Thingiverse

Anet A6 Horizontal Spool Holder by FrankSchwab

by Thingiverse

Last crawled date: 4 years, 9 months ago

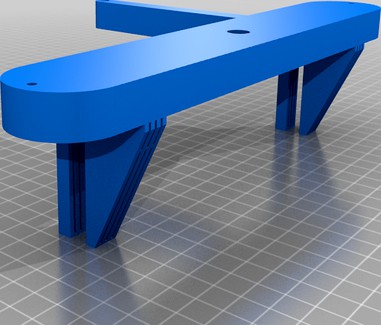

This is a Horizontal Spool Holder that sits on top of the Anet A6 to cleanly feed filament to the printer.

I was running out of room around my printer, and had issues with some of the vertical spool holders due to off-center or out-of-balance conditions causing the spool to overrotate, loosen the filament, and just cause issues. Besides which, they made the printer too tall for the space I had available.

This Thing can be built with any filament you have. However, if you have enclosed your printer, and are printing ABS, you will probably want to make this out of a high-temperature filament (like ABS). The temperature in an enclosure can soften PLA and cause drooping otherwise. Don't ask how I know.

There are a few kinds of parts to this Thing:

The Crossbar that mounts on the printer.

The Spool Holder that sits on top of the crossbar. Note that pre-built STL files for various spool IDs are included with this thing. Use one that reasonably closely matches the spool that you'll be using.

Two Spool Guides that sit on each side of the spool, and keep filament from falling off the spool. After building this, I think they're optional and not particularly needed, but here they are in case you need them. Print two if you use them, and secure them with M3 screws/nuts (an SAE #4 screw/nut will probably also work).

A 10 mm (or 3/8 inch) axle. This goes into the hole in the top of the Crossbar, and into the hole in the bottom of the spool holder. I cut mine from a piece of steel rod I had around; you can use a dowel or whatever you happen to have. It should be at least 25 mm tall, and should be sized so that the spool holder turns easily.

A 10 mm (or 3/8 inch) Fender Washer. This is placed on the axle between the Spool Holder and the Crossbar, and acts as a bearing surface. It provides just enough friction to keep filament from uncontrollably unspooling, and a small enough amount of friction that the extruder can easily pull the filament and rotate the spool.

A short 1/4-20 stainless eyebolt gets threaded into the stinger on the crossbar, and the filament gets threaded through the eyebolt on it's way to the extruder. If you only have access to metric threaded components, the OpenSCAD source file for the crossbar is set up to build with an M6 threaded eyebolt as an option.

Good luck, and good printing to you.

I was running out of room around my printer, and had issues with some of the vertical spool holders due to off-center or out-of-balance conditions causing the spool to overrotate, loosen the filament, and just cause issues. Besides which, they made the printer too tall for the space I had available.

This Thing can be built with any filament you have. However, if you have enclosed your printer, and are printing ABS, you will probably want to make this out of a high-temperature filament (like ABS). The temperature in an enclosure can soften PLA and cause drooping otherwise. Don't ask how I know.

There are a few kinds of parts to this Thing:

The Crossbar that mounts on the printer.

The Spool Holder that sits on top of the crossbar. Note that pre-built STL files for various spool IDs are included with this thing. Use one that reasonably closely matches the spool that you'll be using.

Two Spool Guides that sit on each side of the spool, and keep filament from falling off the spool. After building this, I think they're optional and not particularly needed, but here they are in case you need them. Print two if you use them, and secure them with M3 screws/nuts (an SAE #4 screw/nut will probably also work).

A 10 mm (or 3/8 inch) axle. This goes into the hole in the top of the Crossbar, and into the hole in the bottom of the spool holder. I cut mine from a piece of steel rod I had around; you can use a dowel or whatever you happen to have. It should be at least 25 mm tall, and should be sized so that the spool holder turns easily.

A 10 mm (or 3/8 inch) Fender Washer. This is placed on the axle between the Spool Holder and the Crossbar, and acts as a bearing surface. It provides just enough friction to keep filament from uncontrollably unspooling, and a small enough amount of friction that the extruder can easily pull the filament and rotate the spool.

A short 1/4-20 stainless eyebolt gets threaded into the stinger on the crossbar, and the filament gets threaded through the eyebolt on it's way to the extruder. If you only have access to metric threaded components, the OpenSCAD source file for the crossbar is set up to build with an M6 threaded eyebolt as an option.

Good luck, and good printing to you.