the extruder motor was bad (unmount fan with cooling plate)

It was hard to actually watch the nozzle during print due to a clustered design with lots of components attached to the 'print-head'

High print speeds went along with more inaccurate results, due to the heavy 'print-head' with the extruder motor

The design is inspired / based on the design by Jubaleth (http://www.thingiverse.com/thing:2002778).

Features of this mount:

Slim, light and modular design

Unobstructed view on nozzle / as few things as possible in front of nozzle (cooling fan moved to left side, leveling sensor on back)

Equipped with several slots for zip ties for a proper cable management

Cooling fan in (nearly) same distance to the nozzle as before -> you have good chances to still use your current cooling duct

Fully compatible with x-axis cable chain (http://www.thingiverse.com/thing:2105040)

Customizable sensor holder (optional in customizer interface) - Attention: this sensor mount may interfere with other components (e.g. a cable chain), I still recommend the rear sensor holder (see links below)

Pick your version / file:

CarriageV2_3__63mm_AnetA8_E3Dv6_Mount.stl - For hotends with a total height of ~63mm (top to nozzle tip - measure without push-fit), eg. original E3Dv6

CarriageV2_3__74mm_AnetA8_E3Dv6_Mount.stl - For hotends with a total height of ~74mm (top to nozzle tip - measure without push-fit)

Use the CUSTOMIZER! - Just set your personal preferences and export your custom carriage! (Caution: settings in 'expert' tab are not foolproof and may need firmware adaptations (other then them in this description)!)

DISCLAIMER: There are several variations of hotends out there, I tried to adapt this carriage to the most of them! Nevertheless, in some cases the fan position might be slightly off. You can use the 'expert-fine-tuning' in the CUSTOMIZER to fine tune the position of the fan holder to suite you personal needs or to fit your beloved fan duct! (I used the same coordinate system orientation as the printer in order to make those adjustment parameters as easy graspable as possible.)

Modular extensions and recommended addons:

Bowden extruder motor mount (Anet A8 stock parts) or improved bowden extruder (non-stock parts)

Rear bed leveling sensor mount or rear sensor mount V2 (screw- and customizable)

Belt holder (by Simhopp)

Hotend cooling mount for the E3D v6 clones (by anthonywob)

Mistral 2 fan duct (by Leo) - rotate your heater block in a way that the shorter end points towards the fan

Firmware Adaptation:

Due to a changed nozzle position it is recommended to change the following parameter in your configuration.h file:#define X_MIN_POS -10NOTE: If this parameter is not changed, all prints will be shifted around 1 cm to the right.

If you added a sensor holder, you also have to adapt the probe position in the firmware correspondingly!

Why should I switch to a bowden setup?

A bowden setup has the benefit of moving the (heavy) extruder motor away from the moving carriage. Therefore the printer is able to accelerate way faster due to the reduced weight of the carriage. Based on this fact, the printer is able to achieve higher speeds without getting inaccurate results.

Why do you exchange the stock hotend with a E3D v6 styled one?

In order to avoid jams or clogges it is crucial to have a hot nozzle, but still a cold shaft! Compared to the stock version, E3D v6 styled nozzles provide a large cooling surface which will keep the shaft super cool without any effort!

Things you will need in order to switch to this setup:

E3Dv6 / E3D clone

Teflon tube and pneumatic couplers

Similar models

thingiverse

free

ANET A8 | Customizable E3D v6 Carriage / Bowden Mount Remix by docrenatoms

...ns available for stock anet a8.

carriage for hotends with a total height of ~63mm (top to nozzle tip - measure without push-fit)

thingiverse

free

Anet A8 E3D V6 Bowden ~ Direct Drive

...n be use with this mod for now. i'll make a mount for anet a8 stock fan duct and other compatible aftermarket fan duct later.

thingiverse

free

Anet A8 Fan Duct for E3D Hotend by nitro_216

... fan duct for e3d hotend by nitro_216

thingiverse

part cooling fan duct for use with anet a8 e3d v6 carriage and the e3d hotend

thingiverse

free

Anet A8 V6 hotend and sensor carriage by aborders

...nd sensor carriage by aborders

thingiverse

mount for e3d v6 hotend clone on anet a8 3d printer with 18mm sensor mount included

thingiverse

free

Anet A8 Bowden conversion by Dousi

...rds the part and blows less on the nozzle

-made the radius on the belt holder larger so that its easier to put the belt in place.

thingiverse

free

Stock Anet A8 E3D V6 by UHNanobot

...from : http://www.thingiverse.com/thing:2193695

if you have questions or ideas to make this carriage better , please let me know.

thingiverse

free

ANET A8 | Customizable E3D v6 Carriage / Bowden Mount Remix with Servo Holder by ninharp

...cable chain and x-axis belt attachment part from simhopp

update: the marlin firmware settings for the servo will follow shortly.

thingiverse

free

ANET A8 | Alunar M508 | E3D v6 Carriage / Bowden Mount with 12mm Sensor Mount by peggington

...unt for 12mm proximity sensor - 63mm hot end - optimized fan nozzle included - thanks to all who contributed to original design:)

thingiverse

free

Semi-Circular Anet A8 Fan Duct - Small by ArkDuque

...is a e3d v6 clone, it is smaller than the original one, so the lokster semi-circular fan duct hit the table with this x carriage.

thingiverse

free

Anet A8 | Plotter Mount | Blower Fan Mount by 3dgio

...en mount by tns".

for the stock configuration, you just have to mirror the object, with your slicer.

max pen diameter: 16 mm

Tns

turbosquid

$45

TN-72_a

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Knife TN push dagger 3D Model

...knife tn push dagger 3d model

3dexport

tactical knife push dagger game dev

knife tn push dagger 3d model dustok 76645 3dexport

3ddd

$1

"ОМ" Тумба Элли TN-2

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-12

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-3

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-16

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-14

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-4

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-5

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

3ddd

$1

"ОМ" Тумба Элли TN-11

...остарался оформить максимально аккуратно. автор моделей yn3.

имейте ввиду, конструкция и размеры могут изменятся производителем.

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

A8

turbosquid

$47

Car A8

...

turbosquid

royalty free 3d model car a8 for download as max on turbosquid: 3d models for games, architecture, videos. (1196060)

turbosquid

$50

Audi A8

...yalty free 3d model audi a8 for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1580187)

turbosquid

$15

Audi A8

...lty free 3d model audi a8 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1387519)

turbosquid

$500

Audi A8

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

audi a8 cars car

audi a8 3d model ma 20351 3dexport

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

3d model of audi a8

audi a8 3d model badyaka 12136 3dexport

3d_ocean

$89

Audi A8 2010

...usiness car car class class f f german german luxury luxury s s s8 s8 sedan sedan vehicle vehicle

new audi a8 2010 detaled model.

turbosquid

$39

A8 2018

...a8 2018 for download as 3ds, obj, wrl, c4d, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1345349)

turbosquid

free

audi a8 l

...rbosquid

royalty free 3d model audi a8 l for download as obj on turbosquid: 3d models for games, architecture, videos. (1663016)

3d_ocean

$45

Audi A8 restyled

...our door vehicle was created in blender3d 2.62.realistic renderings were created with yafaray 0.1.2 realistic plugin.rendering...

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

Anet

thingiverse

free

Anet by derbodesign

...anet by derbodesign

thingiverse

logo anet

thingiverse

free

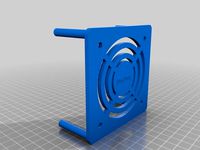

Anet e10 , Anet v1.0 by jonathan_943D

...anet e10 , anet v1.0 by jonathan_943d

thingiverse

soporte de ventilador de 80mm, para controladora anet v1.0

thingiverse

free

Anet A8 Anet AM8 Y belt holder

...anet a8 anet am8 y belt holder

thingiverse

anet a8 anet am8 y belt holder

thingiverse

free

Anet A8 Probe Bracket for anet sensor by chelrix

...anet a8 probe bracket for anet sensor by chelrix

thingiverse

anet a8 probe bracket for anet official sensor and marlin firmware

thingiverse

free

Anet logo by JUST3D_PRNTNG

...anet logo by just3d_prntng

thingiverse

anet logo

thingiverse

free

Fan nozzle for Anet A8 with original Anet levelsensor by peteruhlmann

...et levelsensor by peteruhlmann

thingiverse

here is an improved fan nozzle for the anet a8 with original level sensor from anet.

thingiverse

free

Anet Et4 Box

...anet et4 box

thingiverse

tool box for anet et4

thingiverse

free

Anet Logo by Superflex_Plastic_Fantastic

...anet logo by superflex_plastic_fantastic

thingiverse

anet logo to incorporate into designs.

thingiverse

free

Box for Anet ET4

...box for anet et4

thingiverse

this is a simple box for tool of anet et4

thingiverse

free

Anet V1.0 Board Kühlung (80mm Lüfter) / Anet A8 by MadCre8

...anet v1.0 board kühlung (80mm lüfter) / anet a8 by madcre8

thingiverse

anet v1.0 board kühlung (80mm lüfter) / anet a8

Carriage

archibase_planet

free

Carriage

...arriage

archibase planet

perambulator baby carriage pram

carriage n250908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

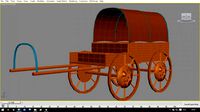

3d_export

free

carriage

...carriage

3dexport

old fashion carriage model, more files here:

turbosquid

$140

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1482052)

turbosquid

$25

Carriage

...urbosquid

royalty free 3d model carriage for download as max on turbosquid: 3d models for games, architecture, videos. (1285944)

3d_export

free

carriage

...carriage

3dexport

game cart

3d_ocean

$15

Barrel Carriage

...ieval oak old transport wheels wine wood

this model contains a barrel and a carriage. it is a medieval type of wood oak carriage.

turbosquid

$40

Carriage

...ty free 3d model carriage for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1290094)

turbosquid

free

Carriage

...yalty free 3d model carriage for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1239157)

3d_export

$5

Medieval carriage

...medieval carriage

3dexport

medieval carriage in fairy style

turbosquid

$58

Carriage

...d model carriage with scene for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1276262)

Customizable

3d_export

$10

customizable sd port

...customizable sd port

3dexport

customizable sd port

turbosquid

$99

Customizable character

...alty free 3d model customizable character for download as max on turbosquid: 3d models for games, architecture, videos. (1152525)

turbosquid

$1

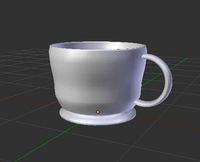

Customizable Mug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Customizable Spider Mech

... free 3d model customizable spider mech for download as blend on turbosquid: 3d models for games, architecture, videos. (1462055)

turbosquid

$20

Customizable Egyptian Pillar

...zable egyptian pillar for download as ma, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1307376)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Customizable Caste Pieces

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Customizable Tea Cup

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Water Bottle(Customizeable)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$49

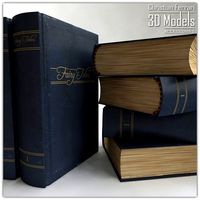

Book customizable 3D Model

...3dexport

book booshelf novel teach library learn read pages cover fairy tales

book customizable 3d model guitargoa 74240 3dexport

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)